A hard rock hobbing cutter rock breaking characteristic testing device

A characteristic test, hob technology, applied in the direction of testing wear resistance, testing machinability, etc., can solve the problem of inability to study the wear process of the hob, the magnitude of the force and the small adjustable range, and the inability to study the impact of the hob on rock breaking, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

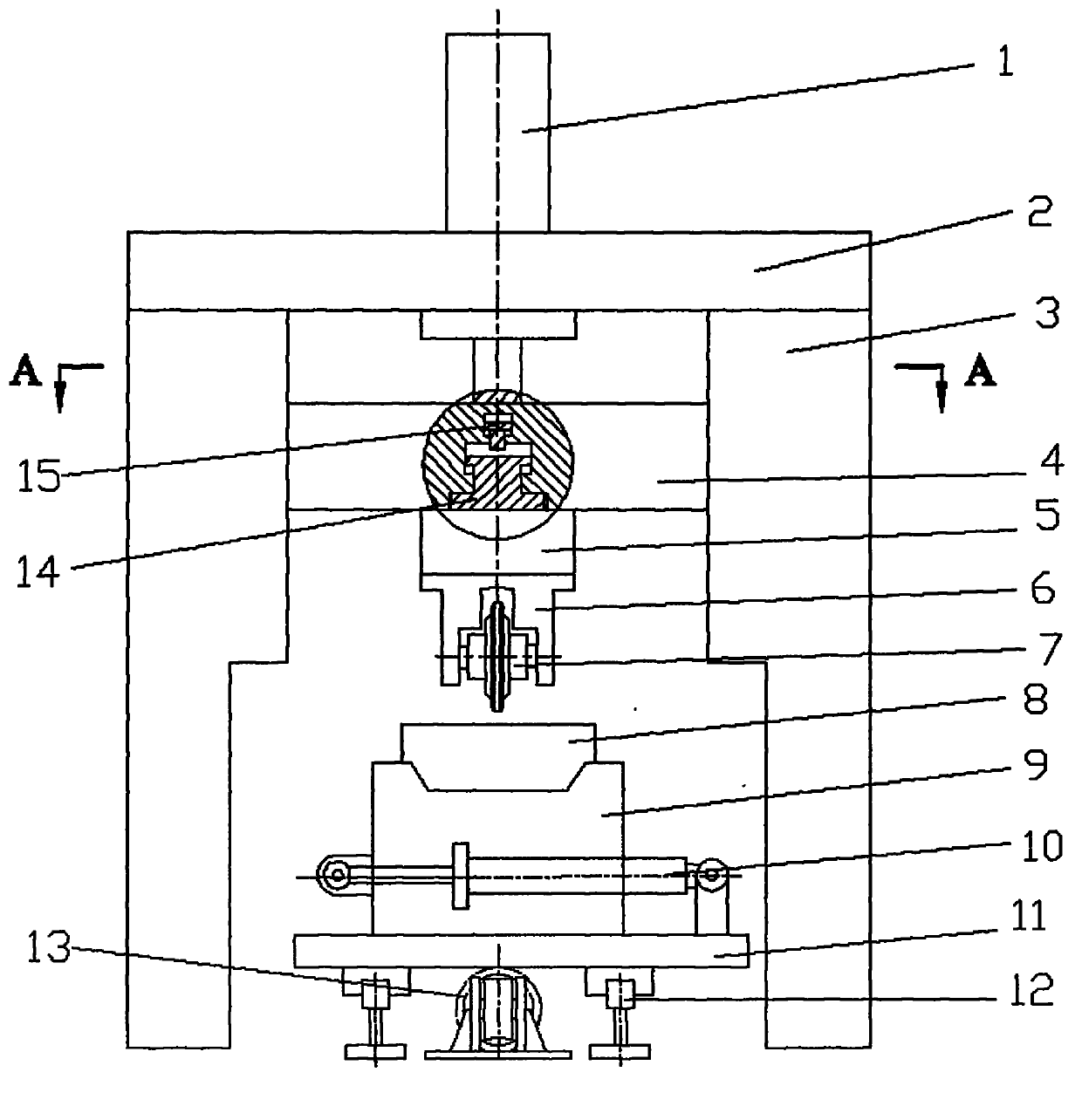

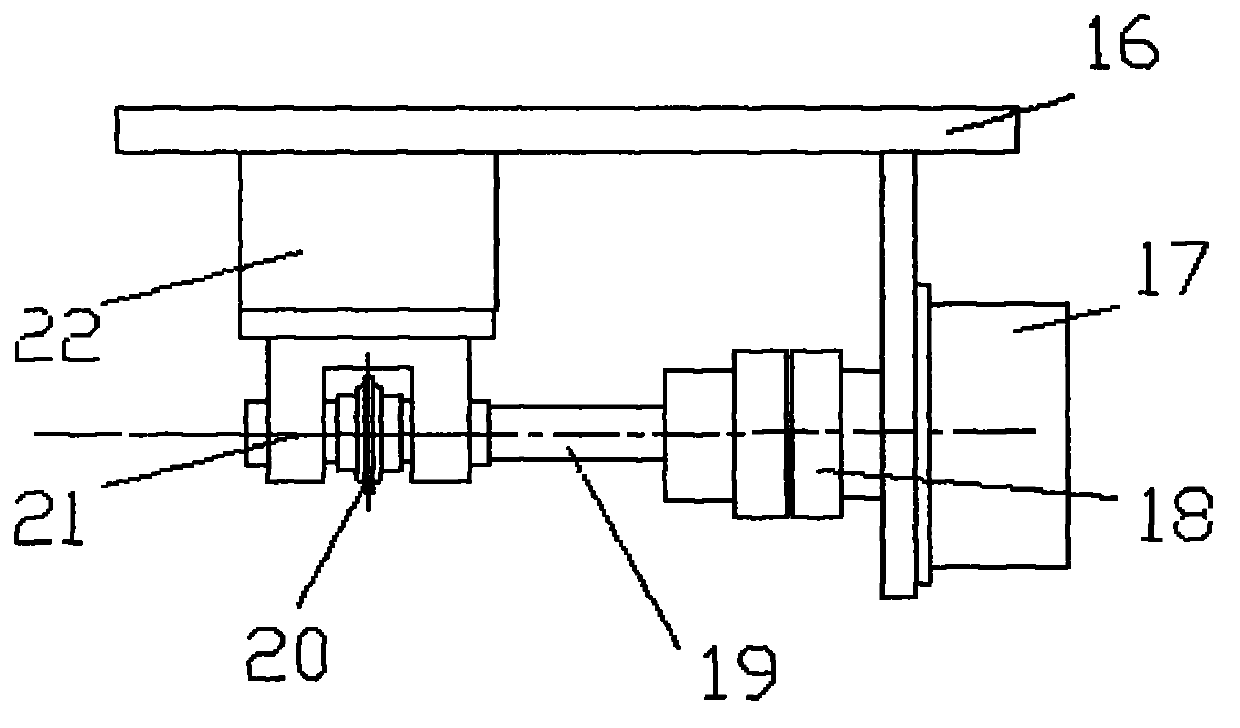

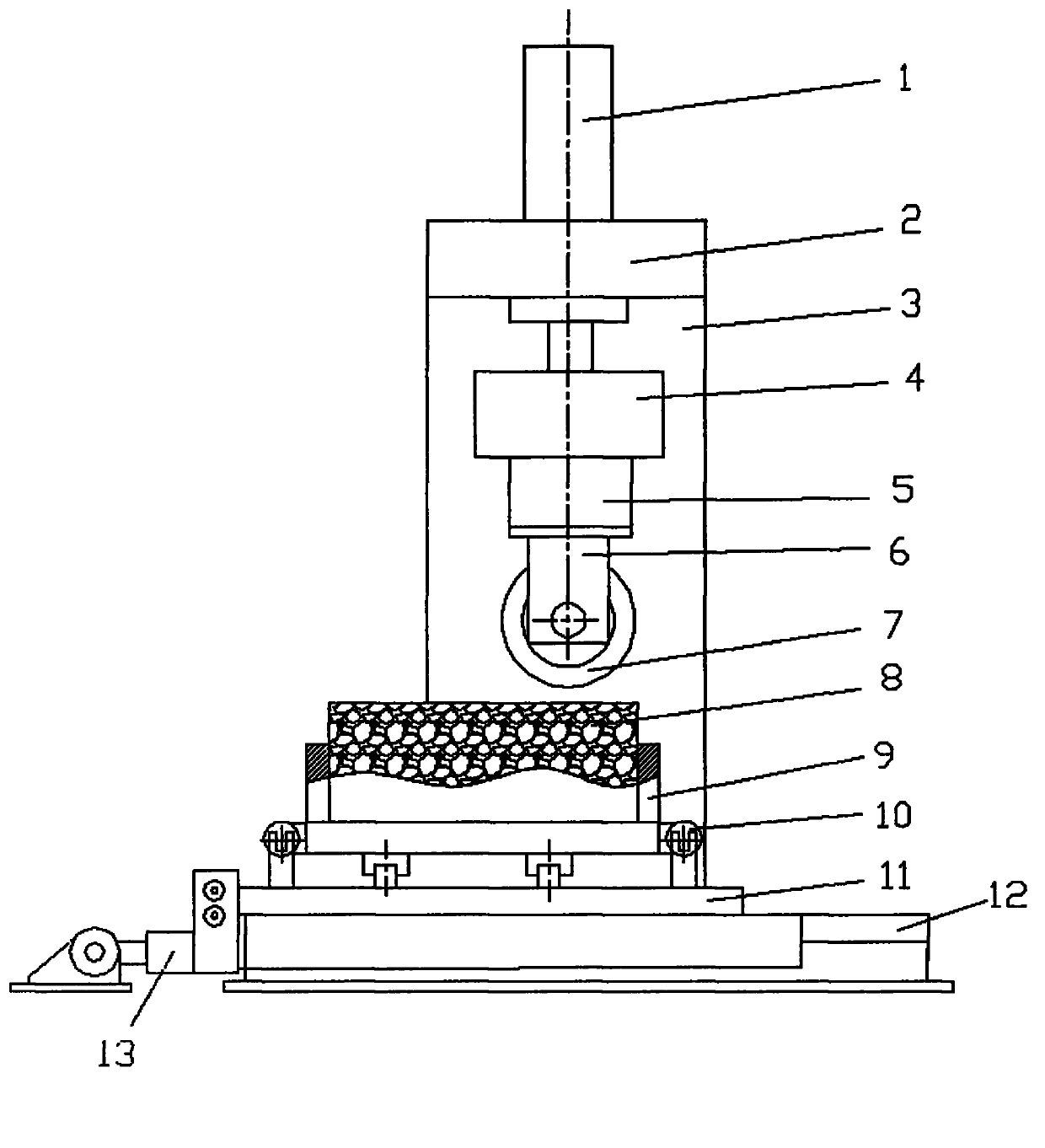

[0021]As shown in the figure, the present invention mainly consists of a vertical hydraulic cylinder 1, a beam 2, a column 3, a movable beam 4, a three-way force sensor 5, a hob mounting seat 6, a hob 7, a rock sample 8, a stone bin 9, a horizontal Shift hydraulic cylinder 10, stone bin support seat 11, guide rail pair 12, longitudinal shift hydraulic cylinder 13, impact rod 14, impact hydraulic cylinder 15, similar hob wear module mounting seat 16, hydraulic motor 17, coupling 18, connecting shaft 19. It consists of a similar hob 20, a similar hob mount 21, a small-range three-way force sensor 22 and a test system. The stone bin support seat 11 is placed on the guide rail pair 12, and the stone bin support seat 11 is connected with a vertical movement hydraulic cylinder 13 fixed on the ground, and the longitudinal movement hydraulic cylinder 13 realizes the feed movement of the stone bin 9 in the longitudinal direction; the stone bin 9 is placed on the stone bin 9. On the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com