Polycrystalline silicon film, preparation method thereof, array substrate and display device

A polysilicon thin film and display device technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of poor repeatability, stability, and uniformity of polysilicon thin films, poor characteristics of polysilicon thin films, and excimer laser energy density. Difficult to control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A first aspect of the present invention provides a method for preparing a polysilicon film, comprising the following steps:

[0027] (1) forming a graphene layer and an amorphous silicon layer, wherein the graphene layer and the amorphous silicon layer are adjacent;

[0028] (2) Crystallize amorphous silicon to form polysilicon to obtain a polysilicon film.

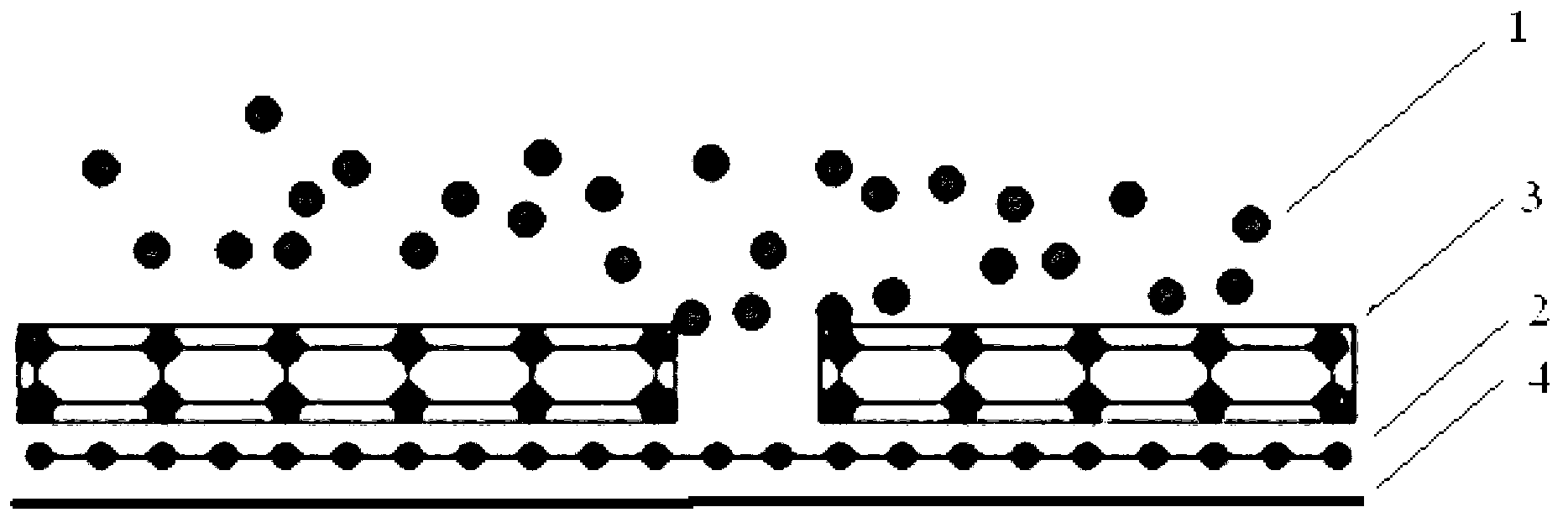

[0029] The polysilicon in the polysilicon thin film prepared by the method has the advantages of no pollution and low defect density, and the obtained polysilicon has uniform grain size, orderly arrangement and large grain size, and better surface flatness. The polysilicon thin film prepared by the method has good repeatability, stability and uniformity, can be crystallized in a large area, and can meet the requirement of producing high-performance polysilicon materials.

specific Embodiment approach 1

[0031] This embodiment provides a method for preparing a polysilicon thin film, comprising the following steps:

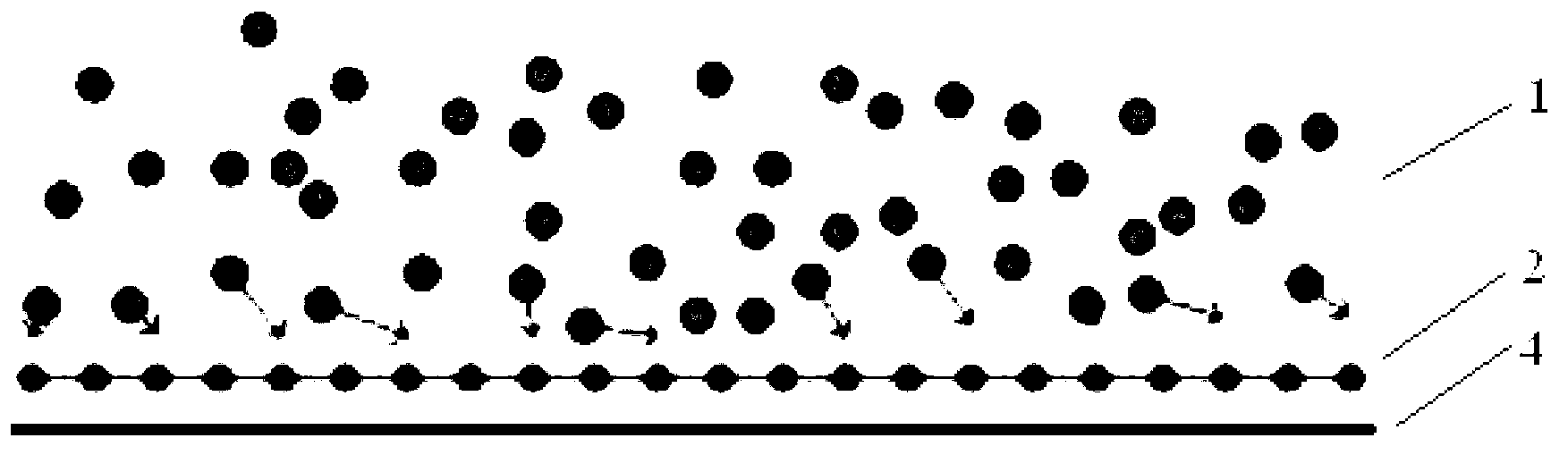

[0032] (1) The base layer 4 of the polysilicon thin film is formed. The formation of the base layer 4 of the polysilicon thin film is an existing known technology, which can include: firstly provide a substrate, this substrate is usually a glass substrate, certainly this substrate can also be a plastic substrate or other transparent substrates, However, the substrate may also be other opaque substrates, such as silicon substrates. Then a buffer layer is formed on the substrate, and the buffer layer is usually composed of a barrier layer and a stress buffer layer. Among them, the barrier layer is usually a silicon nitride layer, and the silicon nitride layer is usually formed by chemical vapor deposition; and the stress buffer layer is usually silicon oxide, and the silicon oxide layer is usually formed by chemical vapor deposition. , the film structure is relativ...

specific Embodiment approach 2

[0042] This specific embodiment provides a kind of preparation method of polysilicon film, comprises the following steps:

[0043] (1) The manufacturing method of the base layer in this embodiment is as in Embodiment 1.

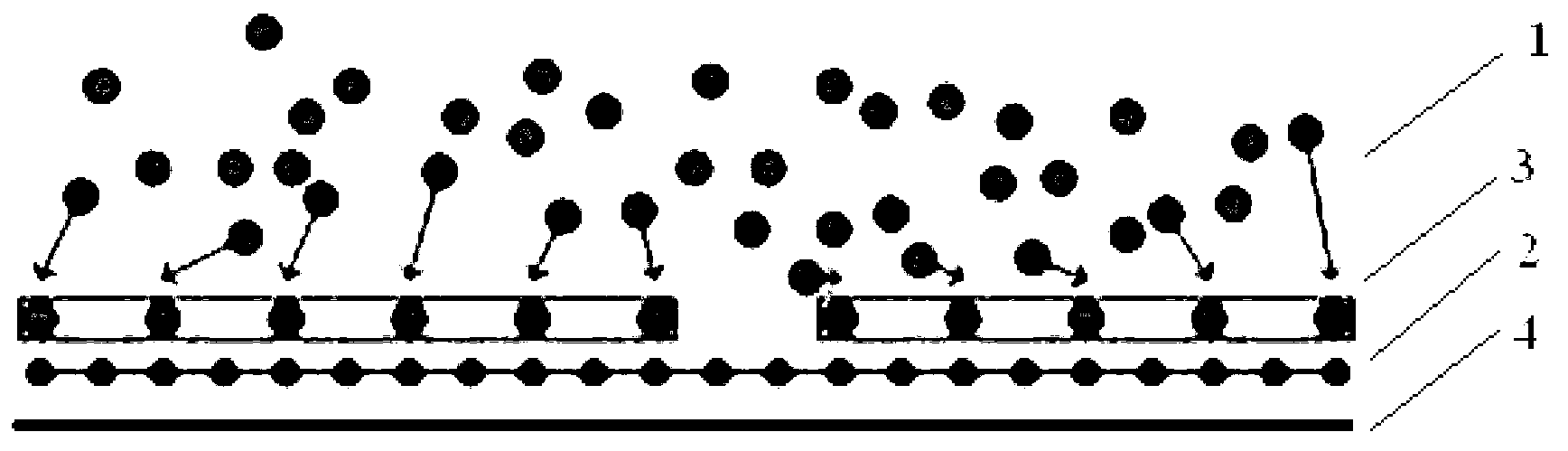

[0044] (2) An amorphous silicon layer with a thickness of preferably 40-50 nanometers is formed on the base layer, and a graphene layer with a thickness of preferably 2-10 layers is formed on the amorphous silicon layer. Wherein, the formation method of the amorphous silicon layer and the formation method of the graphene layer are the same as those in the first embodiment.

[0045] (3) Crystallize amorphous silicon to form polysilicon by excimer laser annealing method, and obtain polysilicon thin film. The crystallization method used in this step is the same as that in Embodiment 1. Graphene crystals can be produced on a large scale, and the crystal quality is very high. Since the thickness of the graphene prepared in the polysilicon film production process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com