High-pressure multi-phase jet-flow cutting performance test system and method

A technology of cutting performance and testing system, which is applied in the direction of testing machinability, etc., can solve the problems of inability to test and study cutting rock-breaking performance and its characteristic parameters, so as to avoid water splashing, ensure personnel safety, and have strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

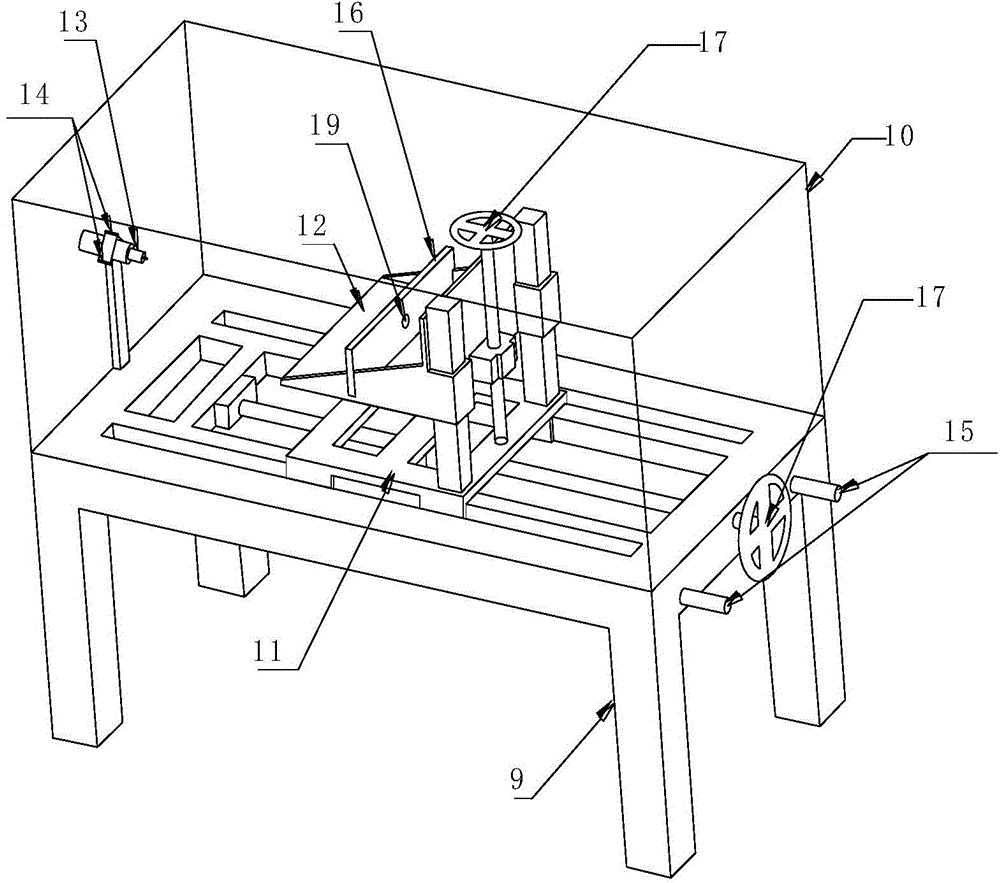

[0031] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

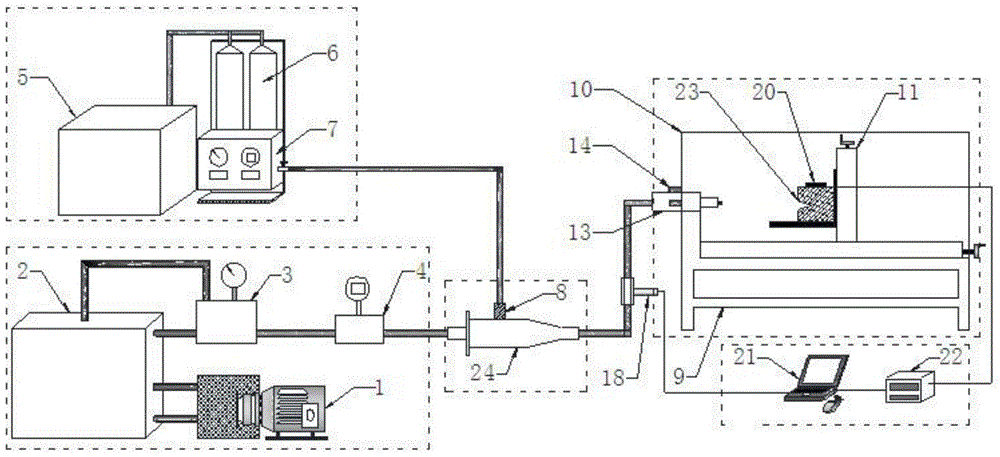

[0032] Such as figure 1 As shown, a high-pressure multi-phase jet cutting performance testing system of the present invention includes a high-pressure water supply system, a high-pressure air supply system, a gas-liquid mixing device 24, a test platform, and a test monitoring system.

[0033] The high-pressure water supply system is mainly composed of an emulsion plunger pump 1, a water tank 2, a pressure regulating valve 3 and an intelligent vortex flowmeter 4, among which the pressure regulating valve 3 and the intelligent vortex flowmeter 4 can control the emulsion plunger pump 1 The outlet water pressure and outlet water flow rate are adjusted and monitored respectively; the high-pressure air supply system is mainly composed of an air compressor 5, a gas storage cylinder 6 and an air source distribution box 7, of which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com