Measure apparatus of machining deformation and dynamic response for thin-wall part of aircraft

A thin-walled parts processing and dynamic response technology, applied in the direction of testing machinability, etc., can solve the problems of thin-walled parts vibration, reducing processing efficiency, and becoming waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

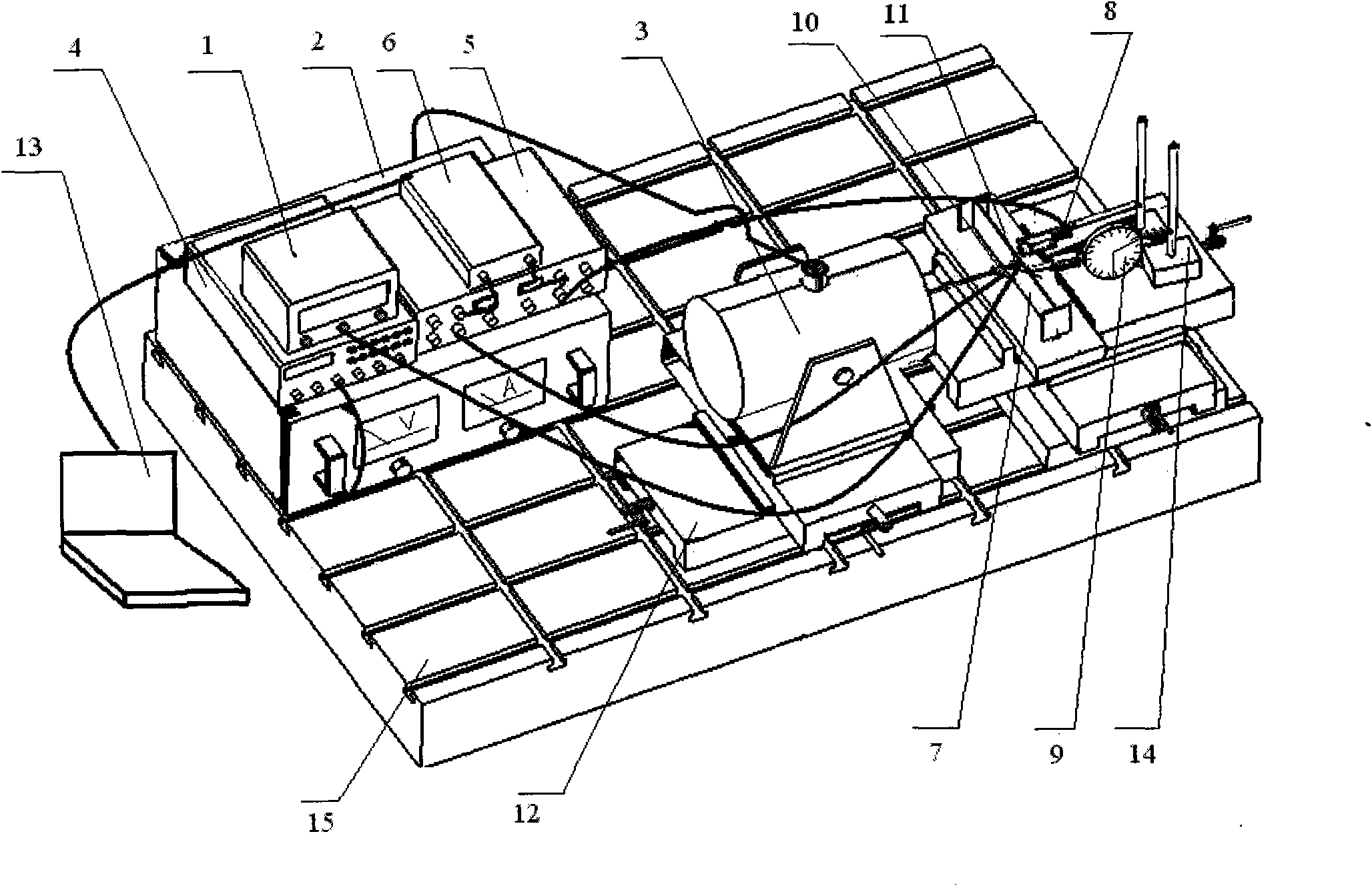

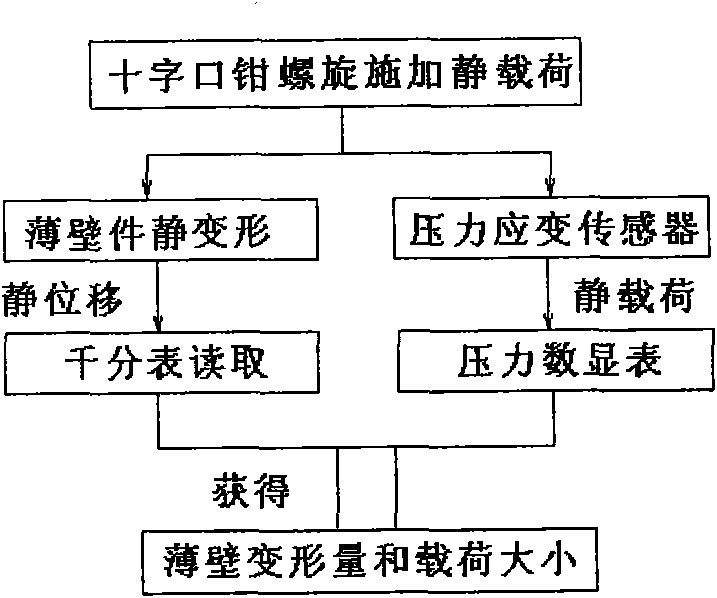

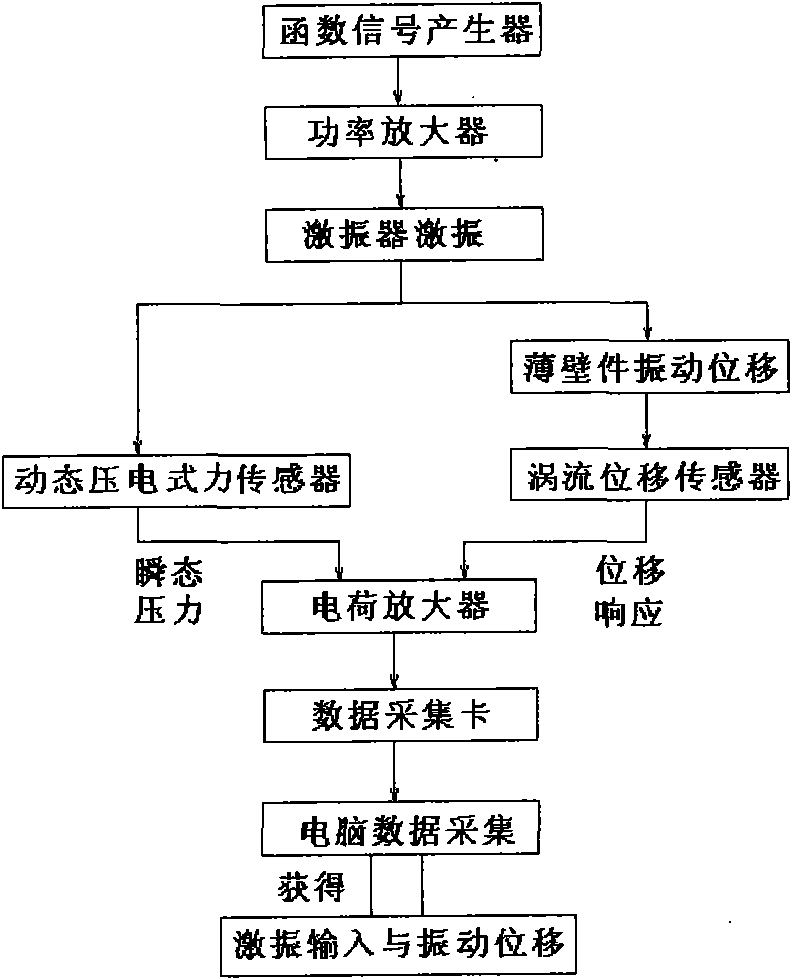

[0042] See figure 1 , the present invention is a measuring device for machining deformation and dynamic response of aviation thin-walled parts. 6. Thin-walled parts to be measured 7. Non-contact eddy current displacement sensor 8. Dial indicator 9. Dynamic piezoelectric force displacement sensor 10. Static pressure sensor 11. Cross vise assembly 12. Data acquisition software and computer system 13 , a magnetic table base 14 and an experimental platform 15;

[0043] The positional connection relationship between them is: the dynamic piezoelectric force sensor 10 is in contact with the thin-walled part 7 to be measured, one end of the data connection line is connected with the charge amplifier 5, and the charge amplifier 5 is connected with the signal acquisition card 6, and the signal acquisition Card 5 is connected with data acquisition software and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com