Preparation method of ageing-resistant and high-resilience extruded carbon black filled conductive shielding silicone rubber

A technology of conductive shielding and high resilience, applied in the field of extruded conductive shielding silicone rubber, can solve the problems of difficult implementation of extrusion process and lower vulcanization efficiency, achieve high elasticity, improve process adaptability, and good durability Effects of Aging Properties and Elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

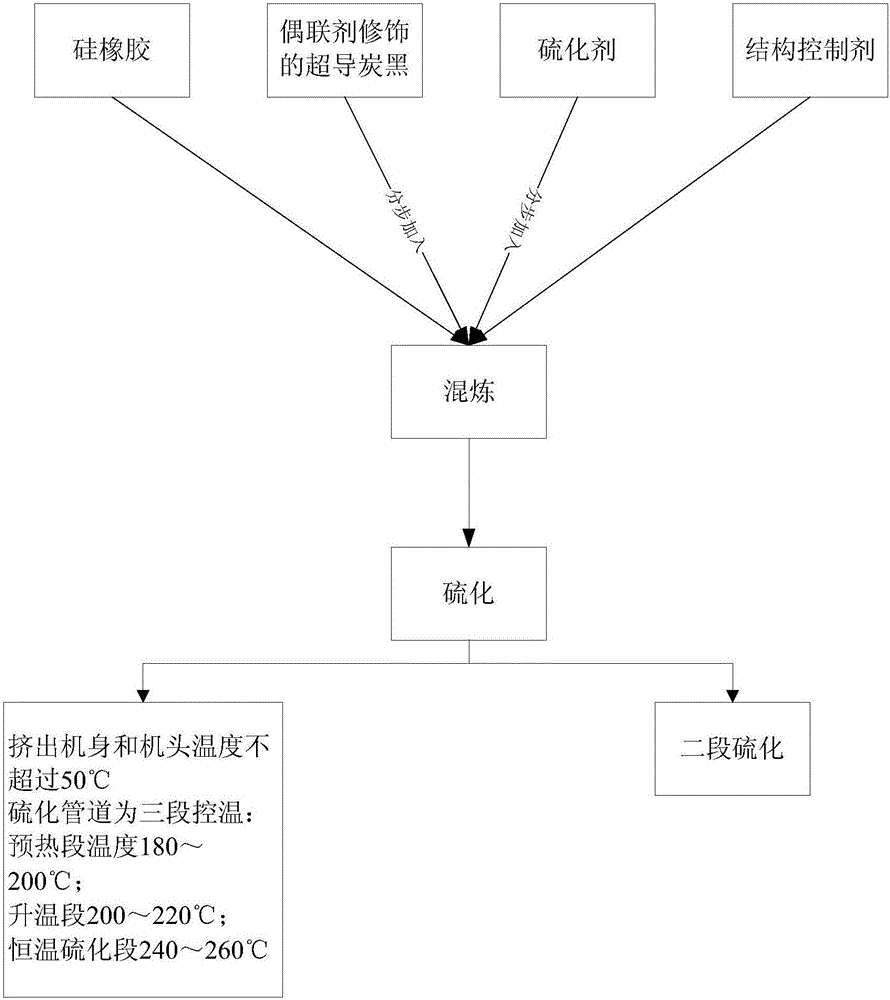

Method used

Image

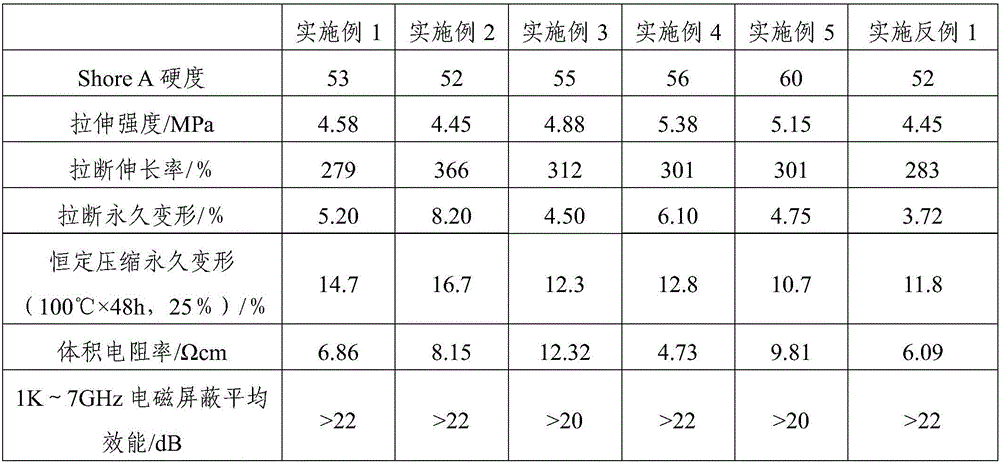

Examples

Embodiment 1

[0025] A kind of preparation method of extrusion type carbon black filling conductive shielding silicon rubber of the present invention, it comprises the steps:

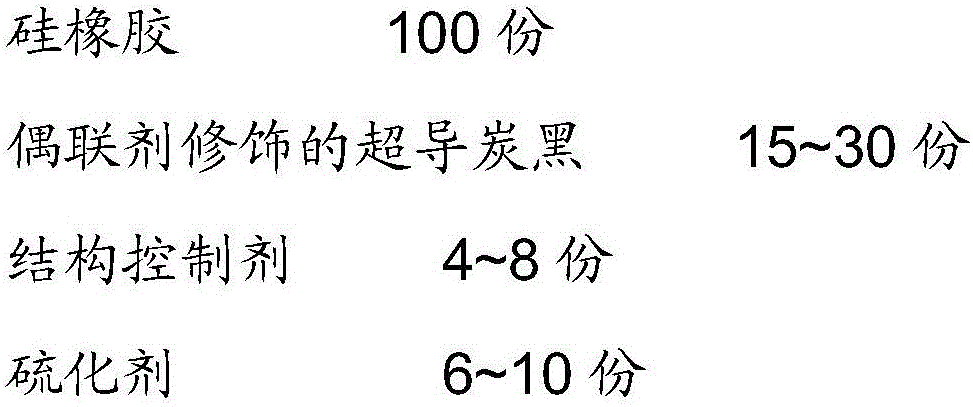

[0026] 1. Prepare the following raw materials (both parts by mass)

[0027] Methyl vinyl silicone rubber (the brand is Zhonglan Chenguang 110-2) 100 parts;

[0028] 6 parts of vulcanizing agent (dicumyl peroxide);

[0029] Superconducting carbon black (Akesu EC-600JD treated with coupling agent KH550) 15 parts

[0030] The treatment method is: mix according to mass parts KH550:EC-600JD=1:8, mix with appropriate amount of ethanol, stir evenly and reflux at 80°C for 4 hours, take out the carbon black, dry it in an oven at 120°C, and grind it Can.

[0031] Structure control agent (hydroxymethyl silicone oil) 4 parts

[0032] 2. Mix the raw materials described in step (1) on an open mill at normal temperature; during the mixing process, the superconducting carbon black of dicumyl peroxide and processing needs to be a...

Embodiment 2

[0036] A kind of preparation method of extrusion type carbon black filling conductive shielding silicon rubber of the present invention, it comprises the steps:

[0037] 1. Prepare the following raw materials (both parts by mass)

[0038] Methyl vinyl silicone rubber (the brand is Zhonglan Chenguang 110-2) 100 parts;

[0039] 7 parts of vulcanizing agent (dicumyl peroxide);

[0040] Superconducting carbon black (cabot's BP2000 treated with coupling agent KH570) 18 parts

[0041] The treatment method is: mix according to mass parts KH570:BP2000=1:6, mix with appropriate amount of ethanol, stir evenly, reflux at 80°C for 4 hours, take out the carbon black, and dry it in an oven at 120°C.

[0042] Structure control agent (polyvinyl silicone oil) 5 parts

[0043] 2. Mix the raw materials described in step (1) on an open mill at normal temperature; during the mixing process, the superconducting carbon black of dicumyl peroxide and processing needs to be added in 5 steps, and kee...

Embodiment 3

[0047] A kind of preparation method of extrusion type carbon black filling conductive shielding silicon rubber of the present invention, it comprises the steps:

[0048] 1. Prepare the following raw materials (both parts by mass)

[0049] 100 parts of methyl vinyl phenyl silicone rubber (the brand is Shanghai Resin Factory 120-1);

[0050] 9 parts of vulcanizing agent (dicumyl peroxide);

[0051] Superconducting carbon black (Huaguang conductive carbon black treated with coupling agent A151) 25 parts

[0052]The treatment method is: mix according to the mass parts A151: Huaguang carbon black = 1:9, add an appropriate amount of ethanol, stir evenly, reflux at 80°C for 6 hours, take out the carbon black, dry it in an oven at 130°C, and grind it That's it.

[0053] Structure control agent (hydroxymethylphenyl silicone oil) 7 parts

[0054] 2. Mix the raw materials described in step (1) on an open mill at normal temperature; during the mixing process, the superconducting carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com