Production process and equipment for corner window glass edge-cladding assembly

A production process and production equipment technology, which is applied to the production process and equipment field of the corner window glass edging assembly, can solve the problems such as the inability to realize the bonding of the lower horizontal edge of the corner window glass and the positioning and supporting iron blocks, and achieve the guarantee The effect of stability and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

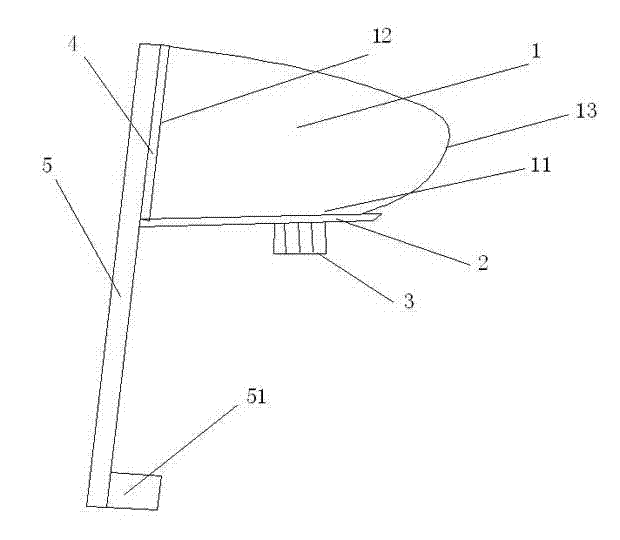

[0035] A specific embodiment of the production process of the corner window glass edging assembly of the present invention is given below, and the flow chart is as follows: figure 2 shown, including the following steps:

[0036] (1) Install the corner window glass 1 to the corresponding position of the first tooling device 20, and then use the clamp 27 to clamp and fix it;

[0037] (2) Apply the one-component polyurethane adhesive to the corresponding position of the lower horizontal edge 11 of the corner window glass 1 where the positioning and supporting iron block 3 needs to be installed, and then press the installation end of the positioning and supporting iron block 3 on the position. on the one-component polyurethane adhesive, and the positioning support iron block 3 is positioned by the clamping device on the first tooling device 20, and then the positioning support iron block 3 and the lower part of the corner window glass 1 are positioned. The transverse edge 11 is ...

Embodiment 2

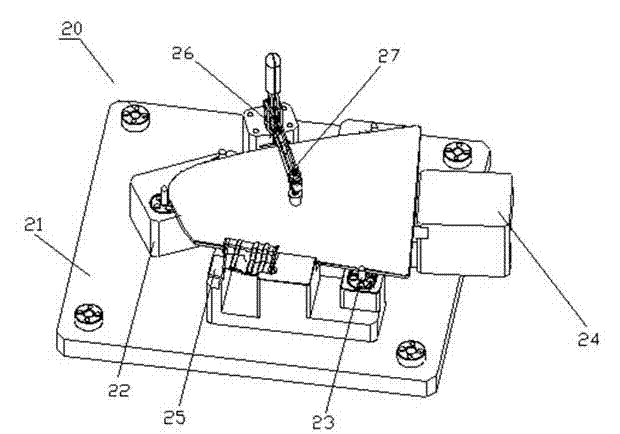

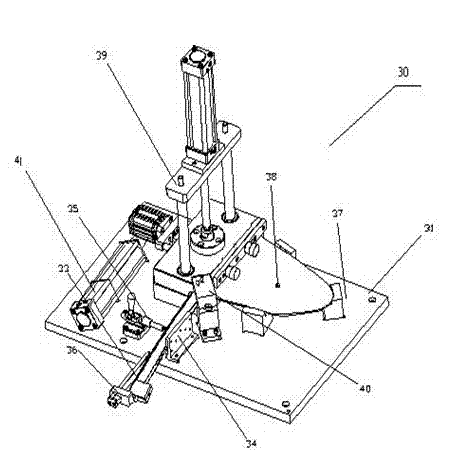

[0045] Specific embodiments of the processing equipment of the corner window glass hemming assembly according to the present invention are given below. The processing equipment includes a first tooling device 20 and a second tooling device 30, and the first tooling device 20 includes the installation The limit pins 23 of the corner window glass 1 are arranged around the limit pins 23 to cooperate with the edge of the corner window glass 1 to support and fix the corner window glass 1 . After the corner window glass 1 is installed on the first tooling device 20 , a clamp 27 for pressing down is vertically disposed above the corner window glass 1 , and the clamp 27 is set through the clamp bracket 26 . The first tooling device 20 is also provided with a locking device for positioning the positioning and supporting iron block 3 to the installation position relative to the corner window glass 1 , in this embodiment, it is the open end of the positioning and supporting iron block 3 ....

Embodiment 3

[0049] In another embodiment of the processing equipment for the corner window glass hemming assembly, the first tooling device 20 includes a bottom plate 21 , a support seat 22 is provided on the bottom plate 21 , and a corner window is formed on the support seat 22 The accommodating space of the glass 1, the limit pins 23 are arranged around the accommodating space of the corner window glass 1, and the horizontal positioner 24 for positioning in the horizontal direction is arranged on one side of the accommodating space of the corner window glass 1. The support base 22 is also provided with an iron block installation slot 25 for installing the positioning and supporting iron block 3, and a clamp 27 for clamping the corner window glass 1 is vertically arranged above the glass corner window accommodating space , installed by the fixture bracket 26 extending into the center of the accommodating space of the corner window glass 1. After the corner window glass 1 is installed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com