Copolymerized resin of melamine phenol and formaldehyde and its production method

A technology of formaldehyde copolymer resin and melamine phenol, applied in the field of resin glue, can solve problems such as insufficient chemical structure, influence on production efficiency and cost, complicated process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

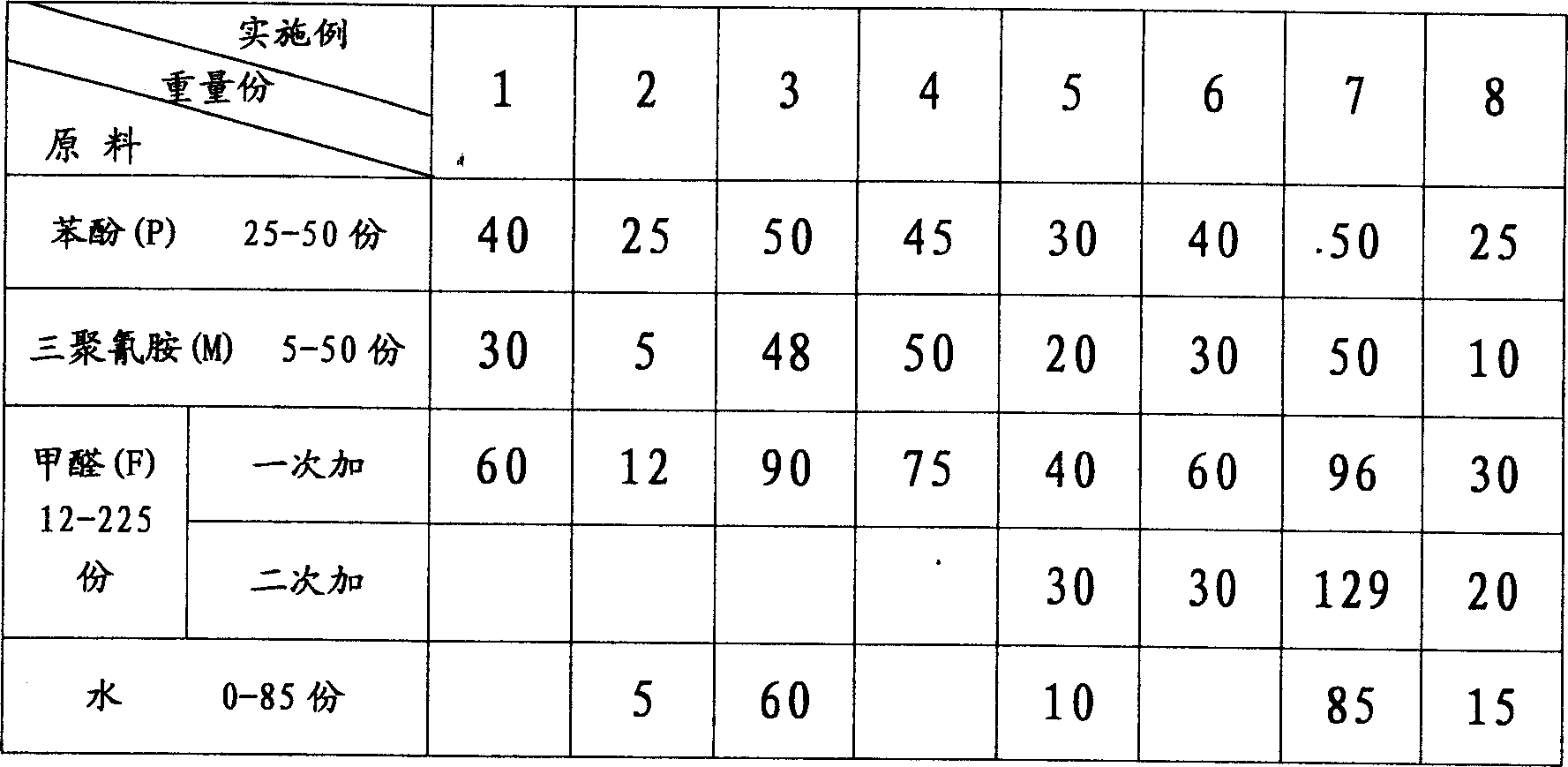

[0007] Embodiment 1 (referring to serial number and the proportioning figure of parts by weight in the table):

[0008] First melt 40 parts of phenol (hereinafter represented by P) in the reactor, add formaldehyde

[0009]

[0010] (hereinafter represented by F) 60 parts, use NaOH solution to adjust PH=7.5-9.5, stir evenly, heat up to 40-60°C, add 30 parts of melamine (hereinafter represented by M), stir evenly, then measure and adjust PH=7.5 -9.5, continue to evenly heat up to 85-95°C, keep warm for 60-90 minutes, measure the water-soluble ratio at 25°C water temperature is 0.5-2.0, cool to 45°C, stop the reaction and discharge.

Embodiment 2

[0012] Melt 25 parts of P in the reaction kettle, add 12 parts of F and 5 parts of M, add 5 parts of water when F is added, or when M is added, or when the pH value is adjusted, and this rubber is obtained by the same method as in Example 1 .

Embodiment 5

[0014] Melt 30 parts of P in the reactor, add F 1 (Indicating adding for the first time) 40 parts, adjust PH=7.5-9.5 with ammonia water or KOH, stir evenly, heat up to 40-60°C, add 20 parts of M, add 10 parts of water at the same time, stir evenly, retest and adjust PH=7.5- 9.5, continue to evenly heat up to 80-95°C, keep warm for 40-60 minutes, add F when the water-soluble ratio is about 2.0 in 25°C warm water 2 (Indicates the second addition) 30 parts, continue to keep warm for 0.5-1 hour on the basis of 80-95 ° C, and then measure the water-soluble ratio of 0.5-1.5, cool to 45 ° C to terminate the reaction and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com