2-methyl furan catalyst and preparation method thereof

A methyl furan catalyst, a catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor catalyst stability and achieve high selectivity , high active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

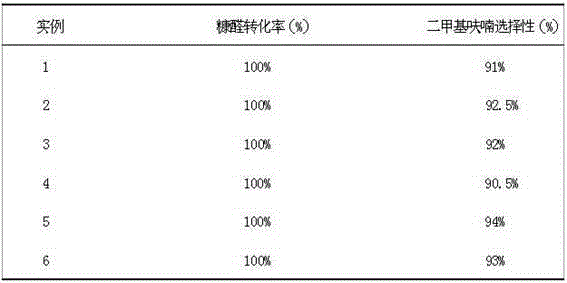

Examples

Embodiment 1

[0018] Dissolve 56 grams of sodium hydroxide in 500 ml of deionized water, dissolve 80 grams of copper nitrate trihydrate, 20 grams of calcium nitrate, and 7 grams of zinc nitrate in 150 ml of deionized water, then add the sodium hydroxide solution to 650 ml of aluminum sol Under the condition of stirring, the aluminum sol solution dissolving the nitrate and the sodium hydroxide aqueous solution were mixed at 60°C to obtain a precipitate with a pH of 7 and then aged for 3 hours. After the precipitate was filtered and washed, it was dried at 140°C for 12 hours, and then in The catalyst was prepared by calcining at 500°C for 4 hours in a muffle furnace.

Embodiment 2

[0020] 186 grams of copper nitrate trihydrate and 28.5 grams of barium nitrate were dissolved in 200 ml of deionized water, and then added to 1500 ml of aluminum sol. Take 740ml of 0.5mol / L ammonia solution, mix the nitrate-dissolved aluminum sol solution and ammonia solution at 50°C under stirring conditions to obtain a precipitate with a pH of 7, then age for 2 hours, filter and wash the precipitate, and store it at 120°C The catalyst was dried under conditions for 12 hours, and then calcined in a muffle furnace at 450° C. for 4 hours.

Embodiment 3

[0022] 32 grams of copper nitrate trihydrate, 2.5 grams of barium nitrate, and 5.0 grams of potassium nitrate were dissolved in 120 ml of deionized water, and then added to 300 ml of aluminum sol. Dissolve 42 grams of sodium carbonate in 250ml of deionized water, mix the aluminum sol solution dissolving nitrate and sodium carbonate aqueous solution at 50°C under stirring conditions to obtain a precipitate, the pH is 7, then age for 2 hours, filter and wash the precipitate Finally, it was dried at 140°C for 12 hours, and then calcined at 500°C for 4 hours in a muffle furnace to prepare the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com