Non-aldehyde recombinant material and manufacturing method thereof

A manufacturing method and technology for reconstituting materials, which can be used in the manufacture of tools, flat products, other household appliances, etc., can solve the problems of inability to dilute with water solvent, difficult to achieve uniform sizing, and high cost of reconstituted bamboo, so as to reduce costs and reduce costs. Environmental pollution, avoid harmful gas pollution to the air, the effect of strong solid wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of formaldehyde-free recombined wood provided by the present invention comprises several pieces of bamboo (wood) bundles formed by parallel grain structures, between adjacent bamboo (wood) bundles and in the cracks of each bamboo (wood) bundle An adhesive layer is arranged in the middle, and the adhesive of the adhesive layer is aromatic diisocyanate.

[0053] The aromatic diisocyanate is diphenylmethane diisocyanate (MDI) or polymeric isocyanate (PMDI).

[0054] The sizing amount of the aromatic diisocyanate is 5% to 20% of the mass of the dry bamboo (wood) bundle.

[0055] If it is bamboo material, the bamboo bundle contains bamboo green and bamboo yellow.

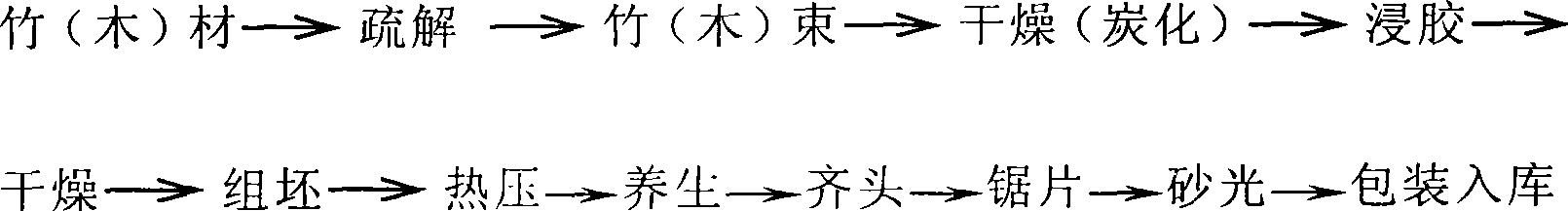

[0056] like image 3 In the process shown, firstly, the fresh moso bamboo is sawn into 2.0m bamboo sections; the moso bamboo is divided into several pieces of bamboo, and after removing the bamboo green and bamboo yellow, it is loosened with a wire press machine to form a network The bamboo bundle of str...

Embodiment 2

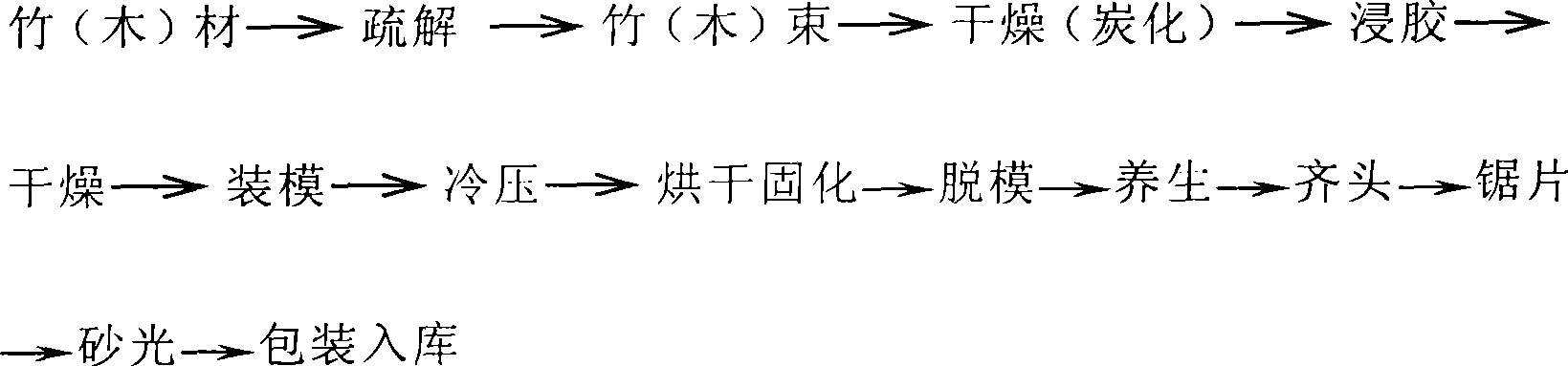

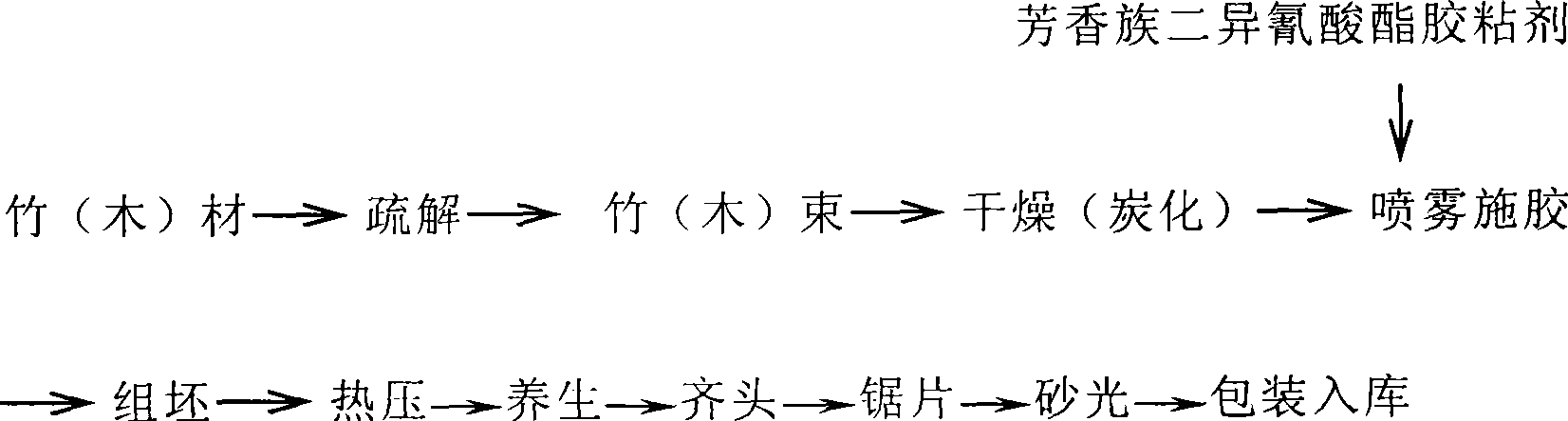

[0071] use as Figure 4 In the process shown, first, fresh green bamboo, dragon bamboo, Ci bamboo, hemp bamboo, thunder bamboo, pole bamboo and other miscellaneous bamboos are cut and sawed into bamboo sections with a length of 2.0m; then they are divided into several bamboo pieces , using a debonding machine to decompose it to form bamboo bundles with a network structure, and the bamboo bundles contain bamboo green and bamboo yellow.

[0072] Drying of bamboo bundles: the above bamboo bundles were dried in an oven at 103° C. so that the final moisture content was 15%.

[0073] Bamboo bundle sizing: use the airless spray sizing method, the glue output pressure is 10MPa, the diameter of the nozzle is 0.35mm, and polymerized isocyanate (PMDI) is evenly sprayed on the bamboo bundle surface, and the sizing amount is the dry bamboo bundle 5% by weight.

[0074] Pavement of slabs: Weigh the wood bundles according to the preset density, and lay the above-mentioned sized wood bundle...

Embodiment 3

[0081] Cut and saw fresh poplar, eucalyptus, masson pine, locust tree, rubber wood, palm tree and other fast-growing wood or economic forest wood into 2.5m long wood sections; form veneers with a thickness of 4mm by rotary cutting, and then form Wood beam blinds with a width of 1220mm.

[0082] Drying of the wood bundle curtain: place the above wood bundle curtain in an oven at 103° C. for drying so that its final moisture content is 20%.

[0083]Glue sizing of wood beam curtains: Airflow spray sizing method is adopted, the air pressure is 0.35MPa, and the diameter of the nozzle is 1.3mm. The polymeric isocyanate (PMDI) will be evenly sprayed on the surface of the wood beam curtain, and the sizing amount is 18%.

[0084] Pavement of slabs: weigh the wood bundle curtain according to the preset density, and stack the above-mentioned glued wood bundle curtains in parallel along the direction of the grain to form blanks.

[0085] Curing molding: send the assembled slabs into a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com