Testing method of interlayer bonding power of asphalt pavement

A technology for asphalt pavement and testing methods, which is applied in the direction of measuring devices, instruments, and mechanical devices, can solve problems such as poor operability, failure to consider vertical loads, and the impact of testing accuracy, and achieve a high degree of automation, accurate and reliable data, and Adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

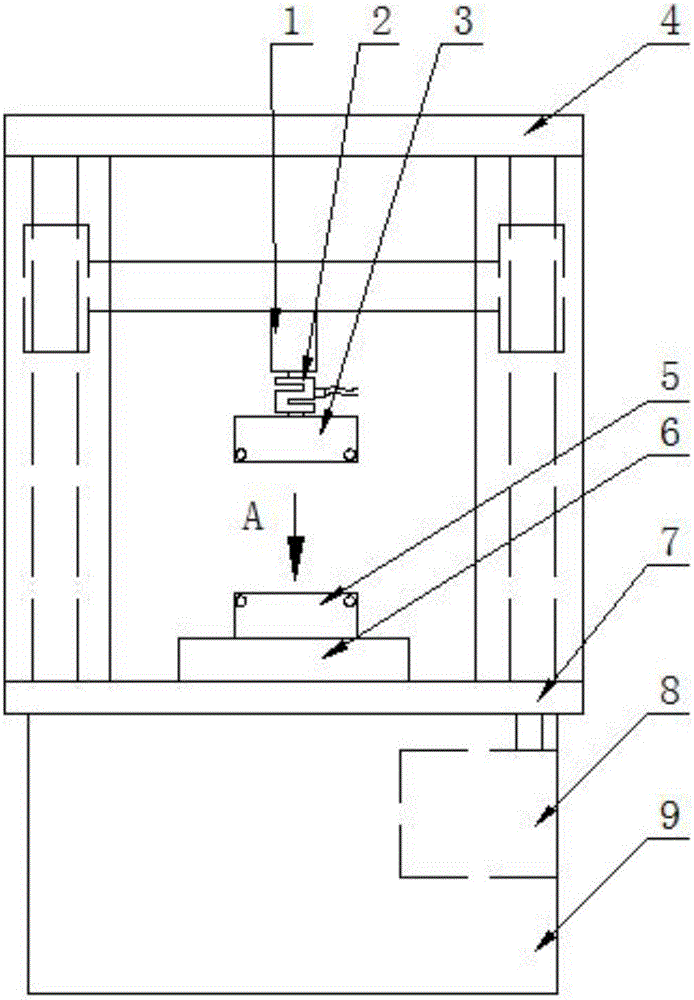

[0025] A test method for interlayer cohesion of asphalt pavement, comprising the steps of:

[0026] (2) Preparation of test piece: Prepare a cement concrete specimen with a length × width × height of 30cm × 30cm × 5cm, put it in a mold of 30cm*30cm*10cm, apply the sticky layer oil evenly, and wait for the sticky layer oil to reach After the surface is dry, the asphalt concrete with the size of 30cm*30cm*5cm is formed on it by wheel rolling method, and the specimen is demoulded after curing to obtain a complete specimen with two layers bonded together. After the specimen is cooled, it is cut. After cutting, the size of the test piece is 10cm*10cm*10cm, marked and ready for pull-out test;

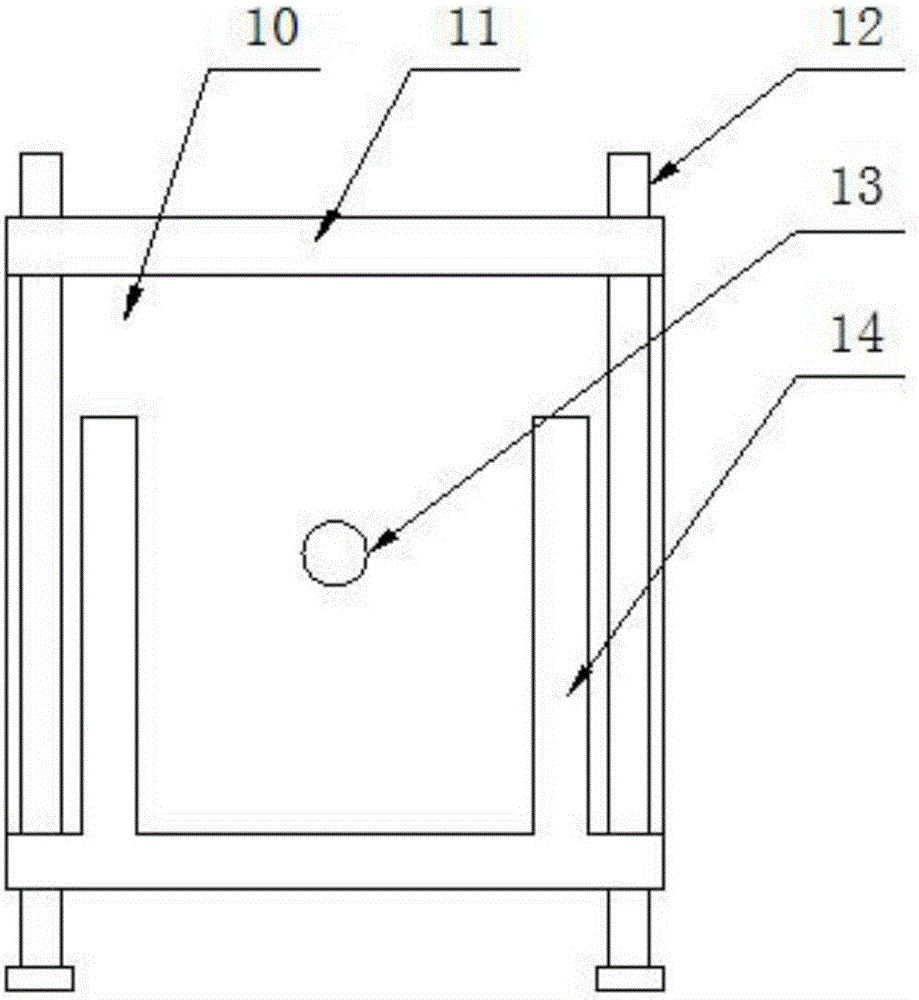

[0027] (2) To install the test piece, first fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com