Electromagnetically driven high-speed cutting simulation experimental device

A high-speed cutting and experimental device technology, applied in the field of metal cutting, can solve problems such as limited energy, complicated equipment, hidden gunpowder safety hazards, etc., and achieve the effects of adjustable electromagnetic energy, short discharge time, and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

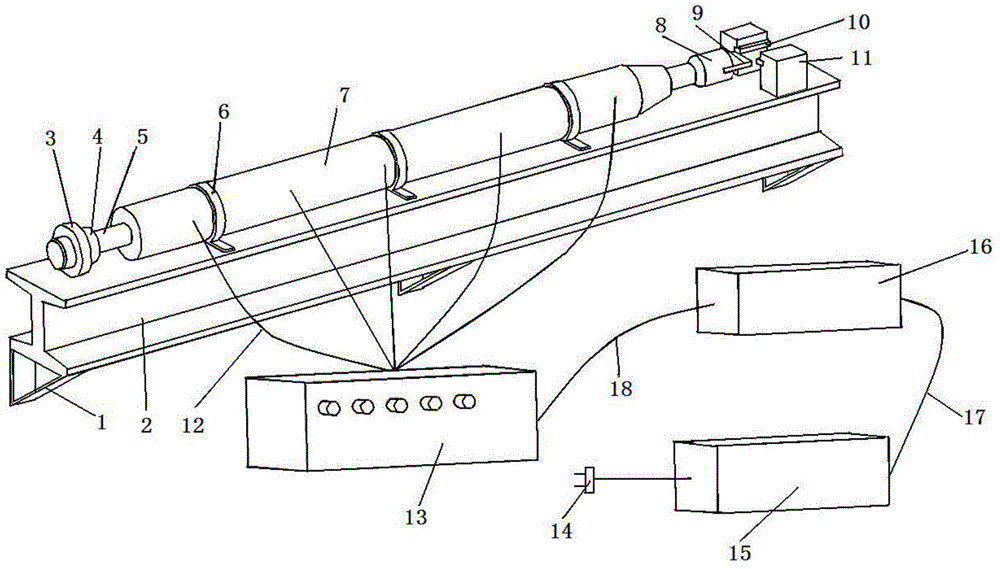

[0029] Such as figure 1 As shown, an electromagnetically driven high-speed cutting experimental device includes a power mechanism, a cutting mechanism and a fixing mechanism. The mechanism includes a tool clamping device 8 and a tool 9 installed thereon. The fixed mechanism includes a support frame 1, a support 2, a fixing hoop 6 and a workpiece clamping and positioning device 11. The electromagnetic driver 7 of the power mechanism It is fixed on the support 2 through the fixing hoop 6 , the support 2 is fixed on the wall through the supporting frame 1 , and the tool holding device 8 is installed on one end of the aluminum alloy rod 5 .

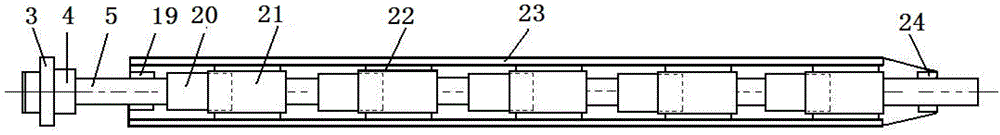

[0030] The electromagnetic driver 7 includes an aluminum alloy rod end stopper 3, a buffer pad 4, an aluminum alloy rod 5, the buffer pad 4 is set on the aluminum alloy rod 5, and the aluminum alloy rod end stopper 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com