Polycrystalline silicon ingots and preparation method thereof, polycrystalline silicon chips and polycrystalline silicon ingot casting crucible

A technology of polycrystalline silicon ingots and polycrystalline silicon wafers, which is applied to the growth of polycrystalline materials, chemical instruments and methods, and crystal growth. It can solve the problems of reducing the crystal quality of the crucible wall area, the leakage probability of cells with induced defects, and the long diffusion distance of impurities. It is suitable for large-scale production, the preparation method is simple and convenient, and the effect of improving the quality of silicon ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of polycrystalline silicon ingot comprises the following steps:

[0039] (1) After coating the silicon nitride layer on the inner wall of the crucible, spray silicon powder with a purity of 99.99% on the silicon nitride layer inside the side wall of the crucible to obtain a barrier layer with a thickness of 3 mm; the particle size of the silicon powder 1~8μm;

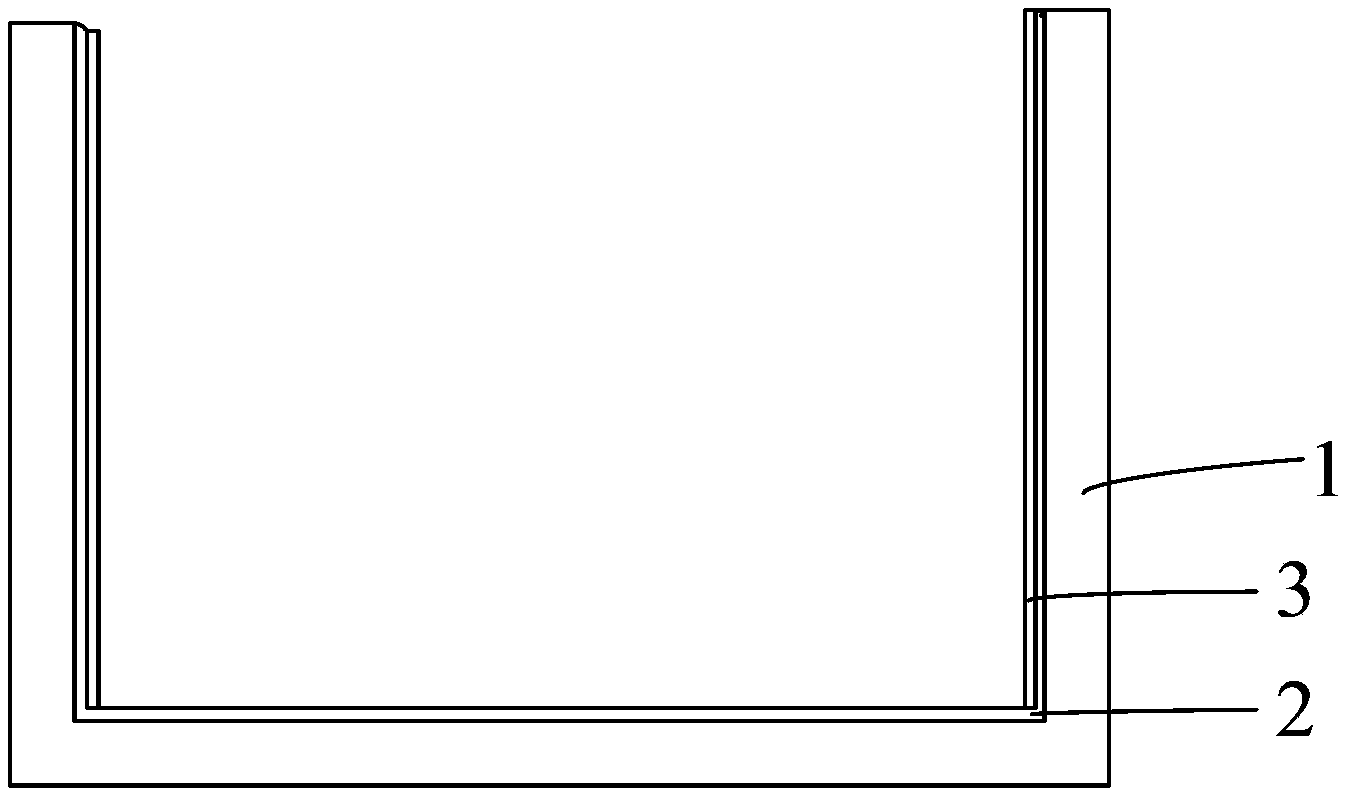

[0040] figure 1 A schematic diagram of a crucible for polysilicon ingots prepared in an embodiment of the present invention. Wherein, 1 is the crucible body, 2 is the silicon nitride layer, and 3 is the barrier layer provided on the side wall of the crucible.

[0041] (2) Then set molten silicon material in the crucible;

[0042] Wherein, setting the silicon material in molten state is as follows: 530 kg of solid silicon material is loaded in the crucible, and the crucible is heated to 1560° C. to melt the solid silicon material.

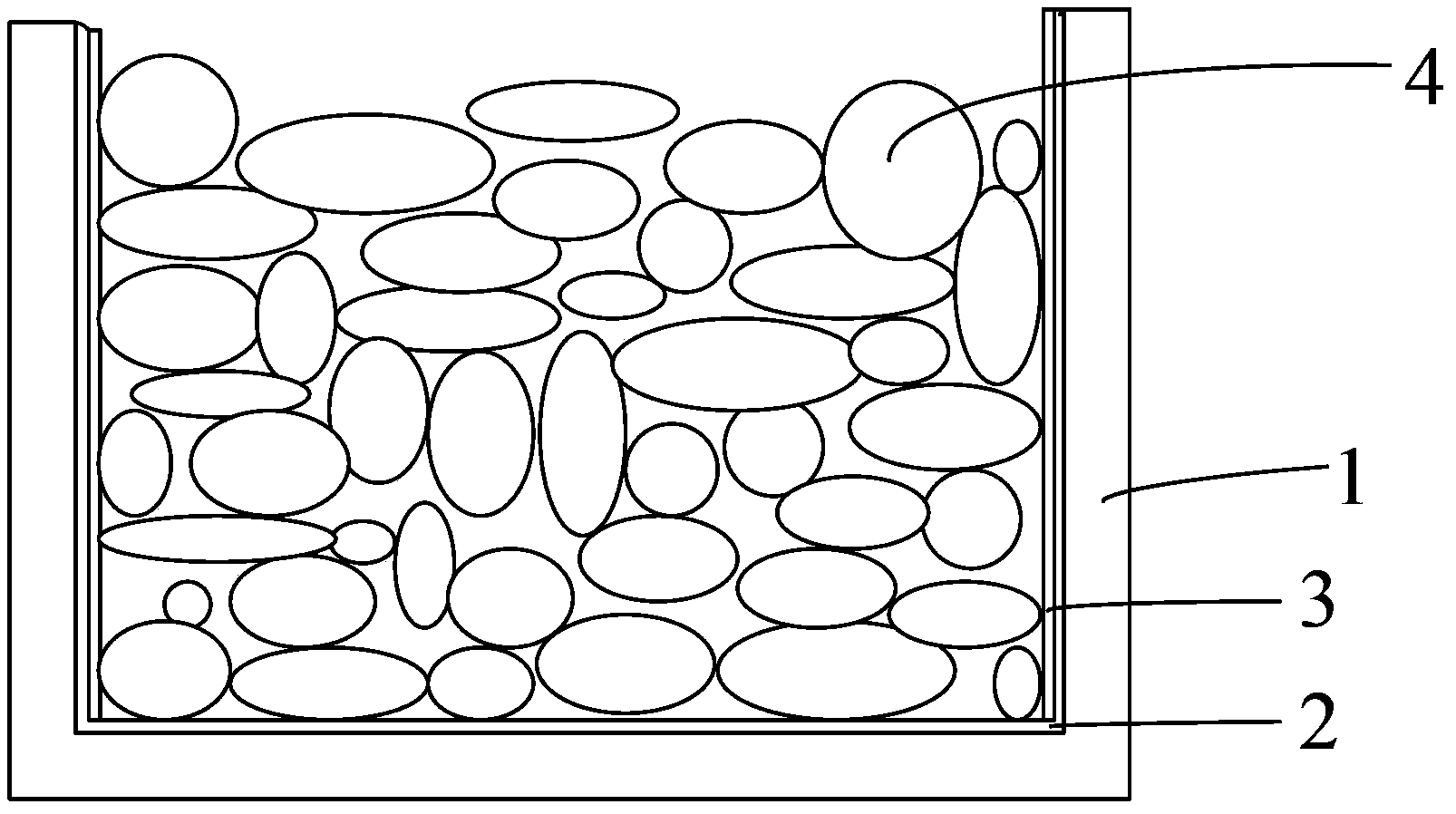

[0043] figure 2 It is a schematic diagram of the prep...

Embodiment 2

[0049] The preparation method of polycrystalline silicon ingot comprises the following steps:

[0050](1) After coating the silicon nitride layer on the inner wall of the crucible, spray quartz powder with a purity of 99.9999% on the silicon nitride layer inside the side wall of the crucible to obtain a barrier layer with a thickness of 2 mm; the particle size of the quartz powder 1~20μm;

[0051] (2) Then set molten silicon material in the crucible;

[0052] Wherein, setting the silicon material in molten state is as follows: 530 kg of solid silicon material is loaded in the crucible, and the crucible is heated to 1560° C. to melt the solid silicon material.

[0053] (3) Controlling the temperature in the crucible to gradually rise in a direction perpendicular to the bottom of the crucible to form a temperature gradient, so that the silicon material in the molten state begins to crystallize; after all crystallization is completed, annealing and cooling is performed to obtain...

Embodiment 3

[0058] The preparation method of polycrystalline silicon ingot comprises the following steps:

[0059] (1) Spray quartz powder with a purity of 99.9999% on the inner wall of the crucible to prepare a barrier layer with a thickness of 5 mm; the particle size of the quartz powder is 1-5 μm, and then spray a silicon nitride coating on the quartz powder barrier layer;

[0060] (2) Then set molten silicon material in the crucible;

[0061] Among them, setting the silicon material in the molten state is: heating 530 kg of solid silicon material in another crucible to 1560 ° C to obtain molten silicon material, and pouring the molten silicon material into the step (1). In the crucible of layers;

[0062] (3) Controlling the temperature in the crucible to gradually rise in a direction perpendicular to the bottom of the crucible to form a temperature gradient, so that the silicon material in the molten state begins to crystallize; after all crystallization is completed, annealing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com