Flow production line of flap disc

A technology of sand tray and production line, which is applied in the field of sand tray flow production line, can solve the problems of high cost input, low production efficiency, high defective rate, etc., and achieve the effects of ensuring bonding relationship, reducing defective rate, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

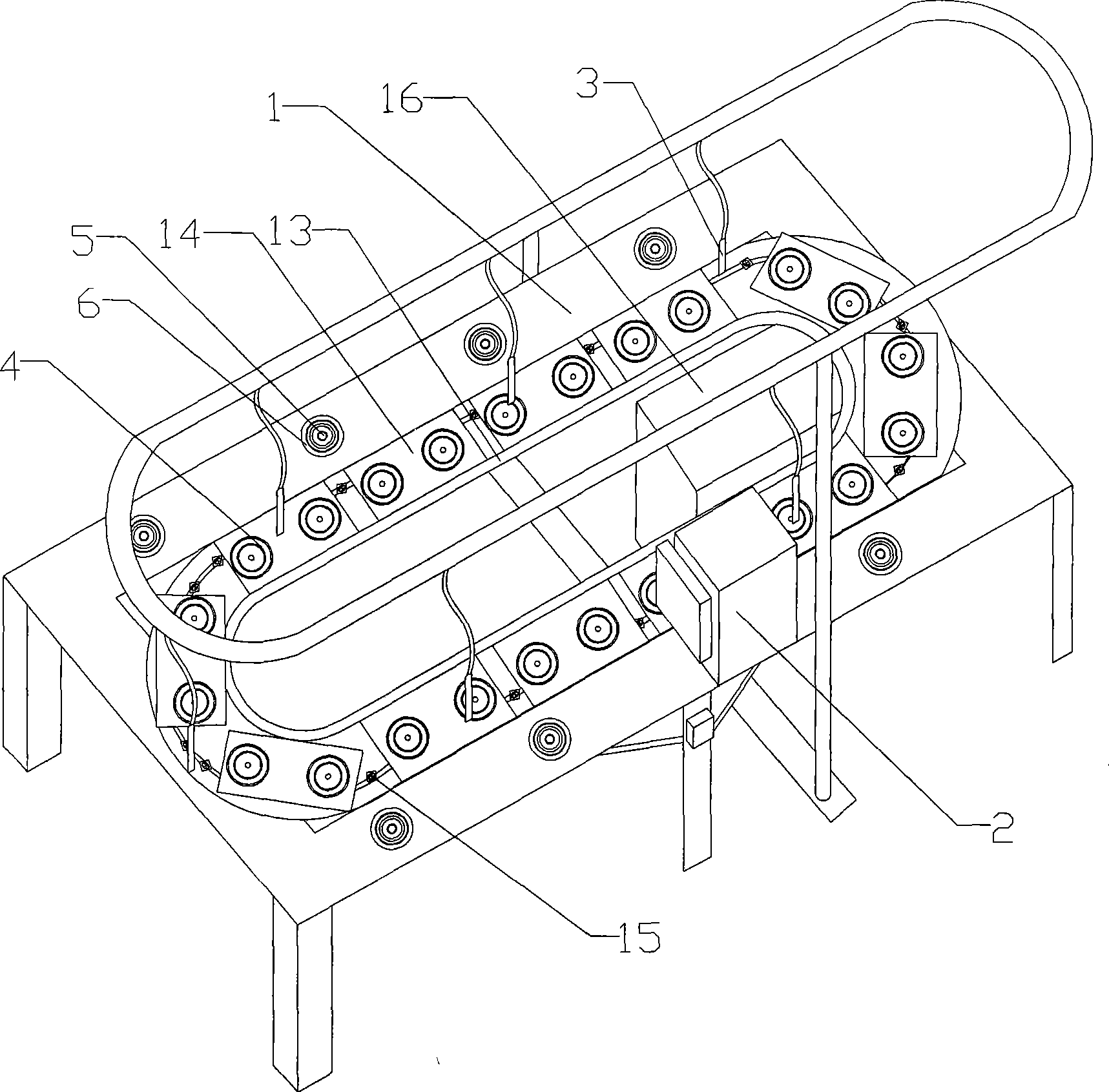

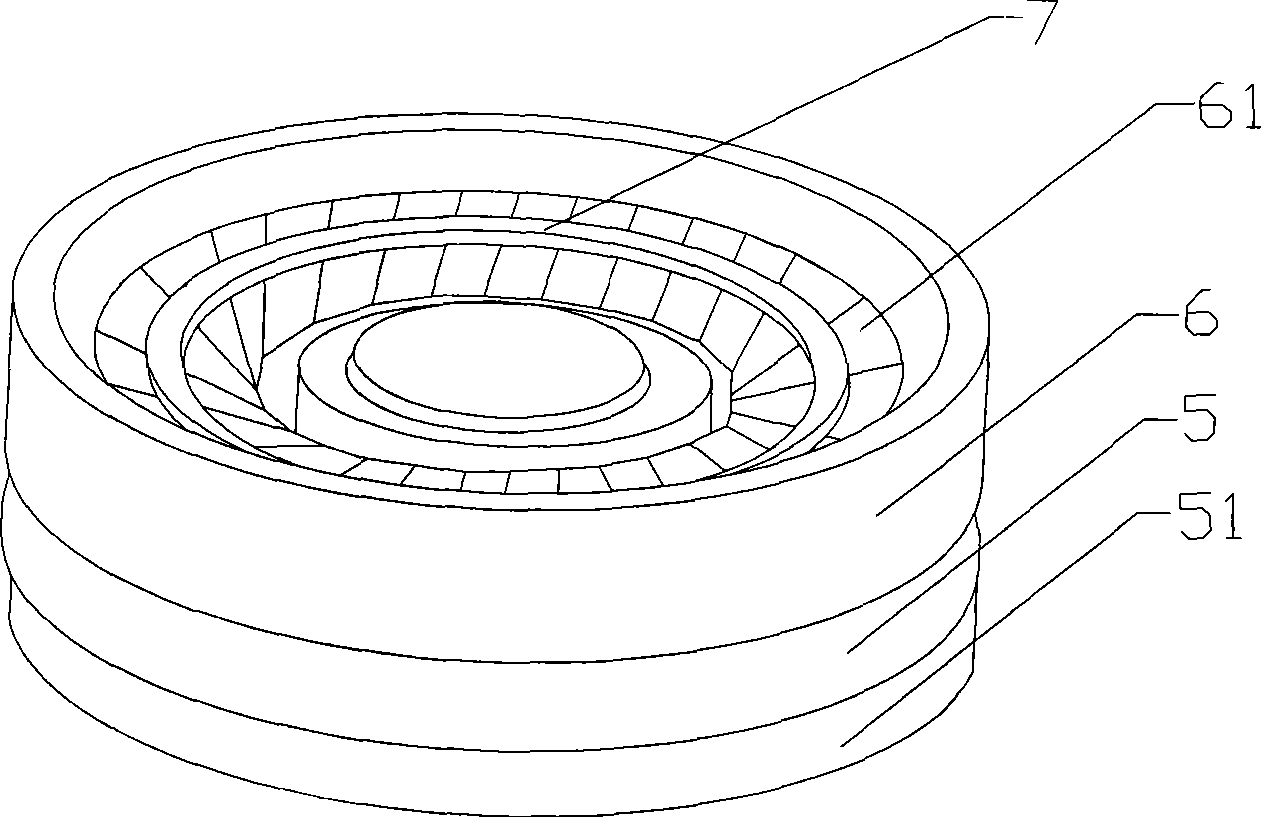

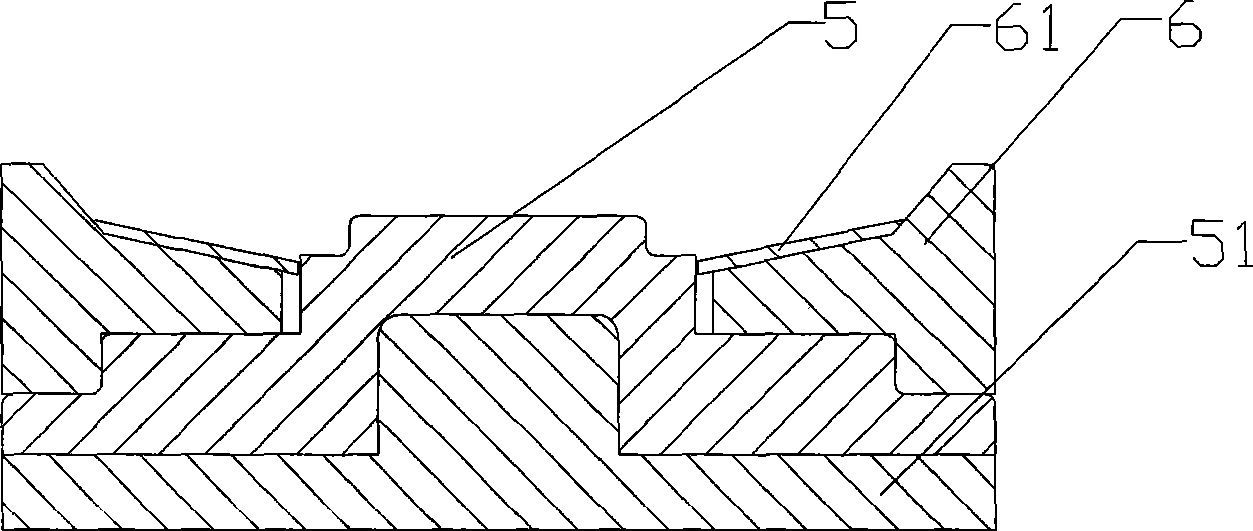

[0018] According to attached Figures 1 to 5 As shown, the assembly line of sand discs of the present invention includes a frame body 1, a mould, a gluing device 2, a screw machine 3, a rotary device and a clamping device. The mold consists of a chassis 4, a rotating base 5, a toothed disc 6 and a pressure ring 7. The chassis 4 is installed on the slewing device, and the middle part of the chassis 4 is provided with a hole adapted to be embedded with the nut 8 or the bolt 9, and the chassis 4 is fixedly connected with the slewing device by adhesive or other connection methods. The rotating base 5 is arranged on the frame body 1, and the frame body 1 is also provided with a bearing 51 which is movably connected with the rotating base 5, and the tooth disc 6 is provided with sand grooves 61, and the arrangement of the sand grooves 61 corresponds to the shape of the sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com