Melamine and urea modified phenolic resin and its production process

A technology of melamine and phenolic resin, applied in the field of melamine, urea-modified phenolic resin and its production, can solve the problems affecting the resin bonding strength, stability, storage period, insufficient copolycondensation reaction, poor wear resistance, fire resistance, etc. problem, to achieve the effect of good fire resistance, low cost and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

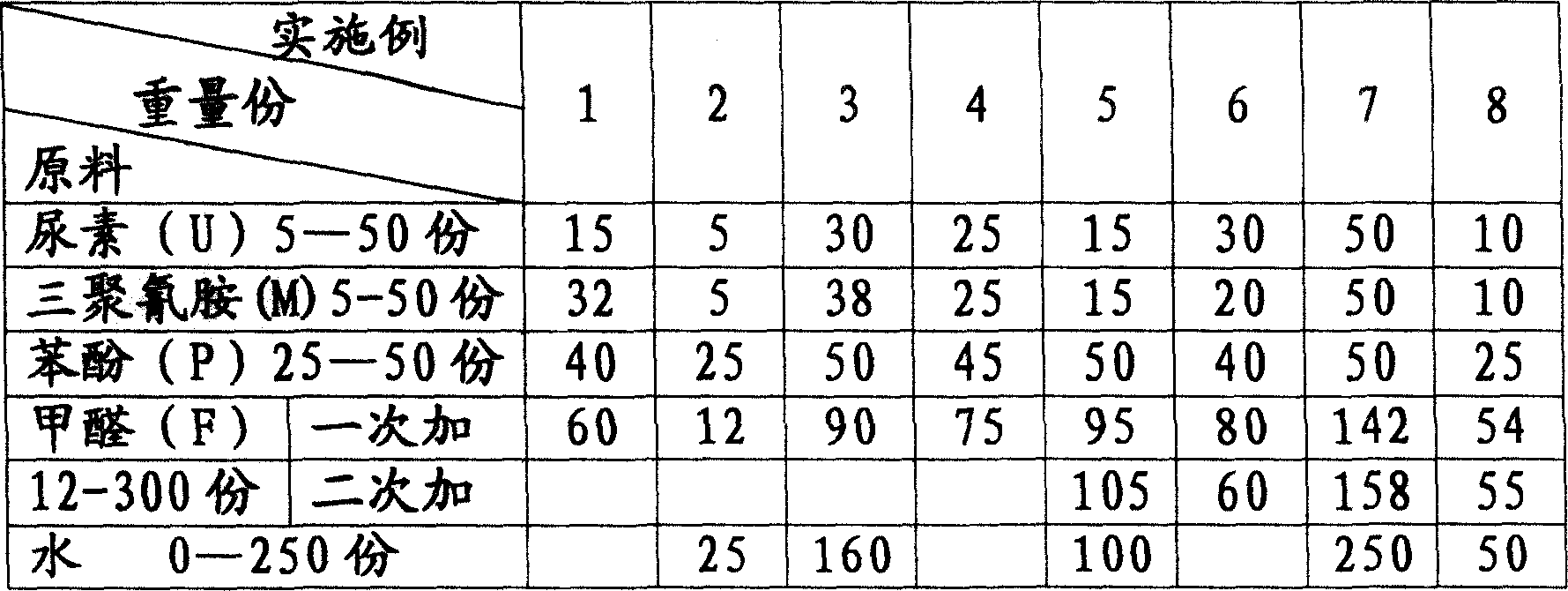

[0010] Embodiment 1 (referring to serial number and the proportioning figure of parts by weight in the table):

[0011] First melt 40 parts of phenol (P) in the reactor, add 60 parts of formaldehyde (F), 15 parts of urea (U), and 32 parts of melamine (M), adjust the pH to 6-8, and raise the temperature to 75-100°C. Insulate for 30-100 minutes, then use ammonium chloride to adjust PH=3.0-5.5, and carry out co-condensation reaction. When the viscosity is ≥20S (20°C, apply 4 cups), use NaoH to adjust PH=7.5-12.0, do not add water, and control the temperature 80-95°C, heat preservation reaction to the end, cooling and discharging.

Embodiment 2

[0013] Melt 25 parts of P in the reactor, then add 5 parts of U, 5 parts of M, 12 parts of F, and 25 parts of water, and obtain the resin in the same way as in Example 1.

[0014] Embodiment 3 and 4 are all according to the proportioning in the table, and the method with reference to embodiment 1, 2 makes this resin. Examples 1-4, molar ratio F: (P+U+M)≤1.3, F added at one time.

Embodiment 5

[0016] Melt P50 parts in the reactor, then add U15 parts, M15 parts, design the total amount of F to be 200 parts, add F95 parts for the first time, adjust the pH to 6-8, raise the temperature to 75-100°C, and keep warm for 30-100min , use hydrochloric acid to adjust PH=3.0-5.5, carry out co-condensation reaction, when the viscosity is ≥20S (20°C, apply 4 cups), use Naco 3 , adjust the pH to 7.5-12.0, add 100 parts of water, add the remaining F105 parts twice, control the temperature at 80-95 ° C, keep warm until the end of the reaction, and cool and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com