High-speed cutting experiment device based on Hopkinson pressure lever loading technology

A Hopkinson pressure bar and high-speed cutting technology, applied in the field of metal cutting, can solve problems such as difficult and steady-state high-speed cutting, and achieve the effect of short duration and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

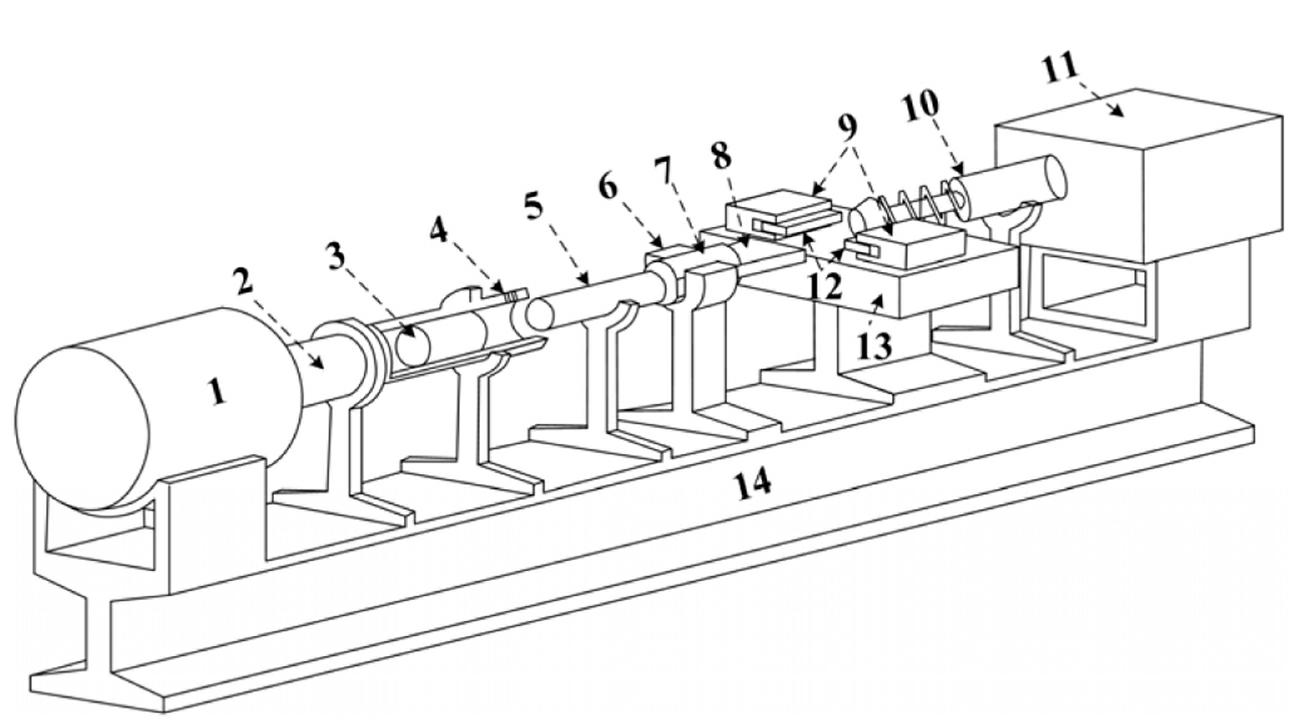

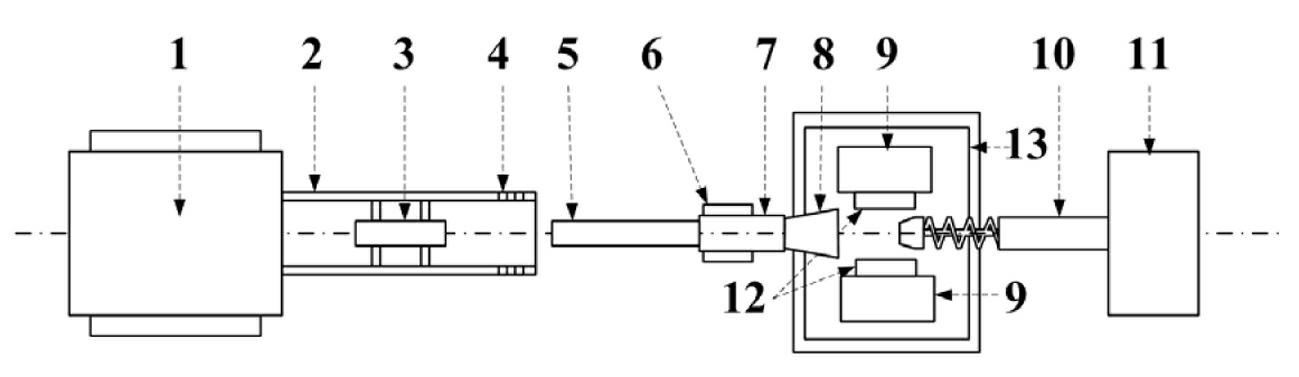

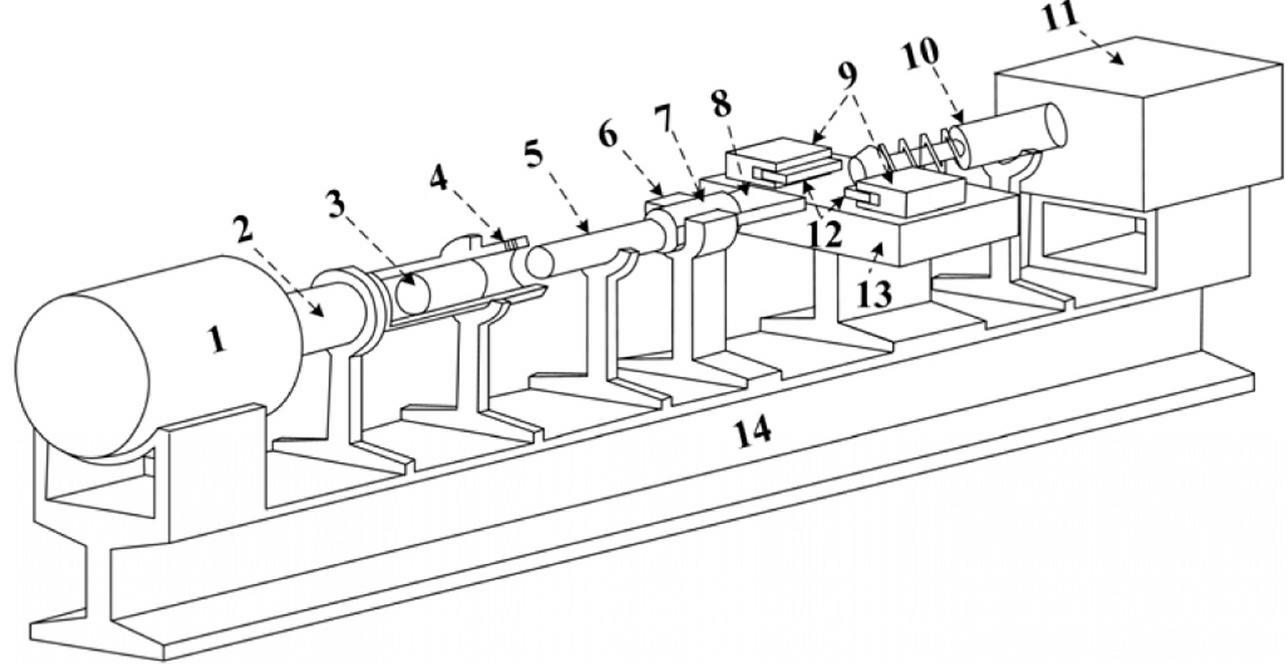

[0025] The whole device is installed on the support, and the specific implementation steps are as follows:

[0026] 1. If figure 1 As shown, the thickness is 6 mm, the rake angle is 0 0 , back angle 15 0 The tool 8 is mounted on one end of the incident rod 5 with a diameter of Φ13 mm through the tool clamping device 7 . The injection rod is placed on the guide groove 6 to ensure that the other end of the injection rod is facing the outlet of the light air gun and keeps a distance of about 100 mm from the muzzle.

[0027] 2. Install the two workpiece clamping and high-precision positioning devices 9 symmetrically on the high-precision lifting platform 13 along the axis of the light air gun and the incident rod. During the installation process, ensure that the distance between the two is slightly larger than the width of the tool and as close as possible to the tool . Process two workpieces with a length of 60 mm, a width of 40 mm, and a thickness of 4 mm and install them on...

Embodiment 2

[0033] In the case of keeping the parameters in Example 1 unchanged, adjust the air pressure value of the light air gun 1 to make it 0.8 MPa, and finally realize the cutting experiment with a cutting speed of 880 m / min.

Embodiment 3

[0035] In the case of keeping the parameters in Example 1 unchanged, adjust the air pressure value of the light air gun 1 to make it 0.25 MPa, and finally realize the cutting experiment with a cutting speed of 200 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com