Non-oriented electrical steel sheets with excellent magnetic properties and method for manufacturing the same

一种取向电工钢板、钢板的技术,应用在磁性材料、制造工具、磁性物体等方向,能够解决观察值范围窄、硫化物和氮化物误差等问题,达到优良磁性、抑制晶核形成、晶粒尺寸均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0077] Each of the steel ingots having the composition as shown in Table 1 below was reheated at a temperature of 1180°C and hot rolled to 2.5 mm, then wound and cooled in the air at a temperature of 720°C. The coiled and cooled steel plate is pickled with acid and then cold rolled to a thickness of 0.5 mm. The cold-rolled steel sheet is finally annealed for 90 seconds at a temperature of 1000°C (Steel 1 and 2) and a temperature of 900°C (Steel 3, 4, 5) in a mixed gas atmosphere of 30% hydrogen and 70% nitrogen . The annealed steel was cut and then checked for magnetic properties, and the results are shown in Table 2 below.

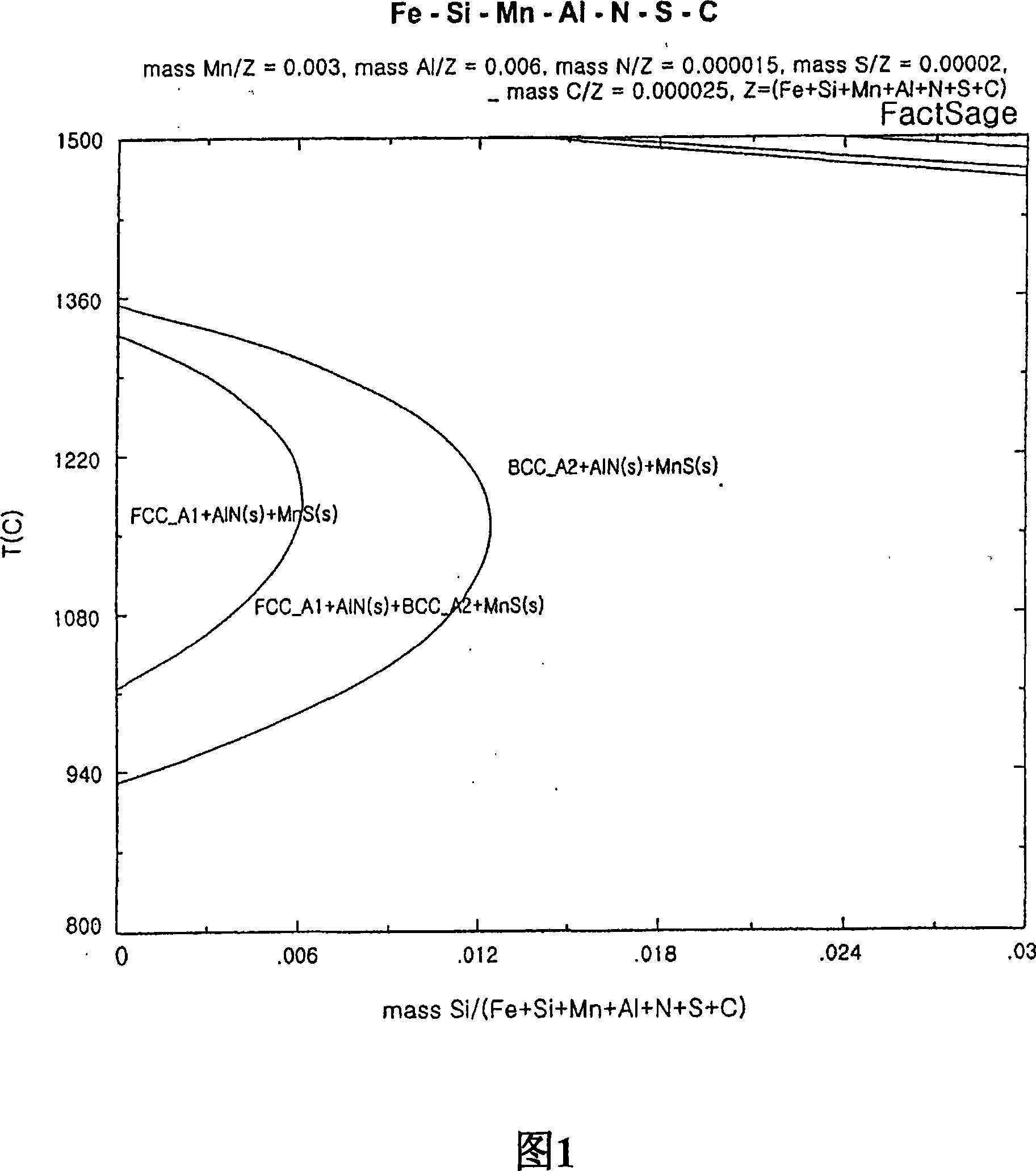

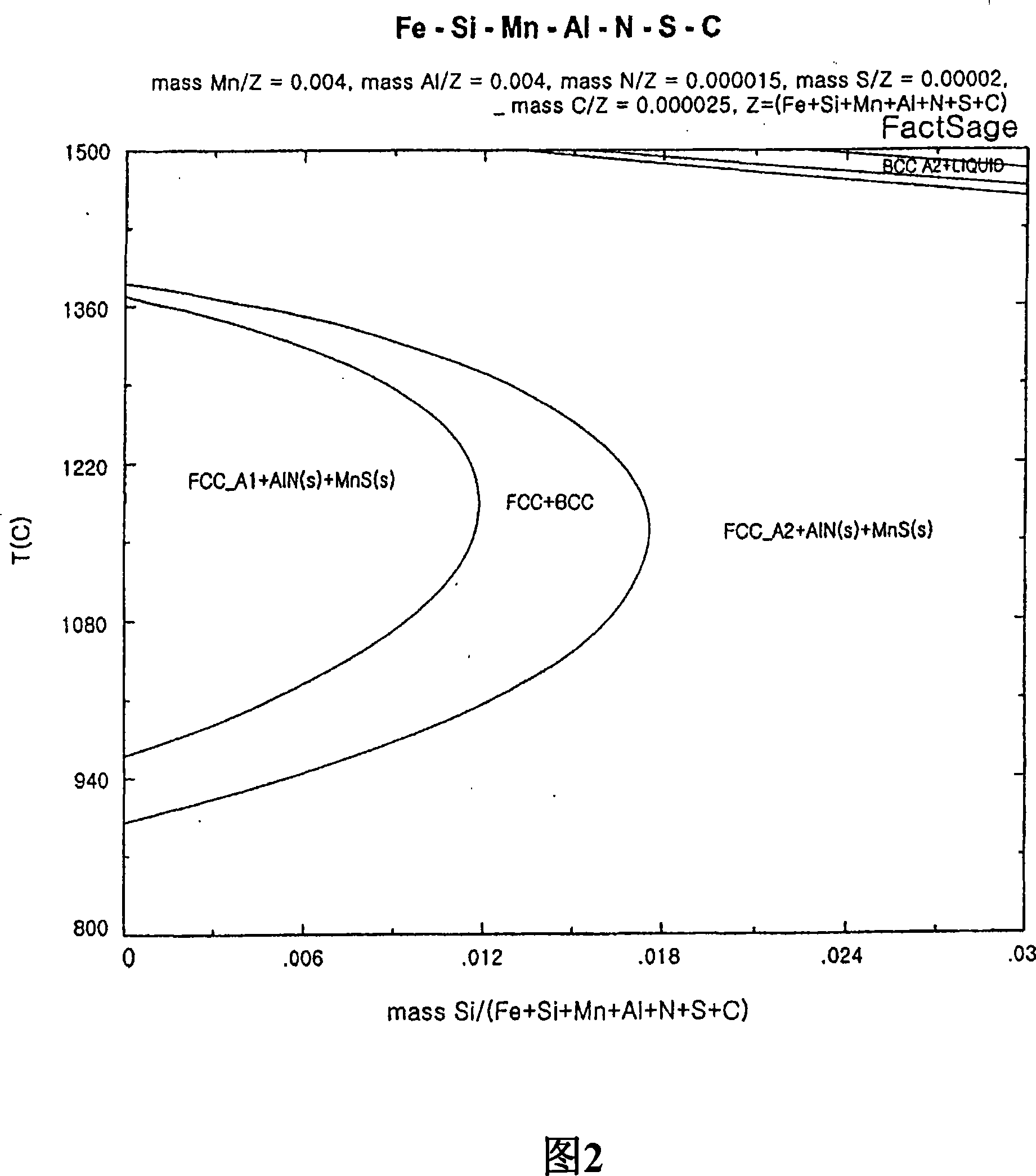

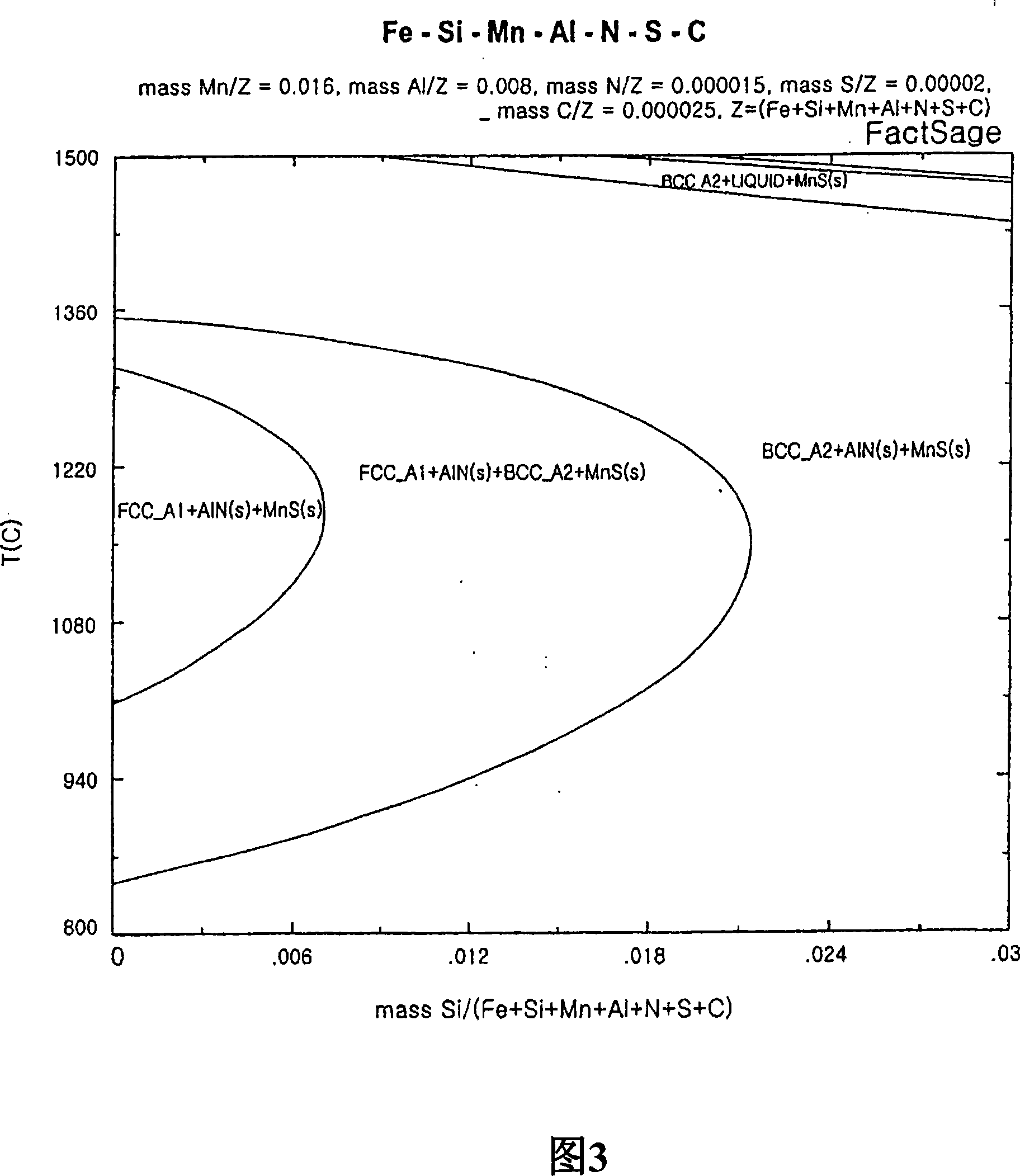

[0078] Figures 1 to 5 show the phase transformation of each steel caused by changes in the content of Si, Al, and Mn. Figures 1 to 5 show the phase changes with temperature (y-axis) and Si content (x-axis) calculated using the FactSage program. The value of m (=Mn-Al) is -0.3 for steel 1, 0 for steel 2, 0.8 for steel 3, 1.2 for steel 4, and 1.4 for steel 5.

...

example 2

[0087] Each of the steel ingots having the composition as shown in Table 3 below was reheated at a temperature of 1180°C and hot rolled to 2.5 mm, then wound and cooled in the air at a temperature of 720°C. The coiled and cooled steel sheet is pickled with acid and then cold rolled to a thickness of 0.5 mm. The cold rolled steel sheet is finally annealed for 90 seconds in a mixed gas atmosphere of 30% hydrogen and 70% nitrogen at a temperature of 1000°C. The annealed steel was cut and then checked for magnetic properties, and the results are shown in Table 4 below.

[0088] table 3

[0089] steel

C

Si

Mn

Al

P

Fe

6

0.0025

1.2

0.6

0.4

0.010

Margin

7

0.0026

1.6

0.6

0.4

0.010

Margin

8

0.0025

1.9

0.6

0.4

0.011

Margin

9

0.0026

1.4

0.8

0.4

0.010

Margin

...

example 3

[0105] The steel ingots for steel 7 and 10 were reheated at a temperature of 1180°C, hot rolled to 2.5 mm and then coiled, while changing the hot finishing rolling conditions as shown in Table 6 below, and then as shown in Table 6. Winding as shown in. The hot rolled plate is pickled with acid and then cold rolled to a thickness of 0.5 mm. The cold-rolled steel sheet is annealed in a mixed gas atmosphere of 30% hydrogen and 70% nitrogen at a temperature of 1000°C for 90 seconds. The annealed steel was cut and then checked for magnetic properties, and the results are shown in Table 6 below.

[0106] Table 6

[0107] No.

steel

In the two-phase area

Of rolling accounted for the total heat

Final rolling ratio (%)

Final rolling

Secondary temperature

(℃)

Final rolling

Press down

Rate (%)

Winding temperature

Degree (℃)

Iron loss

(W15 / 50)

(W / kg)

Magnetic flux density

Degree (B50)

(Tesla)

Mark

1

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| annealing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com