High magnetic conductive low temperature sintered NiCuZn ferrite material

A ferrite material, low-temperature sintering technology, applied in the direction of magnetic properties of inorganic materials, can solve the problems of easy re-agglomeration, cost reduction, particle size reduction, etc., to achieve the effect of improving mechanical strength, reducing manufacturing cost, and increasing sintering density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

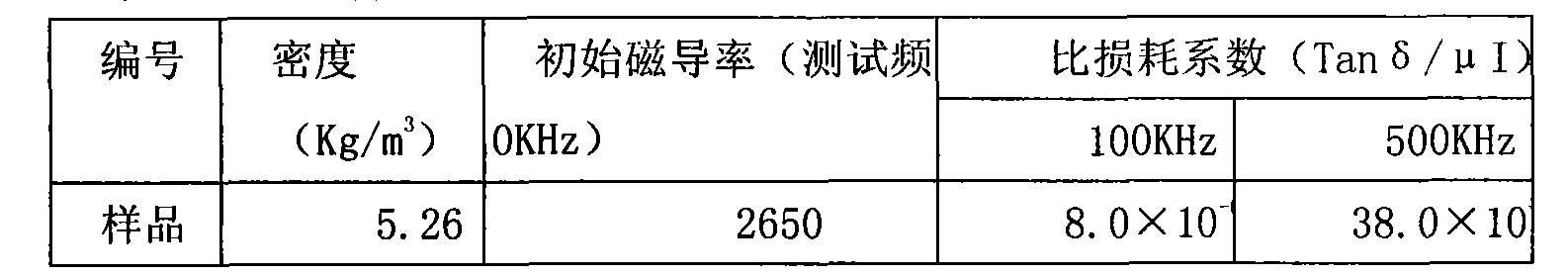

Embodiment 1

[0043] 1) Selection of raw materials: Provide low-temperature sintered NiCuZn ferrite materials to select industrially pure Fe 2 o 3 , ZnO, NiO, CuO.

[0044] 2) Composition design and weighing: according to Fe 2 o 3 48mol%, ZnO is 33mol%, CuO is 10mol%, NiO is 9mol%, and the corresponding weight of Fe is weighed 2 o 3 , ZnO, CuO and NiO.

[0045] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water of equal weight, and sand mill for 0.5 hours.

[0046] 4) Primary spray drying and granulation: add about 10% PVA solution (concentration is about 10%) to the raw material slurry, and perform primary spray drying and granulation.

[0047] 5) Pre-calcination: pre-calcine the primary spray-dried granulated powder through a rotary kiln, and the pre-calcination temperature is 780°C.

[0048] 6) Addition of impurities: using MoO 3 、In 2 o 3 As an additive, where MoO 3 The percentage content is: 0.20wt%, and In 2 o 3 The percentage ...

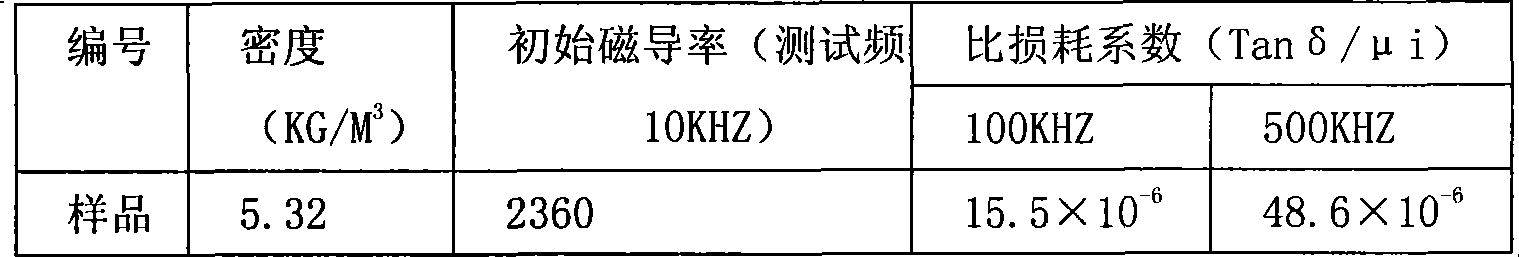

Embodiment 2

[0057] 1) Material selection: Provide low-temperature sintered NiZn ferrite material selection of industrially pure Fe 2 o 3 , ZnO, NiO and CuO.

[0058] 2) Composition design and weighing: according to Fe 2 o 3 48mol%, ZnO is 35mol%, CuO is 12mol%, NiO is 5mol%, and the corresponding weight of Fe is weighed 2 o 3 , ZnO, CuO and NiO.

[0059] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water of equal weight, and sand mill for 0.5 hour.

[0060] 4) Primary spray drying and granulation: add about 10% PVA solution (concentration is about 10%) to the raw material slurry, and perform primary spray drying and granulation.

[0061] 5) Pre-calcination: the primary spray-dried granulated powder is pre-fired through a rotary kiln, and the pre-calcination temperature is 740°C.

[0062] 6) Addition of impurities:

[0063] Using MoO 3 、In 2 o 3 As an additive, where MoO 3 The percentage content is: 0.18wt%, and In 2 o 3 The percen...

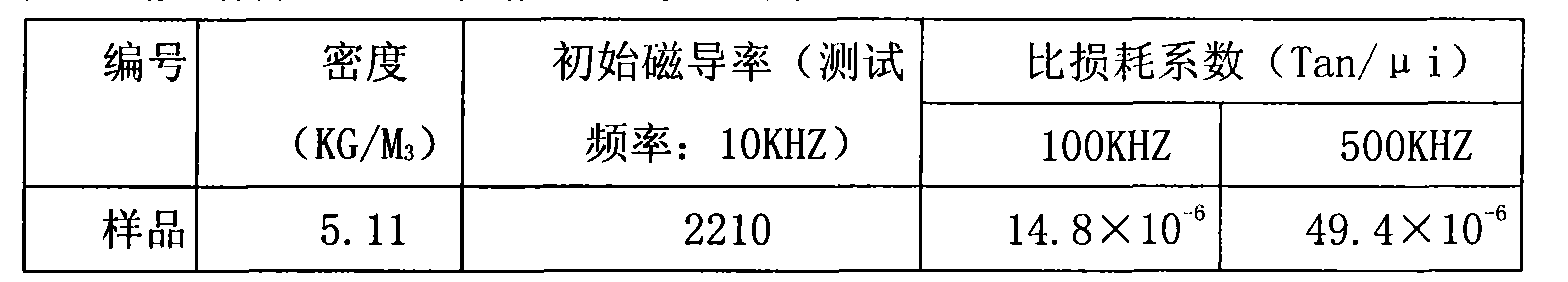

Embodiment 3

[0073] 1) Material selection: Provide low-temperature sintered NiZn ferrite material selection of industrially pure Fe 2 o 3 , ZnO, NiO and CuO.

[0074] 2) Composition design and weighing: according to the formula Fe 2 o 3 is 48.5mol%, ZnO is 36.5mol%, CuO is 3.5mol%, NiO is 11.5mol%, and the corresponding weight of Fe 2 o 3 , ZnO, CuO and NiO.

[0075] 3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water of equal weight, and sand mill for 0.5 hour.

[0076]4) Primary spray drying and granulation: add about 10% PVA solution (concentration is about 10%) to the raw material slurry, and perform primary spray drying and granulation.

[0077] 5) Pre-calcination: The primary spray-dried granulated powder is pre-fired through a rotary kiln, and the pre-calcination temperature is 800°C.

[0078] 6) Addition of impurities (ingredients): MoO is used 3 、In 2 o 3 As an additive, where MoO 3 The percentage content is: 0.25wt%, while In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com