A kind of PE pipe fitting and its production process

A pipe fitting and outer layer technology, applied in the field of PE pipe fittings and its production process, can solve problems such as short service life, and achieve the effects of improving tear strength, improving quality, and reducing the total size of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

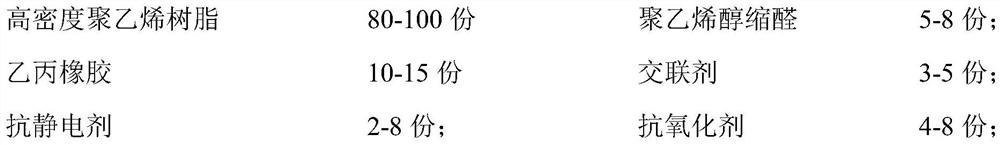

[0027] A PE pipe fitting, comprising an outer layer and an inner layer, and the thickness ratio of the inner layer to the outer layer is 1:4, wherein the outer layer includes by parts by mass:

[0028]

[0029] The inner layer includes in parts by mass (wherein the outer layer and the inner layer are taken separately, that is, there is no corresponding relationship between the "parts" of the two, but there are "parts" in the inner layer and the outer layer. Corresponding relationship):

[0030]

[0031] The high-density polyethylene resin in the outer layer has a density of 0.955 g / cm 3 , HDPE resin with a melt index of 0.5g / 10min. The density of the high-density polyethylene resin in the inner layer is 0.935g / cm 3 , HDPE resin with a melt index of 10g / 10min.

[0032] 2 parts and 0.5 parts of nucleating agent are respectively added into the outer layer and the inner layer (the "parts" in the outer layer and the "parts" in the inner layer correspond to the "parts" in t...

Embodiment 2

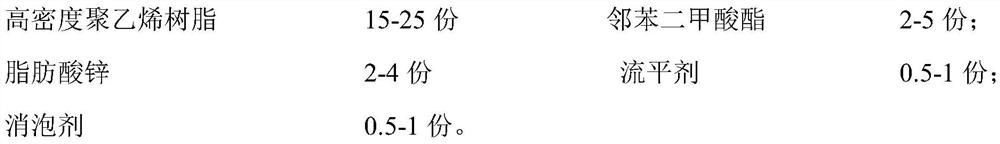

[0040] A PE pipe fitting, comprising an outer layer and an inner layer, and the thickness ratio of the inner layer to the outer layer is 1:5, wherein the outer layer includes by parts by mass:

[0041]

[0042] Described inner layer comprises by mass parts:

[0043]

[0044] The high-density polyethylene resin in the outer layer has a density of 0.975 g / cm 3 , HDPE resin with a melt index of 3g / 10min. The density of the high-density polyethylene resin in the inner layer is 0.950g / cm 3 , HDPE resin with a melt index of 20g / 10min.

[0045] 5 parts and 1 part of nucleating agent are respectively added into the outer layer and the inner layer. The nucleating agent in the outer layer is calcium carbonate, and the nucleating agent in the inner layer is alum.

[0046] The ethylene-propylene rubber is EPDM.

[0047] The present invention also provides a process for producing PE pipe fittings as described in any one of the above, comprising the following steps:

[0048] S1,...

Embodiment 3

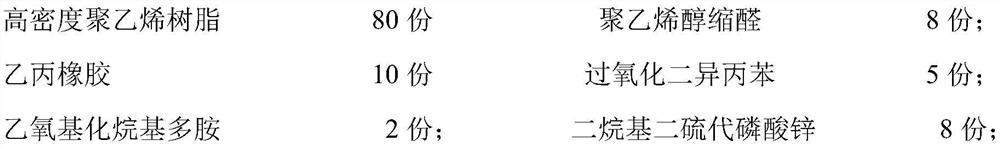

[0053] A PE pipe fitting, comprising an outer layer and an inner layer, and the thickness ratio of the inner layer to the outer layer is 1:4.5, wherein the outer layer includes by parts by mass:

[0054]

[0055] Described inner layer comprises by mass parts:

[0056]

[0057]

[0058] The high-density polyethylene resin in the outer layer has a density of 0.960 g / cm 3, HDPE resin with a melt index of 6g / 10min. The density of the high-density polyethylene resin in the inner layer is 0.940g / cm 3 , HDPE resin with a melt index of 15g / 10min.

[0059] 4 parts and 1 part of nucleating agent are respectively added into the outer layer and the inner layer. The nucleating agent in the outer layer is silicon dioxide, and the nucleating agent in the inner layer is calcium oxide.

[0060] The ethylene-propylene rubber is EPDM.

[0061] In terms of parts by mass, the outer layer also includes 3 parts of zinc oxide.

[0062] The present invention also provides a process for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com