Catalyst for ethylene glycol synthesis through gas phase hydrogenation of dimethyl oxalate, preparation method and applications thereof

A dimethyl oxalate and catalyst technology, applied in the field of catalysts, can solve the problems of high reaction hydrogen ester, low product selectivity, low liquid hourly space velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

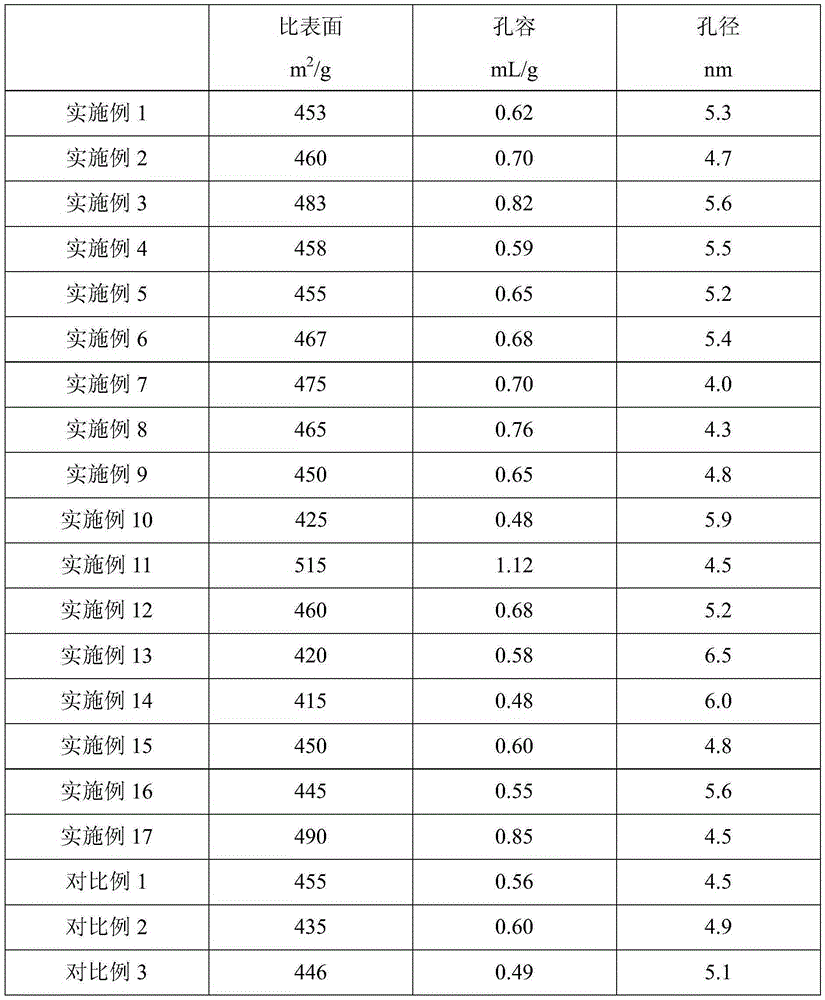

Examples

Embodiment 1

[0054] Prepare the catalyst of gas-phase hydrogenation of dimethyl oxalate to synthesize ethylene glycol, the active component is the oxide of CuO and Ni metal promoter, the carrier is silicon dioxide, the Cu element accounts for 20wt% of the total weight of the catalyst, the Ni metal promoter element Accounting for 3wt% of the total weight of the catalyst, the balance is carrier silica, and the preparation method is as follows:

[0055] Weigh copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) 30g, nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2) 5.9g, add 400ml deionized water to dissolve; Add dropwise concentrated ammonia water, form ammonia complex aqueous solution, control pH value about 11.5; Add white carbon black 28.25g again, mechanical stirring aging 8 hours; Elevate system water bath temperature to 85 DEG C, distill ammonia for 2 to 3 hours until the pH is 6.5 and stop, the catalyst mother liquor becomes a gel state; filter and wash to obtain the catalyst filter cake; add organic modifi...

Embodiment 2

[0058] Preparation of dimethyl oxalate gas phase hydrogenation synthesis of ethylene glycol catalyst, the active component is the oxide of CuO and Ni metal promoters, the carrier is silicon dioxide, the Cu element accounts for 30wt% of the total weight of the catalyst, and the Ni metal promoter element accounts for 3wt% of the total weight of the catalyst, and the balance is carrier silica, the preparation method is as follows:

[0059] Weigh copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) 50g, nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2) 6.5g, add 400ml deionized water to dissolve; Drop concentrated ammonia water, be made into ammonia complex solution, control pH value about 12.5; Add white carbon black 26g again, mechanical stirring aging 8 hours; Elevate system water bath temperature to 85 DEG C, steam ammonia for 2 to 3 hours until the pH is 6.0 and stop, the catalyst mother liquor becomes a gel state; filter and wash to obtain the catalyst filter cake; add organic modifier polyethylen...

Embodiment 3

[0062] Preparation of dimethyl oxalate gas phase hydrogenation synthesis of ethylene glycol catalyst, the active component is the oxide of CuO and Ni metal promoter, the carrier is silicon dioxide, Cu element accounts for 40wt% of the total weight of the catalyst, Ni metal promoter element accounts for 3wt% of the total weight of the catalyst, and the balance is carrier silica, the preparation method is as follows:

[0063] Weigh copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) 70g, nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2) 6.9g, add 400ml deionized water to dissolve; Drop concentrated ammonia water, be made into ammonia complex solution, control pH value about 11.0; Add white carbon black 21g again, mechanical stirring aging 8 hours; Elevate system water bath temperature to 85°C, distill ammonia for 2-3 hours until the pH is 7.5 and stop, the catalyst mother liquor becomes gel state; filter and wash to obtain catalyst filter cake; add organic modifier polyethylene glycol 1.1g (white 5w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com