Excessive asphalt cleaning equipment for petroleum asphalt road joint filling

A technology for petroleum asphalt and cleaning equipment, which is applied to roads, roads, road repair and other directions, and can solve the problems of poor cleaning effect of cleaning equipment, complex structure, and difficult equipment operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

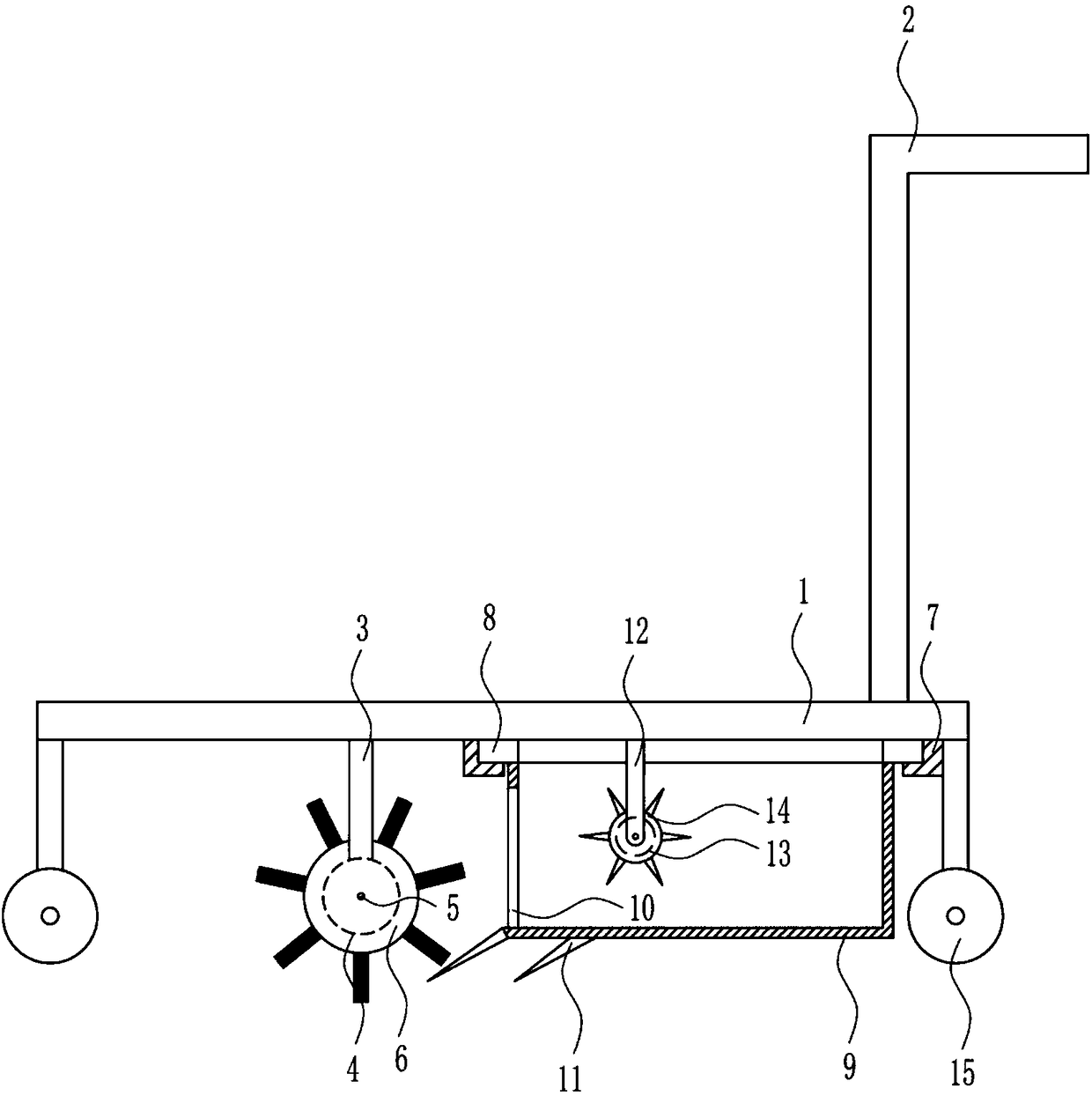

Embodiment 1

[0020] A kind of excess asphalt cleaning equipment for petroleum asphalt road joint filling, such as Figure 1-2 As shown, it includes a base plate 1, a push handle 2, a first pole 3, a first motor 4, a first rotating shaft 5, a roller brush 6, an L-shaped card plate 7, a first fixing plate 8, a collection box 9, and a guide plate 11. The second support rod 12, the second motor 13, the toggle wheel 14 and the travel wheel 15, the push handle 2 is provided on the right side of the top of the base plate 1, the travel wheel 15 is provided at the bottom of the base plate 1, and the middle of the bottom of the base plate 1 is to the left The position is vertically connected with the first pole 3, the bottom of the first pole 3 is installed with the first motor 4, the output shaft of the first motor 4 is connected with the first rotating shaft 5, and the first rotating shaft 5 is provided with a roller Brush 6, the middle and the right side of the bottom of the base plate 1 are symm...

Embodiment 2

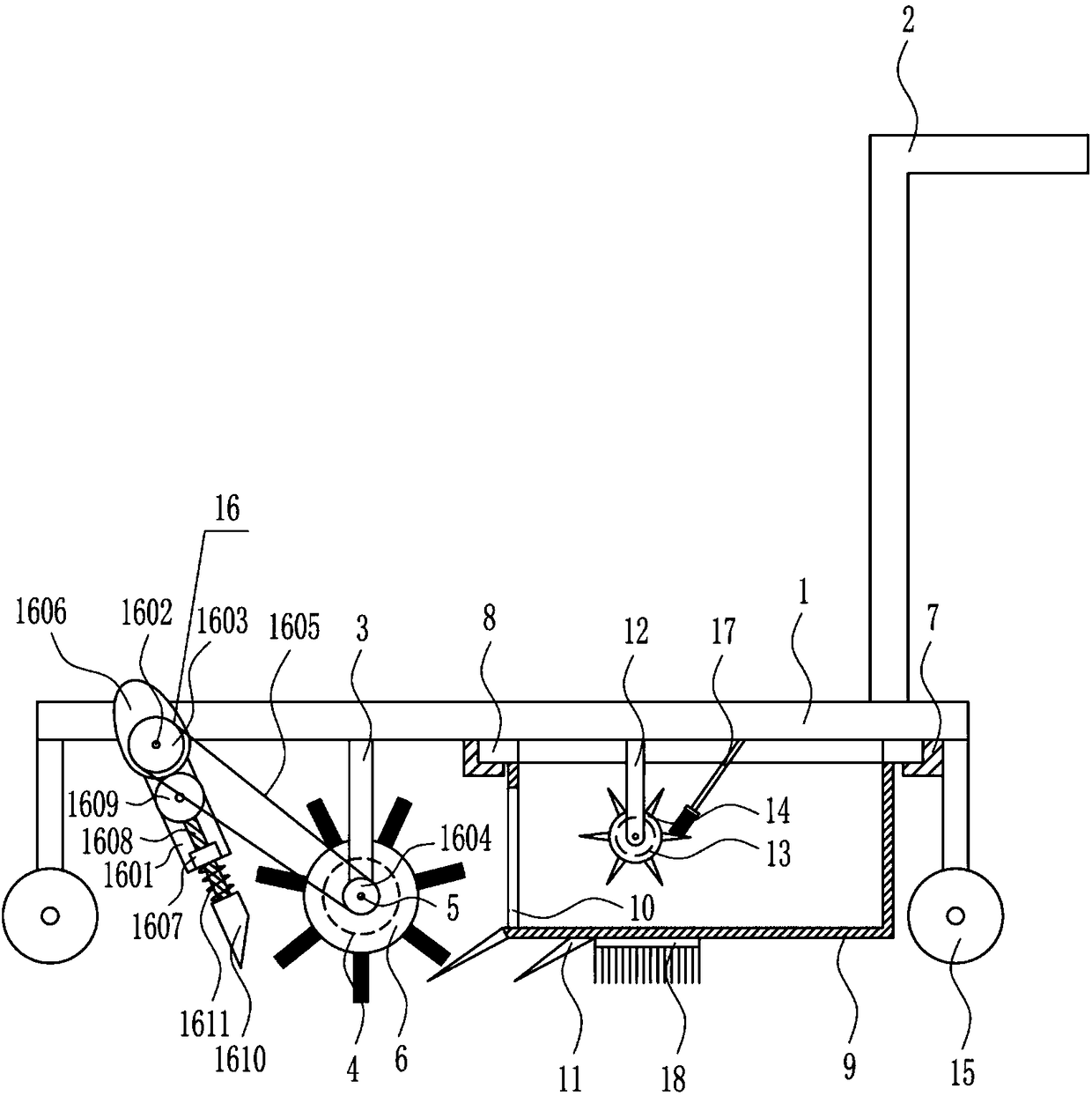

[0022] A kind of excess asphalt cleaning equipment for petroleum asphalt road joint filling, such as Figure 1-2 As shown, it includes a base plate 1, a push handle 2, a first pole 3, a first motor 4, a first rotating shaft 5, a roller brush 6, an L-shaped card plate 7, a first fixing plate 8, a collection box 9, and a guide plate 11. The second support rod 12, the second motor 13, the toggle wheel 14 and the travel wheel 15, the push handle 2 is provided on the right side of the top of the base plate 1, the travel wheel 15 is provided at the bottom of the base plate 1, and the middle of the bottom of the base plate 1 is to the left The position is vertically connected with the first pole 3, the bottom of the first pole 3 is installed with the first motor 4, the output shaft of the first motor 4 is connected with the first rotating shaft 5, and the first rotating shaft 5 is provided with a roller Brush 6, the middle and the right side of the bottom of the base plate 1 are symm...

Embodiment 3

[0025] A kind of excess asphalt cleaning equipment for petroleum asphalt road joint filling, such as Figure 1-2As shown, it includes a base plate 1, a push handle 2, a first pole 3, a first motor 4, a first rotating shaft 5, a roller brush 6, an L-shaped card plate 7, a first fixing plate 8, a collection box 9, and a guide plate 11. The second support rod 12, the second motor 13, the toggle wheel 14 and the travel wheel 15, the push handle 2 is provided on the right side of the top of the base plate 1, the travel wheel 15 is provided at the bottom of the base plate 1, and the middle of the bottom of the base plate 1 is to the left The position is vertically connected with the first pole 3, the bottom of the first pole 3 is installed with the first motor 4, the output shaft of the first motor 4 is connected with the first rotating shaft 5, and the first rotating shaft 5 is provided with a roller Brush 6, the middle and the right side of the bottom of the base plate 1 are symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com