Flotation method for high-content slip manganese rock type low-grade nickel ores

A low-grade nickel ore, high-content technology, applied in flotation, solid separation and other directions, can solve the problems of complex process, affecting nickel flotation index and metal recovery rate, low flotation recovery rate, etc. The effect of high rate and high efficiency flotation recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

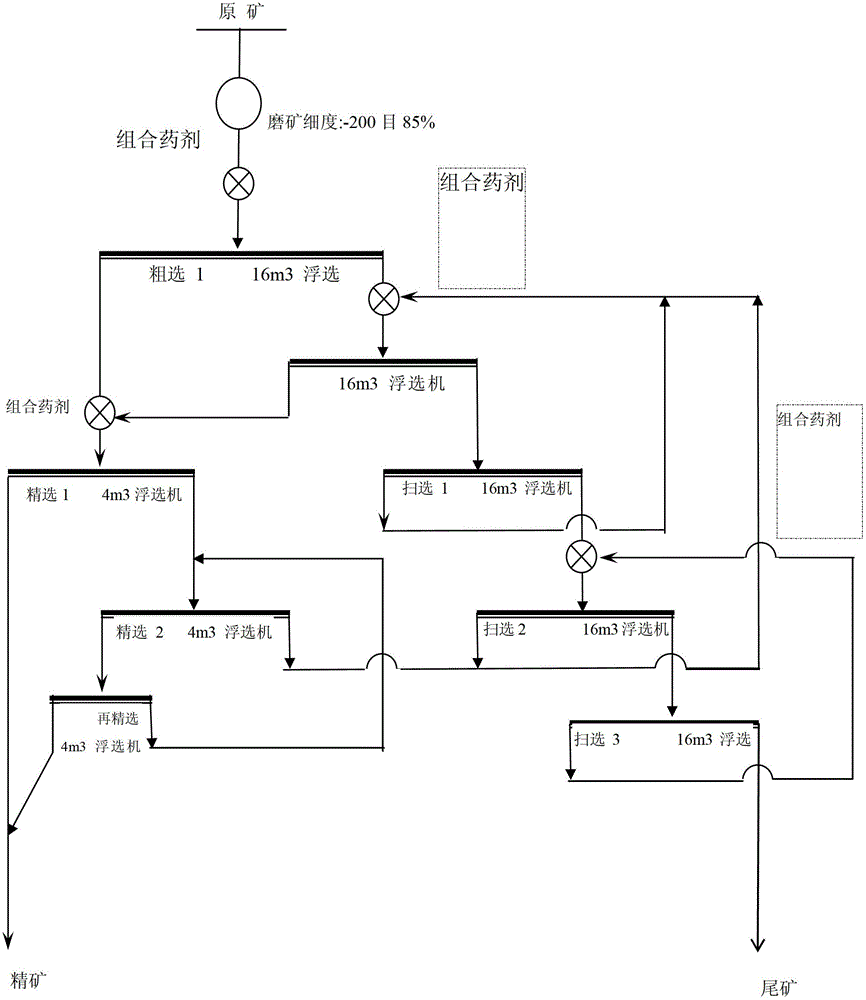

[0056] see figure 1 , a method for flotation of high-content talcite-type low-grade nickel ore, including three continuous cycles of roughing, sweeping, and beneficiation, specifically including the following steps:

[0057] 1) The raw ore is crushed and screened, and then enters the grinding and grading operation. The fineness of the grinding product reaches -200 mesh 85%, and the pulp concentration is 30%. The dosage of each component of the combination agent is: sodium carboxymethylcellulose 200g / t, sodium hexametaphosphate 100g / t, amyl xanthate 100g / t, copper sulfate 50g / t, methyl isobutyl carbinol 50g / t The ore pulp with the combined agent is sent to the flotation machine for a roughing, and the roughing is carried out for 13 minutes, and the foam carrying the nickel ore out of the flotation is separated;

[0058] To the remaining tailings slurry, add combination inhibitors sodium carboxymethyl cellulose 150g / t, sodium hexametaphosphate 100g / t, amyl xanthate 50g / t, coppe...

Embodiment 2

[0067] A method for flotation of high-content talcite-type low-grade nickel ore, including three continuous cycles of roughing, sweeping, and beneficiation, specifically including the following steps:

[0068] 1) The raw ore is crushed and screened, and then enters the grinding and classification operation. The fineness of the grinding product reaches -200 mesh 86%, and the concentration of the pulp is 32%. While stirring the pulp, add a combination of chemicals for roughing; each ton of raw ore The dosage of each component of the combination agent is: sodium carboxymethylcellulose 600g / t, sodium hexametaphosphate 500g / t, sodium carbonate 350g / t; amyl xanthate 300g / t, copper sulfate 100g / t, methyl iso Butylmethanol 80g / t; the ore slurry added with the combined agent is sent to the flotation machine for a rough separation, and the rough separation lasts for 13 minutes to separate the foam carrying nickel ore from the flotation;

[0069] Add combined inhibitor carboxymethylcellu...

Embodiment 3

[0079] A method for flotation of high-content talcite-type low-grade nickel ore, including three continuous cycles of roughing, sweeping, and beneficiation, specifically including the following steps:

[0080] 1) The raw ore is crushed and screened, and then enters the grinding and grading operation. The fineness of the grinding product reaches -200 mesh 84%, and the concentration of the pulp is 31%. While stirring the pulp, add a combination of chemicals for roughing; each ton of raw ore The dosage of each component of the combination agent is: sodium carboxymethylcellulose 400g / t, sodium hexametaphosphate 300g / t, sodium carbonate 260g / t; amyl xanthate 310g / t, copper sulfate 150g / t, methyl iso Butylmethanol 80g / t; the ore slurry added with the combined agent is sent to the flotation machine for a rough separation, and the rough separation lasts for 13 minutes to separate the foam carrying nickel ore from the flotation;

[0081] Add 200g / t of sodium carboxymethyl cellulose, 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com