Process for producing modified polymer rubber

A technology of active polymers and polymers, which is applied in the field of producing modified polymer rubbers with excellent impact elasticity, and can solve the problems of unsatisfactory, copolymers without impact elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A 20 liter internal volume stainless steel polymerization reactor was washed, dried, and then purged with dry nitrogen. 1405 g of 1,3-butadiene, 395 g of styrene, 328 g of tetrahydrofuran, 10.2 kg of hexane and 12.8 mmol of n-butyllithium (n-hexane solution) were charged to the reactor. Polymerization was carried out at 65° C. under stirring for 3 hr, whereby a polymerization mixture was obtained.

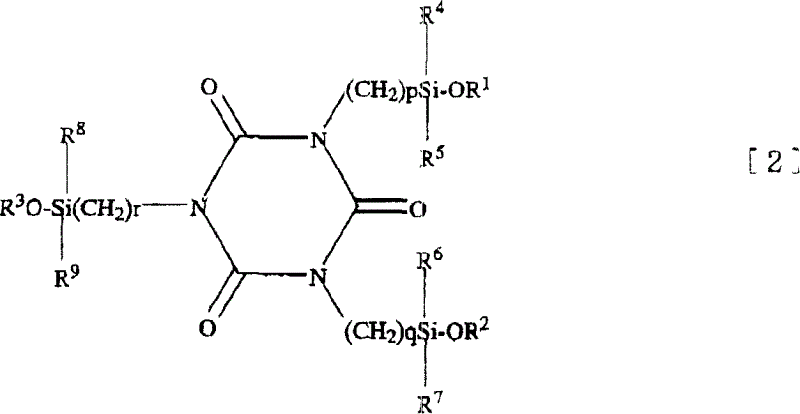

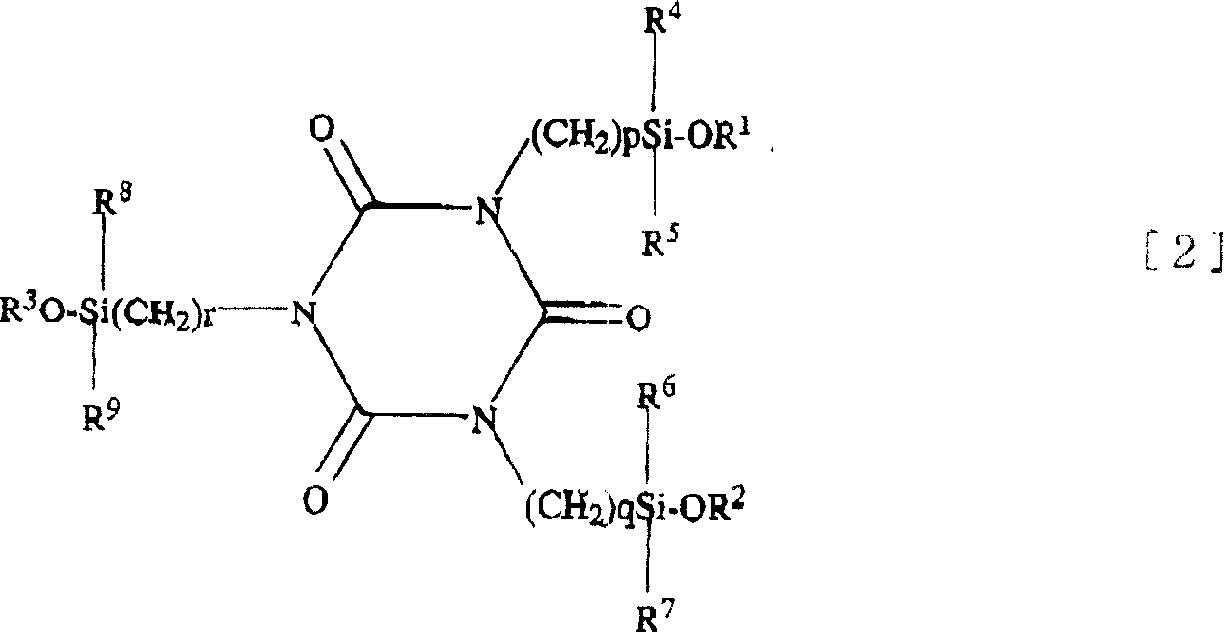

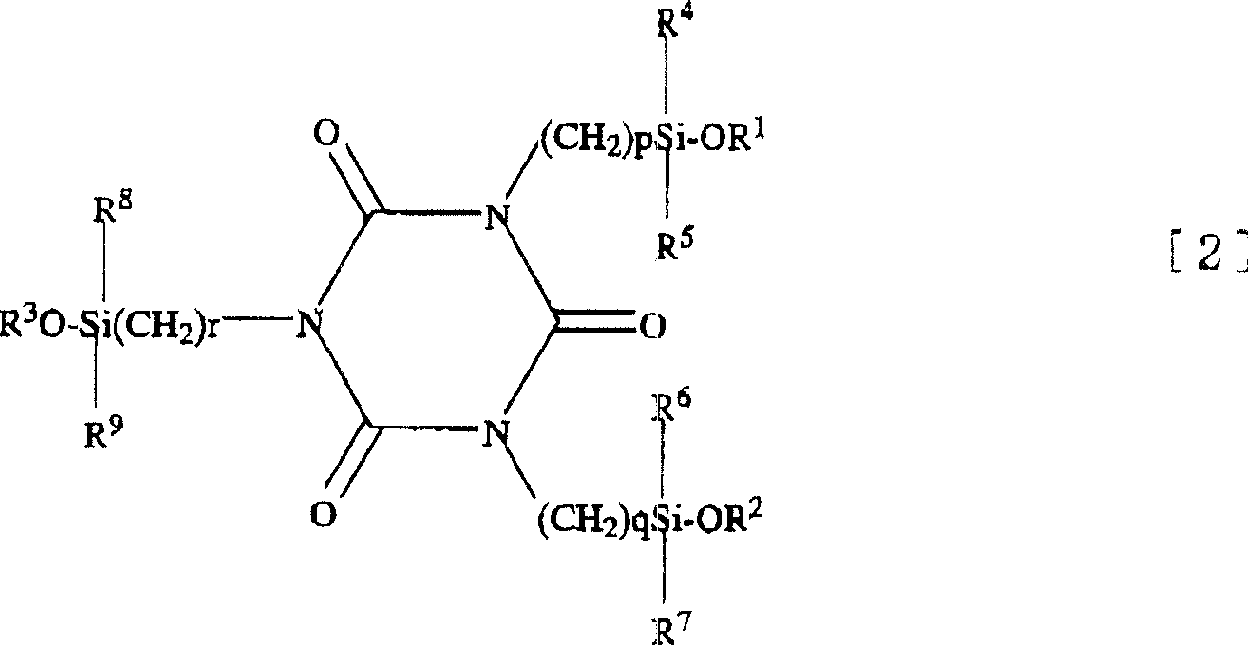

[0060] 1.70 g (2.76 mmol) of 1,3,5-tris(3-trimethoxysilylpropyl) isocyanurate was added to the obtained polymerization mixture, and the obtained mixture was reacted at 65° C. for 30 min while stirring.

[0061] To the resulting reaction mixture was added 10 ml of methanol, and the resulting mixture was further stirred at 65° C. for 5 min, whereby a reaction mixture was obtained.

[0062] The resulting reaction mixture was taken out and mixed with 10 g of 2,6-di-tert-butyl-p-cresol (SUMILIZERBHT, manufactured by Sumitomo Chemical Co., Ltd.), after which most of the hexane wa...

Embodiment 2

[0064] Repeat Example 1 to obtain a modified polymer rubber, but (i) change the amount of n-butyllithium (n-hexane solution) to 11.3 mmol, (ii) add 0.039 g (0.23 mmol) tetrachloro Silica coupling agent, and (iii) 2.70 g (4.39 mmol) of 1,3,5-tris(3-trimethoxysilylpropyl)isocyanurate were added 15 min after the addition of silicon tetrachloride.

Embodiment 3

[0066] Repeat Example 1 to obtain a modified polymer rubber, but (i) change the amount of n-butyllithium (n-hexane solution) to 12.0 mmol, (ii) add 0.041 g (0.24 mmol) tetrachloro Silica, and (iii) 1.43 g (2.33 mmol) of 1,3,5-tris(3-trimethoxysilylpropyl)isocyanurate were added 15 min after the addition of silicon tetrachloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com