A kind of high temperature resistant and anti-aging rubber sealing strip material for vehicle and preparation method thereof

A rubber sealing strip, high temperature resistance technology, applied in the field of rubber materials, can solve the problems affecting the sealing performance, vibration damping performance and service life of the sealing strip, aging, easy deformation, etc., to achieve good compression deformation resistance and sealing performance, Good weather resistance and the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

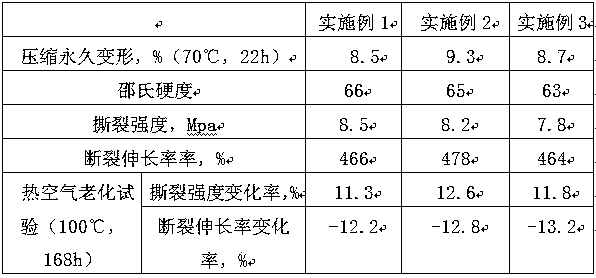

Examples

Embodiment 1

[0015] A high-temperature-resistant and anti-aging rubber sealing strip material for vehicles, which is prepared from the following raw materials in parts by weight (kg): natural rubber 100, EPDM rubber 30, ethylene-butylene elastomer 15, anti-aging agent BLE 3, Jojoba oil 2, chloropropyltriethoxysilane silane 3, dibutyl phthalate 4, di-n-butyl thiodiglycolate 2, triethanolamine 3, stearic acid 5, accelerator DPTT 1, Zinc oxide 6, nano tin antimony oxide 20, epoxy soybean oil 6, cordierite powder 10, sulfur 2, calcined loess 5, barium chromate 6, fumed silica 7, polypropylene glycol diglycidyl ether 8.

[0016] A method for preparing a high-temperature-resistant and anti-aging rubber sealing strip material for vehicles, comprising the following steps:

[0017] (1) Put natural rubber, EPDM rubber, and ethylene-butylene elastomer into the kneader, knead for 40-50 minutes at 60-70°C, and then add antioxidant BLE, jojoba oil, and chloropropane Triethoxysilane silane, dibutyl phth...

Embodiment 2

[0021] A high-temperature and anti-aging rubber sealing strip material for vehicles, which is prepared from the following raw materials in parts by weight (kg): natural rubber 105, EPDM rubber 35, ethylene-butylene elastomer 17.5, anti-aging agent BLE 4, Jojoba oil 2.5, chloropropyltriethoxysilane silane 3.5, dibutyl phthalate 5, di-n-butyl thiodiglycolate 3, triethanolamine 4, stearic acid 6, accelerator DPTT 1.5, Zinc oxide 7, nano-tin antimony oxide 25, epoxy soybean oil 7.5, cordierite powder 11, sulfur 2.5, calcined loess 6.5, barium chromate 7, fumed silica 8, polypropylene glycol diglycidyl ether 9.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0024] A high-temperature and anti-aging rubber sealing strip material for vehicles, which is prepared from the following raw materials in parts by weight (kg): natural rubber 110, EPDM rubber 40, ethylene-butylene elastomer 20, anti-aging agent BLE 5, Jojoba oil 3, chloropropyl triethoxysilane silane 4, dibutyl phthalate 6, di-n-butyl thiodiglycolate 4, triethanolamine 5, stearic acid 7, accelerator DPTT 2, Zinc oxide 8, nano tin antimony oxide 30, epoxy soybean oil 9, cordierite powder 12, sulfur 3, calcined loess 8, barium chromate 8, fumed silica 9, polypropylene glycol diglycidyl ether 10.

[0025] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com