Transparent ceramic for high brightness white light-emitting diode and preparation method thereof

A technology of light-emitting diodes and transparent ceramics, which is applied in the field of preparation of special optical functional ceramics. It can solve the problems of high-brightness white LED thermal-induced light decay, LED chip temperature rise, and phosphor conversion efficiency decline, etc., to improve luminous intensity and heat conduction. Excellent thermal stability and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

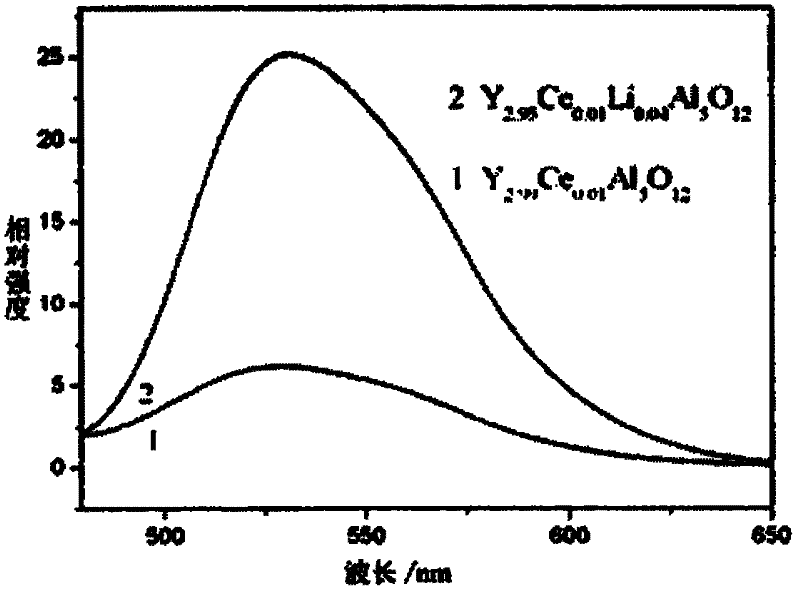

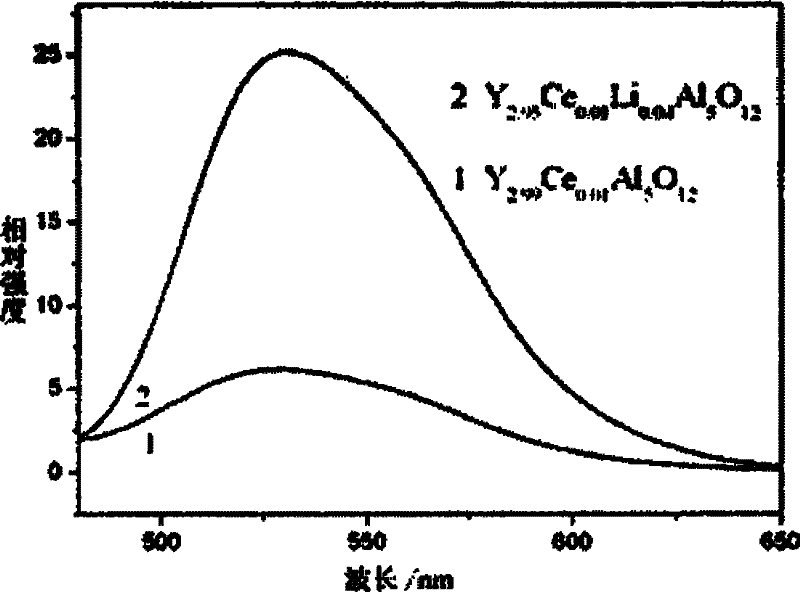

Image

Examples

Embodiment 1

[0025] Y with a purity greater than 99.9% 2 o 3 、Al 2 o 3 , CeO 2 , Li 2 CO 3 , R 2 o 3 And the oxide powder of M is the raw material, according to the molecular formula (Y 3-x-y-z Ce xLi y R z )(Al 5-n m n )O 12 The batch is weighed where x=0.003, y=0.003, z=0, n=0. Use absolute ethanol as the ball milling medium, high-purity alumina balls as the balls, tetraethyl orthosilicate as the sintering aid, polyethylene glycol 400 as the dispersant, high-speed ball milling for 24 hours, and dry in a drying oven for 24 hours , ground, sieved, put into a muffle furnace for calcination at 600°C for 3 hours, sieved again, and then uniaxially pressed into a green sheet, cold isostatic pressed at 210MPa, put the green sheet in a vacuum furnace, raised to 1700 ~1750°C for 20 hours to obtain the required transparent ceramics.

Embodiment 2

[0026] Embodiment 2: The implementation process is different from the above embodiment 1 in that x=0.003, y=0.003, z=0, n=0.75. Wherein M can be at least one of Sc, Ti, V, Cr and Mn, and the required transparent ceramics can be obtained at 1700-1800°C for 15-30 hours.

Embodiment 3

[0027] Embodiment 3: The implementation process is different from the above embodiment 1 in that x=0.003, y=0.003, z=0.75, n=0. Wherein R can be selected from at least one of La, Pr, Sm, Gd, Tb and Dy, and the required transparent ceramics can be obtained at 1400-1750° C. for 5-30 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com