Automatic high-efficiency cleaning device for workpiece machining

A cleaning device and automation technology, which is applied in the field of machinery, can solve the problems of low cleaning efficiency and troublesome operation, and achieve the effects of improving cleaning effect, good environmental protection, and enhancing cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

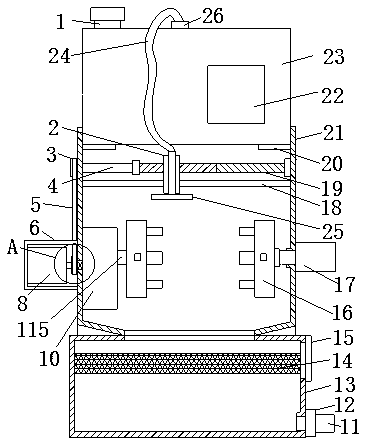

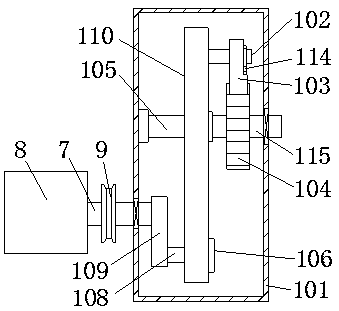

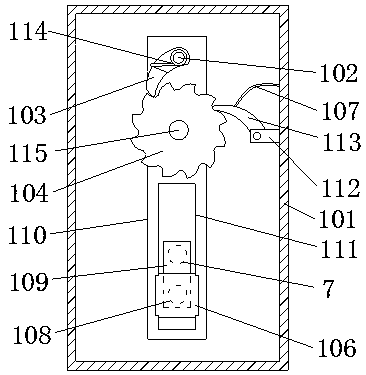

[0030] Embodiment: the workpiece is placed in the three jaws of the three-jaw centering chuck 16 on one side of the drive mechanism 10, and then one end of the workpiece is clamped and fixed by the three jaws (the three-jaw centering chuck 16 is an existing There are mature products often used in mechanical processing, whose structure and clamping and fixing methods can be clearly understood by those skilled in the art, and will not be described in detail here without affecting the clear description of the structure of the present invention), and then start The cylinder 17, the cylinder 17 works, can drive the three-jaw centering chuck 16 on the power output rod of the cylinder 17 to approach the workpiece, and then use the three claws on the three-jaw centering chuck 16 to clamp the other end of the workpiece Fix, then start the motor 8, the motor 8 works to drive the second transmission shaft 7 to rotate, the rotating second transmission shaft 7 drives the first transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com