Position adjustable multi-hob rotary cutting test-bench

A cutting test and hob technology, applied in the field of rotary cutting test platform, can solve problems such as no patent publication, and achieve the effects of prolonging cutting life, intuitive and accurate experiments, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

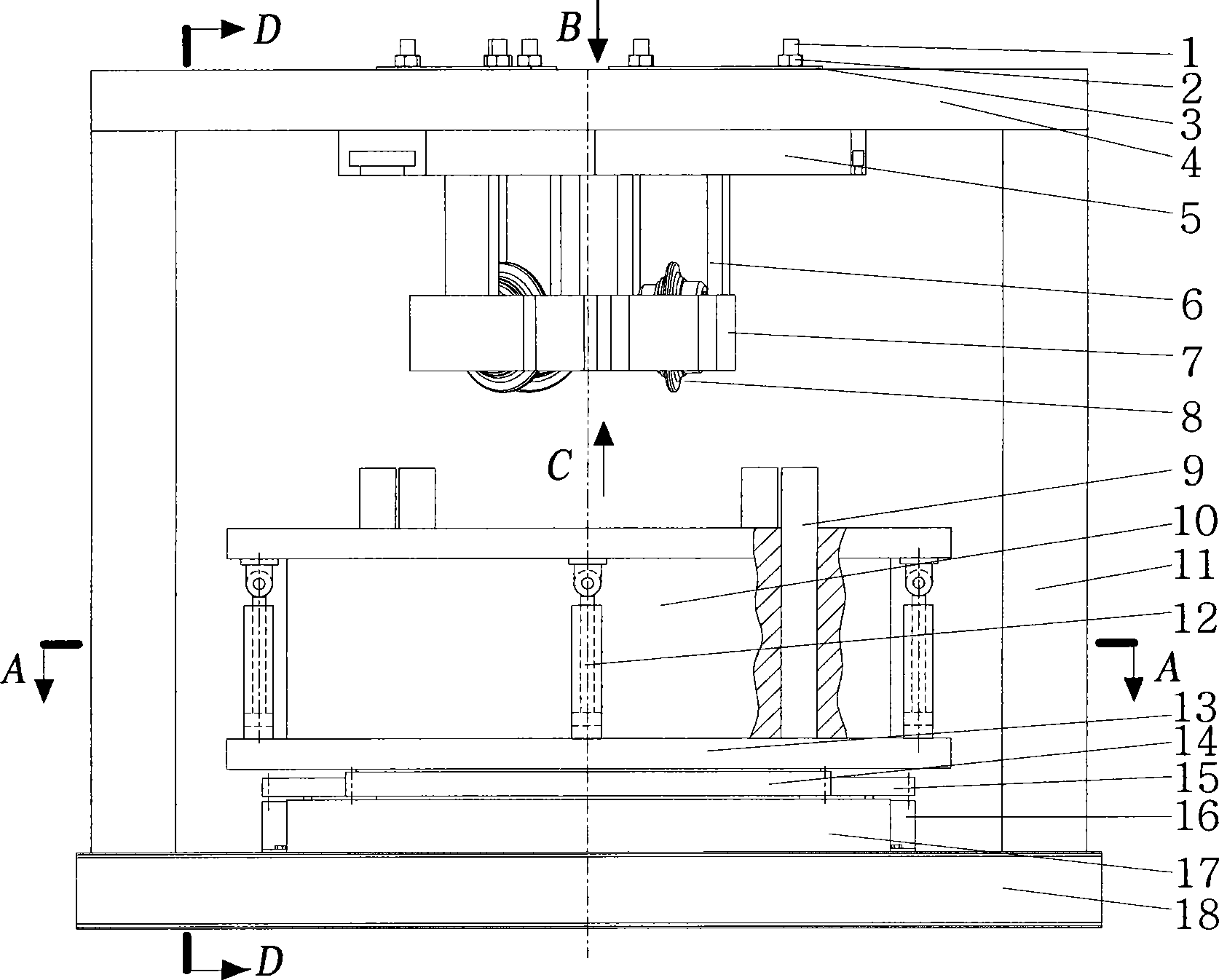

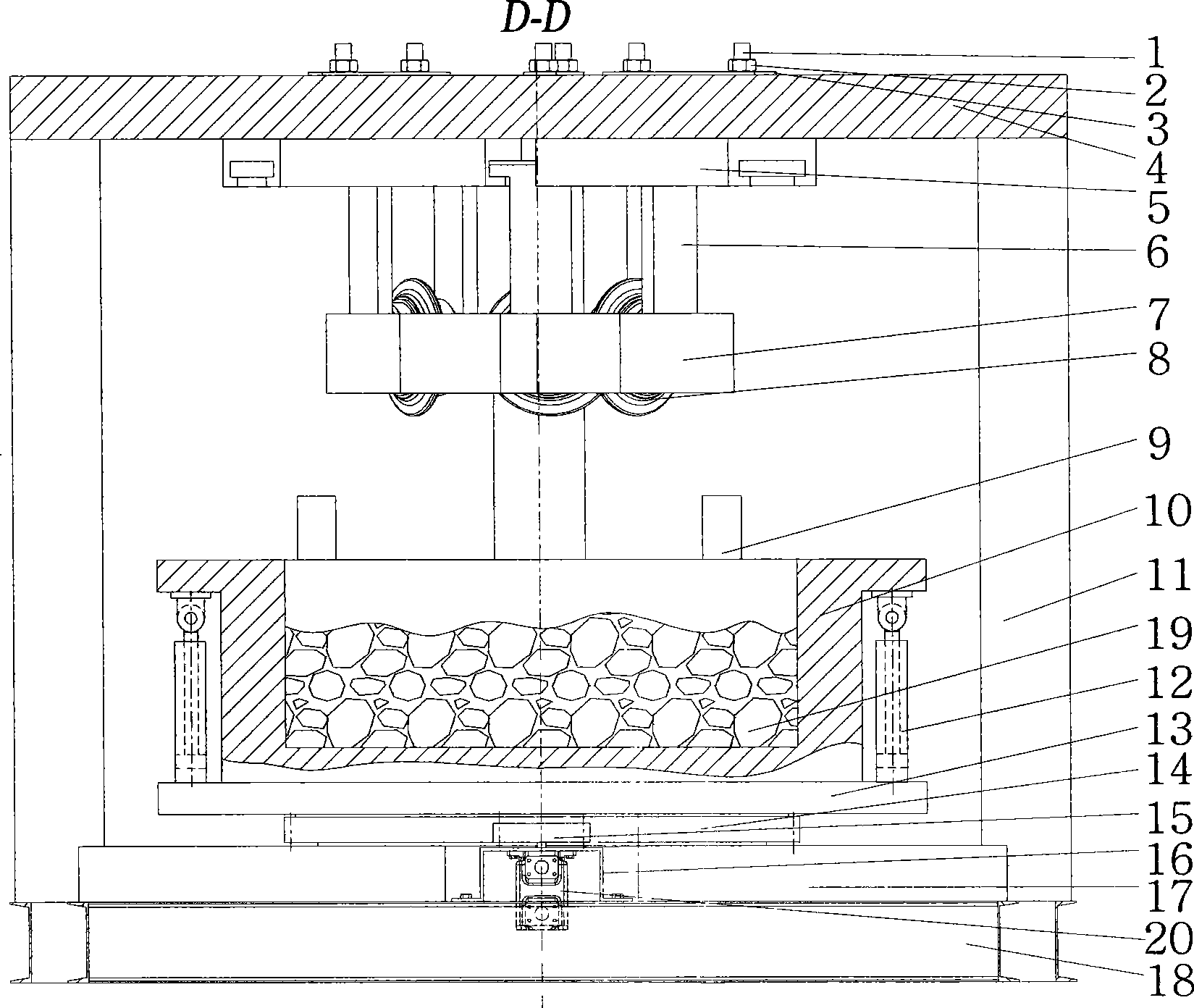

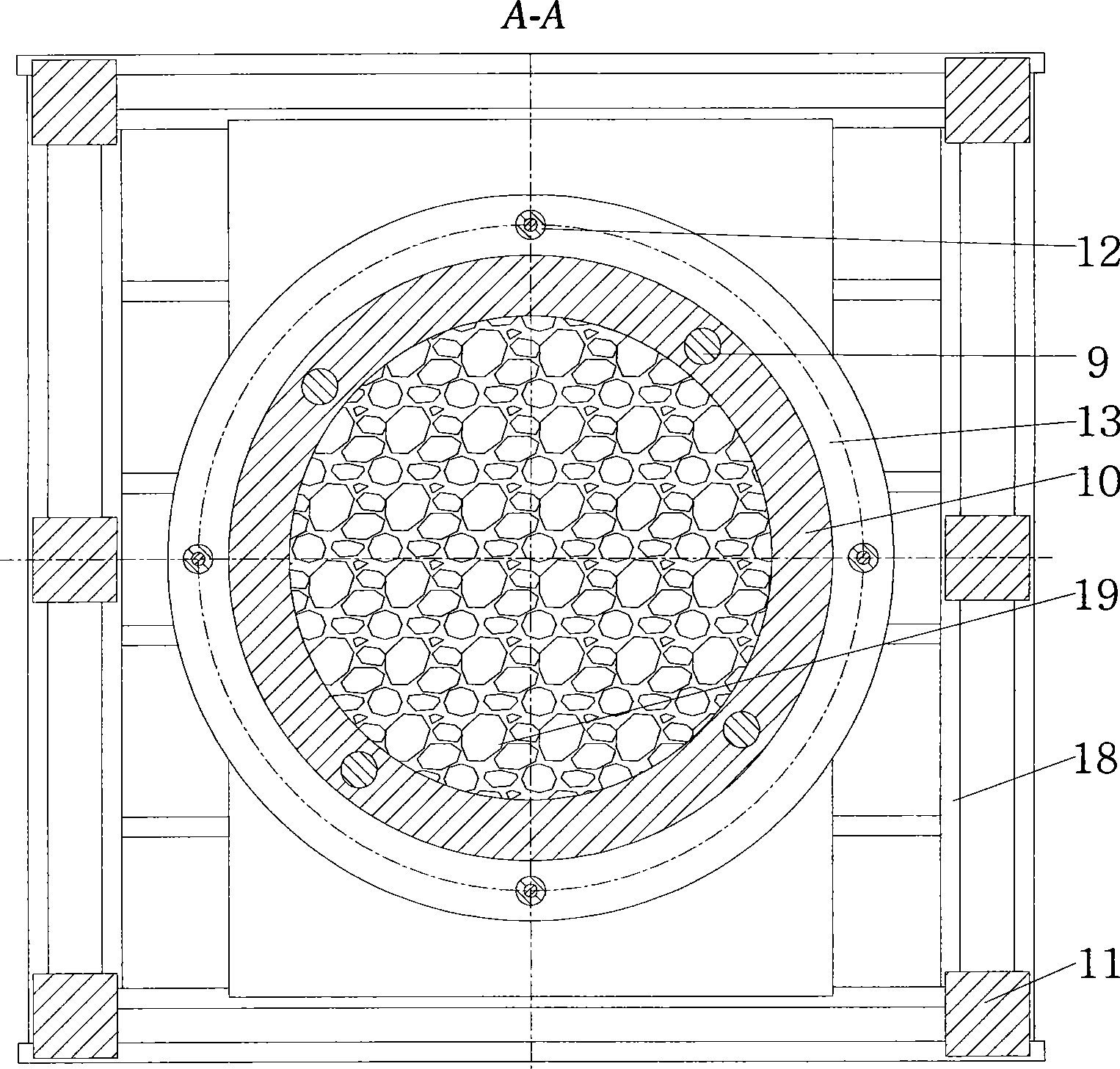

[0022] Such as figure 1 As shown, the present invention includes a bolt 1, a nut 2, a backing plate 3, a top bracket 4, a chute guide rail 5, a connecting body 6, a hob seat 7, a disc hob 8, a guide column 9, a column 11, and an earth bin 10. Vertical hydraulic cylinder 12, hydraulic motor 20, soil bin support seat 13, slewing bearing 14, pinion gear 15, base 17 and foundation frame 18, etc. The slewing support 14 is used between the soil silo support seat 13 of the fixed soil silo 10 and the rectangular base 17 fixed on the foundation frame 18, and is driven to rotate synchronously by two hydraulic motors 20, and the hydraulic motor 20 is installed on the motor mounting frame 16. The motor mounting frame is installed on the foundation frame 18 . The inner ring of the slewing bearing 14 is fixed on the rectangular base 15, and the outer ring is connected with the soil bin support seat 13. The soil bin 10 has a flange, and four evenly distributed vertical hydraulic cylinders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com