Building material powder mixing machine

A technology for building material powder and mixers, which is applied in the direction of mixers, shaking/oscillating/vibrating mixers, mixer accessories, etc. It can solve the problems that building material powders cannot be fully stirred and mixed, and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

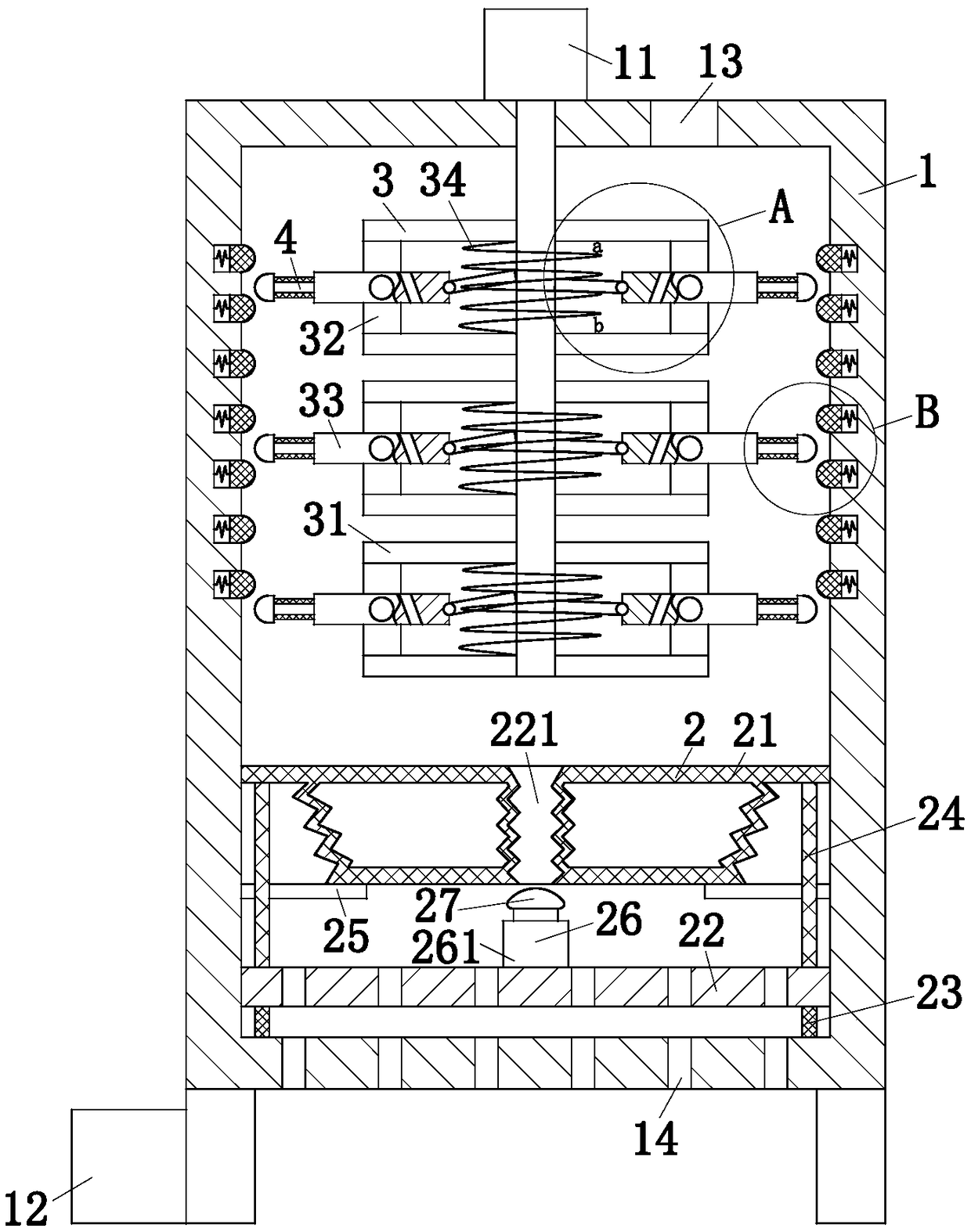

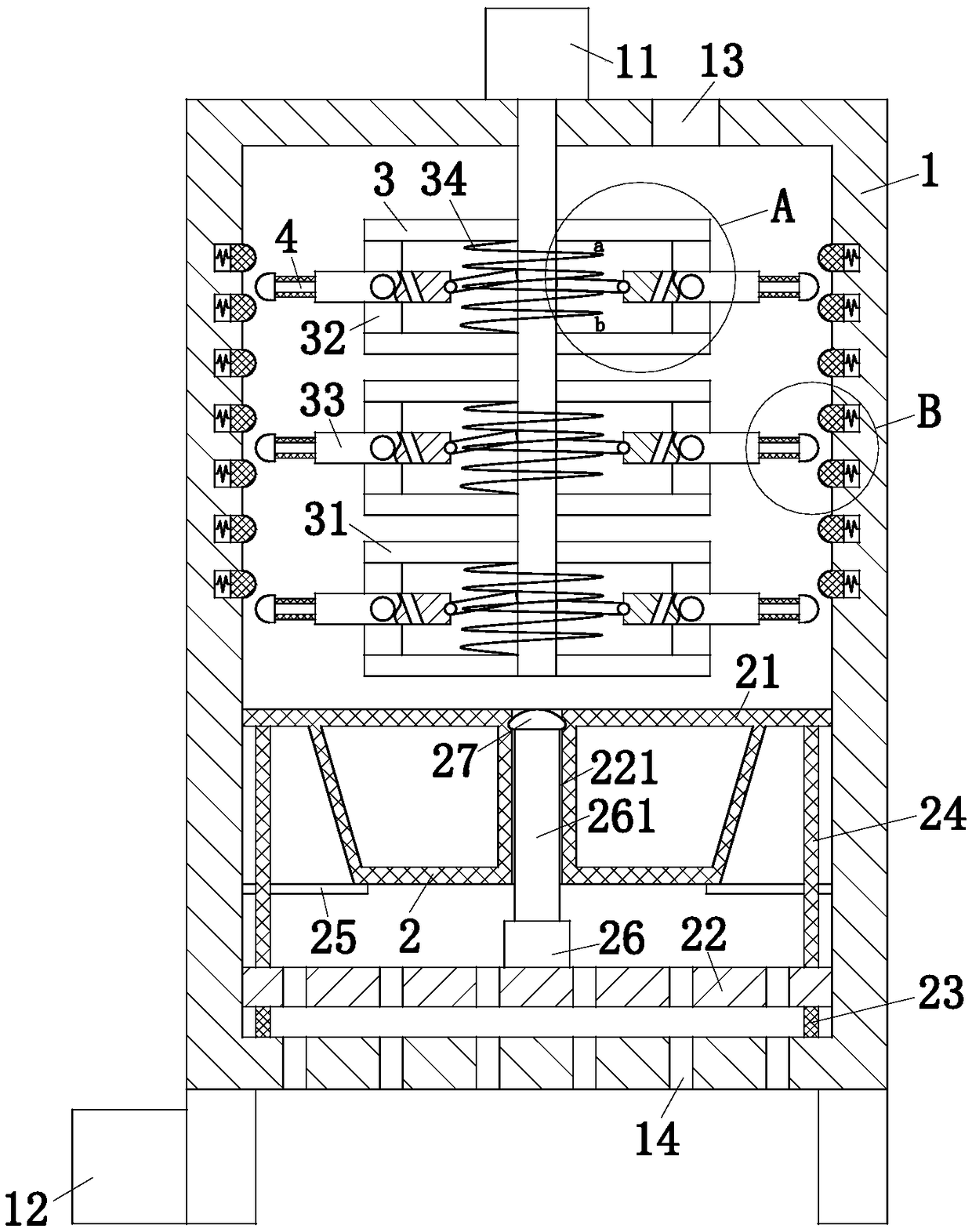

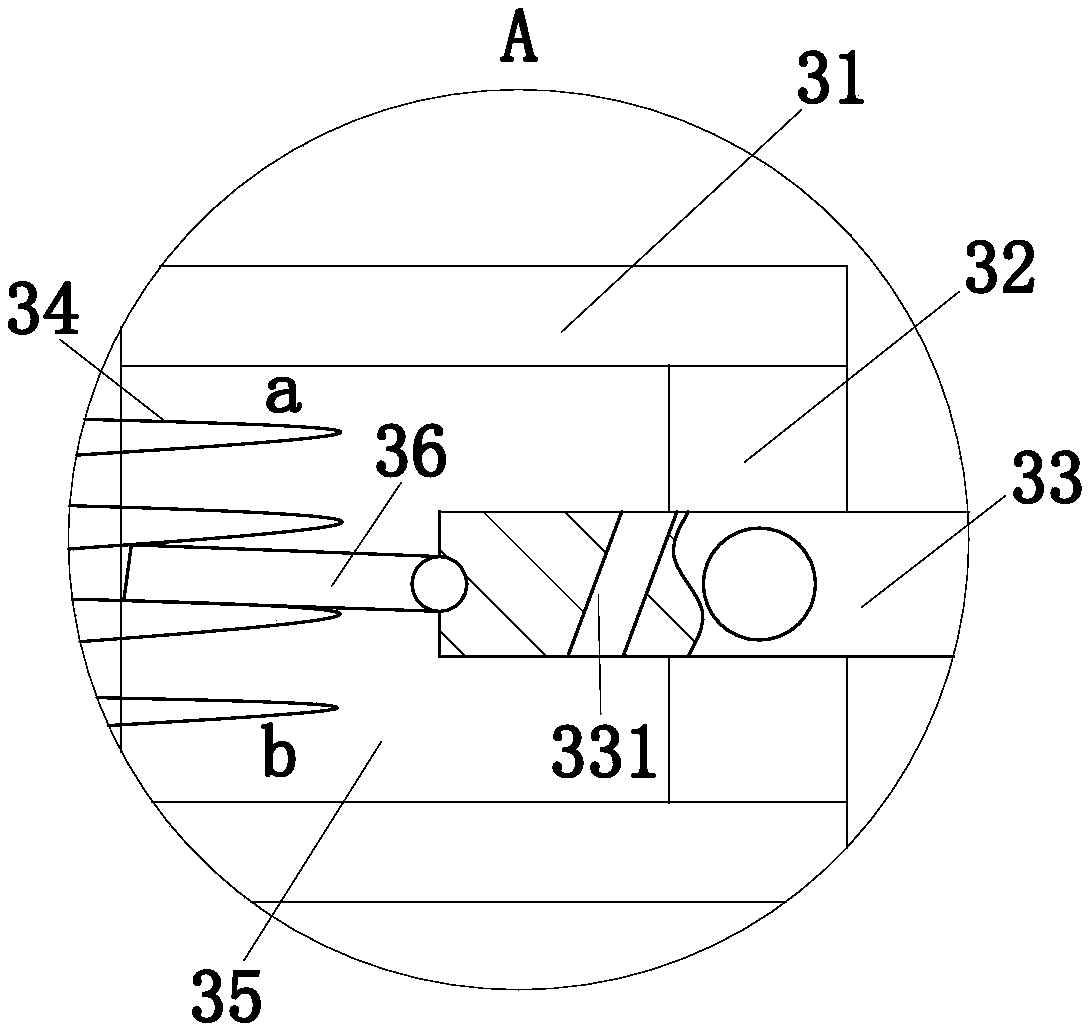

[0029] As an embodiment of the present invention, the stirring unit 3 includes a fixed plate 31, a fixed plate 32, a stirring plate 33 and a No. 1 spring 34; the number of the fixed plate 31 is two, and the fixed plate 31 is sleeved on the drive On the output shaft of the motor 11; the quantity of the fixed plate 32 is two, the fixed plate 32 is arranged symmetrically along the output shaft of the driving motor 11, and the two ends of the fixed plate 32 are fixedly connected on the fixed disk 31, the fixed plate 32, the two fixed disks No. 1 area 35 is formed between 31 and the output shaft of the drive motor 11; the No. 1 spring 34 is sleeved on the output shaft of the drive motor 11, and the No. 1 spring 34 is located between the two fixed discs 31; the middle part of the stirring plate 33 Hinged on the fixed plate 32, and the end of the stirring plate 33 is provided with a guide block 36; one end of the guide block 36 is hinged on the stirring plate 33, and the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com