Patents

Literature

31results about How to "Good impact elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing modified dienopolymer rubber

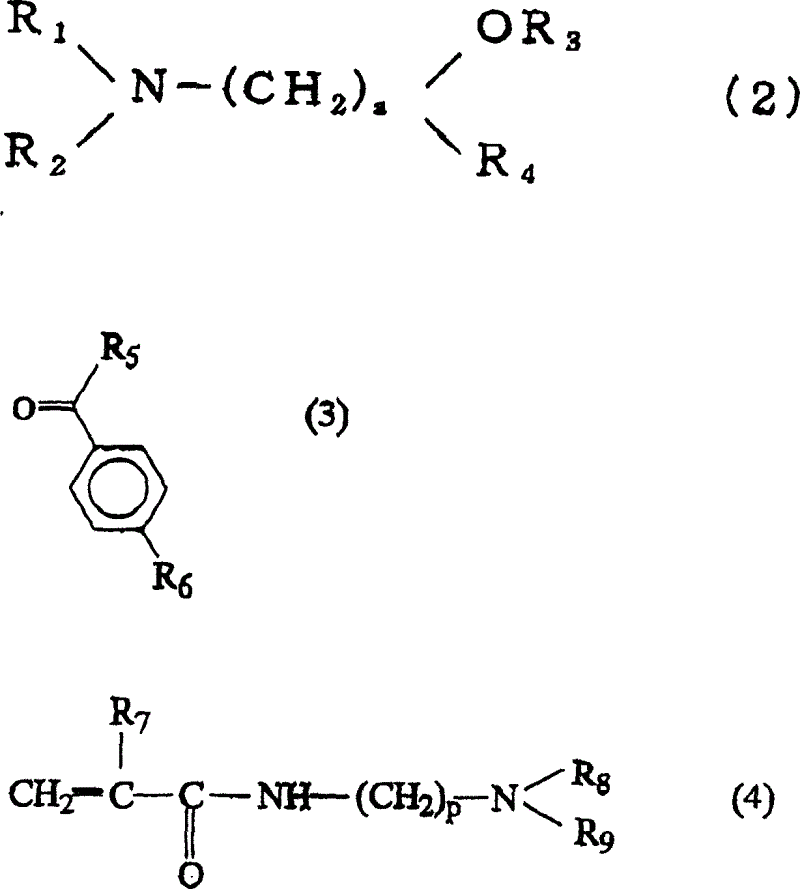

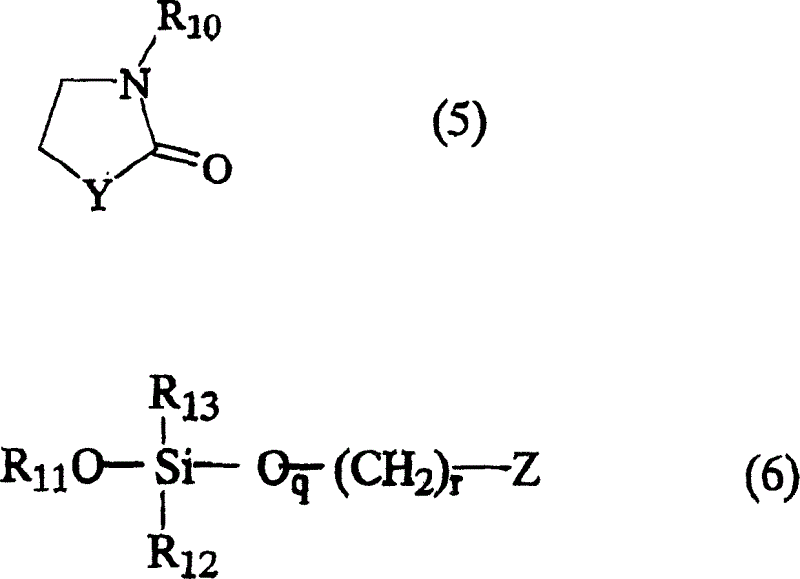

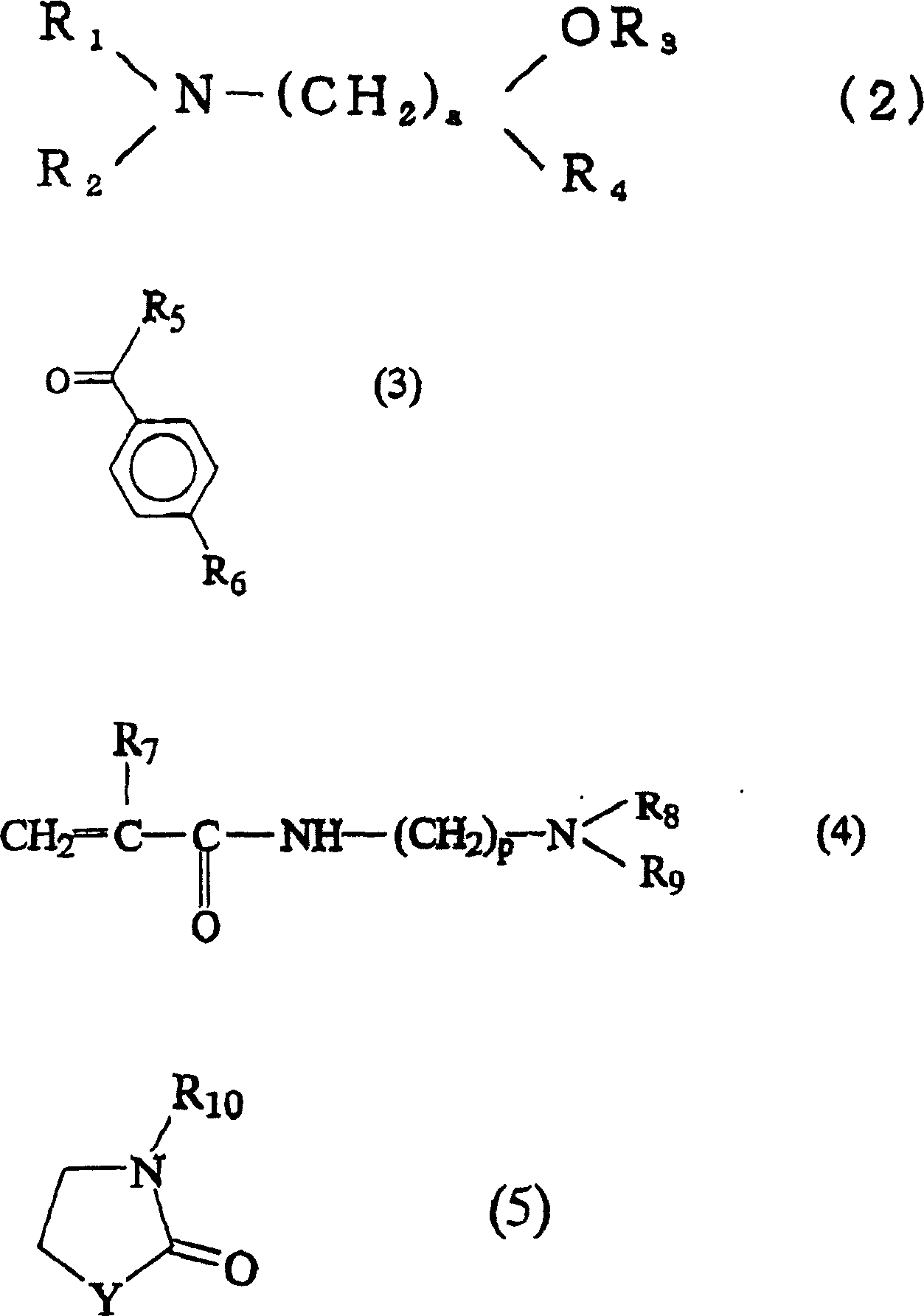

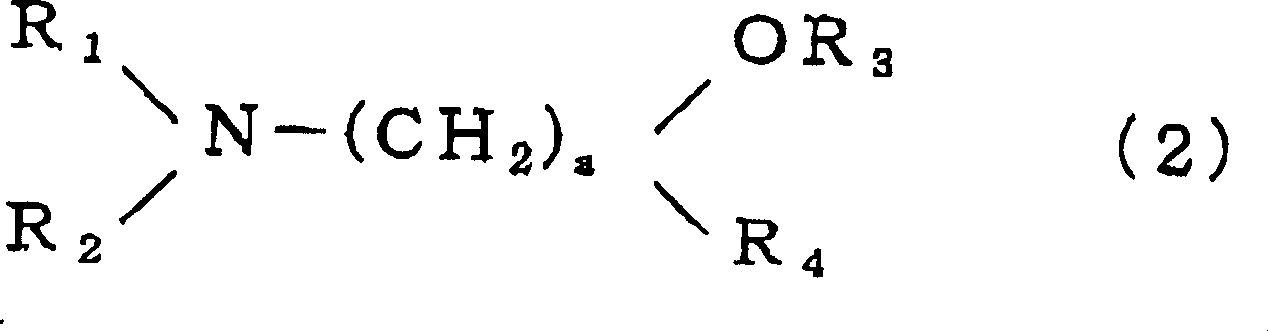

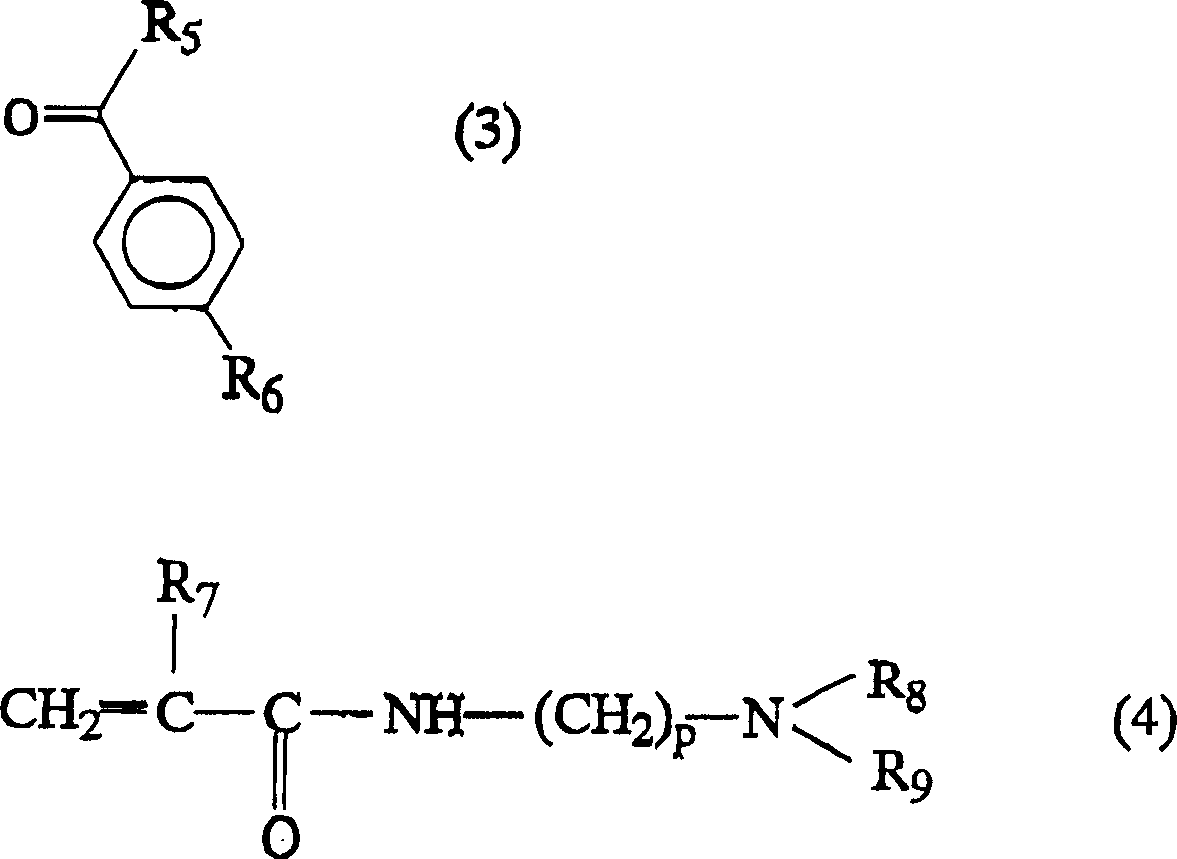

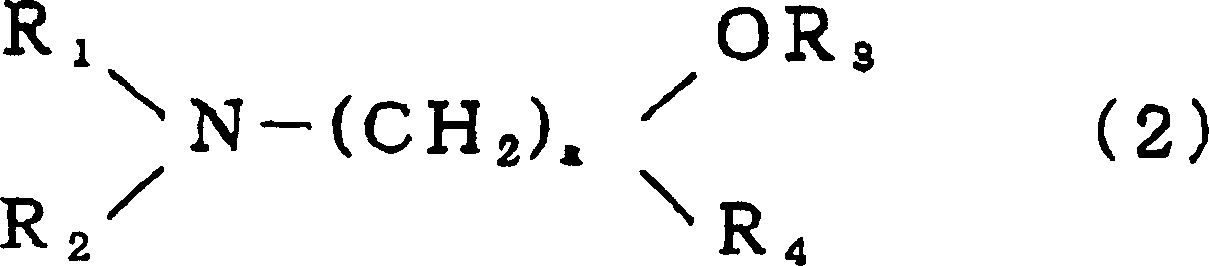

There is provided a process for producing a both end-modified diene polymer rubber comprising the steps of: (1) polymerizing a conjugated diene monomer or a combination thereof with an aromatic vinyl monomer in the presence of a compound represented by the following formula (1) to produce an alkali metal end-carrying active polymer, and (2) reacting the alkali metal end-carrying active polymer with an amine compound, a ketone compound, an acrylamide compound, a heterocyclic compound or a silyl compound represented by specific formulas, respectively: R-(CH2)n-X-M (1) wherein R is a functional group containing a substituent group-carrying nitrogen atom, X is a saturated or unsaturated hydrocarbon group comprising from 0 to 10 conjugated diene monomer units or aromatic vinyl monomer units, n is an integer of from 1 to 10, and M is an alkali metal.

Owner:SUMITOMO CHEM CO LTD

Acrylic ester rubber and preparation method thereof

InactiveCN101633768AImprove the defect of sticky rollerReasonable ratioSodium stearatePolymer science

The invention provides acrylic ester rubber and a preparation method thereof. The acrylic ester rubber is characterized by comprising the following components by weight: 70-90 portions of tri-acrylate rubber AR840, 10-30 portions of butyronitrile rubber NBR, 55-75 portions of fast extruding carbon black N550, 1-2 portions of anti-aging agent RD, 1-2 portions of anti-aging agent MB, 0.5-1 portion of anti-scorching agent CTP, 3-5 portions of dioctyl phthalate DOP, 1-2 portions of dispersant rhine powder-42, 0.3-0.5 portion of common sulphur, 0.2-0.4 portion of tetramethyl thiuram disulfide TMTD, 3.5-4.0 portions of sodium stearate and 0.3-0.5 portion of potassium stearate. The sticking phenomenon is reduced and the elasticity, extensile intensity and low temperature resistance of the acrylic ester rubber are improved.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

Preparation method for conductive polymer sheathing material

InactiveCN102153878AImprove mechanical propertiesGood compatibilityInsulated cablesNon-conductive material with dispersed conductive materialFiberCarbon fibers

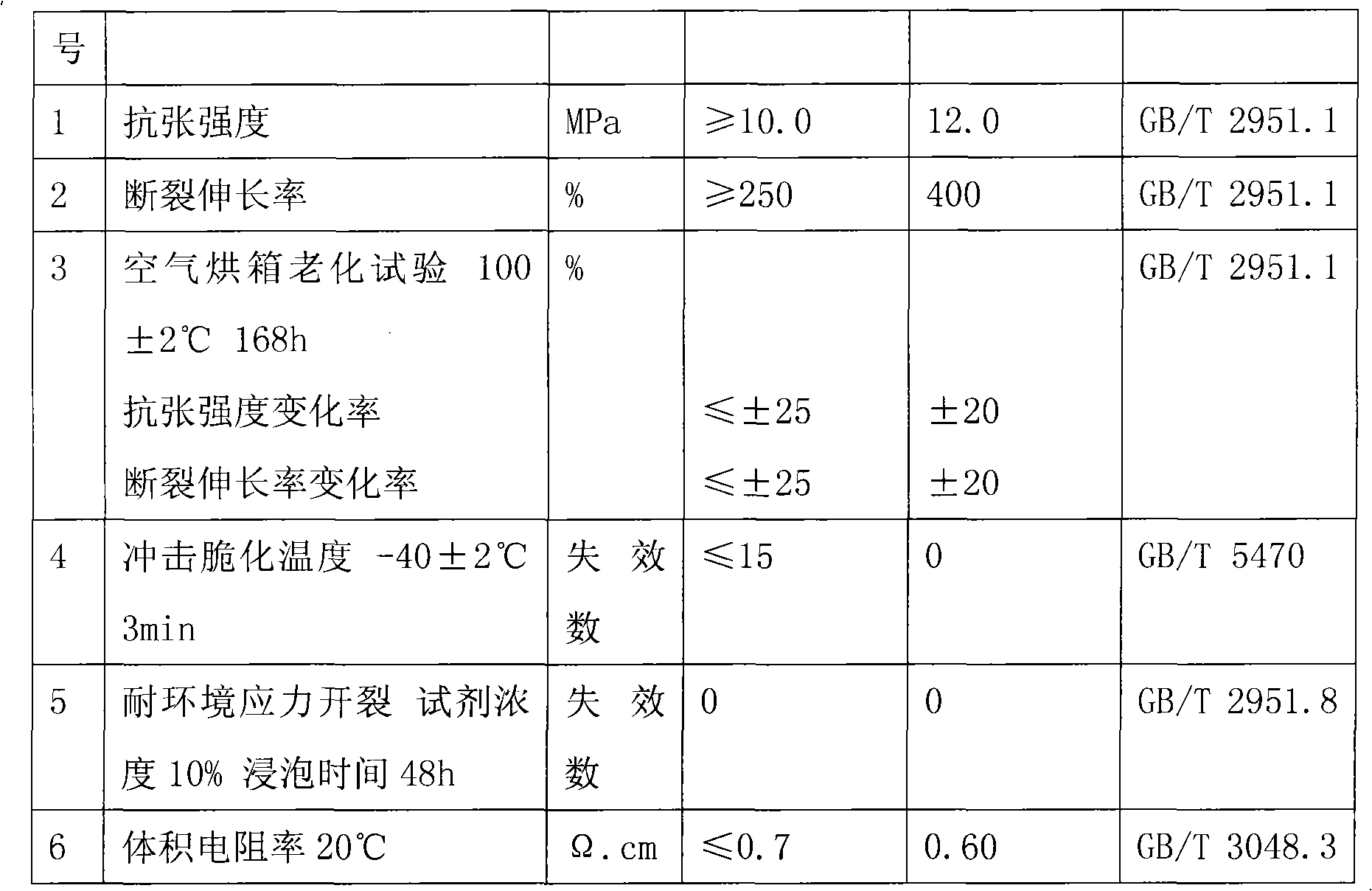

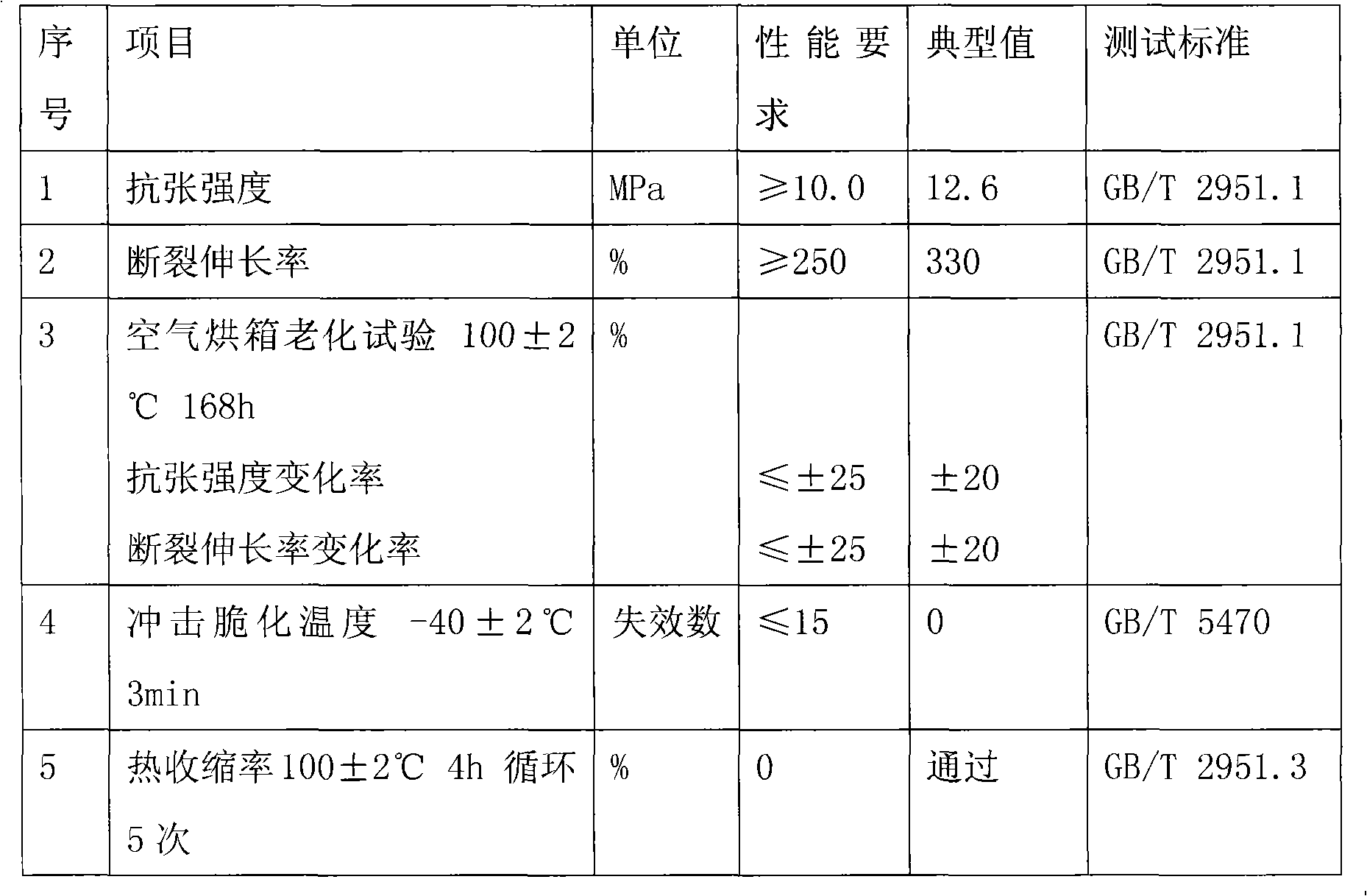

The invention belongs to the technical field of organic materials, relating to a preparation method for a conductive polymer sheathing material. The conductive polymer sheathing material comprises the following components in percent by mass: 60-30 percent of thermoplastic polymer resin, 25-30 percent of nanometer conductive carbon black, 5-14 percent of conductive carbon fiber or conductive agent, 10-18 percent of flexibilizer and 0.5-1.5 percent of processing aid and 1-3 percent of dispersing agent. The preparation method comprises the steps of: mixing and stirring well the raw materials of all the components and forming a product by melting, extruding, cooling, granulating, drying and packaging with a double-screw extruder; or adding a mixture consisting of the raw materials of all the components into an internal mixer for complete kneading, mixing and dispersing, then conducting mixing, rolling, laminating and crushing with a double-roller open mill and forming the product by melting, extruding, cooling, granulating, drying and packaging with a single-screw extruder. The preparation method has a simple process, and the conductive polymer sheathing material has the advantages of good electrical properties, low cost and production environment protection performance.

Owner:QINGDAO WEDONK POLYMER MATERIAL

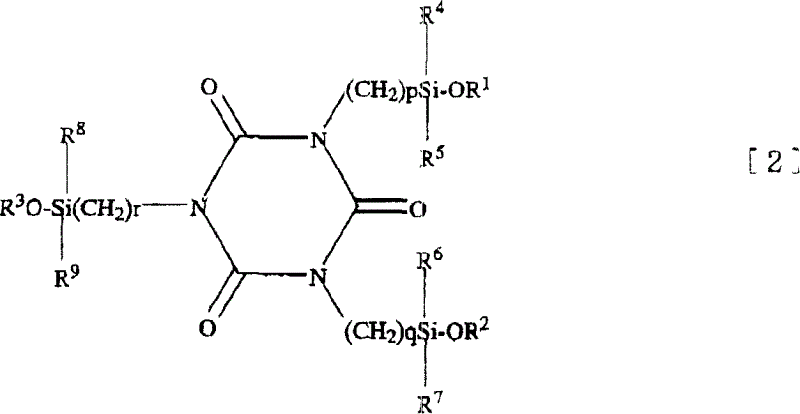

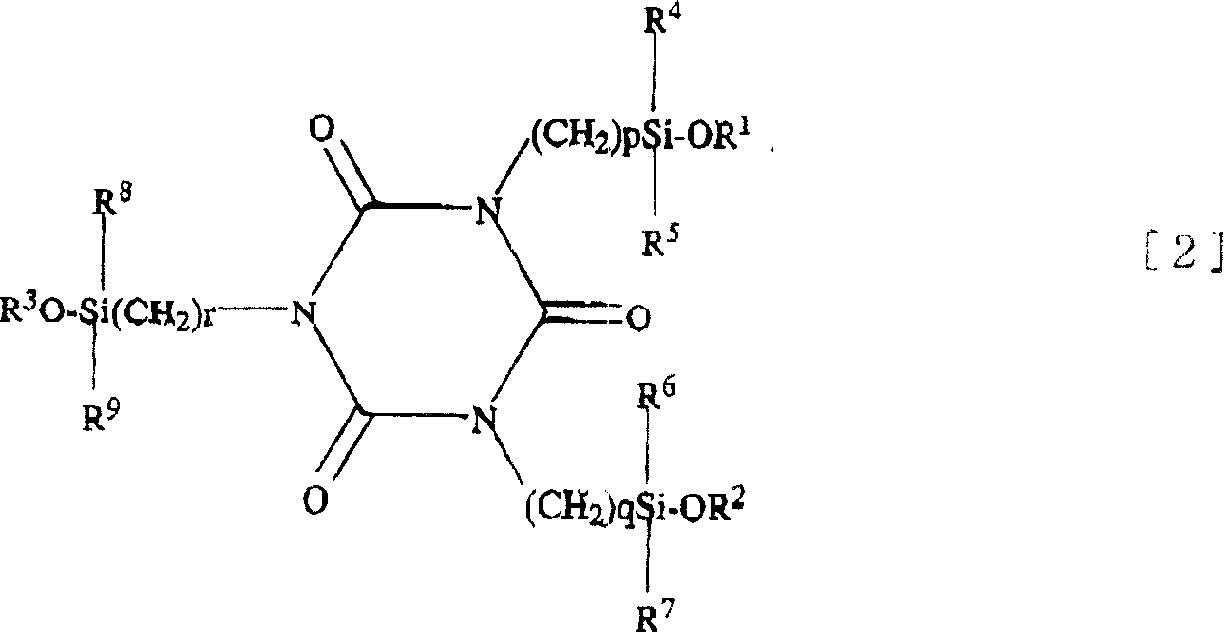

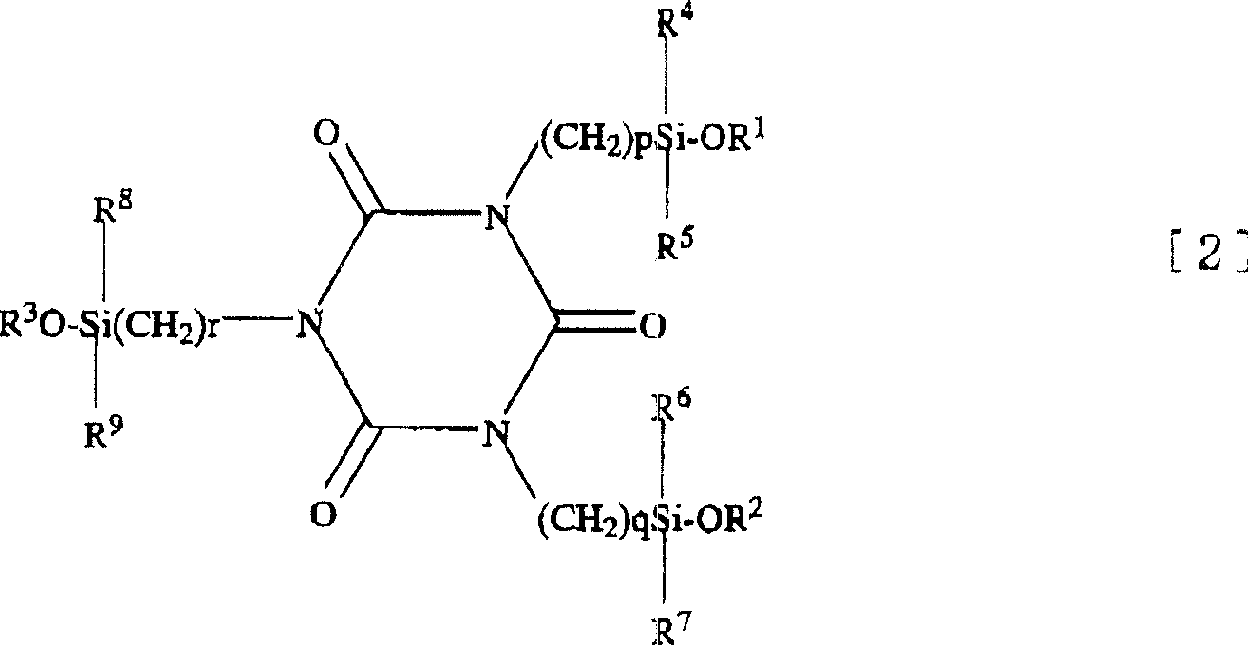

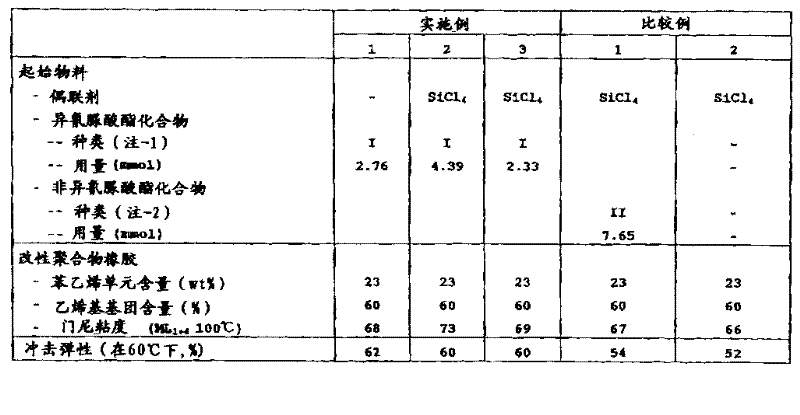

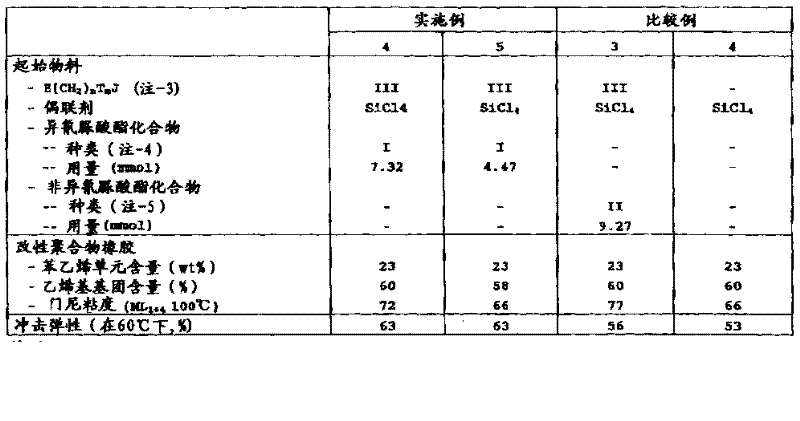

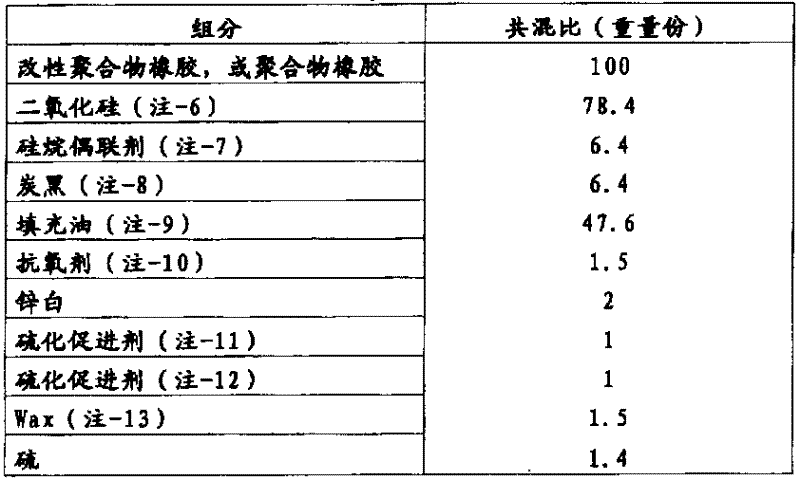

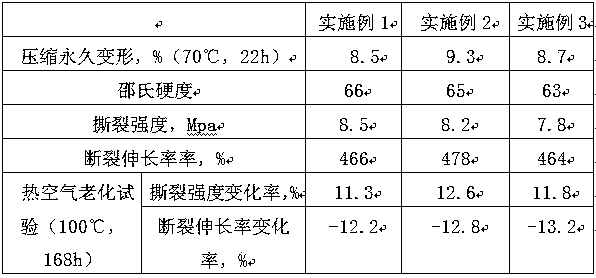

Process for producing modified polymer rubber

A method for producing modified polymer rubber, comprising the steps of: (1) making a conjugated diene monomer or its combination with an aromatic vinyl monomer, in a hydrocarbon solvent, in an alkali metal catalyst or specified In the presence of an alkali metal compound, carry out polymerization to form an active polymer with an alkali metal end group; and (2) couple the resulting active polymer with an alkali metal end group to a prescribed isocyanurate compound or to a prescribed The combination of reagents is carried out in a hydrocarbon solvent.

Owner:SUMITOMO CHEM CO LTD

Wear-resistant and aging-resistant cable sheath material

InactiveCN105623112AHigh mechanical strengthImprove wear resistanceRubber insulatorsPolymer scienceWear resistant

The invention discloses a wear-resistant and aging-resistant cable sheath material. The material is prepared from, by weight, 40-60 parts of ethylene propylene diene monomer rubber, 15-30 parts of polyamide 66, 10-20 parts of modified white mica powder, 2-5 parts of a wear-resisting auxiliary agent, 10-20 parts of semi-reinforced carbon black, 1-4 parts of a flame-retardant auxiliary agent, 1-2 parts of N-tertiary butyl-2-benzothiazole sulfenamide, 2-4 parts of N, N'-m-phenylene dimaleimide, 3-8 parts of stearic acid, 0.5-1 part of zinc dibutyl dithiocarbamate, 0.5-1 part of an anti-aging agent DPPD, 2-5 parts of white oil and 2-3 parts of fortifier DH-3. The wear-resistant and aging-resistant cable sheath material is good in mechanical strength, wear resistance, aging resistance, weatherability, impact elasticity, chemical corrosion resistance and excellent in electrical insulation property, and meanwhile the modified white mica powder is adopted, so that the processing property of the ethylene propylene diene monomer rubber is improved, and the obtained cable sheath material can be used in environments with various climatic conditions.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

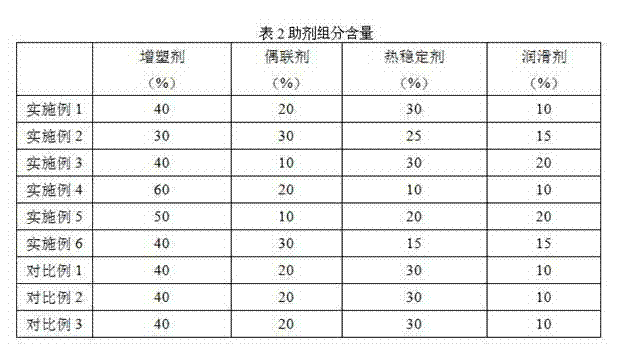

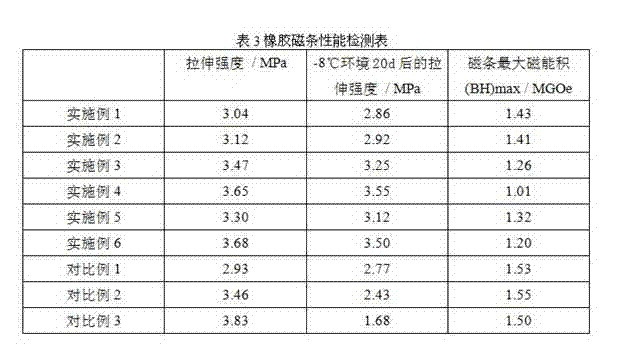

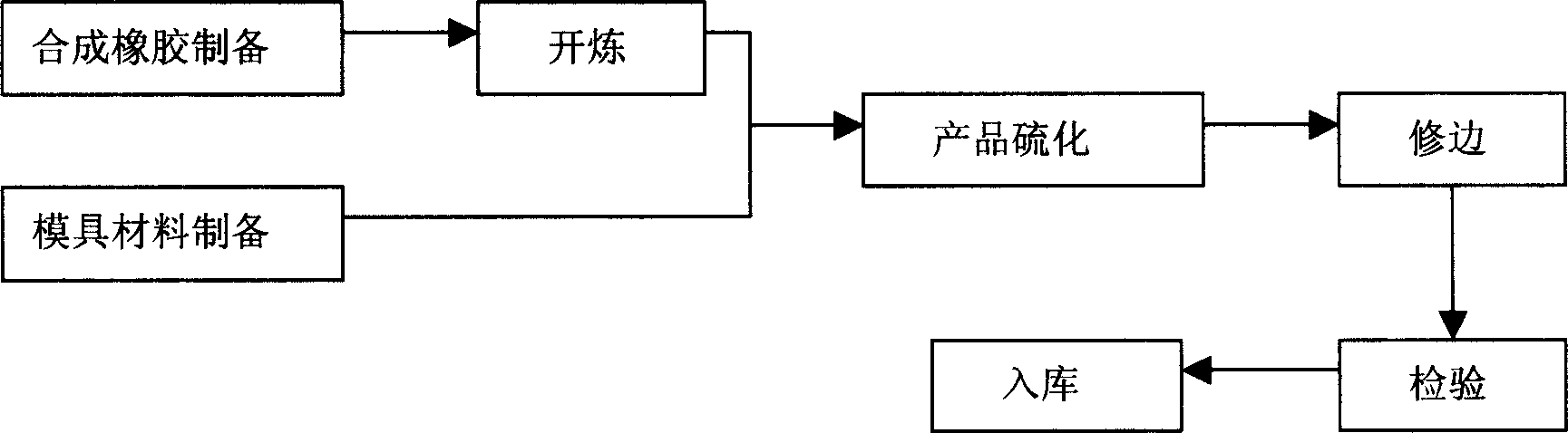

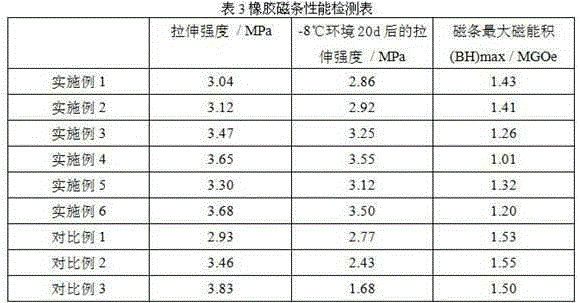

Rubber magnetic strip used under low temperature and preparation method thereof

ActiveCN103578683AExcellent adhesionImprove aging resistancePermanent magnetsInductances/transformers/magnets manufacturePolymer sciencePlasticizer

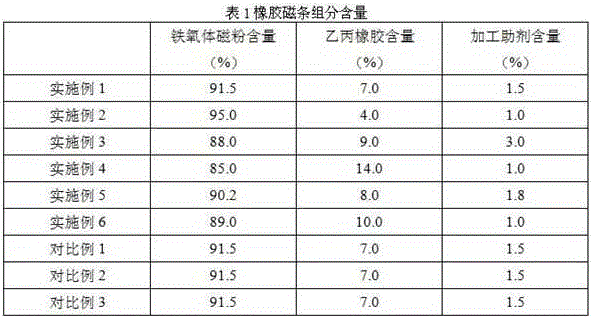

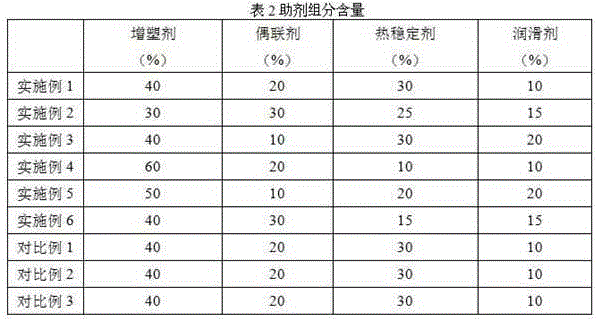

The invention discloses a rubber magnetic strip used under low temperature and a preparation method thereof. The rubber magnetic strip consists of the following ingredients in percentage by mass: 85-95% of ferrite magnetic powder, 4-14% of ethylene propylene rubber and 1-3% of addition agent, wherein the addition agent comprises plasticizer, coupling agent, heat stabilizer and lubricating agent. The preparation method comprises the steps of high-speed blending, mixing, forming and cutting for packaging. The ethylene propylene rubber is used as a carrier for replacing the traditional chlorinated polyethylene, so that the prepared rubber magnetic strip is excellent in ageing-resistant performance, good in impact elasticity, good in chemical resistance, free of halogen, more environmental friendly and unlikely to embrittle and break when being used under low temperature.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Flame-retardant building power sheath material and preparation method thereof

InactiveCN106751936AHigh strengthImprove wear resistancePlastic/resin/waxes insulatorsLinear low-density polyethyleneAntioxidant

The invention discloses a flame-retardant building power sheath material and a preparation method thereof. The flame-retardant building power sheath material is prepared from the following raw materials in parts by weight: 21-38 parts of linear low density polyethylene, 15-25 parts of SG-2 type polyvinyl chloride resin, 16-22 parts of methylpentachlorostearate, 10-15 parts of quartz sand, 14-23 parts of semi-reinforced carbon black, 10-20 parts of lithium base bentonite, 11-15 parts of triphenyl phosphate, 33-36 parts of chlorinated paraffin, 10-20 parts of brominated polystyrene, 3-9 parts of attapulgite, 6-10 parts of a light screening agent, 2-6 parts of an antioxidant, 5-8 parts of a flame retardant and 2-6 parts of a stabilizer. According to the sheath material disclosed by the invention, the main body consists of linear low density polyethylene and lithium base bentonite, and SG-2 type polyvinyl chloride resins, methylpentachlorostearate, quartz sand, semi-reinforced carbon black, triphenyl phosphate, chlorinated paraffin, brominated polystyrene and attapulgite are added, so that the obtained cable sheath material has the advantages of high flame-retardant property, short burning distance and fast self-extinguishing time. The preparation process is simple and easy to operate.

Owner:芜湖浩权建筑工程有限公司

Rubber assembly for booster of automobile brake system

InactiveCN1847295AHigh tensile strengthHigh elongationBraking action transmissionRubber materialSulfur

The present invention relates to sealing rubber assembly for booster of automobile brake system and its making process. The materials include styrene butadiene rubber, carbon black, dioctyl phthalate, indirectly prepared zinc oxide, stearic acid, antiager, sulfur S-80, vulcanizing agent DTDM and promoter in certain weight proportion. The making process includes mixing the materials and synthesizing the rubber in a Banbury mixer; roll mixing the rubber material in a blending roll to form and vulcanizing in a vulcanizer at the pressure of 120-160 Kgf / sq cm and temperature of 190-200 deg.c for 80-100 sec. The product of the present invention has high tensile strength, great elongation, high tear strength, etc.

Owner:ANHUI ZHONGDING HLDG (GRP) CO LTD +1

High strength and flame retardant cable insulation sheath material and preparation method thereof

InactiveCN105936706AImprove flame retardant performanceShort burning distanceRubber insulatorsPlastic/resin/waxes insulatorsFiberPolymer science

The invention discloses a high strength and flame retardant cable insulation sheath material and a preparation method thereof. The cable insulation sheath material comprises 22-35 parts of PVC (polyvinyl chloride), 15-25 parts of polyether-ether-ketone resin, 16-22 parts of trioctyl trimellitate, 10-15 parts of nano bauxite, 15-22 parts of silicon micropowder, 10-20 parts of ethylene propylene rubber, 11-15 parts of copper sulfate, 33-36 parts of liquid wax, 10-20 parts of carbon fiber, 3-9 parts of aluminium naphthenate, 6-10 parts of a stabilizer, 2-6 parts of an antiager, 5-8 parts of a flame retardant and 2-6 parts of a plasticizer. According to the invention, PVC and ethylene propylene rubber are adopted as the main body, and polyether-ether-ketone resin, trioctyl trimellitate, nano bauxite, silicon micropowder, copper sulfate, liquid wax, carbon fiber and aluminium naphthenate are added to endow the obtained cable sheath material with high flame retardancy, the burning distance is short, and the self-extinguishing time is short. The preparation process is simple, and is easy to operate.

Owner:马晓权

Elastic rubber material applicable to work at high temperature

InactiveCN105400006AHigh strengthImprove thermal conductivityArtifical filament manufactureRubber materialSodium sulfate

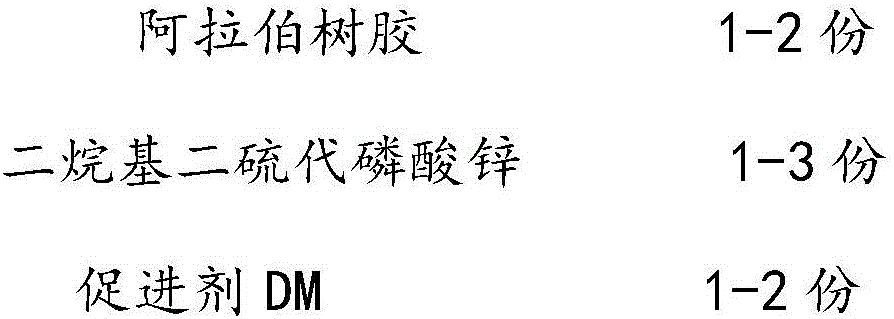

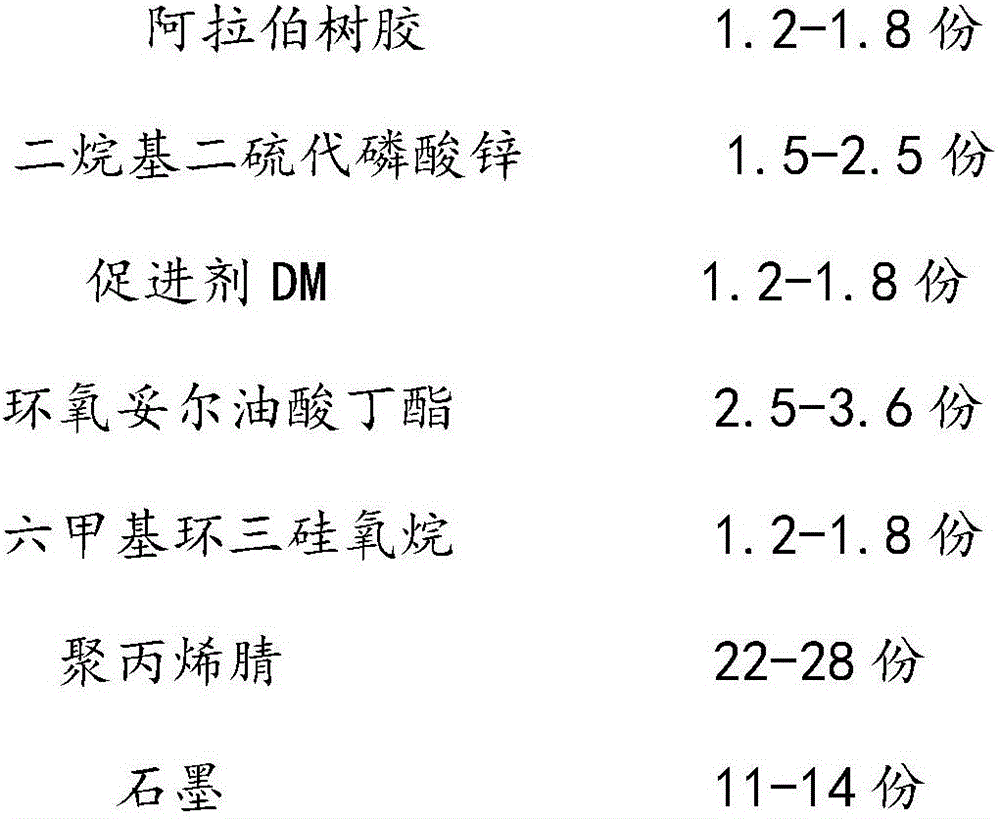

The invention discloses an elastic rubber material applicable to work at a high temperature. The elastic rubber material is prepared from, by weight, 1.6-2 parts of Arabic gum, 1-2 parts of zinc dialkyl dithiophosphate, 1-1.4 parts of accelerant DM, 2-3 parts of epoxy tall butyl oleate, 1-1.4 parts of hexamethyl cyclotrisiloxane, 24-27 parts of polyacrylonitrile, 12-13 parts of graphite, 3-4 parts of coal ash microbeads, 0.7-1 part of lauryl sodium sulfate, 42-55 parts of liquid nitrile rubber, 0.6-1 part of methacrylic acid, 52-60 parts of chemigum, 20-25 parts of butadiene styrene rubber, 23-25 parts of coking coal powder, 4-5 parts of urea, 8-11 parts of carbon black, 14-17 parts of aluminium nitride and 2-3 parts of thiuram. The prepared rubber material is good in stability, high in thermal conductivity, capable of bearing the high temperature, free of deformation and damage, meanwhile good in strength, good in chemical corrosion resistance, good in impact elasticity, high in wear resistance and long in service life.

Owner:安徽创奇乐智能游乐设备有限公司

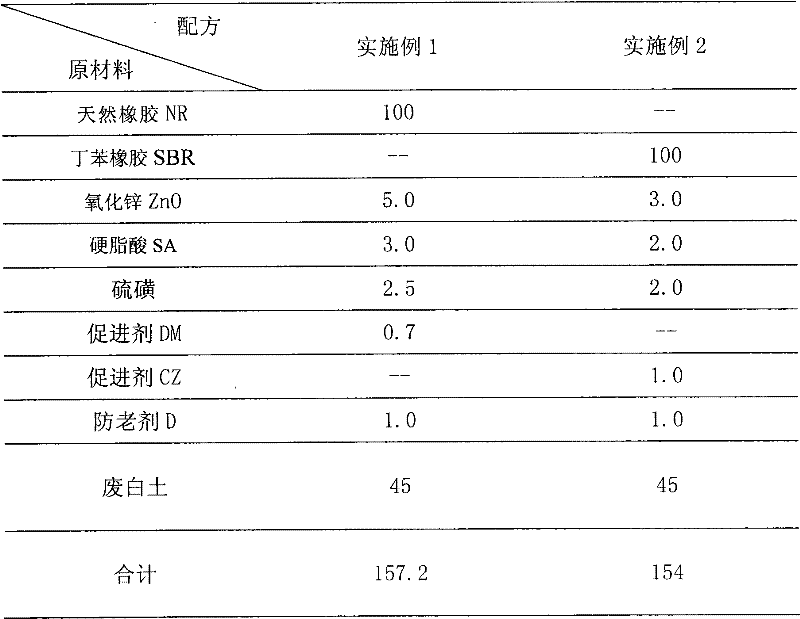

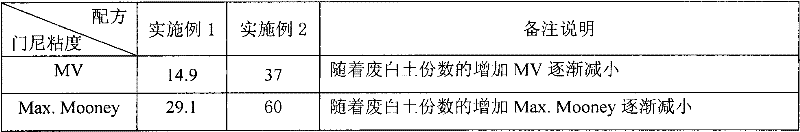

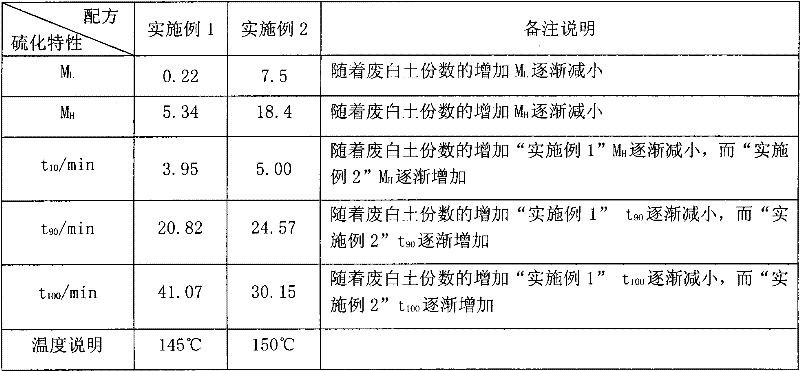

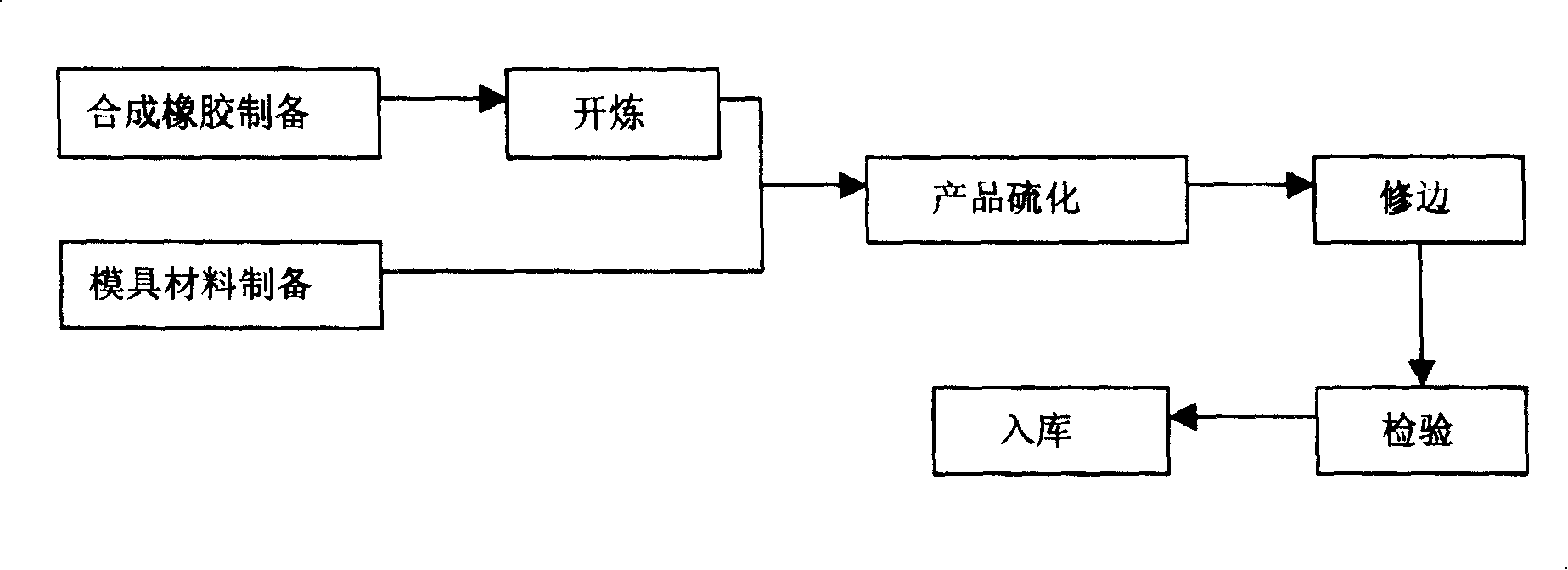

Glue taking waste argil as filler and softener

The invention discloses glue taking waste argil as a filler and softener, and belongs to the field of rubber. The glue is prepared from natural rubber or butadiene styrene rubber serving as a main raw material by steps of drying the waste argil serving as the filler and softener, mixing, plastifying crude rubber, mixing masterbatch, mixing the crude rubber and vulcanizing. The glue comprises the following raw materials in part by weight: 100 parts of natural rubber or butadiene styrene rubber, 2.5 to 5.5 parts of zinc oxide, 1.5 to 4.0 parts of stearic acid, 1.5 to 3.0 parts of sulfur, 0.8 to 1.2 parts of anti-aging agent D, 15 to 75 parts of waste argil, and 0.5 to 0.7 part of accelerator DM or 0.8 to 1.2 parts of accelerator CZ. The invention has the advantages that: the waste argil has low cost and can be used as the filler and softener, so the production cost of the glue is saved; waste and environmental pollution are reduced, the waste of the waste argil is reduced, and the environmental pollution caused by accumulating, landfilling and burning is reduced simultaneously; and compared with glue taking argil in the same parts as the waste argil as the filler and aromatic hydrocarbon oil as the softener, the glue has higher performance.

Owner:XUZHOU COLLEGE OF INDAL TECH

Rubber assembly for booster of automobile brake system and its manufacuturing process

InactiveCN100398593CHigh tensile strengthHigh elongationBraking action transmissionRubber materialVulcanization

The present invention relates to sealing rubber assembly for booster of automobile brake system and its making process. The materials include styrene butadiene rubber, carbon black, dioctyl phthalate, indirectly prepared zinc oxide, stearic acid, antiager, sulfur S-80, vulcanizing agent DTDM and promoter in certain weight proportion. The making process includes mixing the materials and synthesizing the rubber in a Banbury mixer; roll mixing the rubber material in a blending roll to form and vulcanizing in a vulcanizer at the pressure of 120-160 Kgf / sq cm and temperature of 190-200 deg.c for 80-100 sec. The product of the present invention has high tensile strength, great elongation, high tear strength, etc.

Owner:ANHUI ZHONGDING HLDG (GRP) CO LTD +1

Stink and wear resistant rubber pad

The invention discloses a stink and wear resistant rubber pad. The stink and wear resistant rubber pad is made from, by weight, 3-5 parts of styrene butadiene rubber, 2-4 parts of white carbon black, 3-5 parts of a promoter, 4-6 parts of a foaming agent, 9-16 parts of ethylene propylene diene monomer, 6-10 parts of naphthenic oil and 2-4 parts of zinc oxide. The stink and wear resistant rubber pad has the advantages of increase of the wear resistance of soles, prolonged service life, simple material and low cost; and the ethylene propylene diene monomer is used as one of the raw materials, so the stink resistance of the rubber pad is very good, the impact elasticity is good, and the market prospect is very wide.

Owner:青岛欧美亚橡胶工业有限公司

Method for preparing modified dienopolymer rubber

There is provided a process for producing a both end-modified diene polymer rubber comprising the steps of: (1) polymerizing a conjugated diene monomer or a combination thereof with an aromatic vinyl monomer in the presence of a compound represented by the following formula (1) to produce an alkali metal end-carrying active polymer, and (2) reacting the alkali metal end-carrying active polymer with an amine compound, a ketone compound, an acrylamide compound, a heterocyclic compound or a silyl compound represented by specific formulas, respectively: R-(CH2)n-X-M (1) wherein R is a functional group containing a substituent group-carrying nitrogen atom, X is a saturated or unsaturated hydrocarbon group comprising from 0 to 10 conjugated diene monomer units or aromatic vinyl monomer units, n is an integer of from 1 to 10, and M is an alkali metal.

Owner:SUMITOMO CHEM CO LTD

Rubber material applied in high-temperature working environment and preparation method thereof

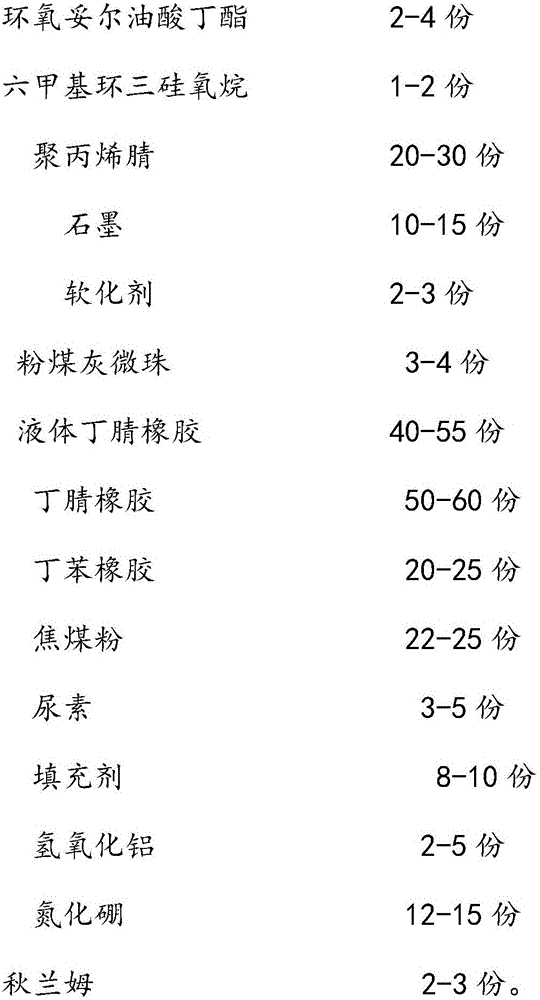

The invention discloses a rubber material applied in a high-temperature working environment and a preparation method thereof. The rubber material is prepared from, by weight, 1-2 parts of arabic gum, 1-3 parts of zinc dialkyl dithiophosphate, 1-2 parts of an accelerant DM, 2-4 parts of epoxy tall oil acid butyl ester, 1-2 parts of hexamethyl cyclotrisiloxane, 20-30 parts of polyacrylonitrile, 10-15 parts of graphite, 2-3 parts of a softening agent, 3-4 parts of fly ash microspheres, 40-55 parts of liquid nitrile rubber, 50-60 parts of nitrile rubber, 20-25 parts of butadiene styrene rubber, 22-25 parts of coking coal powder, 3-5 parts of urea, 8-10 parts of a filling agent, 2-5 parts of aluminum hydroxide, 12-15 parts of boron nitride and 2-3 parts of thiuram. The rubber material has the good high temperature resistance, acid resistance, oil resistance and flame retardance and can be well applied to a high-temperature area.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

A kind of rubber magnetic strip for low temperature and preparation method thereof

ActiveCN103578683BExcellent adhesionImprove aging resistancePermanent magnetsInductances/transformers/magnets manufacturePolymer scienceHalogen

The invention discloses a rubber magnetic strip used under low temperature and a preparation method thereof. The rubber magnetic strip consists of the following ingredients in percentage by mass: 85-95% of ferrite magnetic powder, 4-14% of ethylene propylene rubber and 1-3% of addition agent, wherein the addition agent comprises plasticizer, coupling agent, heat stabilizer and lubricating agent. The preparation method comprises the steps of high-speed blending, mixing, forming and cutting for packaging. The ethylene propylene rubber is used as a carrier for replacing the traditional chlorinated polyethylene, so that the prepared rubber magnetic strip is excellent in ageing-resistant performance, good in impact elasticity, good in chemical resistance, free of halogen, more environmental friendly and unlikely to embrittle and break when being used under low temperature.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Improved type abrasion resistant rubber

The invention relates to an improved type abrasion resistant rubber which is prepared from the following raw materials in parts by weight: 20-35 parts of ethylene propylene diene rubber, 10-20 parts of nanometer reinforcing agents, 2-6 parts of vulcanization accelerators, 4-6 parts of zinc oxide, 5-9 parts of coupling agents, 8-14 parts of barium sulfate, 8-11 parts of vulcanizing agents and 8-12 parts of vaseline. The improved type abrasion resistant rubber disclosed by the invention has the advantages of very excellent ageing resistant property, chemical corrosion resistance, and better impact elasticity.

Owner:QINGDAO GUOQIANG ENVIRONMENTAL PROTECTION TECH

Rubber gasket containing modified vermiculite nano-powder

InactiveCN103937132AHigh strengthImprove temperature resistancePolyvinyl chlorideTemperature resistance

The invention discloses a rubber gasket containing modified vermiculite nano-powder. The rubber gasket is prepared from the following raw materials in parts by weight: 110-130 parts of fluororubber, 22-30 parts of polyvinyl chloride, 5-8 parts of dibenzothiazyl disulfide, 8-12 parts of bismaleimide, 3.3-3.5 parts of bis-dodecyl alcohol ester, 3-5 parts of glass fiber, 5-7 parts of modified vermiculite nano-powder, 15-20 parts of asbestos, 12-16 parts of spraying carbon black, 10-12 parts of coumarone, 5-10 parts of calcium carbonate, 5-6 parts of magnesium oxide, 6-7 parts of calcium hydroxide, 7-9 parts of chlorinated paraffin, 2.2-2.5 parts of polyethylene wax, 3.5-5 parts of naphthenic oil and 5-7 parts of modified wood ash. The rubber gasket is reasonable in formula, has excellent comprehensive performances of high temperature resistance, cold-hot resistance, corrosion resistance, aging resistance, radiation resistance and the like, has self-lubrication and air tightness, is excellent in insulation performance, good in impact elasticity and long in service life, and can be widely applied in various electronic and electrical equipment.

Owner:ANHUI MENGLING PRECISION ELECTRONICS

High-performance cable sheath material for building engineering and preparation method of high-performance cable sheath material

InactiveCN107674423AImprove flame retardant performanceShort burning distanceRubber insulatorsLinear low-density polyethyleneNitrocellulose

The invention discloses a high-performance cable sheath material for building engineering and a preparation method of the high-performance cable sheath material. The high-performance cable sheath material is prepared from 22 to 35 parts of methyl vinyl phenyl raw silicone rubber, 15 to 25 parts of linear low density polyethylene, 16 to 22 parts of trioctyl trimellitate, 10 to 15 parts of kaolin, 15 to 22 parts of calcined clay, 10 to 20 parts of hydrogenated butadiene-acrylonitrile rubber, 11 to 15 parts of dibutyl maleate, 33 to 36 parts of organic silicon resin, 10 to 20 parts of nitrocellulose, 3 to 9 parts of ethylene-chlorotrifluoroethylene copolymer, 6 to 10 parts of stabilizer, 2 to 6 parts of antiager, 5 to 8 parts of fire retardant and 2 to 6 parts of plasticizer. According to thehigh-performance cable sheath material for the building engineering, disclosed by the invention, the methyl vinyl phenyl raw silicone rubber and the hydrogenated nitrile-butadiene rubber are used asa main body, and the linear low density polyethylene, the trioctyl trimellitate, the kaolin, the calcined clay, the dibutyl maleate, the organic silicon resin, the nitrocellulose and the ethylene-chlorotrifluoroethylene copolymer are added, so that the obtained cable sheath material has the advantages of high flame retardant performance, short burning distance and short self-extinguish time; in addition, the preparation process is simple and is easy to operate.

Owner:安徽嘉中金属材料有限公司

Formula of ozone-resistant rubber part

The invention relates to a formula of an ozone-resistant rubber part. The formula of the ozone-resistant rubber part is characterized by comprising the following components in parts by weight: 75 parts of chloroprene rubber, 25 parts of butadiene-styrene rubber, 100 parts of ethylene propylene rubber, 3 parts of a plasticizer, 1 part of white carbon black, 1 part of zinc oxide, 2 parts of an antiager, 3 parts of polypropylene cellulose, 12 parts of an antioxidant, 2 parts of fibers, 3 parts of modified coal ash, 10 parts of epichlorohydrin rubber, 12 parts of polyamide wax micropowder, 5 parts of polycaprolactone, 3 parts of dibenzothiazyl disulfide and 5 parts of paraffin. According to the formula of the ozone-resistant rubber part provided by the invention, a rubber main material which is good in ozone resistance is selected and meanwhile, the antiager and paraffin which are good in ozone resistance are further used in the formula, so that the ozone resistance of the ozone-resistant rubber part for a transformer is improved. The ozone-resistant rubber part provided by the invention is simple in processing process, the raw materials are easily available and the cost is low; therefore, the ozone-resistant rubber part has potential economic benefit and social meaning.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

High-pressure-resistant rubber

The invention discloses high-pressure-resistant rubber relating to the technical field of rubber. The high-pressure-resistant rubber is prepared from the following raw materials in parts by weight: 70-80 parts of ethylene propylene rubber, 17-25 parts of butadiene-acrylonitrile rubber, 3-5 parts of epichlorohydrin rubber, 2-10 parts of stearic acid, 15-30 parts of carbon black, 2-10 parts of dithiocarbamate, 2-10 parts of polyethylene wax, 3-15 parts of paraffin and 12-15 parts of cured resin. By using the high-pressure-resistant rubber, the problem of poor high pressure resistance of the existing rubber is solved.

Owner:LIUZHOU YINGHANG AUTO PARTS

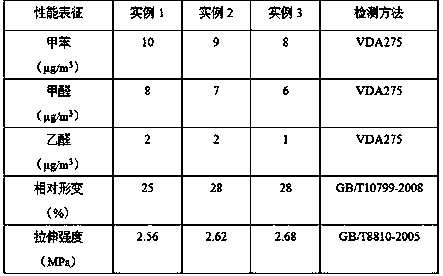

Method for preparing interior trim material for automobile seat cover

PendingCN110512433AGood extensibilitySoftness can be adjustedElectro-spinningVehicle componentsFiber bundleElectrospinning

The invention relates to a method for preparing an interior trim material for an automobile seat cover, and belongs to the technical field of automobile interior trim. According to the method, base cloth is prepared from ethylene propylene rubber-modified neoprene and nylon through an electrostatic spinning method, and casein protein is used for performing graft modification on polyurethane to prepare a modified coating, the base cloth is impregnated in a methylbenzene solution after being impregnated in the modified coating and pressed, so that through impregnation and compression roller treatment, the interior trim material for the automobile seat cover is prepared; the nylon and the ethylene propylene rubber-modified neoprene are impregnated in the methylbenzene solution, through the impregnation and compression roller treatment, 'sea' components in sea-island fibers are extracted out to obtain bundled ultra-fine fibers formed by 'island'; sea-island ultra-fiber leather entirely composed of the ultra-fine fiber bundle and a networked PU resin sponge body is formed; the interior trim material for the automobile seat cover is free of toxicity and environmentally friendly, and cannot generate unpleasant odors.

Owner:胡赛辉

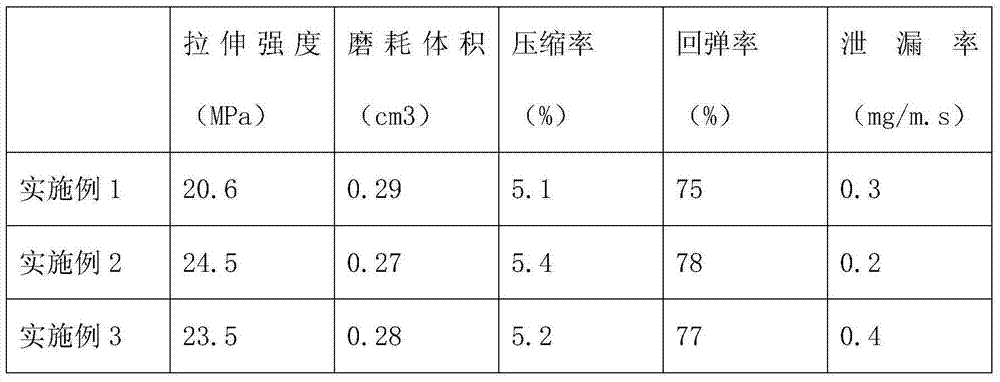

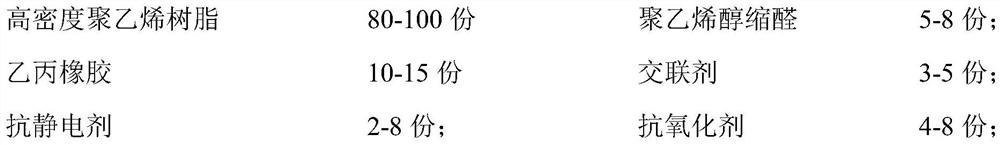

A kind of PE pipe fitting and its production process

ActiveCN110726013BAvoid breakingLess likely to breakCorrosion preventionPipe protection against corrosion/incrustationPolymer sciencePolyvinyl alcohol

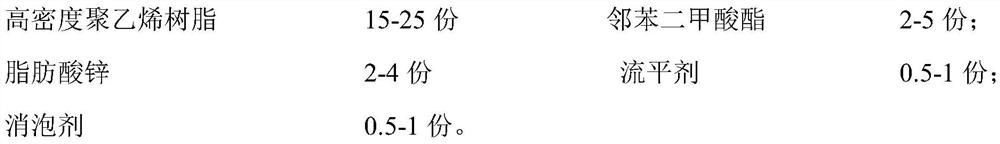

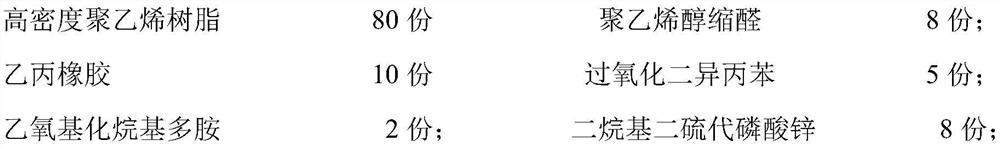

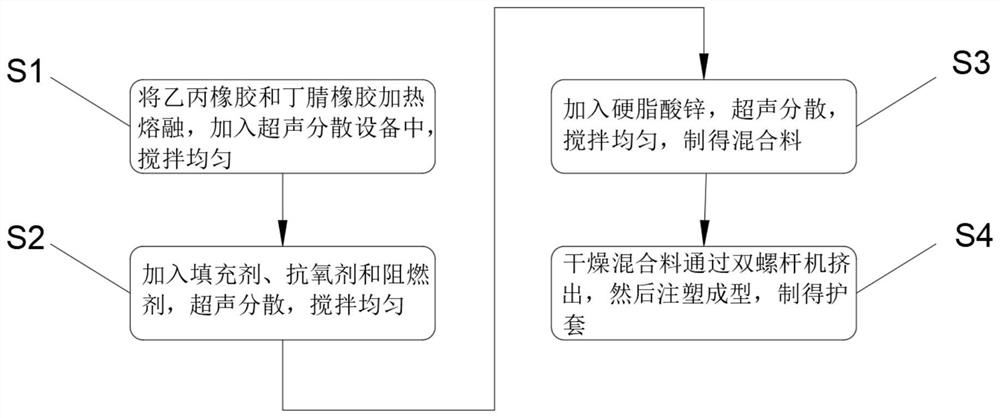

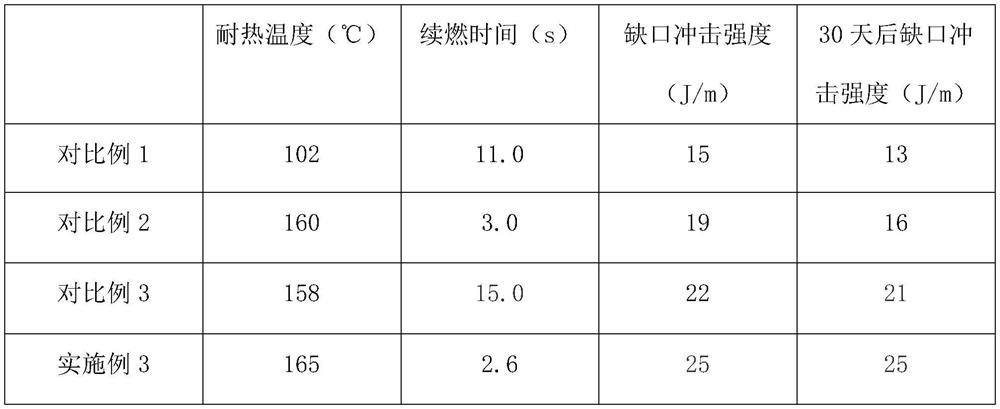

The invention relates to the technical field of PE pipe fittings, and discloses a PE pipe fitting. The PE pipe fitting comprises an outer layer and an inner layer, wherein the thickness ratio of the inner layer to the outer layer is 1: (4 to 5); the outer layer comprises the following components in parts by mass: 80-100 parts of high-density polyethylene resin, 5-8 parts of polyvinyl acetal, 10-15parts of ethylene propylene rubber, 3-5 parts of cross-linking agent, 2-8 parts of antistatic agent, and 4-8 parts of antioxidant agent; and the inner layer comprises the following components in parts by mass: 15-25 parts of high-density polyethylene resin, 2-5 parts of phthalic acid ester, 2-4 parts of fatty acid zinc salt, 0.5-1 part of leveling agent and 0.5-1 part of defoaming agent. According to the PE pipe fitting, the service life of the pipe fitting can be prolonged.

Owner:湖北凯科塑业有限公司

Busbar heat shrinkable sleeve pipe masterbatch formula

The invention discloses a busbar heat shrinkable sleeve pipe masterbatch formula, and belongs to the technical field of busbar heat shrinkable pipes. The component of the busbar heat shrinkable sleevepipe masterbatch formula comprises ethylene propylene diene methylene, EVA, PE, aluminum powder, environment-friendly decabromine, environment-friendly antimony oxide, zinc stearate, an antioxidant,a special wax and color masterbatch, and the component further comprises a stabilizer, an antibacterial agent and a reinforcing fiber. Chemical corrosion resistance and impact elasticity of a busbar heat shrinkable pipe are improved through excellent chemical stability of ethylene propylene diene methylene, EVA and PE, the viscosity of a mixed material is improved through EVA, flame retardant performance of the busbar heat shrinkable pipe is improved through excellent thermal stability of environment-friendly decabromine and environment-friendly antimony oxide, the softening property of othercomponents is reduced by zinc stearate, and thus all the components can be well mixed, and an oxidation process of the busbar heat shrinkable pipe is retarded or inhibited through the antioxidant, sothat the service life of the usbar heat shrinkable pipe is improved. The prepared heat-shrinkable pipe has stable physical and chemical properties, and chemical corrosion resistance is improved, so that popularization and application are convenient.

Owner:苏州市亚博冷热缩制品有限公司

Electric tracing band capable of effectively preventing electric leakage

PendingCN112300498AImprove performanceGood chemical resistanceHeating element materialsThermodynamicsNitrile rubber

The invention relates to an electric tracing band capable of effectively preventing electric leakage, which comprises a self-adjusting heat conduction core, a galvanized copper stranded wire is arranged in the self-adjusting heat conduction core, the outer surface of the self-adjusting heat conduction core is sleeved with a fluorine-containing polymer sleeve, and the outer surface of the fluorine-containing polymer sleeve is sleeved with a metal wire braided layer. The outer surface of the metal wire braided layer is sleeved with a fluorine-containing polymer outer sleeve, the surface of the fluorine-containing polymer outer sleeve is sleeved with a sheath, and the sheath is composed of ethylene propylene rubber, nitrile rubber, zinc stearate, an antioxidant, a filler and a flame retardant. The comprehensive performance of the electric tracing band can be improved, so that the electric tracing band has good chemical resistance, electric insulation performance, impact elasticity, low-temperature performance, hot water resistance, water vapor resistance and the like.

Owner:ANBANG ELECTRICAL GRP

A kind of electrical insulation rubber and its preparation method

ActiveCN103254518BSimplified Recipe StructureMeet production needsRubber insulatorsRubber materialSulfur

The invention belongs to the technical field of rubber, discloses electric insulating rubber and a fabrication method thereof, and aims at providing electric insulating rubber which is good in insulativity and simple in fabrication method. The electric insulating rubber adopts the technical scheme that the electric insulating rubber comprises the following components in parts by weight: 100 parts of EPDM (Ethylene-Propylene-Diene Monomer), 20-30 parts of calcined kaolin, 0.1-0.3 parts of thiofide PZ, 1-2 parts of stearic acid, 30-40 parts of paraffin oil, 5-8 parts of indirect-method zinc oxide, 0.3-0.5 parts of rubber accelerator CZ, 5 parts of liquid EPDM, 15-25 parts of fumed silica, 0.5-1.5 parts of silane coupling agent, 1-2 parts of sulfur and 1-2 parts of rubber accelerator DM. The fabrication method of the electric insulating rubber comprises the following steps of 1) weighing the components, 2) conducting internal mixing by sections, 3) adding sulfur to an open mill for mixing, and outputting sheet rubber, and 4) placing for 4-8h to allow rubber materials to be more uniform.

Owner:武汉科能电气有限公司

Cable sheath for high strength building and preparation method of cable sheath

InactiveCN106188994AHigh strengthImprove wear resistancePlastic/resin/waxes insulatorsClimate change adaptationEpoxyFiber

The invention discloses a cable sheath for a high strength building and a preparation method of the cable sheath. The cable sheath comprises 22-35 parts of polyvinylfluoride resin, 15-25 parts of modified epoxy resin, 16-22 parts of methyl pentachlorostearate, 10-15 parts of hydrotalcite, 15-22 parts of exfoliated graphite, 10-20 parts of butadiene acrylonitrile rubber, 11-15 parts of ethylene bis stearamide, 33-36 parts of chlorcosane, 10-20 parts of carbon fibers, 3-9 parts of calcium stearate, 6-10 parts of an accelerant, 2-6 parts of an antioxidant, 5-8 parts of a fire retardant and 2-6 parts of a plastifier. The polyvinylfluoride resin and the butadiene acrylonitrile rubber are used as main bodies, and the modified epoxy resin, the methyl pentachlorostearate, the hydrotalcite, the exfoliated graphite, the ethylene bis stearamide, the chlorcosane, the carbon fibers and the calcium stearate are added, so that the prepared cable sheath material is good in fire retardance, short in combustion distance, and quick in self extinguishing time. The preparation method is simple in preparation technology and easy to operate.

Owner:芜湖浩权建筑工程有限公司

Method for producing modified polymer rubber

Owner:SUMITOMO CHEM CO LTD

A kind of high temperature resistant and anti-aging rubber sealing strip material for vehicle and preparation method thereof

The invention discloses a high-temperature resistant and aging resistant rubber sealing strip material for a vehicle and a preparation method thereof. The high-temperature resistant and aging resistant rubber sealing strip material for the vehicle is prepared from the following raw materials: natural rubber, ethylene-propylene-diene monomer rubber, ethylene-butene elastomer, anti-aging agent BLE, jojoba oil, chloropropyltriethoxysilane, dibutyl phthalate, di-n-butyl dimethly thiodiglycolate, triethanolamine, stearic acid, accelerant DPTT, zinc oxide, nano antimony tin oxide, epoxidized soybean oil, cordierite powder, sulphur, calcined loess and the like. The used ethylene-propylene-diene monomer rubber has an excellent sealing function, better agint resistant performance and good weather resistant performance; the added ethylene-butene elastomer is beneficial to improving the impact elasticity of the overall rubber material; the added anti-aging agent BLE and the nano antimony tin oxide are beneficial to enhancing the aging resistant performance of the rubber; with the reasonable coordination of the other additives, the heat resistant performance, the abrasion resistance and the elasticity of the rubber are improved, and favorable compression deformation resistant performance and sealing performance of the rubber material are played, so that the material is safer.

Owner:福州福光橡塑有限公司

Ethylene-propylene rubber cable insulation material

InactiveCN105131437AGood chemical resistanceImprove insulation performanceRubber insulatorsAcetic acidPolymer science

The present invention relates to a rubber cable material, and in particular relates to an ethylene-propylene rubber cable insulation material. The ethylene-propylene rubber cable insulation material comprises the following raw materials: ethyl acetoacetate sodium salt, 4-keto-thyl valerate, succinic acid mono-2- (2- acryloyloxy) hydroxy ethanol, N- (1,1- dimethyl-3 - oxobutyl) acrylamide, 5 - [(2-methoxyphenoxy) methyl] -2-oxazolidinone, and the like. The ethylene-propylene rubber cable insulation material has good chemical resistance, electrical insulation properties, impact elasticity, low temperature performance, low density, high filling properties, resistance to hot water and steam, and the like, and is suitable for being widely used in rubber cable insulation material.

Owner:烟台顺隆化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com