Method for forming Pt-modified NiAl+Ni3Al thermal barrier adhering layer on surface of nickel-based super alloy

A nickel-based superalloy and superalloy technology, which is applied in the field of metal surface coating, can solve the problems of excessive difference in aluminum content and martensitic transformation of the bonding layer, and achieve stable coating structure, increased life, and adhesion. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Select superalloy DZ417G as the substrate, cut it into 15mm×10mm×3mm sheet, use 120#, 400#, 800# and 1200# water abrasive paper to polish the surface, and then put it into In a beaker filled with acetone, use ultrasonic cleaning for twenty minutes. After taking the sample out of the beaker, rinse the acetone on the surface of the sample with clean water, rinse with absolute ethanol, and finally dry it with a hair dryer for use.

[0026] A Pt layer with a thickness of 5 μm was electroplated on the surface of the cleaned sample, and then the electroplated substrate was heat-treated at 1050 °C for 2 h.

[0027] Put the evenly mixed infiltration agent in the corundum crucible, the composition of the infiltration agent used in powder aluminization is 6wt.%Cr-Al, 2wt.%NH 4 Cl and 92wt.% Al 2 o 3 . Embedding the heat-treated Pt-plated superalloy substrate into the infiltration agent, ensuring that the superalloy substrate is basically in the center of the crucibl...

Embodiment 2

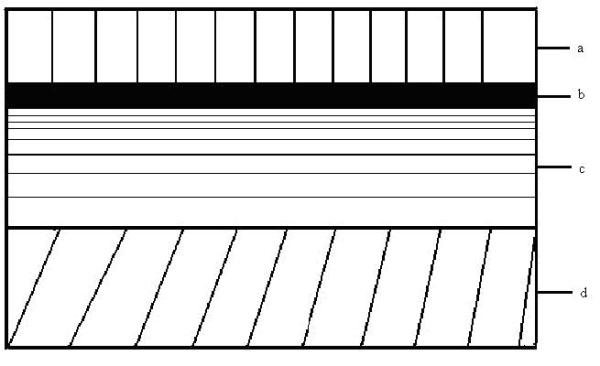

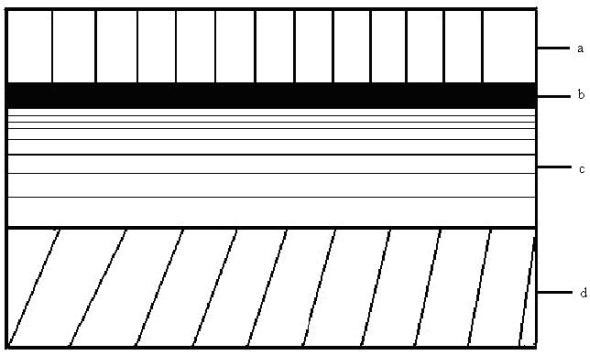

[0028] Example 2 Pt with a thickness of 7 μm was plated on the surface of the cleaned superalloy substrate, and then it was heat-treated at 1100° C. for 3 hours. The components of powder aluminizing agent are: 8wt.%Ni-Al, 2wt.%NH 4 Cl and 90 wt.% Al 2 o 3 , other processes are the same as the above-mentioned processes. figure 1 Medium Pt modified NiAl+Ni 3 Al-based thermal barrier coating bonding layer (c), located in the middle of the thermal barrier coating system, the upper part is TGO (b) layer, the upper part of TGO is ceramic layer (a), and the lower part of the bonding layer is superalloy substrate (d ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com