Rubber material applied in high-temperature working environment and preparation method thereof

A technology for working environment and rubber materials, applied in the field of rubber materials, can solve problems such as not fully meeting the requirements of use, and achieve the effects of reducing mechanical properties, improving thermal conductivity, and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

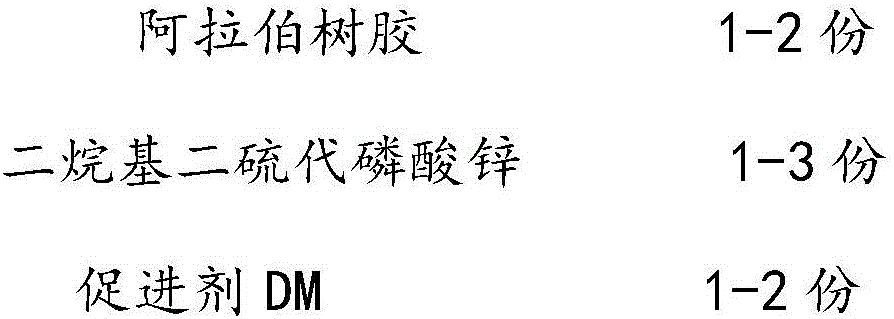

[0026] The present invention proposes a kind of working environment is the rubber material of high temperature, and raw material comprises by weight:

[0027]

[0028]

[0029] The invention also discloses a method for preparing a rubber material whose working environment is high temperature, comprising the following steps:

[0030] (1) Dilute the gum arabic with 5 times the amount of deionized water and stir evenly, mix and disperse the coke powder, hydrated silicon dioxide and boron nitride evenly, then add the mixed powder to the gum arabic solution, heat and stir Until the water evaporates, dry and grind for later use;

[0031] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and make an oar, the concentration is controlled at 16-18%, dry the graphite and fly ash microbeads in a vacuum drying oven, according to the solid-to-liquid ratio of 1: 4 Add deionized water, then add sodium lauryl sulfate and continue ultrasonic stirring, take its supernatan...

Embodiment 2

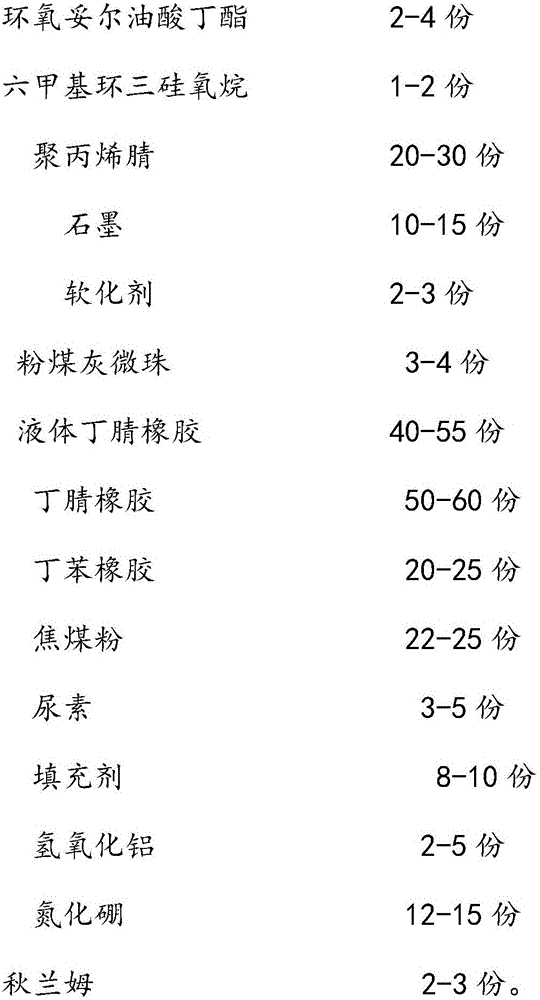

[0035] The present invention provides a kind of working environment is the rubber material of high temperature, and raw material comprises by weight:

[0036]

[0037] The invention also discloses a method for preparing a rubber material whose working environment is high temperature, comprising the following steps:

[0038] (1) Dilute the gum arabic with 5 times the amount of deionized water and stir evenly, mix and disperse the coke powder, hydrated silicon dioxide and boron nitride evenly, then add the mixed powder to the gum arabic solution, heat and stir Until the water evaporates, dry and grind for later use;

[0039] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and make an oar, the concentration is controlled at 16-18%, dry the graphite and fly ash microbeads in a vacuum drying oven, according to the solid-to-liquid ratio of 1: 4 Add deionized water, then add sodium lauryl sulfate and continue ultrasonic stirring, take its supernatant and add it...

Embodiment 3

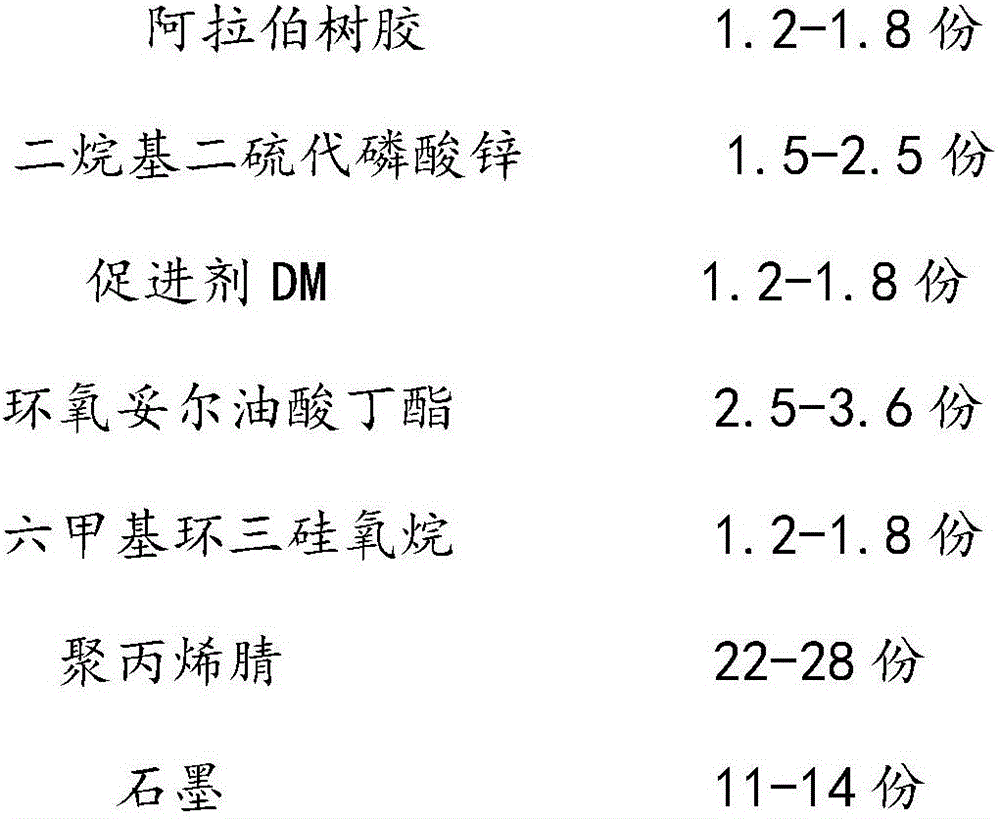

[0043] The present invention proposes a kind of working environment is the rubber material of high temperature, and raw material comprises by weight:

[0044]

[0045]

[0046] The invention also discloses a method for preparing a rubber material whose working environment is high temperature, comprising the following steps:

[0047] (1) Dilute the gum arabic with 5 times the amount of deionized water and stir evenly, mix and disperse the coke powder, hydrated silicon dioxide and boron nitride evenly, then add the mixed powder to the gum arabic solution, heat and stir Until the water evaporates, dry and grind for later use;

[0048] (2) Add polyacrylonitrile to the dimethyl sulfoxide solution, stir and make an oar, the concentration is controlled at 16-18%, dry the graphite and fly ash microbeads in a vacuum drying oven, according to the solid-to-liquid ratio of 1: 4 Add deionized water, then add sodium lauryl sulfate and continue ultrasonic stirring, take its supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com