Method for preparing lyophobic heat conduction material with micro-nano core-shell structure

A core-shell structure, thermally conductive material technology, applied in heat exchange materials, chemical instruments and methods, fibrous fillers, etc., can solve problems such as preparation and application that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0040] (1) SiO 2 Nanoparticles or Al 2 o 3 Synthesis of Nanoparticles

[0041] SiO 2 Synthesis of nanoparticles: put 80mL of ethanol, 5mL of ammonia water and 1mL of water in a flask, mechanically stir evenly, slowly add 3mL of TEOS dropwise, and react at room temperature for 12h; after the reaction, the reaction solution is centrifuged and washed several times, discarded The upper layer of waste liquid, that is, white nano-SiO 2 Particles are dried at 40-50°C for later use;

[0042] Al 2 o 3 Synthesis of nanoparticles: Dissolve 6g of aluminum isopropoxide in isopropanol, transfer the solution to a flask, add an appropriate amount of water and 5mL of concentrated nitric acid to the flask, and react at room temperature for 24 hours; after the reaction, the reaction solution is centrifuged And wash several times, discard the upper layer of waste liquid, and obtain white about 100nm Al 2 o 3 Particles were dried at 80°C for later use.

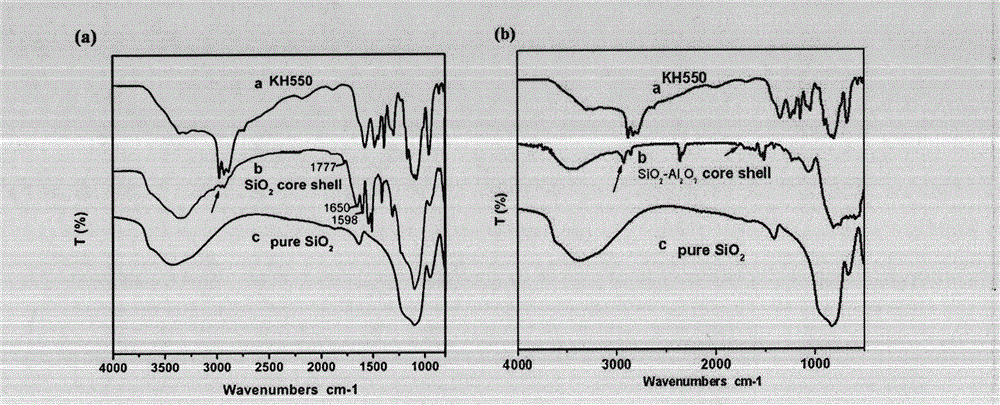

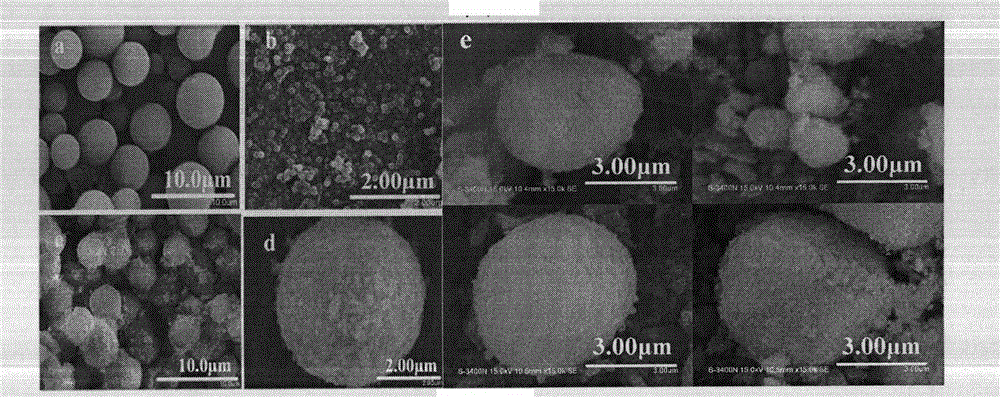

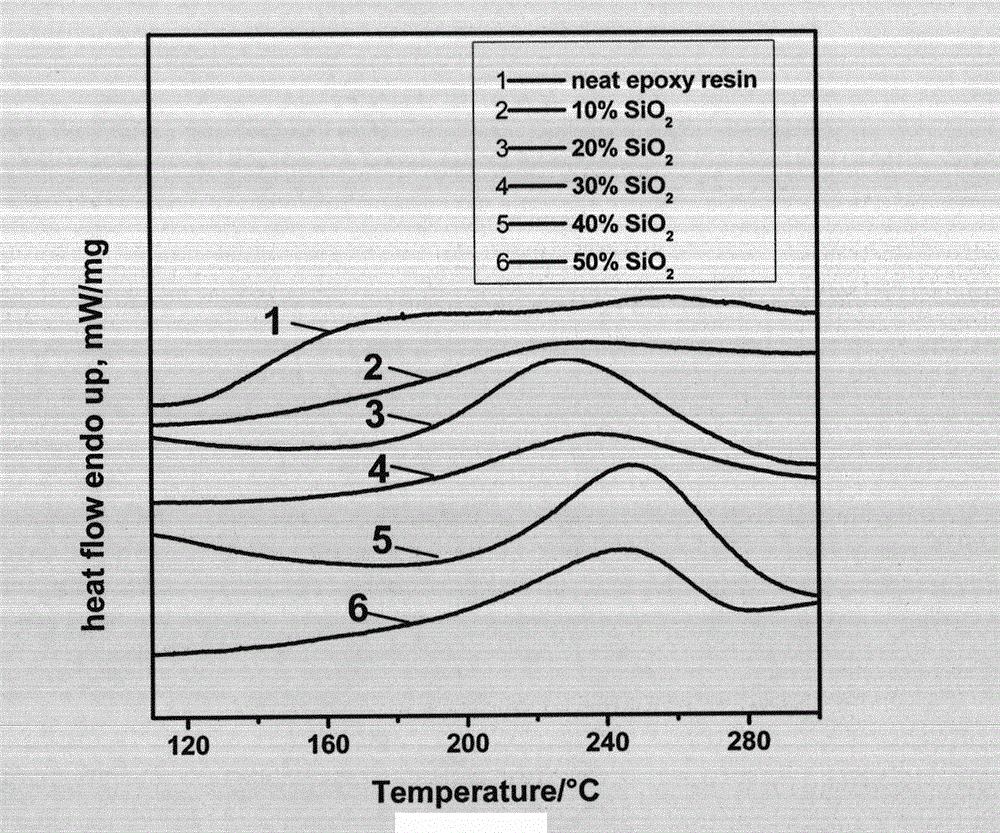

[0043] (2) Modified SiO 2 Nanopa...

specific Embodiment approach 2

[0053] (1) SiO 2 Nanoparticles or Al 2 o 3 Synthesis of Nanoparticles

[0054] SiO 2 Synthesis of nanoparticles: put 120mL ethanol, 10mL ammonia water and 5mL water in a flask, mechanically stir evenly, slowly add 8mL tetraethyl orthosilicate dropwise, and react at 40°C for 10h; after the reaction, the reaction solution is centrifuged and washed several times. Second, discard the upper waste liquid to obtain white nano-SiO 2 Particles are dried at 40-50°C for later use.

[0055] 100nm Al 2 o 3 Synthesis of particles: Dissolve aluminum isopropoxide in isopropanol, transfer the solution to a flask, add water and 15mL concentrated nitric acid to the flask, and react at 40°C for 16h; after the reaction, the reaction solution is centrifuged and washed Several times, discard the upper layer of waste liquid, that is, white about 80nm Al 2 o 3 Particles were dried at 80°C for later use.

[0056] (2) Modified SiO 2 Nanoparticles or modified Al 2 o 3 Synthesis of Nanopartic...

specific Embodiment approach 3

[0065] (1) SiO 2 Nanoparticles or Al 2 o 3 Synthesis of Nanoparticles

[0066] 10nm-200nm SiO 2 Synthesis of nanoparticles: Put 100mL ethanol, 8mL ammonia water and 3mL water in a flask, mechanically stir evenly, slowly add 5mL tetraethyl orthosilicate dropwise, and react at 80°C for 8h; after the reaction, the reaction solution is centrifuged and washed several times. Second, discard the upper waste liquid to obtain white nano-SiO 2 Particles are dried at 40-50°C for later use.

[0067] 10-100nmAl 2 o 3 Synthesis of particles: Dissolve 10g of aluminum isopropoxide in isopropanol, transfer the solution to a flask, add water and 10mL of concentrated nitric acid to the flask, and react at 80°C for 10h; after the reaction, the reaction solution is centrifuged and Wash several times, discard the upper waste liquid, and obtain white nano-Al 2 o 3 Particles were dried at 80°C for later use.

[0068] (2) Modified SiO 2 Nanoparticles or modified Al 2 o 3 Synthesis of Nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com