TBM rock breaking test apparatus

A test device and rock-breaking technology, which is applied in the field of hard rock tunnel excavators, can solve the problems of inability to study the cutting tools, inability to obtain the relationship between the installation positions of the cutting tools through tests, and the inability to truly simulate the working process of the cutting tools, so as to achieve high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention is not limited to the following examples.

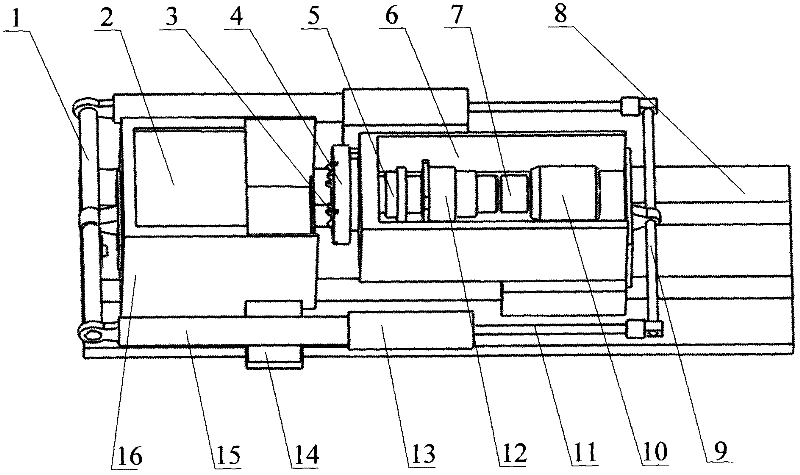

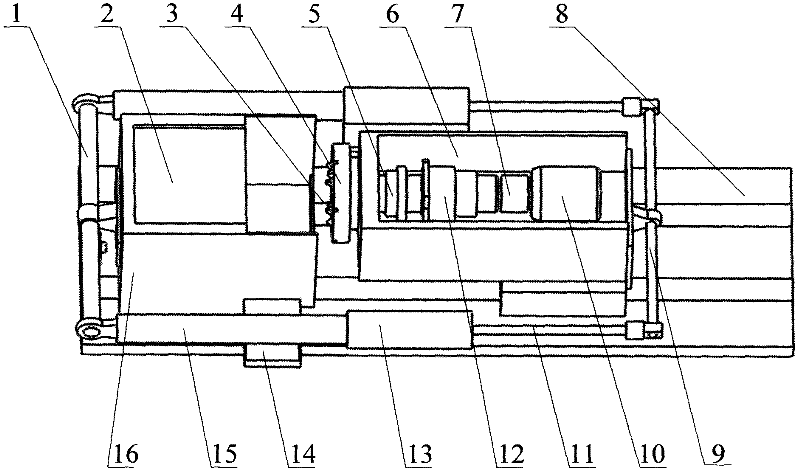

[0012] like figure 1 Shown: A TBM rock-breaking test device includes rock box rear thrust rod 1, cutter 3, cutter head 4, coupling 5, transmission box 6, torque speed sensor 7, workbench 8, front thrust rod 9, motor 10. Hydraulic rod 11, reducer 12, guide bracket 13, thrust mechanism and rock box 16. The rock box 16 and the transmission box body 6 are all arranged on the workbench 8 and are slidably connected with the workbench 8 . In order to improve the stability of operation, the rock box 16, the transmission box body 6 and the worktable 8 are connected by dovetail grooves, that is, dovetail guide grooves are opened at the bottom of the rock box 16 and the transmission box body 6, and a dovetail guide groove is provided on the workbench 8. guide. The outer side of the rock box 16 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com