Preparation method for conductive polymer sheathing material

A technology of conductive polymer and sheath material, applied in conductive materials, conductors, circuits and other directions dispersed in non-conductive inorganic materials, can solve the problems of poor soil corrosion resistance, affecting service life and high price, and achieve soil resistance The effect of good corrosion performance, good aging resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] In this embodiment, the thermoplastic resin is used as a mixture of one or more of 59-30% LLDPE, LDPE or EVA by thermoplastic resin by mass percentage; -35%; conductive carbon fiber is 5-14%; toughening agent is 10-18% of POE, EPDM or both; dispersant polyethylene wax is 1.0-3.0%; processing aid is 0.5-1.5 %; The processing aid is one or more of the thermal oxygen aging agent B225, the acid absorbing agent zinc stearate and the diluent white oil; the above-mentioned raw materials are mixed and stirred through a twin-screw extruder combined with a special screw , under the condition of controlling the processing temperature at 180-220°C, melt, extrude, cool, pelletize, dry and pack to obtain the conductive sheath material product; The technical specifications of the wire are tested for performance, and the physical performance parameters are shown in Table 1.

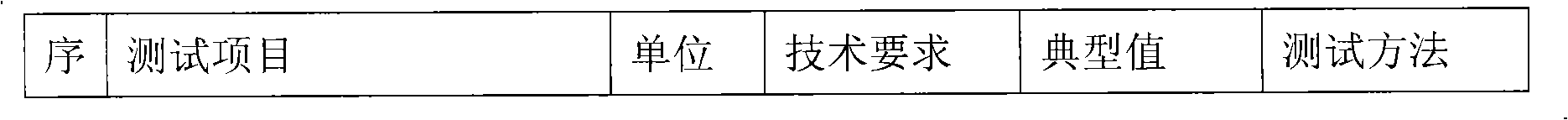

[0014] Table 1: Product physical properties and test methods

[0015]

[0016]

[0017] The conductive ...

Embodiment 2

[0022] This embodiment uses the conductive polymer sheath material prepared in Example 1 to prepare a through-ground wire suitable for the conductive polymer sheath. First, the thermoplastic polymer resin, conductive carbon black, and carbon fiber , toughening agent, dispersant and processing aids, mixed and stirred, and then melted, extruded, cooled, pelletized, dried and packaged into a sheath material by a twin-screw extruder with a special screw combination. Wherein the mass percent of each component of the mixture can be adjusted according to the product specification and the raw materials of different manufacturers, and the three kinds of products prepared respectively by the three proportionings in Table 3 have their properties shown in Table 4 respectively.

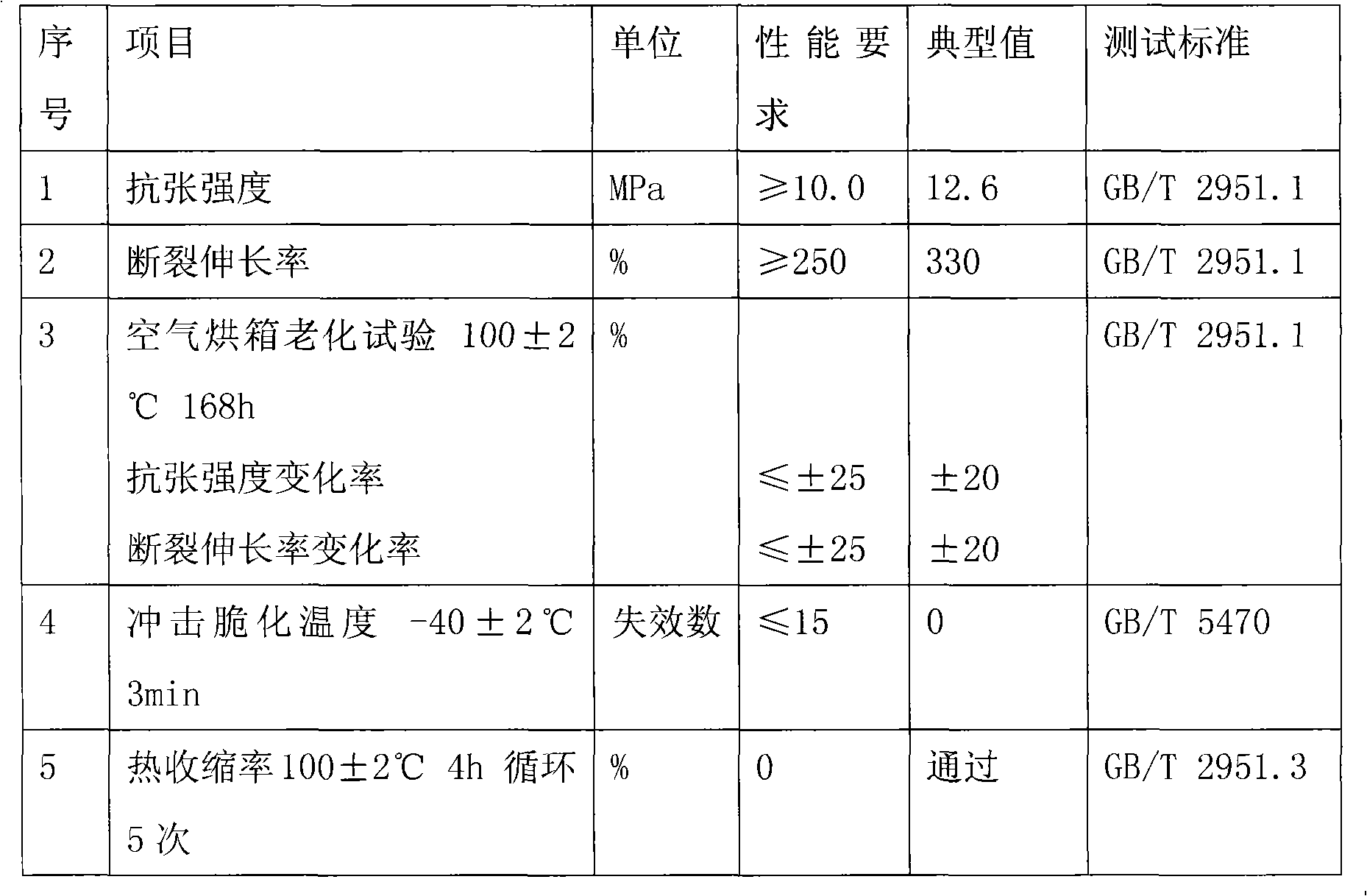

[0023] Table 3: Composition and ratio of conductive polymer sheath material

[0024]

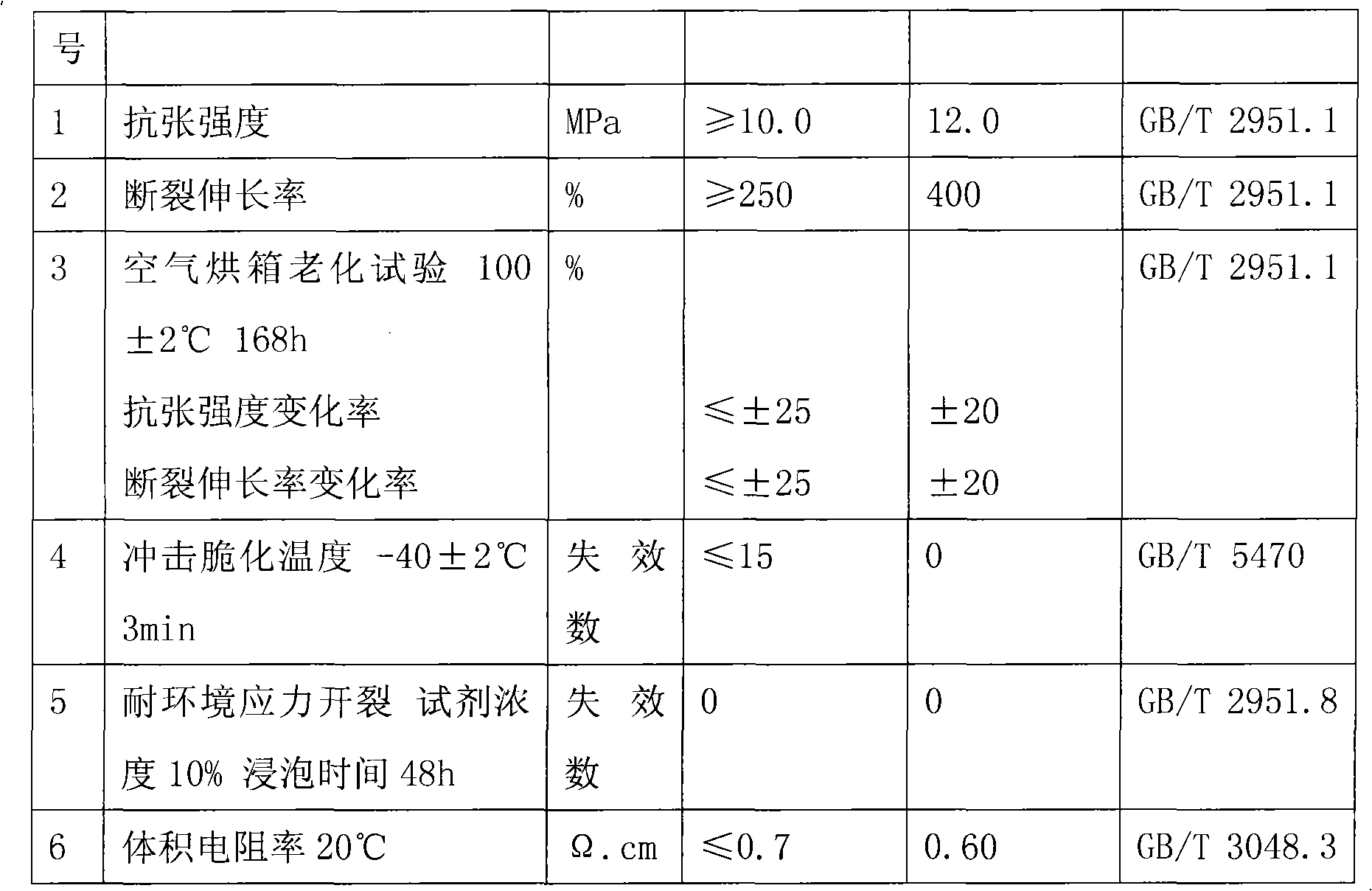

[0025] Table 4: Product physical properties and test methods

[0026]

[0027]

[0028] The test results of this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com