A non-earthing composite structure for a waterproof pavement layer of a top plate for a road tunnel

A technology of composite structure and pavement layer, which is applied in the direction of roads, roads, on-site paved condensing pavements, etc., to achieve the effects of prolonging service life, improving waterproof performance, and mitigating impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

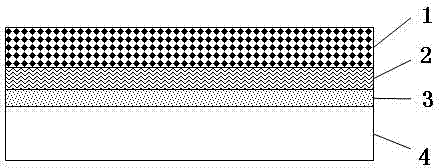

[0017] In the waterproof pavement layer composite structure of the roof under zero-covered soil of the present invention, the structural layers from top to bottom are rubber asphalt protection layer 1-waterproof layer 2-epoxy resin bottom coating 3-cement concrete roof 4.

[0018] The cement concrete roof 4 is leveled first, the leveling layer is composed of fine-grained cement concrete, and the construction joints, expansion joints and seams are treated with caulking paste.

[0019] Epoxy resin base coat 3 adopts epoxy resin adhesive, and paints one layer (about 0.5kg / m2) as the case may be 2 ) or two layers (0.9~1kg / m 2 ), and spread quartz sand of appropriate particle size on the surface of the treatment agent.

[0020] Epoxy resin binder (or epoxy resin waterproof coating) is widely used in bridge deck waterproofing, but it is relatively rare in underground road roof waterproofing. Epoxy resin adhesive has strong cohesive power, and has outstanding cohesive power to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com