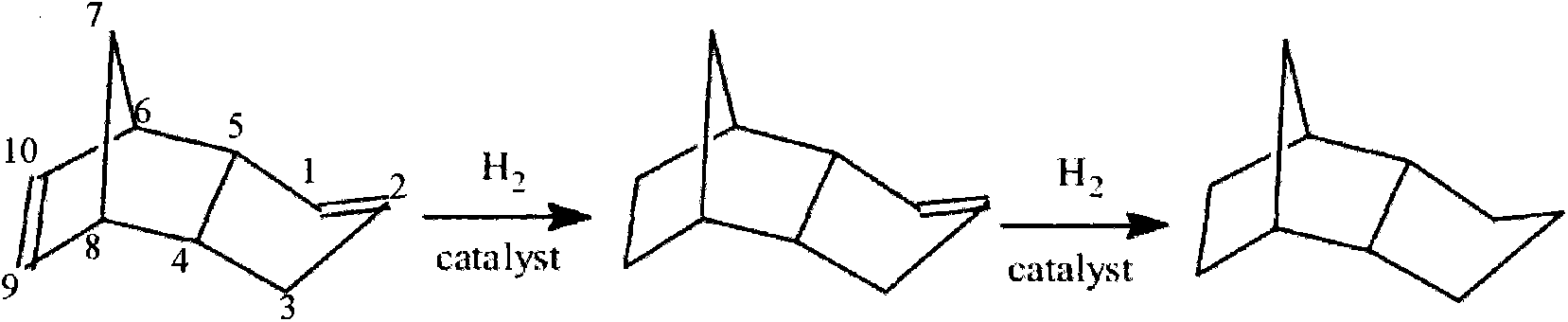

Supported Ni-based catalyst for DCPD (dicyclopentadiene) continuous hydrogenation and hydrogenating method

A catalyst, supported technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low operating temperature, high catalyst cost, catalyst hydrogenation activity reduce problems such as reducing reaction temperature and pressure, and achieve the effects of low reaction temperature and pressure, high yield and selectivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

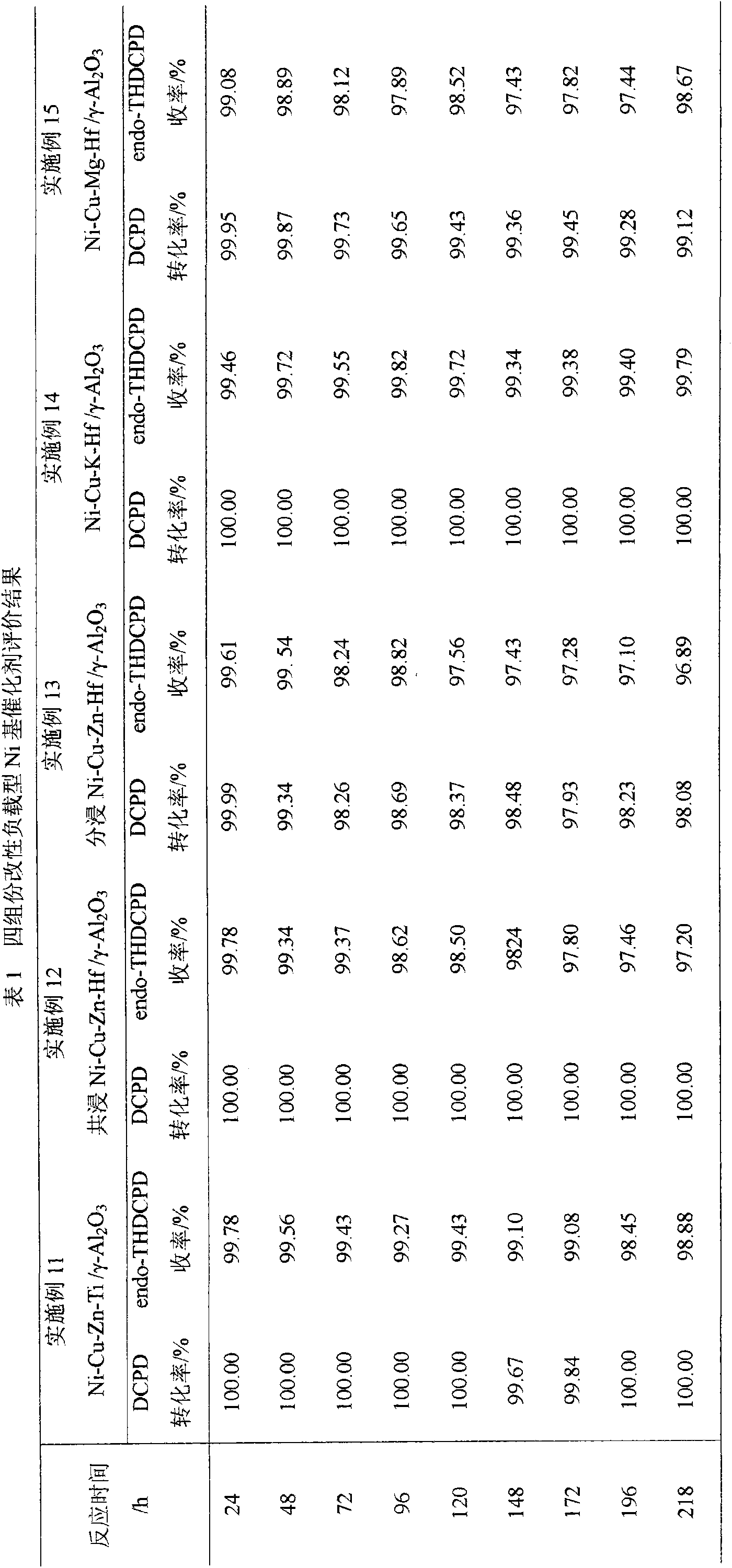

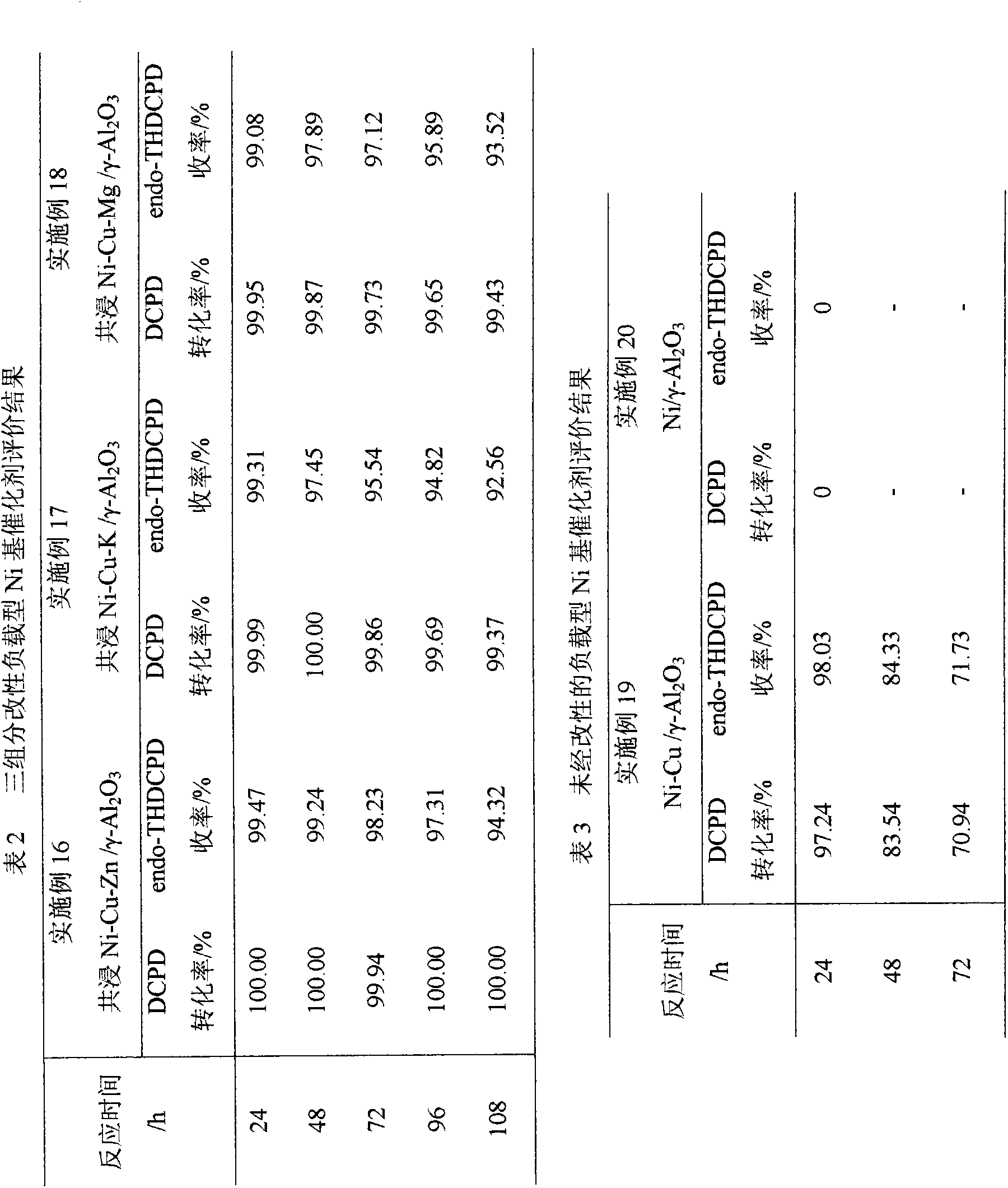

Examples

Embodiment 1

[0026] Embodiment 1: preparation of catalyst A

[0027] Weigh Ni(NO 3 ) 2 ·6H 2 O crystal 49.82g, Cu(NO 3 ) 2 ·3H 2 O crystal 9.72g, Zn(NO 3 ) 2 ·6H 2 O crystals 8.77g, TiCl 4 Crystal 0.95g, dissolved in 30mL deionized water to prepare impregnation solution, weighed the dried and roasted clover-type γ-A0 with a diameter of 1.6mm 2 o 3 Carrier 60g, add the above impregnating solution drop by drop under stirring to impregnate with equal volume, dry at room temperature, dry at 80°C for 4h, and bake at 500°C for 4h to obtain NiO loading of 16%, CuO loading of 4%, and ZnO loading of 60g. 3% TiO 2 Ni-Cu-Zn-Ti / γ-Al with a loading of 0.5% 2 o 3 Catalyst A.

Embodiment 2

[0028] Embodiment 2: preparation of catalyst B

[0029] Weigh Ni(NO 3 ) 2 ·6H 2 O crystal 49.82g, Cu(NO 3 ) 2 ·3H 2 O crystal 9.72g, Zn(NO 3 )2 ·6H 2 O crystals 8.77g, HfCl 4 Crystal 0.61g, dissolved in 30mL deionized water to prepare impregnation solution, weighed the dried and roasted clover-type γ-Al with a diameter of 1.6mm 2 o 3 Carrier 60g, add the above impregnating solution drop by drop under stirring for equal volume impregnation, dry at room temperature, dry at 80°C for 4h, and bake at 500°C for 4h to obtain NiO loading of 16%, CuO loading of 4%, ZnO loading 3% HfO 2 Ni-Cu-Zn-Hf / γ-Al with a loading of 0.5% 2 o 3 Catalyst B.

Embodiment 3

[0030] Embodiment 3: preparation of catalyst C

[0031] Weigh Zn(NO 3 ) 2 ·6H 2 8.77g of O crystals were dissolved in 50mL of deionized water to prepare an impregnation solution, and the dried and roasted clover-type γ-Al with a diameter of 1.6mm was weighed 2 o 3 Carrier 55g, add the above impregnation solution drop by drop under stirring for equal volume impregnation, dry and roast according to the method of Example 1 to obtain surface ZnO modified γ-Al 2 o 3 carrier; then weigh Ni(NO 3 ) 2 ·6H 2 O crystal 49.82g, Cu(NO 3 ) 2 ·3H 2 O crystals 9.72g, HfCl 4 Crystal 0.61g, dissolved in 30mL deionized water to prepare impregnating liquid, dropwise add above impregnating liquid to ZnO modified γ-Al 2 o 3 Equal volume impregnation was carried out on the carrier, the drying and roasting process was the same as in Example 1, and the NiO loading was 16%, the CuO loading was 4%, the ZnO loading was 3%, and the HfO loading was 16%. 2 Ni-Cu-Zn-Hf / γ-Al with a loading of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com