Mold energy-saving cleaning equipment

A technology for cleaning equipment and molds, which is applied to lighting and heating equipment, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as poor mold cleaning effects, eliminate sewage treatment steps, improve cleaning effects, and airflow impact powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

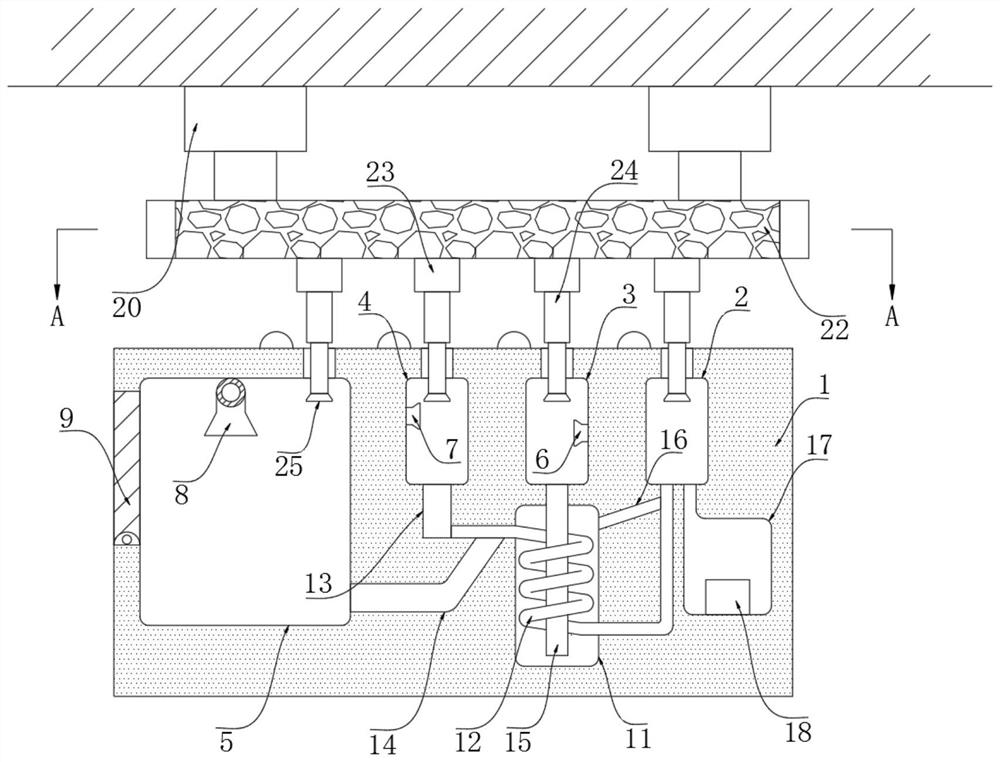

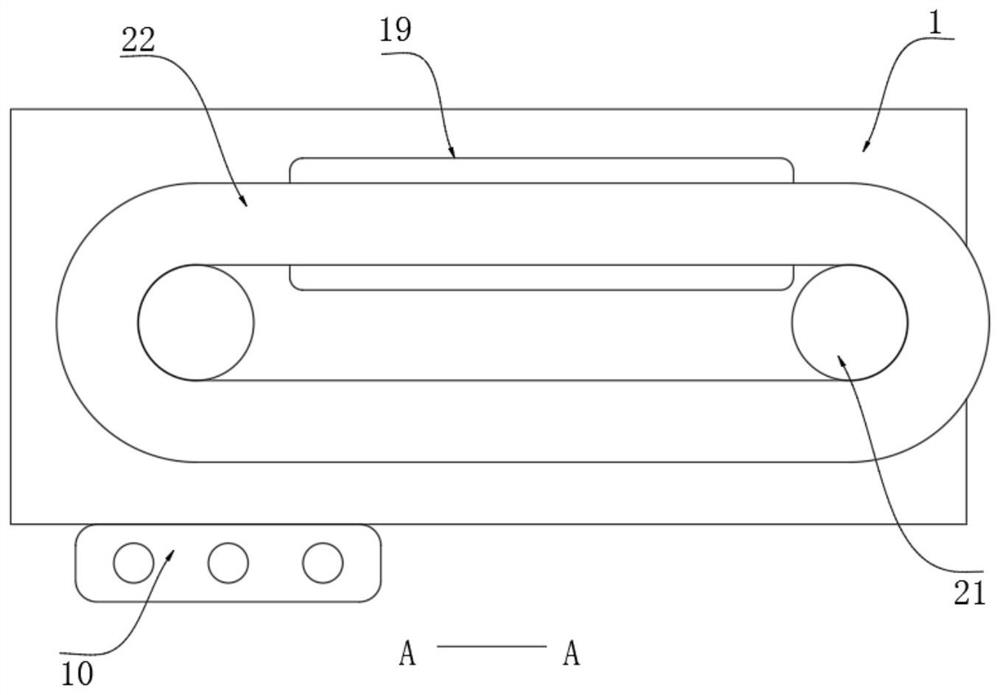

[0018] refer to Figure 1-2 , a mold energy-saving cleaning equipment, including a platform 1 and a conveying mechanism arranged on the top of the platform 1, the upper end of the platform 1 is provided with a preheating tank 2, a cleaning tank 3, a drying tank 4 and a cold storage tank 5, the cleaning tank 3. The inside of the drying tank 4 and the cold storage tank 5 are respectively fixed with a water spray head 6, a hot air nozzle 7 and a cold air nozzle 8, and the side wall of the cold storage tank 5 is rotatably connected with a take-out plate 9, and a recovery chamber is provided inside the platform 1 11. There is no waste heat utilization mechanism in the recovery chamber 11. A water storage tank 17 is provided at the bottom of the preheating tank 2. A high-pressure pump 18 connected to the water spray head 6 is provided inside the water storage tank 17. The side wall of the stand 1 is fixed There is a vortex tube 10, the hot and cold air outlets of the vortex tube 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com