Cashew nut oil-modified phenolic resin and preparation method thereof

A technology of phenolic resin and cashew nut oil, which is applied in the field of cashew nut oil modified phenolic resin and its preparation, can solve the problems of uncontrollable, gel, violent reaction, etc., and achieve the effect of improving compatibility, easy availability of raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

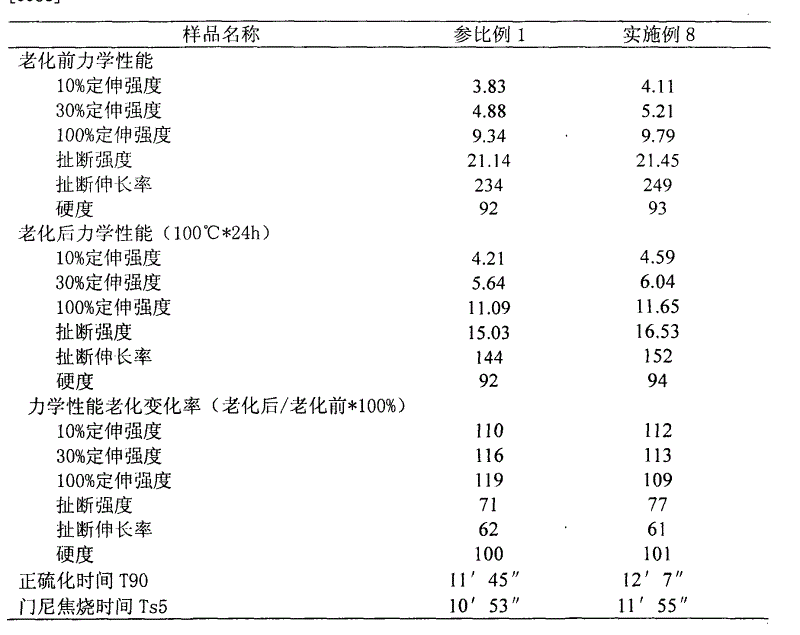

Examples

Embodiment 1

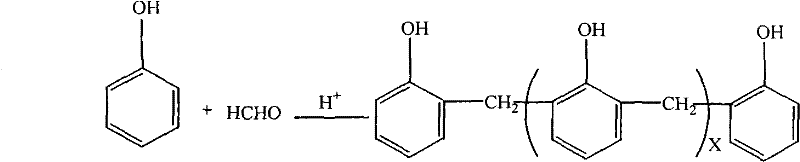

[0035] 147 kg of phenol and 2.29 kg of p-toluenesulfonic acid were added to the reactor, the temperature was raised to 100°C and 45.9 kg of formaldehyde solution with a mass concentration of 37% and 14.1 kg of paraformaldehyde were sequentially added. The water generated by the reaction is distilled off to obtain a phenol-formaldehyde polycondensate. Then add 52 kg of cashew nut oil into the phenol-formaldehyde polycondensate, control the reaction temperature at 160°C and react for 2.5 hours, keep it under the condition of vacuum degree -0.08MPa for 15 minutes, and then neutralize it with 2.07 kg of DBU to obtain modified cashew nut oil. Reactive phenolic resin. The resin has a softening point of 92.5°C and a free phenol content of 0.69%.

Embodiment 2

[0037] Add 147 kg of phenol and 2.9 kg of p-toluenesulfonic acid into the reactor, heat up to 90°C and add 90 kg of formaldehyde solution with a mass concentration of 37%, react at 100°C for 1 hour after the addition of formaldehyde, and steam the water generated by the reaction. A phenol-formaldehyde condensation polymer was obtained. Then add 52 kg of cashew nut oil into the phenol-formaldehyde condensation polymer, control the reaction temperature at 180°C and react for 1 hour, keep it under the condition of vacuum degree -0.09MPa for 15 minutes, and then neutralize with 2.26 kg of triethanolamine to obtain modified cashew nut oil. Reactive phenolic resin. The resin has a softening point of 97.3°C and a free phenol content of 0.05%.

Embodiment 3

[0039] Add 147 kg of phenol and 3.41 kg of dodecylbenzenesulfonic acid into the reactor, raise the temperature to 90°C and add 62.9 kg of formaldehyde solution with a mass concentration of 37%, react at 100°C for 1 hour after the addition of formaldehyde, and evaporate to form of water to obtain phenol-formaldehyde condensation polymers. Then add 36 kg of cashew nut oil into the phenol-formaldehyde polycondensate, control the reaction temperature at 180°C and react for 1.5 hours, keep it for 15 minutes under the condition of vacuum degree -0.1MPa, and then neutralize with 0.88 kg of 50% NaOH to obtain cashew nut oil. Reactive phenolic resin. The resin had a softening point of 104°C and a free phenol content of 1.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com