Organic electroluminescent display panel and manufacturing method thereof, and display apparatus

An electroluminescence display and display panel technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of loss of organic electroluminescence structure, large molecular gap, and reduced service life of organic electroluminescence display panels, etc. Achieve the effect of improving sealing performance and effectively blocking water and oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

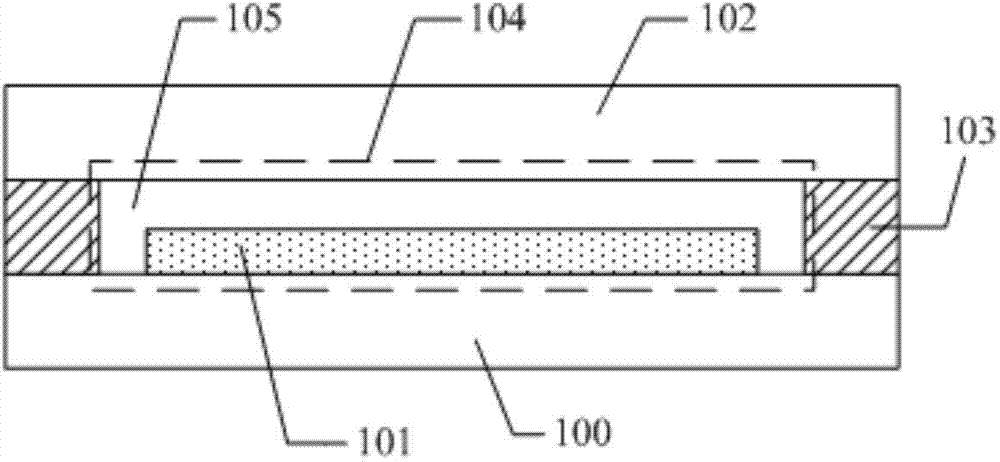

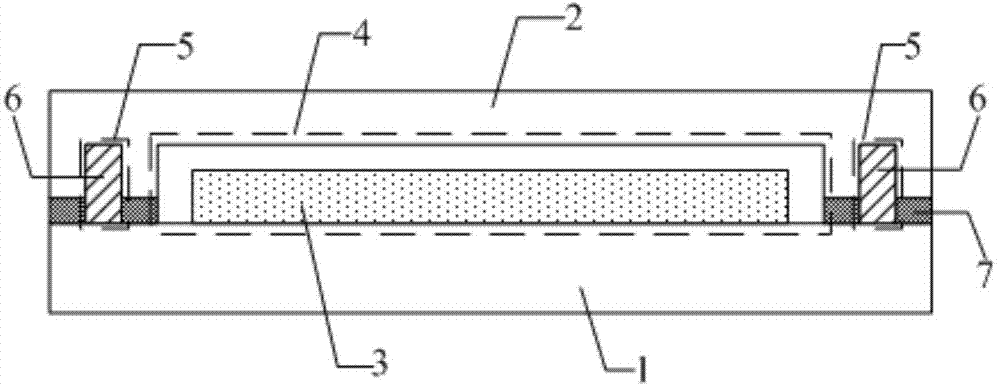

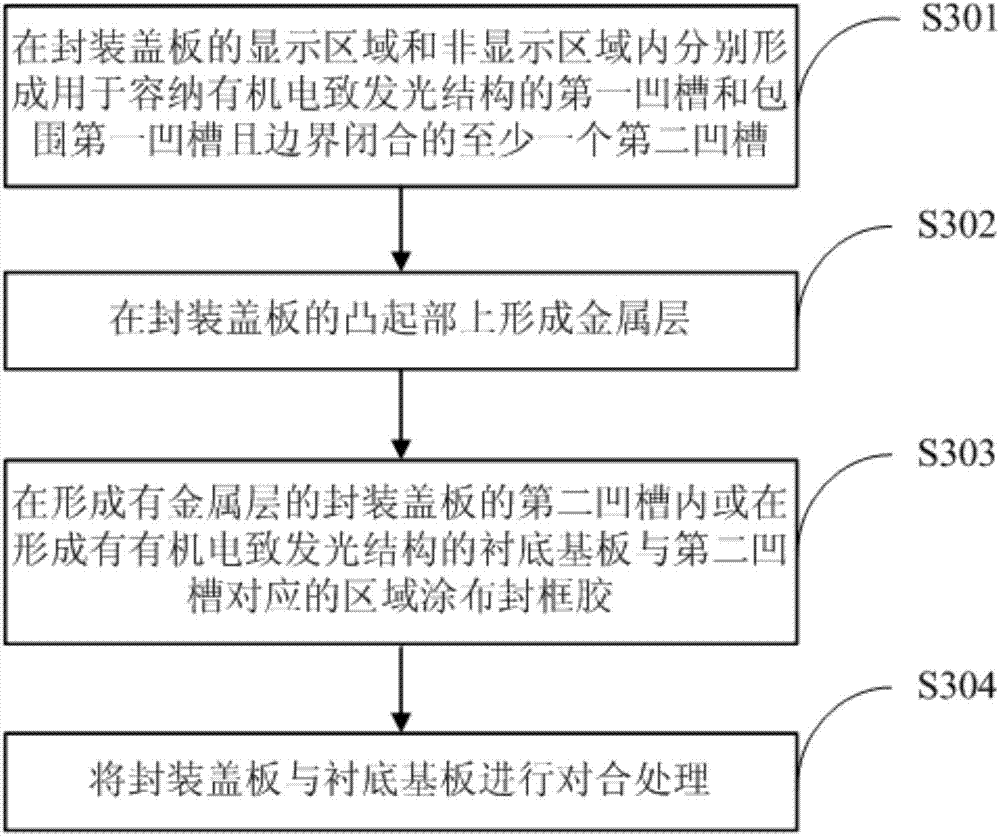

[0067] Example 1: If figure 2 The manufacturing method of the organic electroluminescent display panel shown, such as Figure 5a-5c As shown, it specifically includes the following steps:

[0068] 1. In the display area and the non-display area of the packaging cover plate 2, respectively form a first groove 4 for accommodating the organic electroluminescence structure and a second groove 5 surrounding the first groove 4 with a closed boundary, as shown in Figure 5a shown;

[0069] 2. Form a metal layer 7 on the raised portion of the package cover 2 formed with the first groove 4 and the second groove 5, such as Figure 5b shown;

[0070] 3. Coating the sealant 6 in the second groove 5 of the package cover plate 2 formed with the metal layer 7, such as Figure 5c shown;

[0071] 4. Bond the package cover plate coated with sealant and the base substrate formed with the organic electroluminescent structure, and the organic electroluminescent structure on the base substr...

example 2

[0075] Example 2: If figure 2 The manufacturing method of the organic electroluminescent display panel shown, such as Figure 5a , Figure 6a-Figure 6c As shown, it specifically includes the following steps:

[0076] 1. In the display area and the non-display area of the packaging cover plate 2, respectively form a first groove 4 for accommodating the organic electroluminescence structure and a second groove 5 surrounding the first groove 4 with a closed boundary, as shown in Figure 5a shown;

[0077] 2. Form a metal layer 7 on the raised portion of the package cover 2 formed with the first groove 4 and the second groove 5, such as Figure 6a shown;

[0078] 3. Form a metal layer 7 on the base substrate 1 on which the organic electroluminescent structure 3 is formed, corresponding to the raised portion, such as Figure 6b shown;

[0079] 4. Coating the sealant 6 in the second groove 5 of the package cover plate 2 formed with the metal layer 7, such as Figure 6c sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com