Environment-friendly 2-methyl furan catalyst and preparation method thereof

A methyl furan catalyst, an environment-friendly technology, applied in the field of environment-friendly 2-methyl furan catalyst and its preparation, can solve the problems of poor catalyst stability and achieve stable performance and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

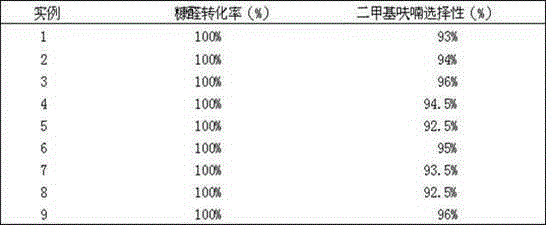

Examples

Embodiment 1

[0020] Example 1 30.6 grams of copper nitrate trihydrate and 8.36 grams of zinc nitrate hexahydrate were dissolved in 100 ml of deionized water, and then added to 250 ml of aluminum sol. Dissolve 32 grams of sodium carbonate in 200ml of deionized water, mix the nitrate-dissolved aluminum sol solution and sodium carbonate aqueous solution at 40°C under stirring conditions to obtain a precipitate with a pH of 7.5, then age for 2 hours, filter and wash the precipitate Finally, it was dried at 110° C. for 12 hours, and then calcined at 500° C. for 4 hours in a muffle furnace to obtain a catalyst.

Embodiment 2

[0021] Example 2 24 grams of copper nitrate trihydrate, 8.36 grams of barium nitrate, and 4.2 grams of calcium nitrate were dissolved in 100 ml of deionized water, and then added to 250 ml of aluminum sol. Dissolve 36 grams of sodium carbonate in 200ml of deionized water, mix the nitrate-dissolved aluminum sol solution and sodium carbonate aqueous solution at 40°C under stirring conditions to obtain a precipitate with a pH of 7.5, then age for 2 hours, filter and wash the precipitate Finally, it was dried at 110° C. for 12 hours, and then calcined at 500° C. for 4 hours in a muffle furnace to obtain a catalyst.

Embodiment 3

[0022] Example 3 72 grams of copper nitrate trihydrate, 30 grams of calcium nitrate, and 8.2 grams of zinc nitrate were dissolved in 100 ml of deionized water, and then added to 600 ml of aluminum sol. Dissolve 50 grams of sodium hydroxide in 500 ml of deionized water, mix the aluminum sol solution dissolving nitrate and sodium hydroxide aqueous solution at 50°C under stirring conditions to obtain a precipitate, the pH is 8 and then aged for 2 hours, the precipitate is filtered and After washing, it was dried at 110° C. for 12 hours, and then calcined at 500° C. for 4 hours in a muffle furnace to prepare the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com