Method for preparing modified dienopolymer rubber

A technology of diene polymer and active polymer, which is applied in the field of diene polymer rubber with both ends modified, and can solve problems such as difficult to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

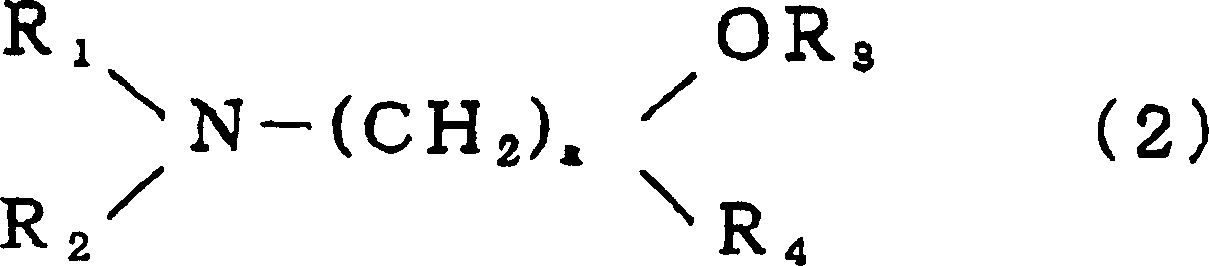

[0077] A stainless steel polymerization reactor having an internal volume of 20 liters was cleaned and dried, then purged with dry nitrogen. Next, 11.2 mmol of two isoprene monomer units and 3-(N,N-dimethylamino)-1-propyllithium (AI-200 CE, prepared from FMC lithium and cyclohexylamine solution) were added thereto. Prepared) Active saturated or unsaturated hydrocarbons obtained by polymerization reaction, 1420g 1,3-butadiene, 580g styrene, 324g tetrahydrofuran and 10.2kg hexane were polymerized under stirring at 65°C for 3 hours.

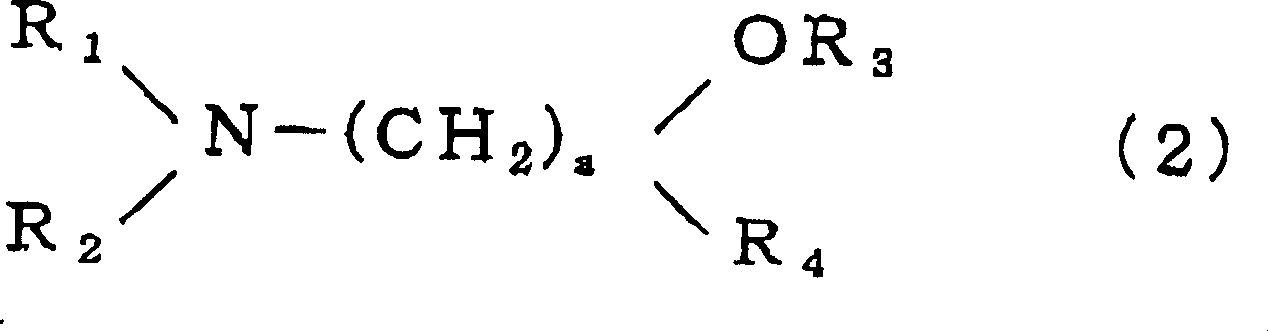

[0078] 0.4 mol of tin tetrachloride (coupling agent) was added to the obtained polymerization reaction mixture, and the reaction was continued for 30 minutes under stirring at 65°C. Further, 9.6 mmol of 1,1-dimethoxytrimethylamine (amine compound) was added to the obtained reaction mixture, and the reaction was continued for another 30 minutes under stirring at 65°C.

[0079] To the resulting reaction mixture was added 10 ml of methanol, and stirri...

Embodiment 2

[0081] Except (1) will be produced by two isoprene monomer units and 3-(N,N-dimethylamino)-1-propyllithium (AI-200CE, prepared from FMC lithium, cyclohexylamine solution) The amount of active saturated or unsaturated hydrocarbons obtained by the polymerization reaction is changed to 10.3mmol, and (2) 1,1-dimethoxytrimethylamine (amine compound) is changed to 8.68mmol, and the implementation is repeated In Example 1, a polymer rubber having both ends modified was obtained.

Embodiment 3

[0083] Except (1) will be produced by two isoprene monomer units and 3-(N,N-dimethylamino)-1-propyllithium (AI-200CE, prepared from FMC lithium, cyclohexylamine solution) The amount of active saturated or unsaturated hydrocarbons that the polymerization reaction obtains is changed to 14.9mmol, and (2) 1,1-dimethoxytrimethylamine (amine compound) is changed to 14.9mmol, and the embodiment is repeated 1 Obtain a polymer rubber in which both ends have been modified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com