Producing method of fluxed composite pellet

A technology of composite pellets and production methods, which is applied in the field of ironmaking raw materials, can solve the problems of product metallurgical performance degradation, difficult process implementation, and lack of excellent metallurgical performance of high-basic sintered ore, and achieve high-temperature metallurgical performance improvement and simplification. The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

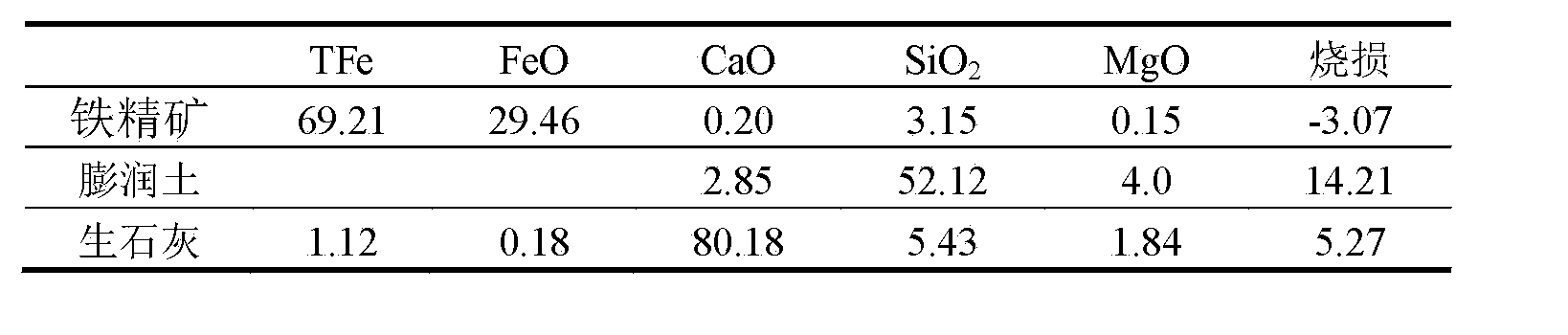

[0018] Mix the iron material, flux and binder into a mixture, wherein the iron material is high-iron low-silicon iron concentrate, the flux is quicklime powder; the binder is bentonite, and its mass fraction in the mixture is 0.8%; adjust the quicklime powder Content, so that the alkalinity of the mixture is 0.6, wet the mixture with water and mix evenly. The iron concentrate, bentonite and quicklime were all taken from the production raw material warehouse of the Iron Works, and their chemical compositions are shown in Table 1.

[0019] Table 1 Test raw material composition (%)

[0020]

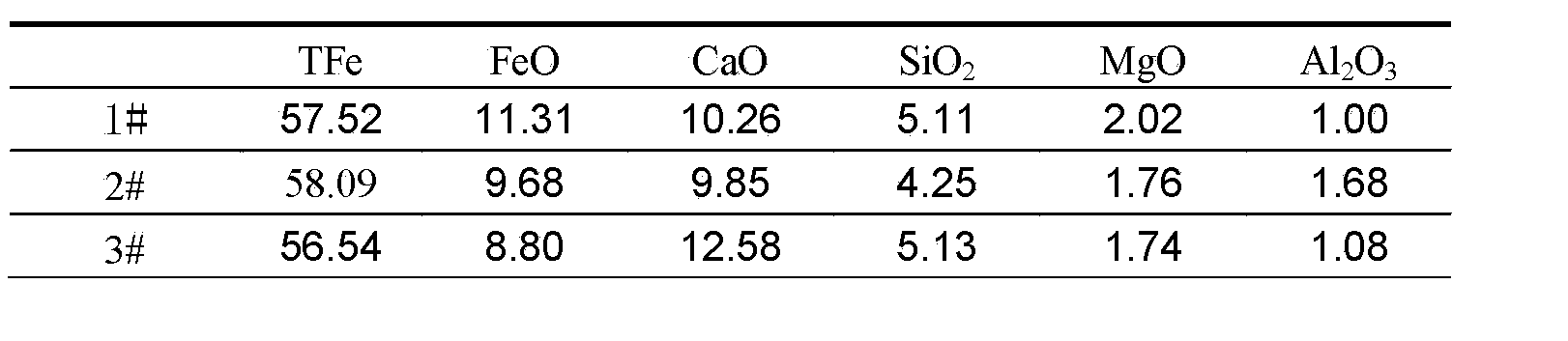

[0021] The high-alkalinity sintered ore with a particle size of 3mm~6mm and an alkalinity of 2.01 is used as the pellet core, and the above-mentioned mixture is used to pelletize once on a disc pelletizer to produce green pellets. The chemical composition of the high alkalinity sintered ore returned is shown in Table 2 (1# returned ore).

[0022] Table 2 Chemical composition of sintered...

Embodiment 2

[0026] Mix the iron material, flux and binder into a mixture, wherein the iron material is high-iron and low-silicon iron concentrate, the flux is quicklime powder; the binder is water glass, and its mass fraction in the mixture is 1%; adjust the quicklime Powder content, so that the alkalinity of the mixture is 0.8, wet the mixture with water and mix evenly. Both iron concentrate and quicklime powder are taken from the production raw material warehouse of the Iron Works, and their chemical compositions are shown in Table 3.

[0027] Table 3 Test raw material composition (%)

[0028]

[0029] The high-alkalinity sintered ore with a particle size of 3mm~6mm and an alkalinity of 2.32 is used as the pellet core, and the above-mentioned mixture is used to pelletize once on a disc pelletizer to produce green pellets. The chemical composition of the high alkalinity sintered ore returned is shown in Table 2 (2# returned ore).

[0030] Put the raw balls into the roasting furnace ...

Embodiment 3

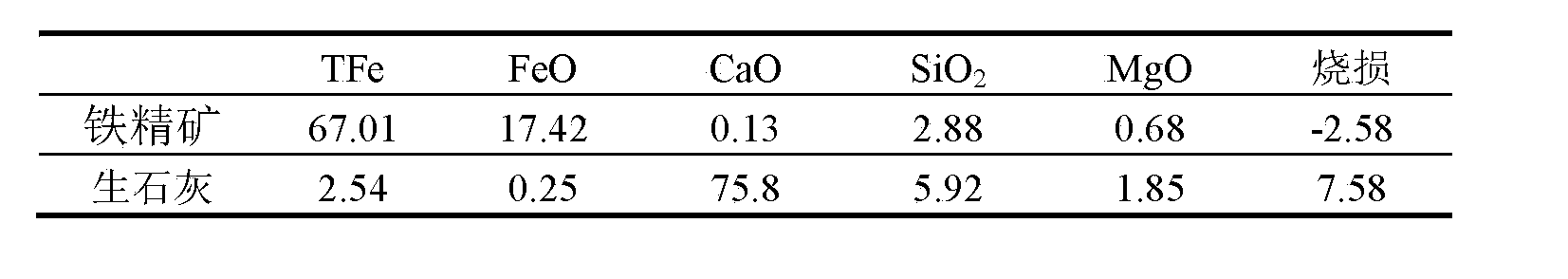

[0032] Mix iron material, flux and binder to form a mixture, wherein the iron material is high-iron and low-silicon iron concentrate, the flux is quicklime powder; the binder is sodium humate, and its mass fraction in the mixture is 1.2%; Adjust the content of quicklime powder so that the alkalinity of the mixture is 1, wet the mixture and mix evenly. The iron concentrate and quicklime powder were taken from the production raw material warehouse of the Iron Works, and their chemical compositions are shown in Table 4.

[0033] Table 4 Test raw material composition (%)

[0034]

[0035] The high-alkalinity sintered ore with a particle size of 3mm~6mm and an alkalinity of 2.45 is used as the pellet core, and the above-mentioned mixture is used to pelletize once on a disc pelletizer to produce green pellets. The chemical composition of the high alkalinity sintered ore returned is shown in Table 2 (3# returned ore).

[0036] Put the raw balls into a roasting furnace or a rotar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com