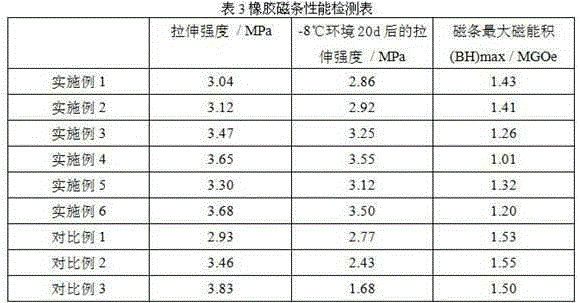

A kind of rubber magnetic strip for low temperature and preparation method thereof

A rubber magnetic strip, low-temperature technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of containing halogens, brittle fracture, etc., and achieve excellent aging resistance, good chemical resistance, The effect of improving the magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

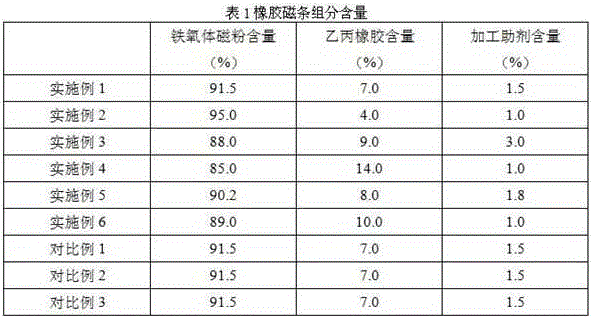

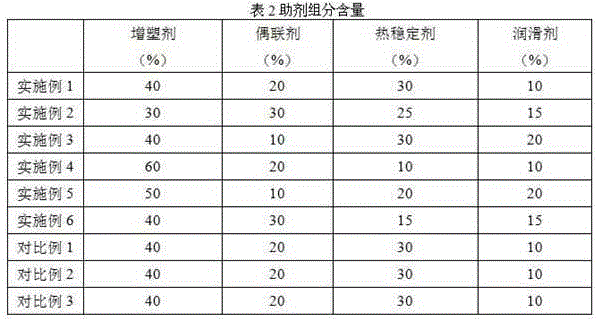

[0024] 1) Weigh an appropriate amount of plasticizer, coupling agent and ethanol into the high-speed mixer, mix in a closed manner and heat up to 70-110°C to reach an atomized state, then add ferrite magnetic powder and mix evenly, take it out after cooling The mixture is dried to remove ethanol to obtain pretreated magnetic powder. Among them, the plasticizer is dibutyl phthalate, the coupling agent is KH550, and the ferrite is barium ferrite. The contents are shown in Table 1 and Table 2. The ethanol content is twice the plasticizer content.

[0025] 2) Weigh an appropriate amount of ethylene-propylene rubber, heat stabilizer and lubricant, mix them with the pretreated magnetic powder and put them into the mixer for 2 hours. Among them, the ethylene-propylene rubber is binary ethylene-propylene rubber, the heat stabilizer is calcium 2-ethylhexanoate, and the lubricant is zinc stearate. The contents are shown in Table 1 and Table 2.

[0026] 3) Pulverize the kneaded mixture...

Embodiment 2

[0030] 1) Weigh an appropriate amount of plasticizer, coupling agent and ethanol into the high-speed mixer, mix in a closed manner and heat up to 70-110°C to reach an atomized state, then add ferrite magnetic powder and mix evenly, take it out after cooling The mixture is dried to remove ethanol to obtain pretreated magnetic powder. Among them, the plasticizer is dioctyl phthalate, the coupling agent is KH560, and the ferrite is strontium ferrite. The contents are shown in Table 1 and Table 2. The ethanol content is three times the plasticizer content.

[0031] 2) Weigh an appropriate amount of ethylene-propylene rubber, heat stabilizer and lubricant, mix them with pretreated magnetic powder and put them into the open mill for 0.5 hours. Among them, the ethylene-propylene rubber is binary ethylene-propylene rubber, the heat stabilizer is calcium 2-ethylhexanoate, and the lubricant is oleic acid. The contents are shown in Table 1 and Table 2.

[0032] 3) The kneaded mixture i...

Embodiment 3

[0036] 1) Weigh an appropriate amount of plasticizer, coupling agent and ethanol into the high-speed mixer, mix in a closed manner and heat up to 70-110°C to reach an atomized state, then add ferrite magnetic powder and mix evenly, take it out after cooling The mixture is dried to remove ethanol to obtain pretreated magnetic powder. Among them, the plasticizer is a mixture of dioctyl phthalate and diisooctyl phthalate in equal proportions, the coupling agent is KH792, and the ferrite is barium ferrite. The contents are shown in Table 1 and Table 2. . The ethanol content is twice the plasticizer content.

[0037]2) Weigh an appropriate amount of ethylene-propylene rubber, heat stabilizer and lubricant, mix them with pretreated magnetic powder and put them into the internal mixer for internal mixing for 1 hour. Among them, the ethylene-propylene rubber is EPDM rubber, the heat stabilizer is calcium stearate, and the lubricant is magnesium stearate. The contents are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com