Patents

Literature

99results about How to "Eliminate processing steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

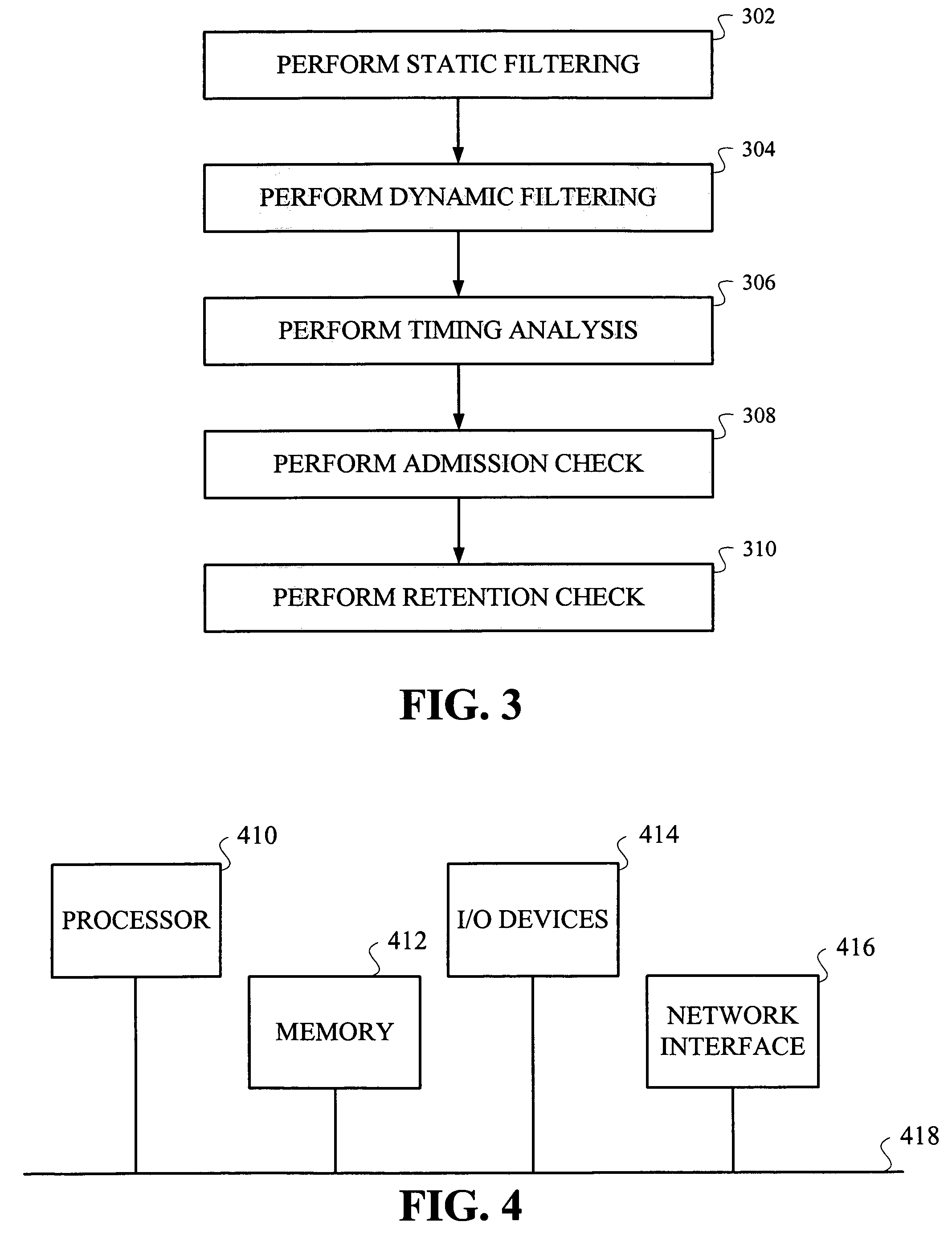

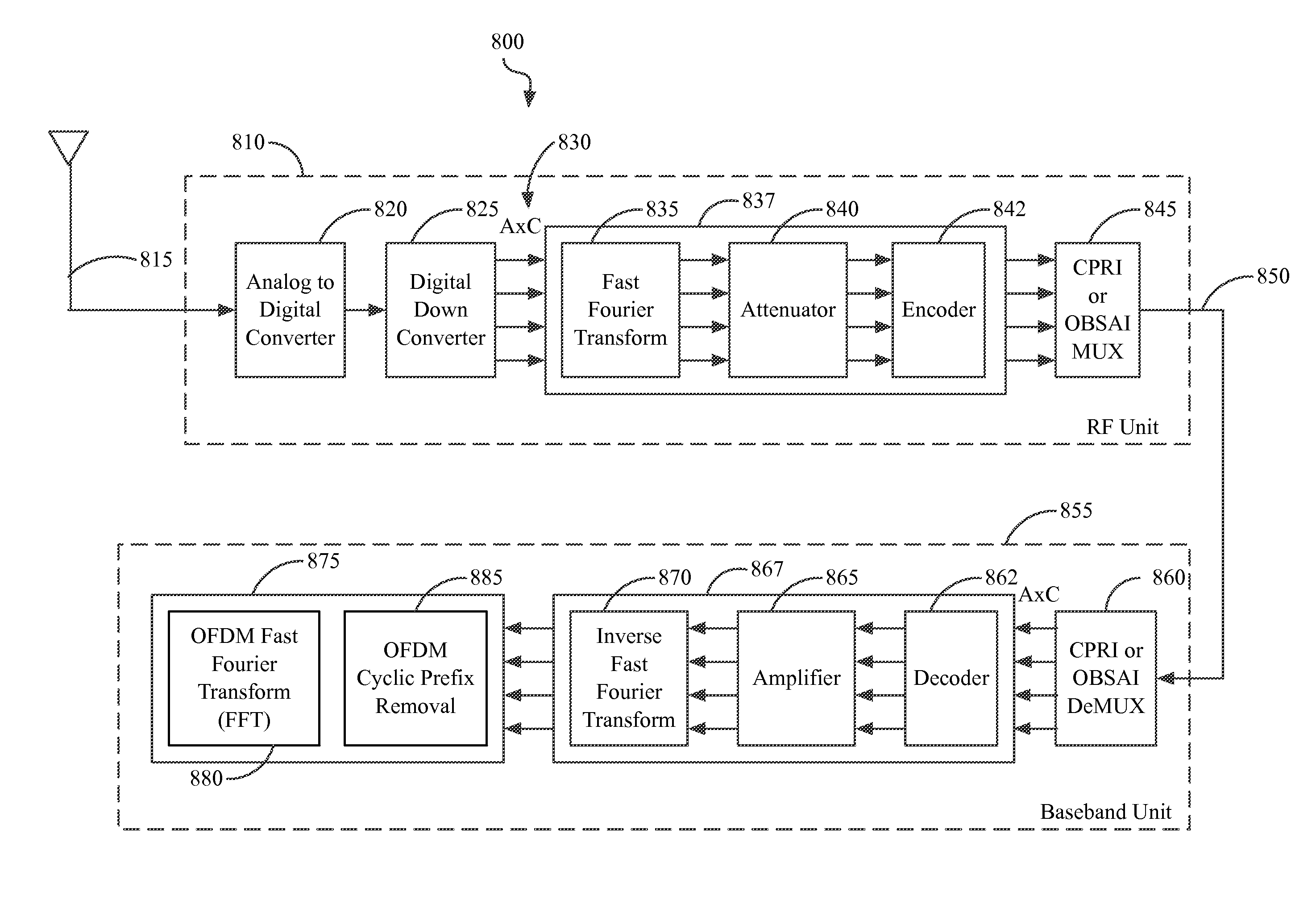

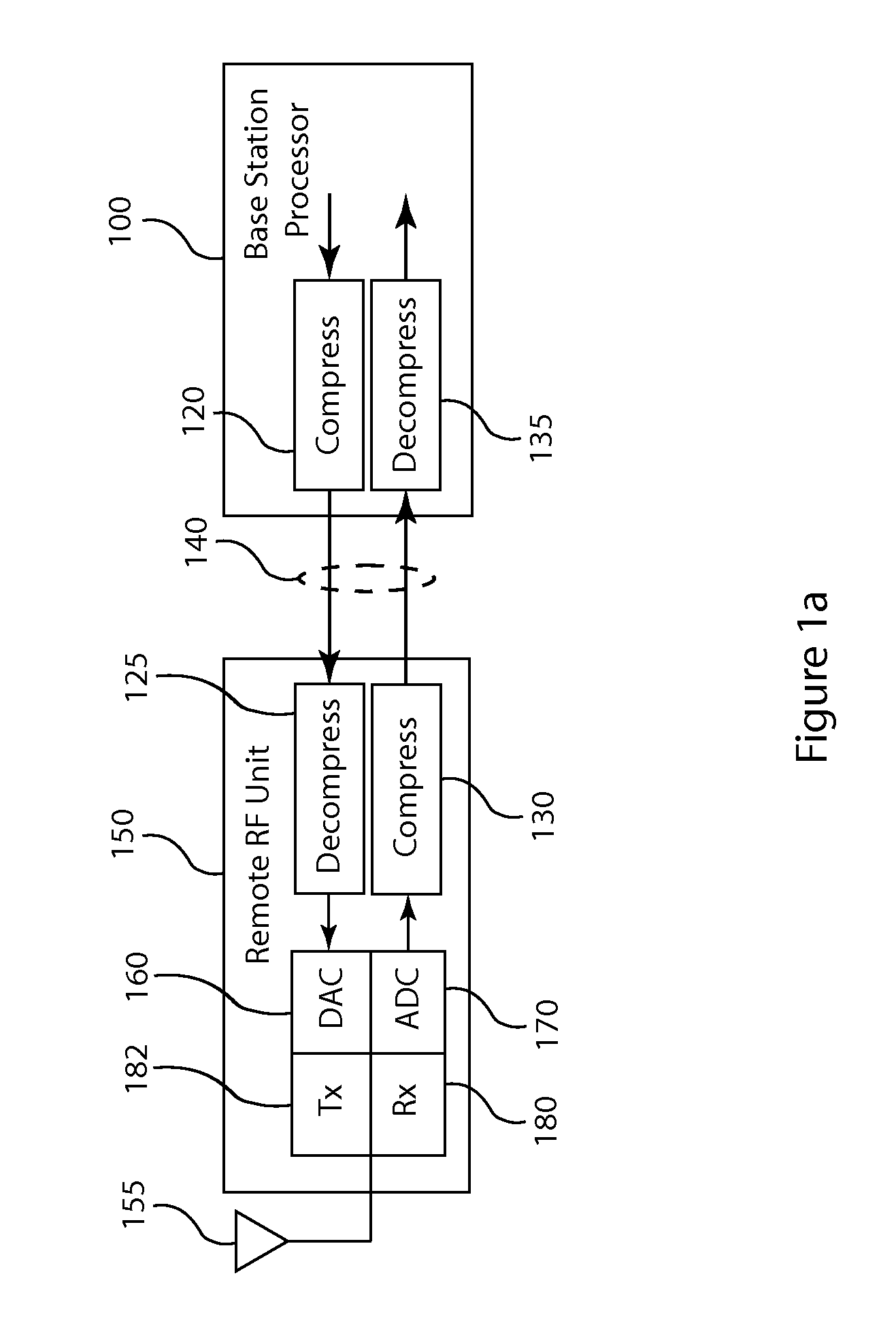

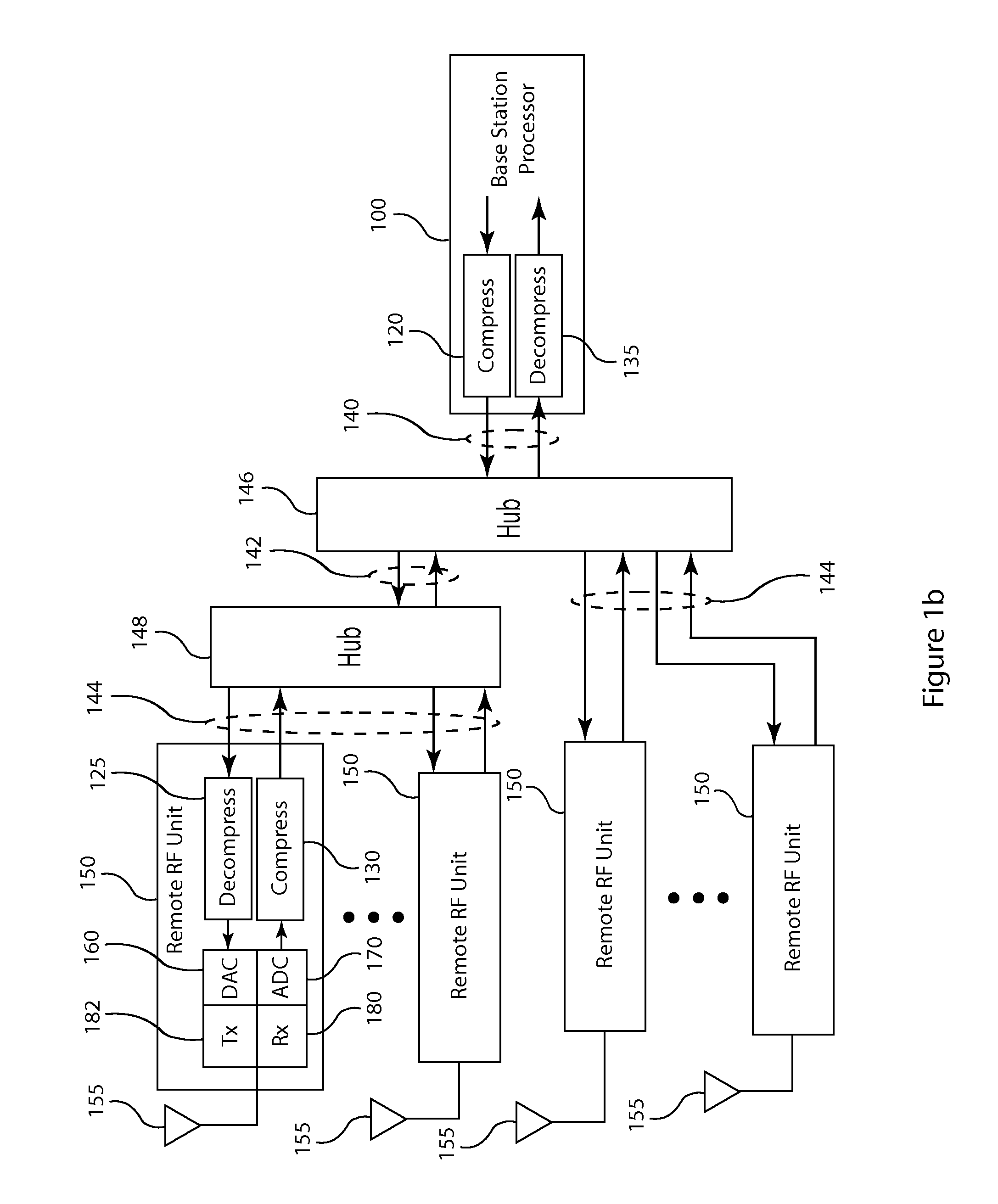

OFDM signal processing in a base transceiver system

ActiveUS20120250740A1Removing unnecessary processing stepSimple designModulated-carrier systemsCode conversionTransceiverDigital down conversion

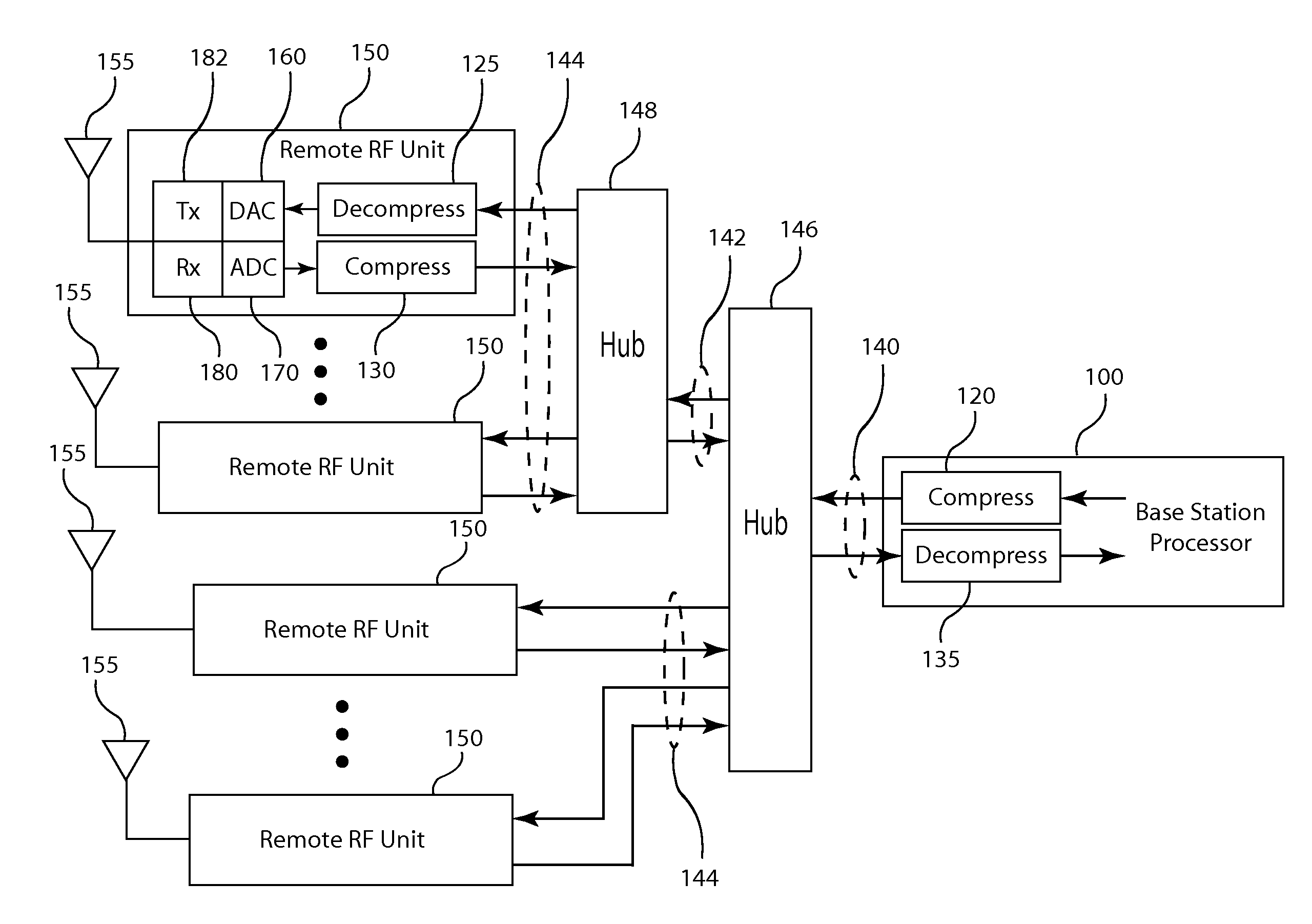

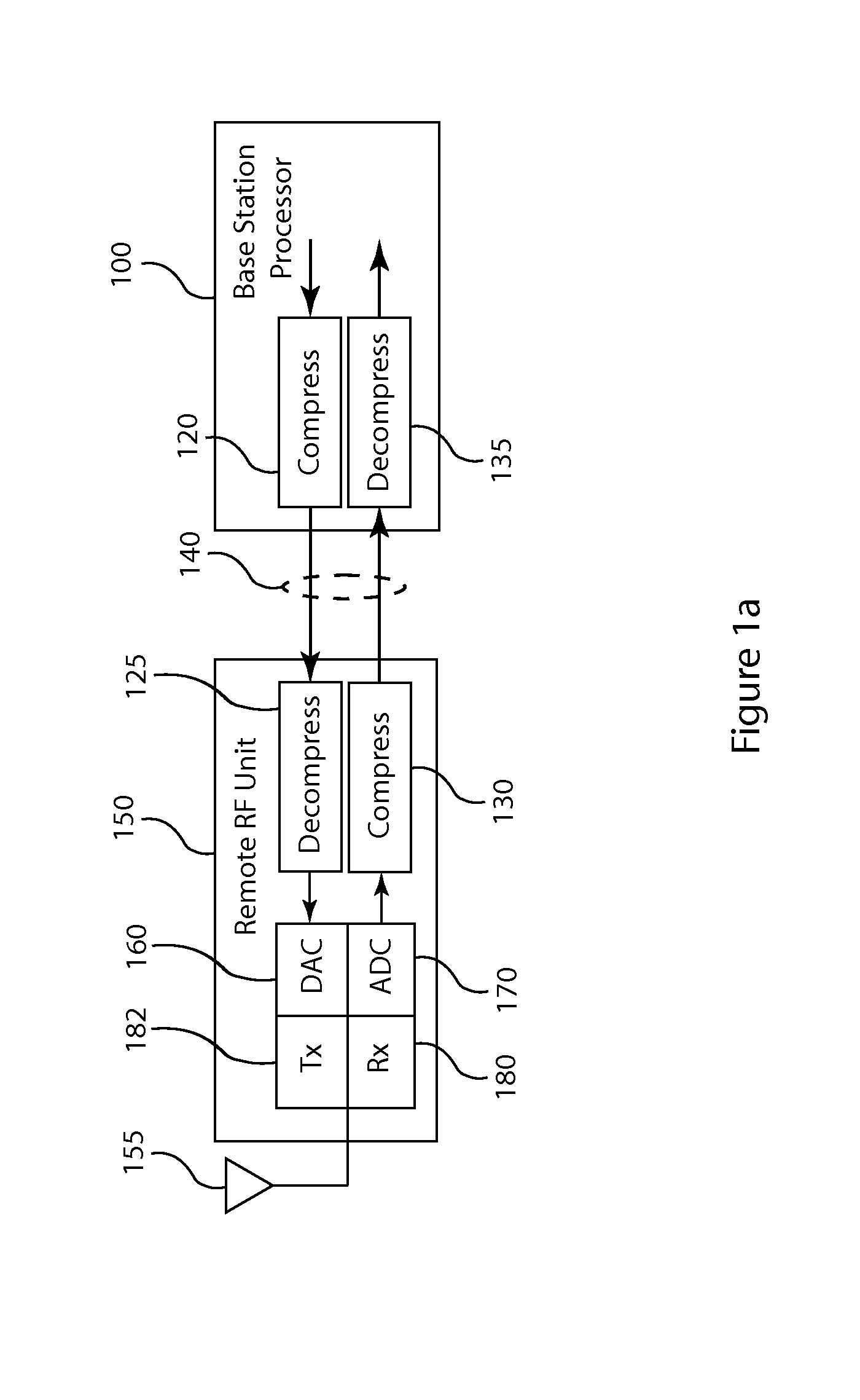

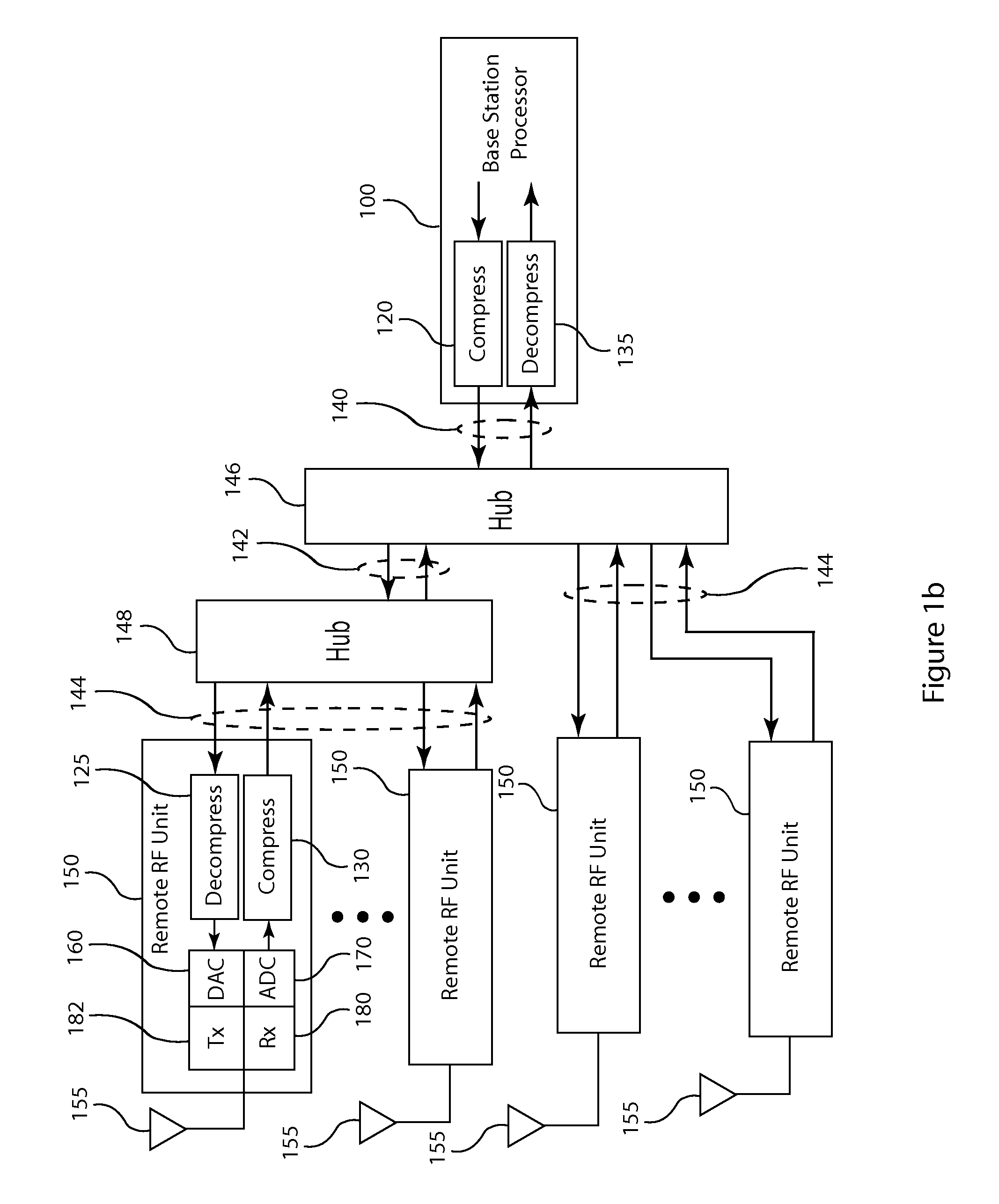

A method and apparatus provides OFDM signal compression for transfer over serial data links in a base transceiver system (BTS) of a wireless communication network. For the uplink, an RF unit of the BTS applies OFDM cyclic prefix removal and OFDM frequency transformation of the baseband signal samples followed by frequency domain compression of the baseband signal samples, resulting from analog to digital conversion of received analog signals followed by digital downconversion, forming compressed coefficients. After transfer over the serial data link, the baseband processor applies frequency domain decompression to the compressed coefficients prior to further signal processing. For the downlink, the RF unit performs frequency domain decompression of the compressed coefficients and applies OFDM inverse frequency transformation of the decompressed coefficients and OFDM cyclic prefix insertion prior to digital upconversion and digital to analog conversion, generating the analog signal for transmission over the antenna.

Owner:INTEGRATED DEVICE TECH INC

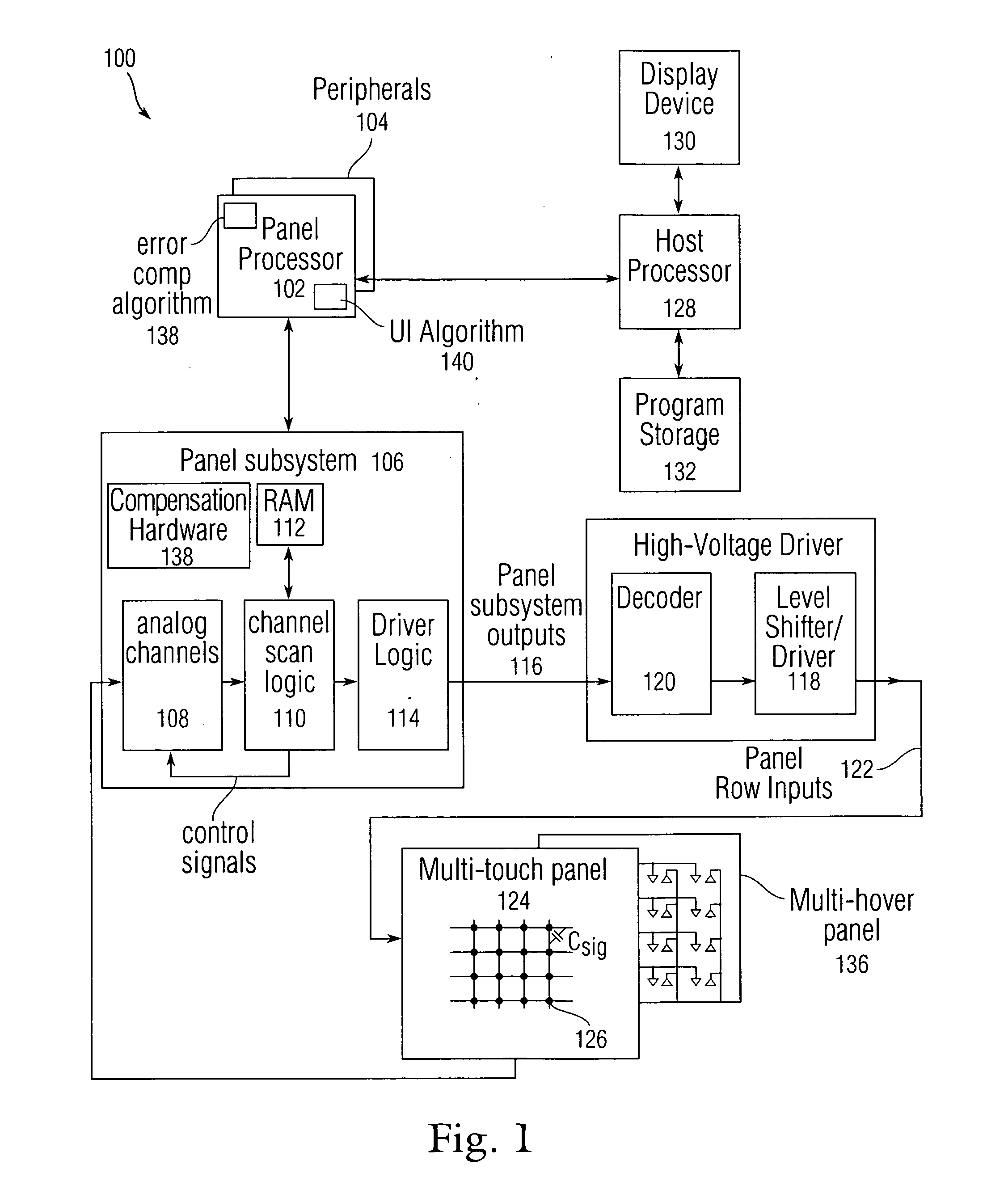

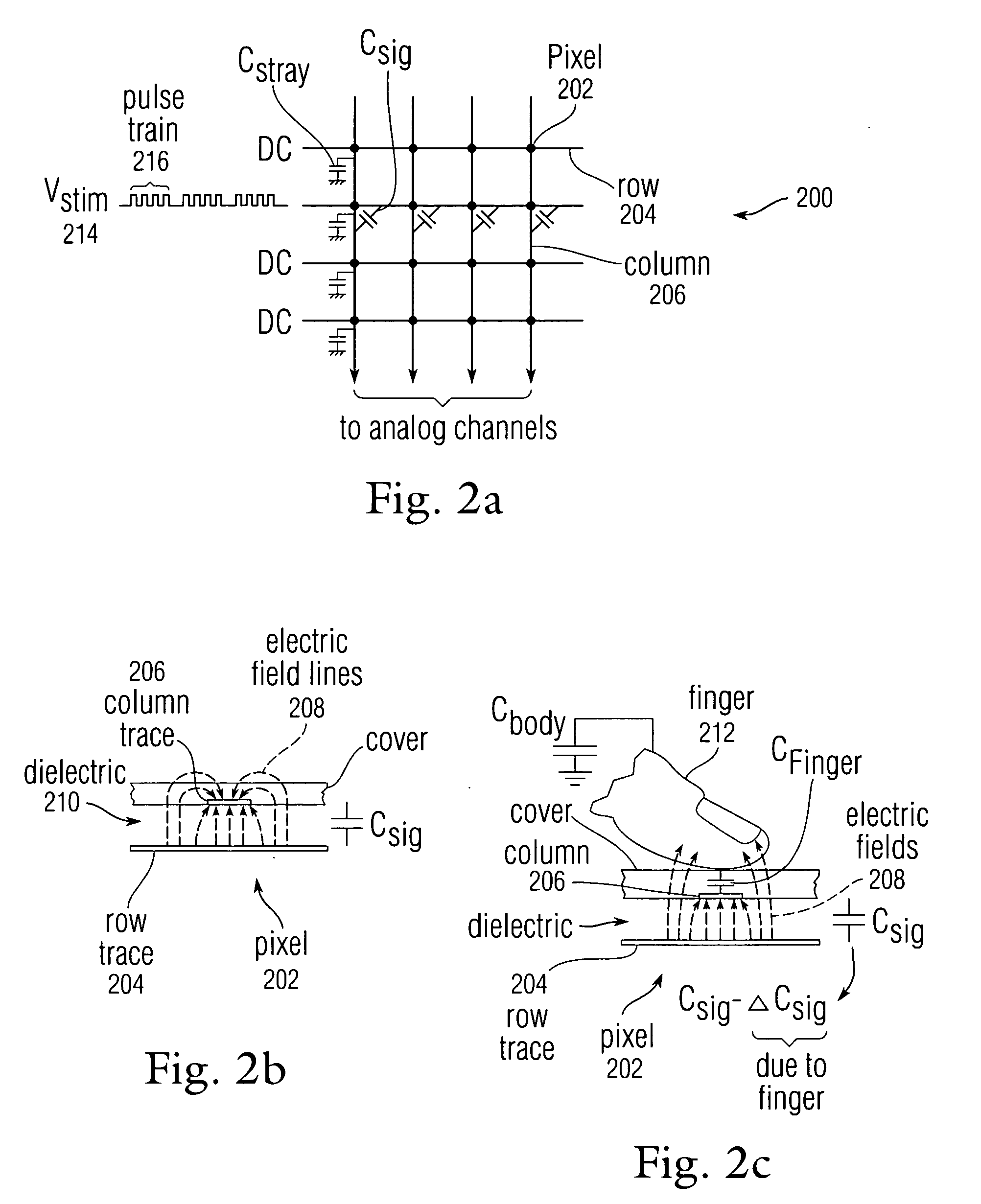

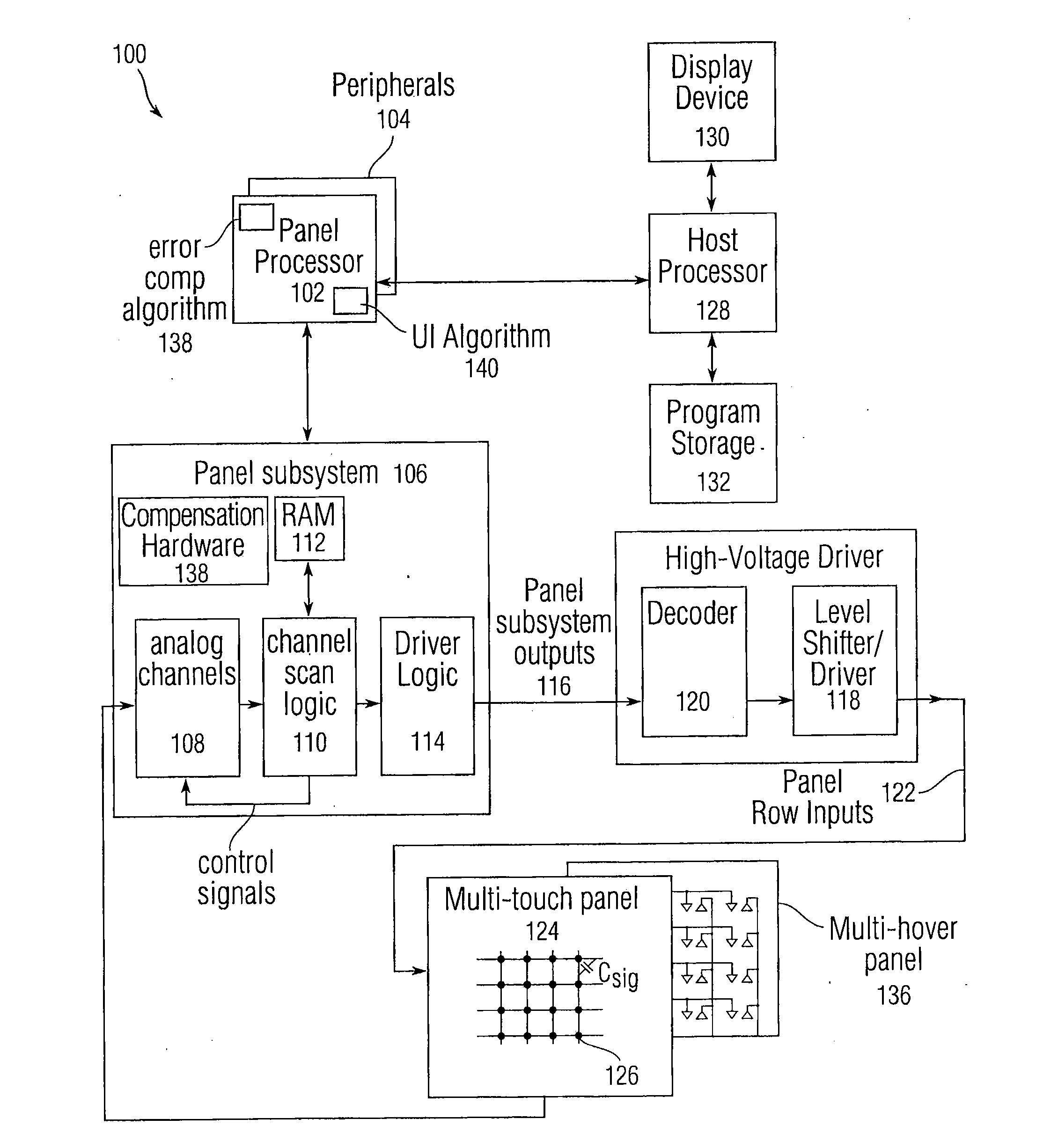

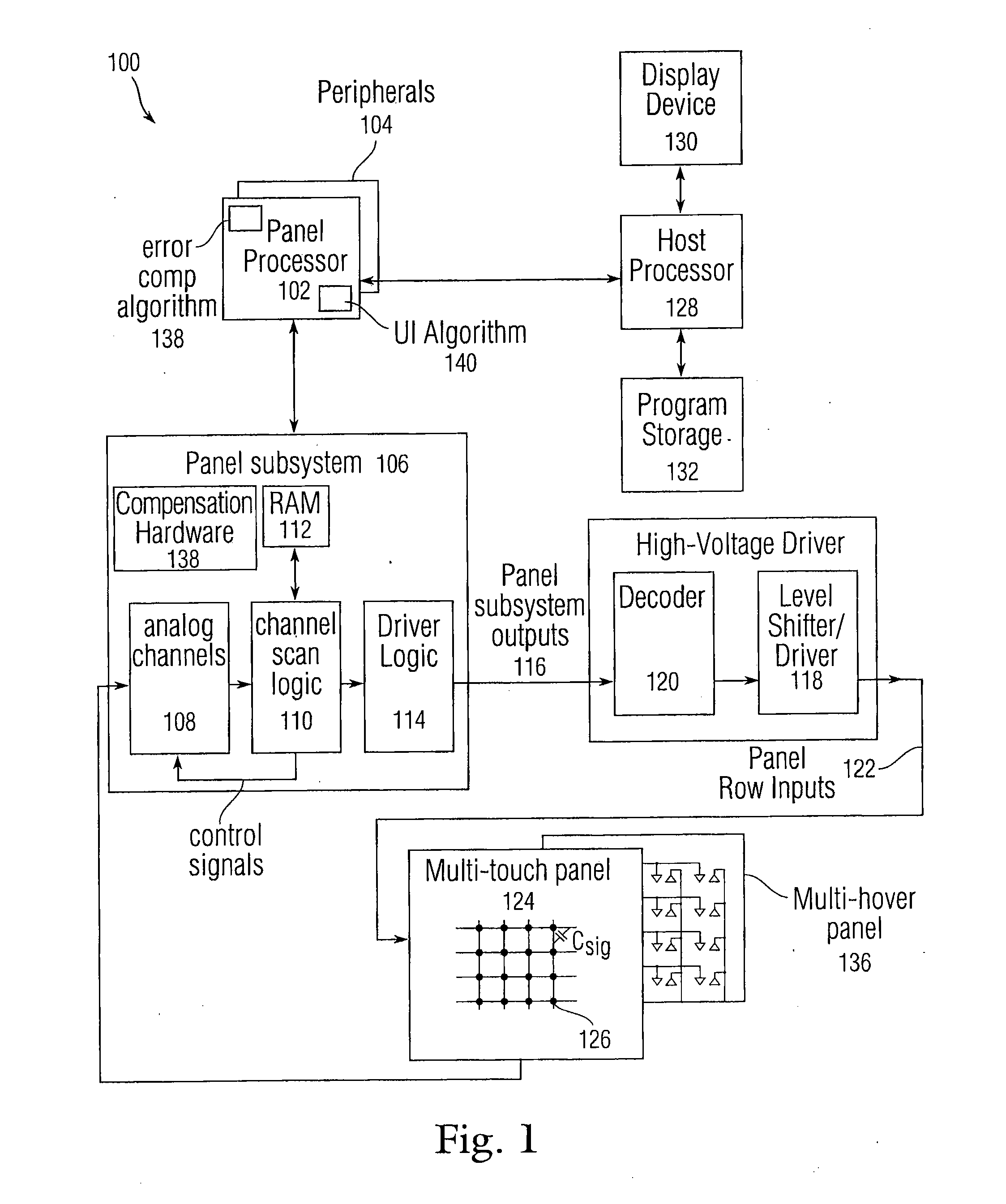

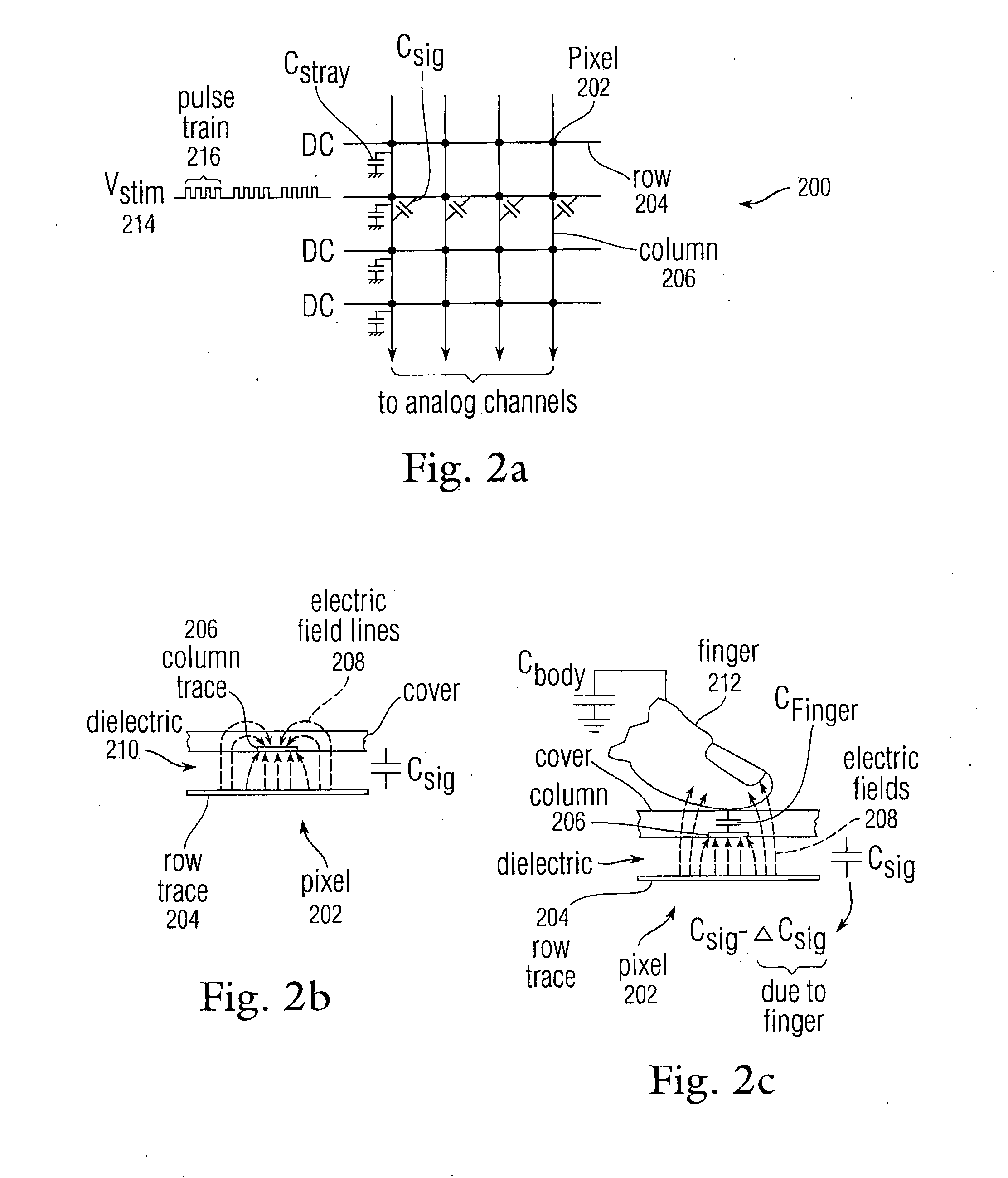

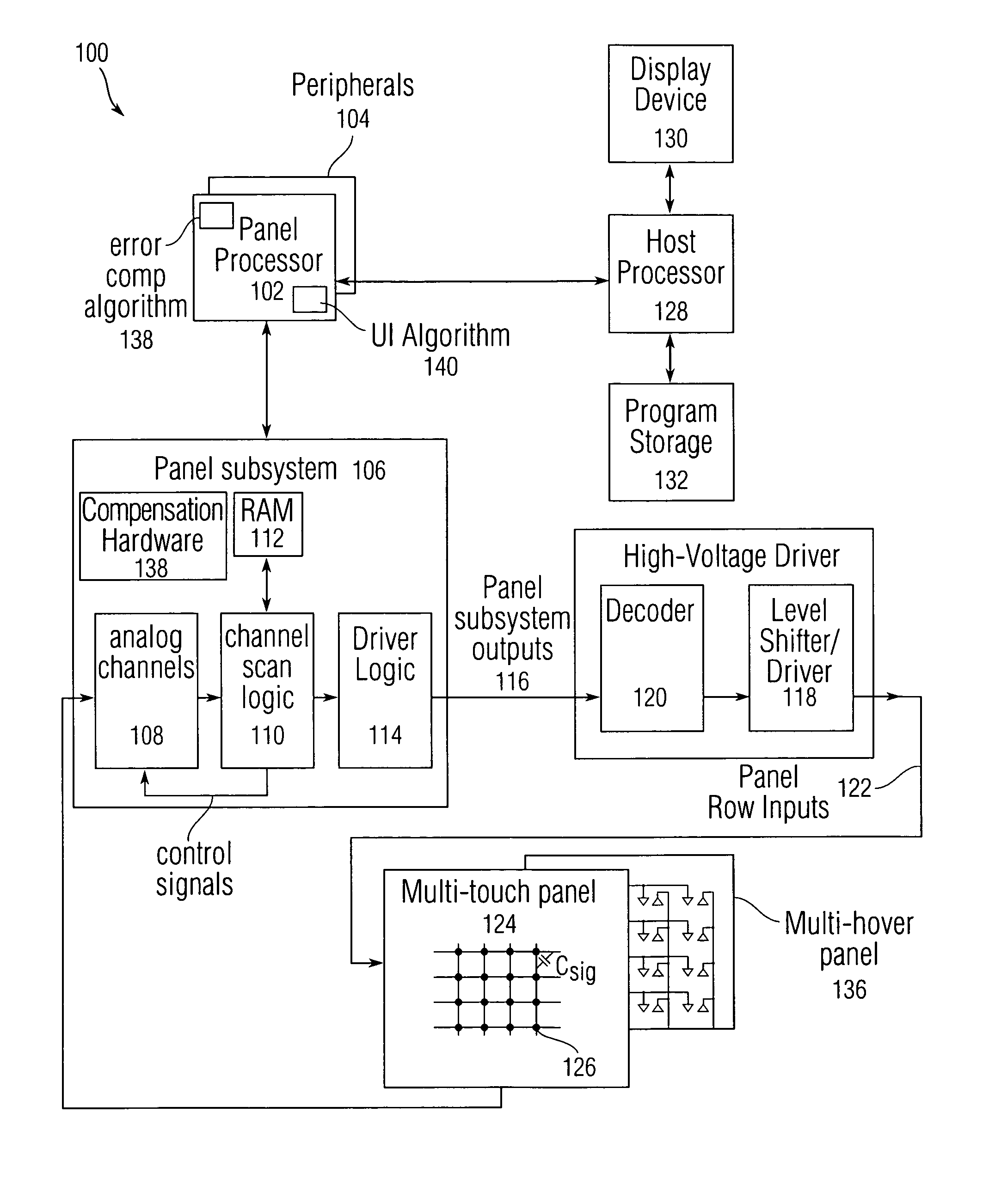

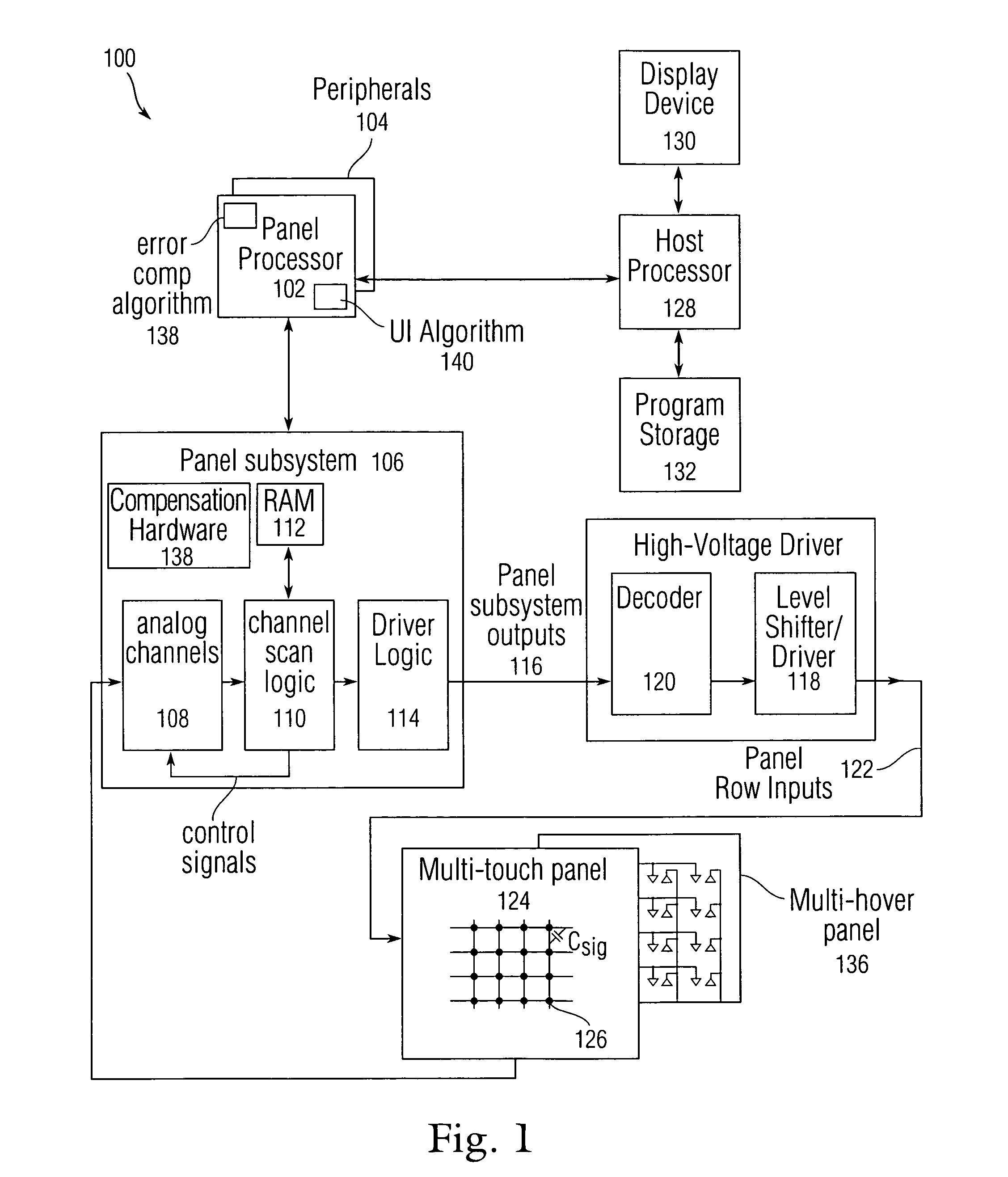

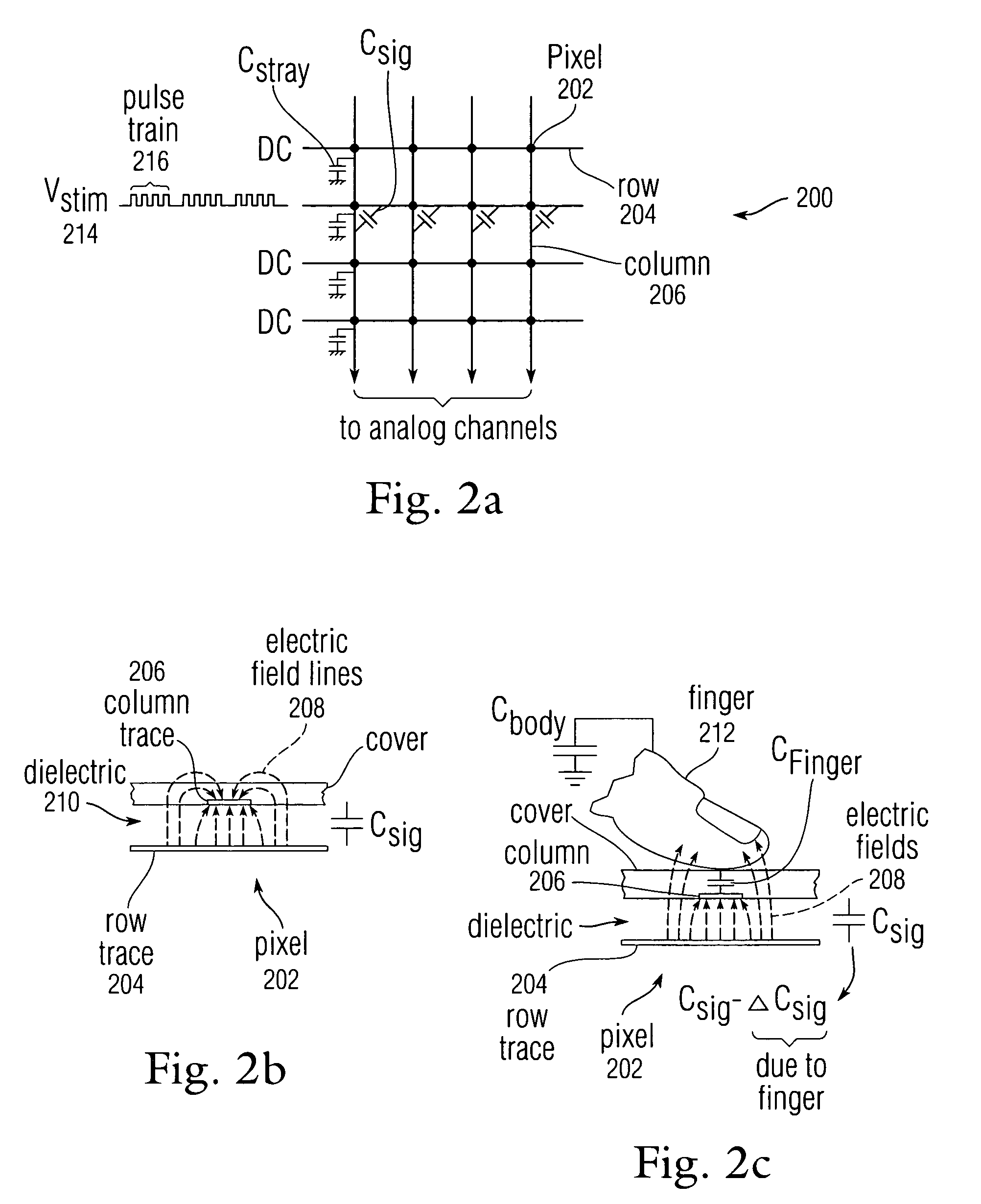

Full scale calibration measurement for multi-touch surfaces

ActiveUS20080158176A1Easy to eliminateLow costInput/output processes for data processingFull scaleNon-volatile memory

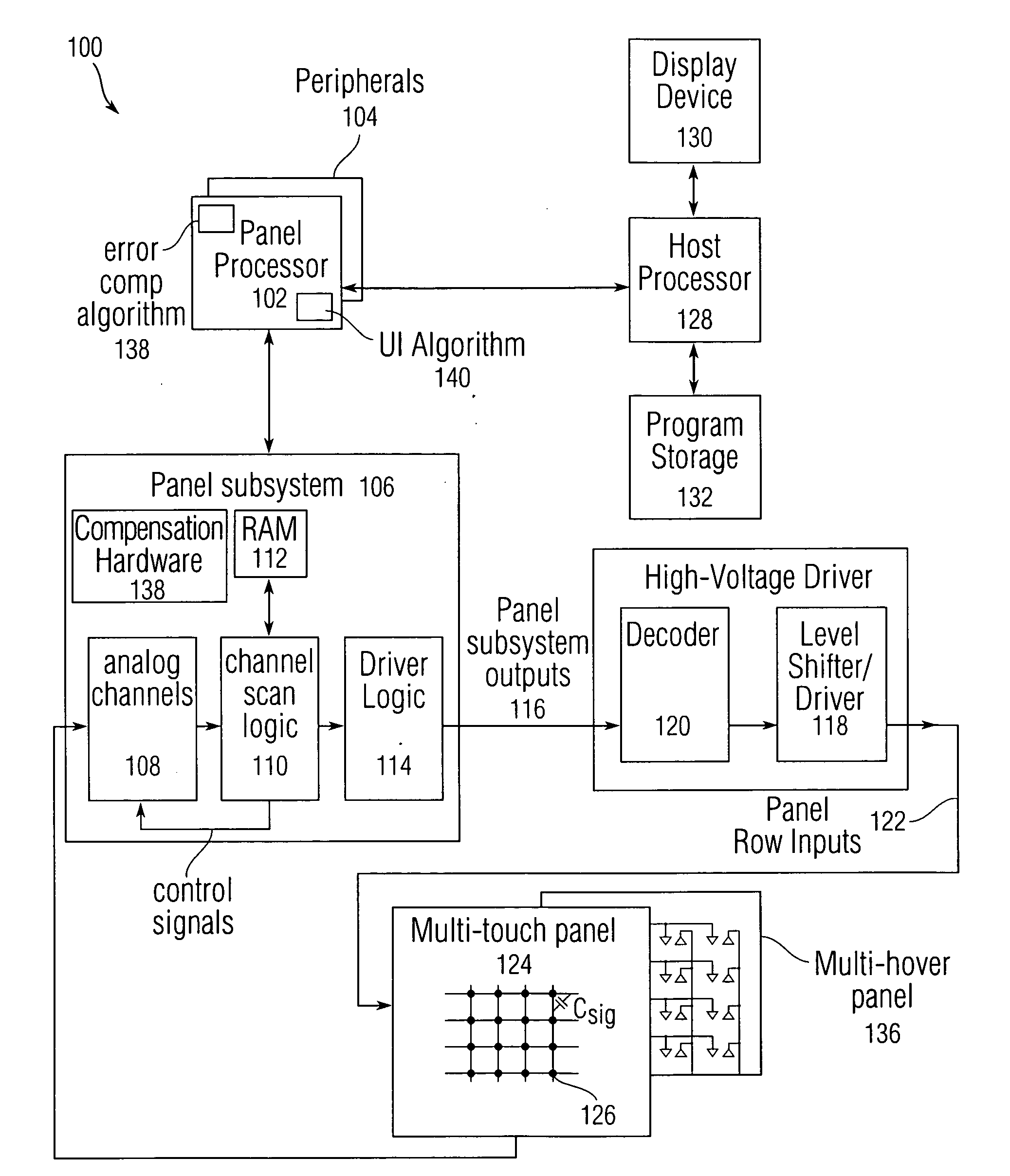

Normalization of regions of a sensor panel capable of detecting multi-touch events, or a sensor panel capable of detecting multi-hover events, is disclosed to enable each sensor in the sensor panel to trigger a virtual button in a similar manner, given the same amount of touch or hover. Each sensor produces an output value proportional to the level or amount of touch or hover. However, due to processing, manufacturing and physical design differences, the sensor output values can vary from region to region or panel to panel for a given amount of touch or hover. To normalize the sensor output values across regions, gain and offset information can be obtained in advance, stored in nonvolatile memory, and later used to normalize the sensor output values so that all regions in the sensor panel can trigger virtual buttons similarly, providing a uniform “response function” at any location on the sensor panel.

Owner:APPLE INC

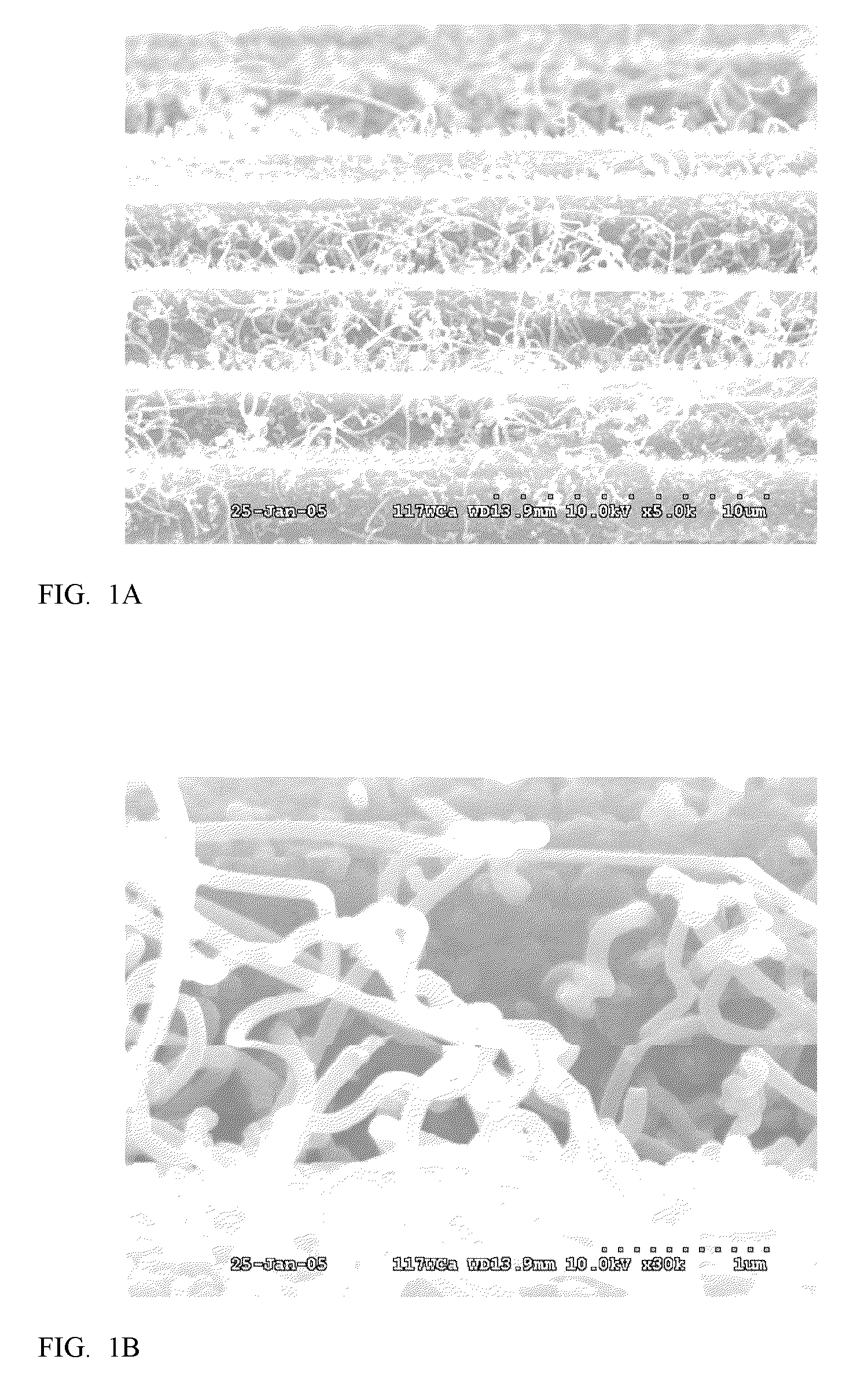

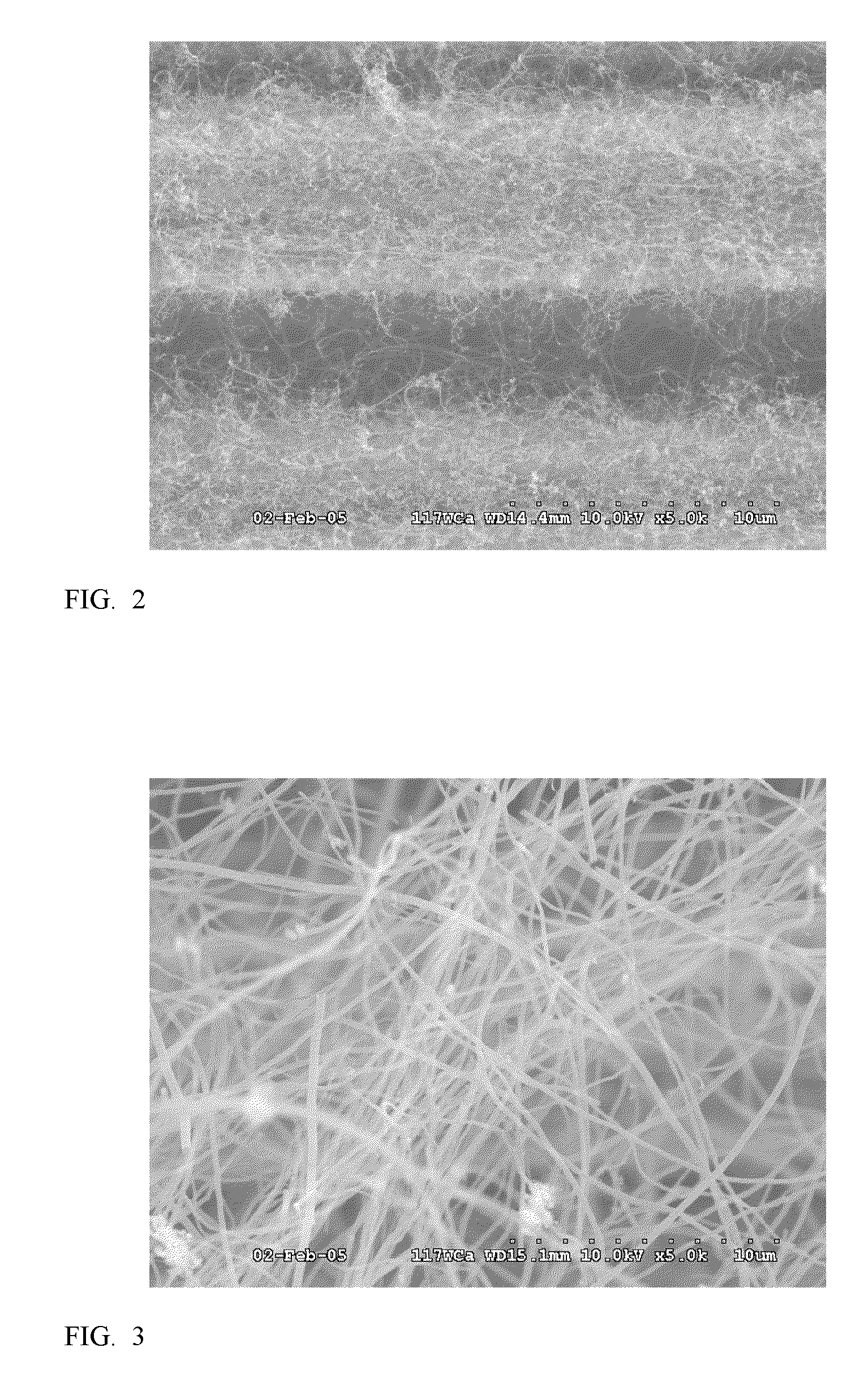

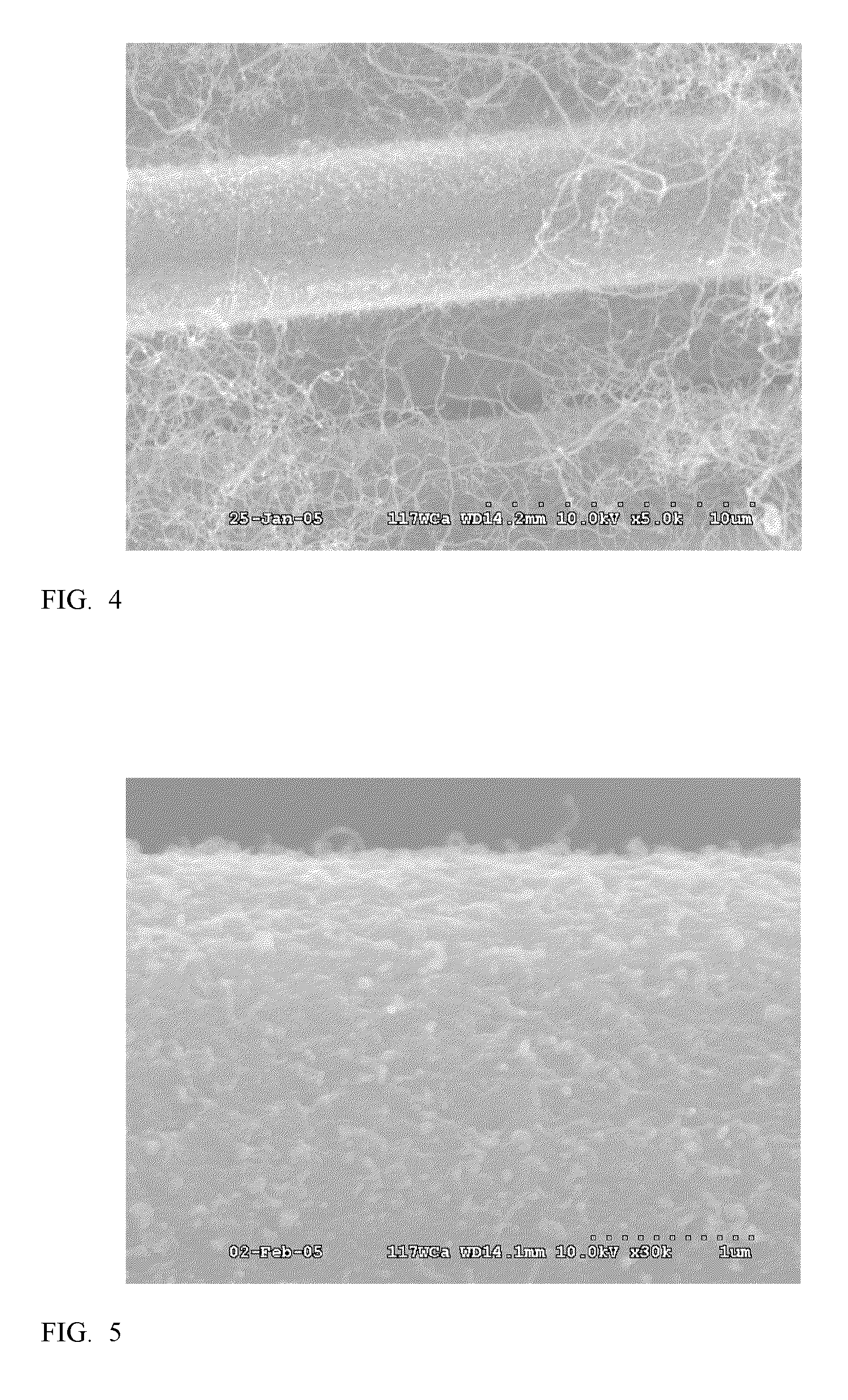

Continuous process for the production of carbon nanofiber reinforced continuous fiber preforms and composites made therefrom

ActiveUS20090220409A1Limited utilityLow yieldMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

This invention provides a continuous process for the growth of vapor grown carbon fiber (VGCNT) reinforced continuous fiber preforms for the manufacture of articles with useful mechanical, electrical, and thermal characteristics. Continuous fiber preforms are treated with a catalyst or catalyst precursor and processed to yield VGCNT produced in situ resulting in a highly entangled mass of VGCNT infused with the continuous fiber preform. The continuous process disclosed herein provides denser and more uniform carbon nanotubes and provides the opportunity to fine-tune the variables both within an individual preform and between different preforms depending on the characteristics of the carbon nanotubes desired. The resulting continuous fiber preforms are essentially endless and are high in volume fraction of VGCNT and exhibit high surface area useful for many applications. The invention also provides for composites made from the preforms.

Owner:PERFORMANCE POLYMER SOLUTIONS

Full scale calibration measurement for multi-touch surfaces

ActiveUS20110037735A1Easy to eliminateLow costInput/output processes for data processingEngineeringFull scale

Normalization of regions of a sensor panel capable of detecting multi-touch events, or a sensor panel capable of detecting multi-hover events, is disclosed to enable each sensor in the sensor panel to trigger a virtual button in a similar manner, given the same amount of touch or hover. Each sensor produces an output value proportional to the level or amount of touch or hover. However, due to processing, manufacturing and physical design differences, the sensor output values can vary from region to region or panel to panel for a given amount of touch or hover. To normalize the sensor output values across regions, gain and offset information can be obtained in advance, stored in nonvolatile memory, and later used to normalize the sensor output values so that all regions in the sensor panel can trigger virtual buttons similarly, providing a uniform “response function” at any location on the sensor panel.

Owner:APPLE INC

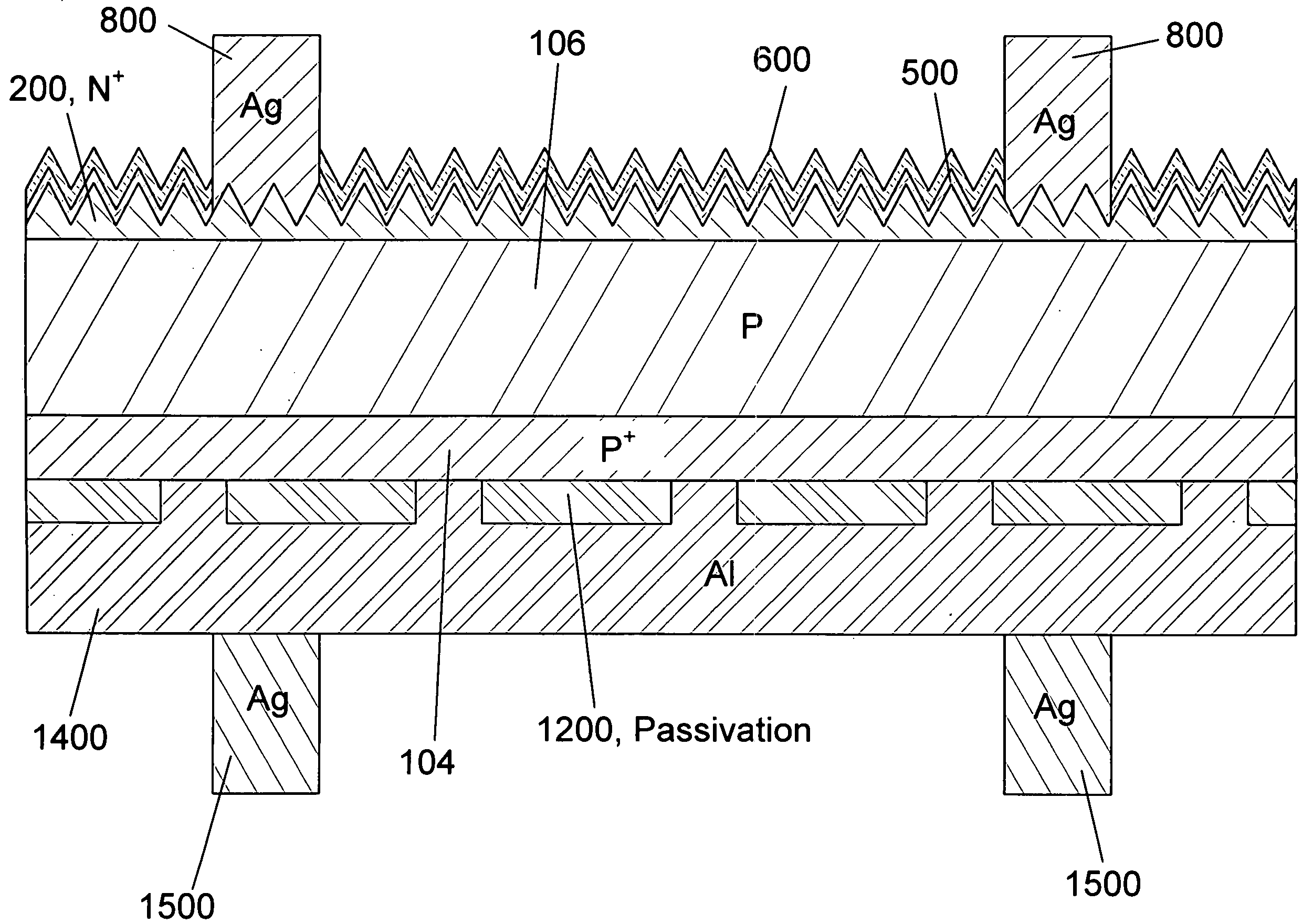

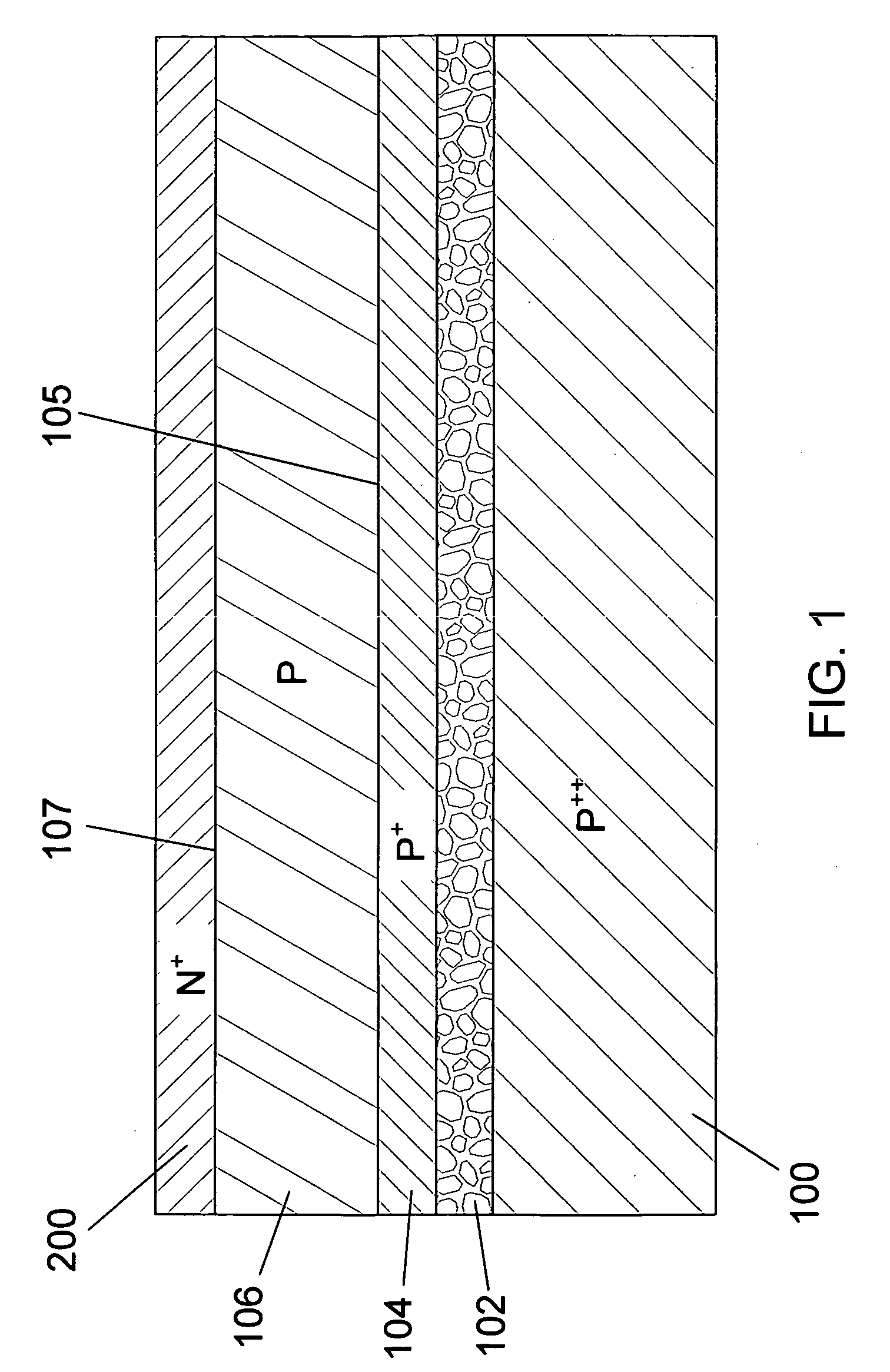

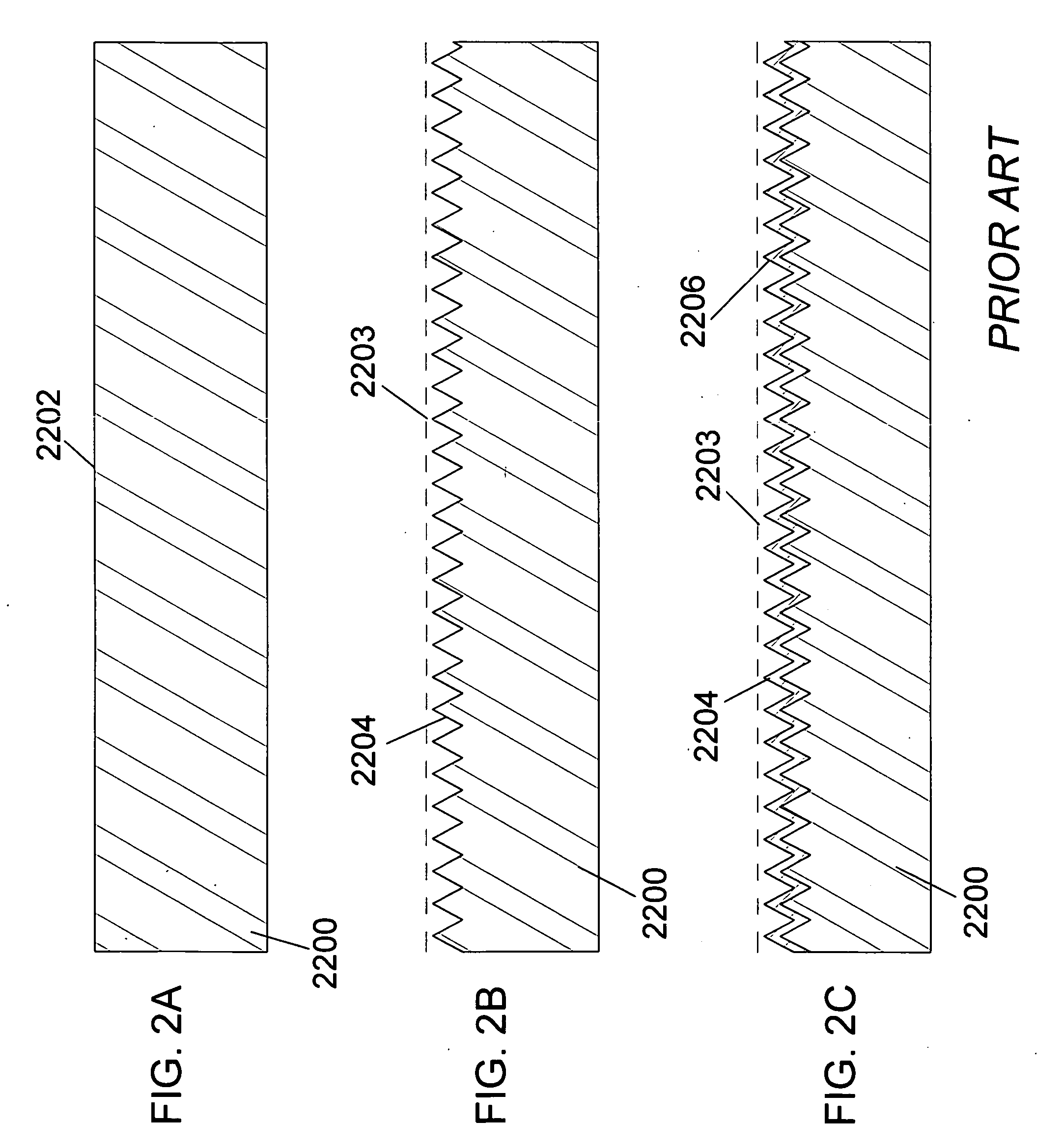

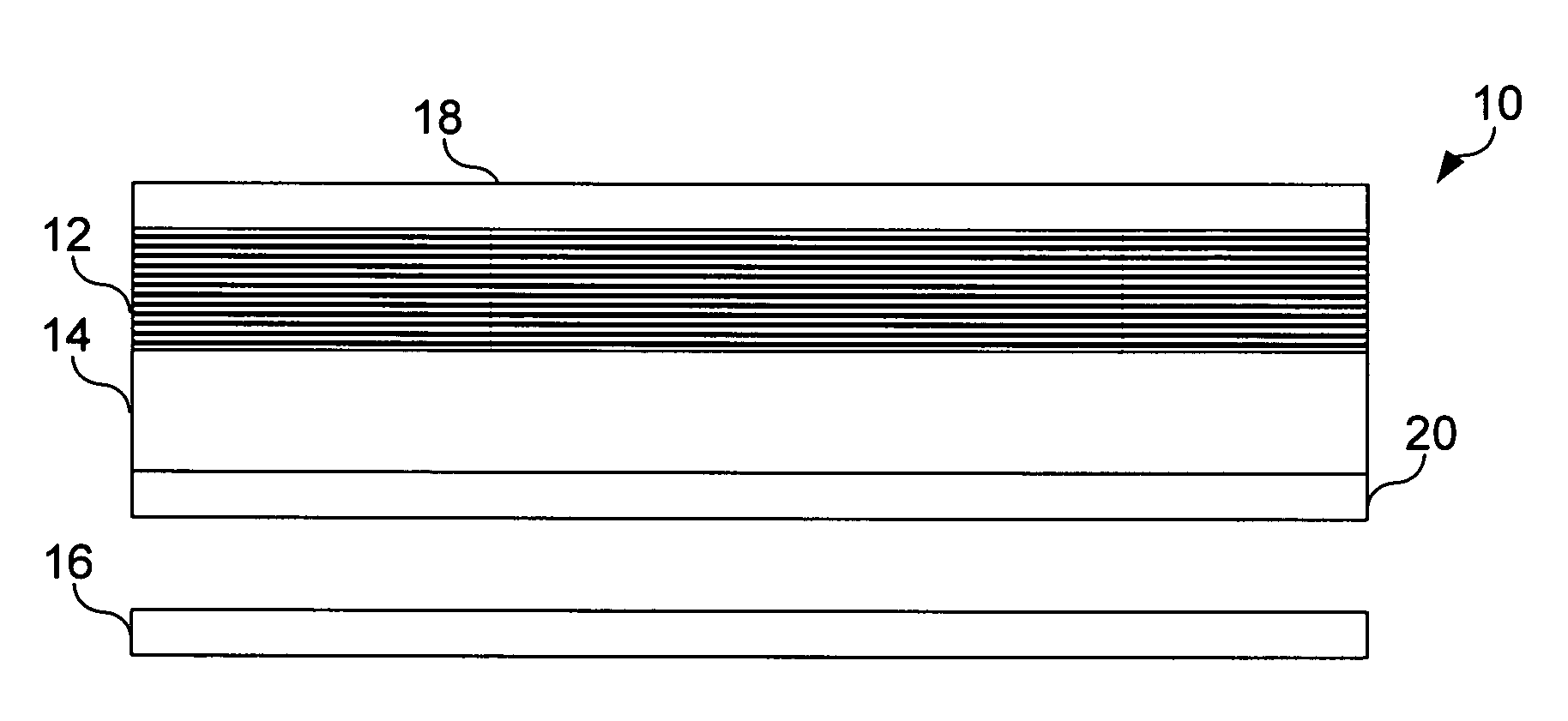

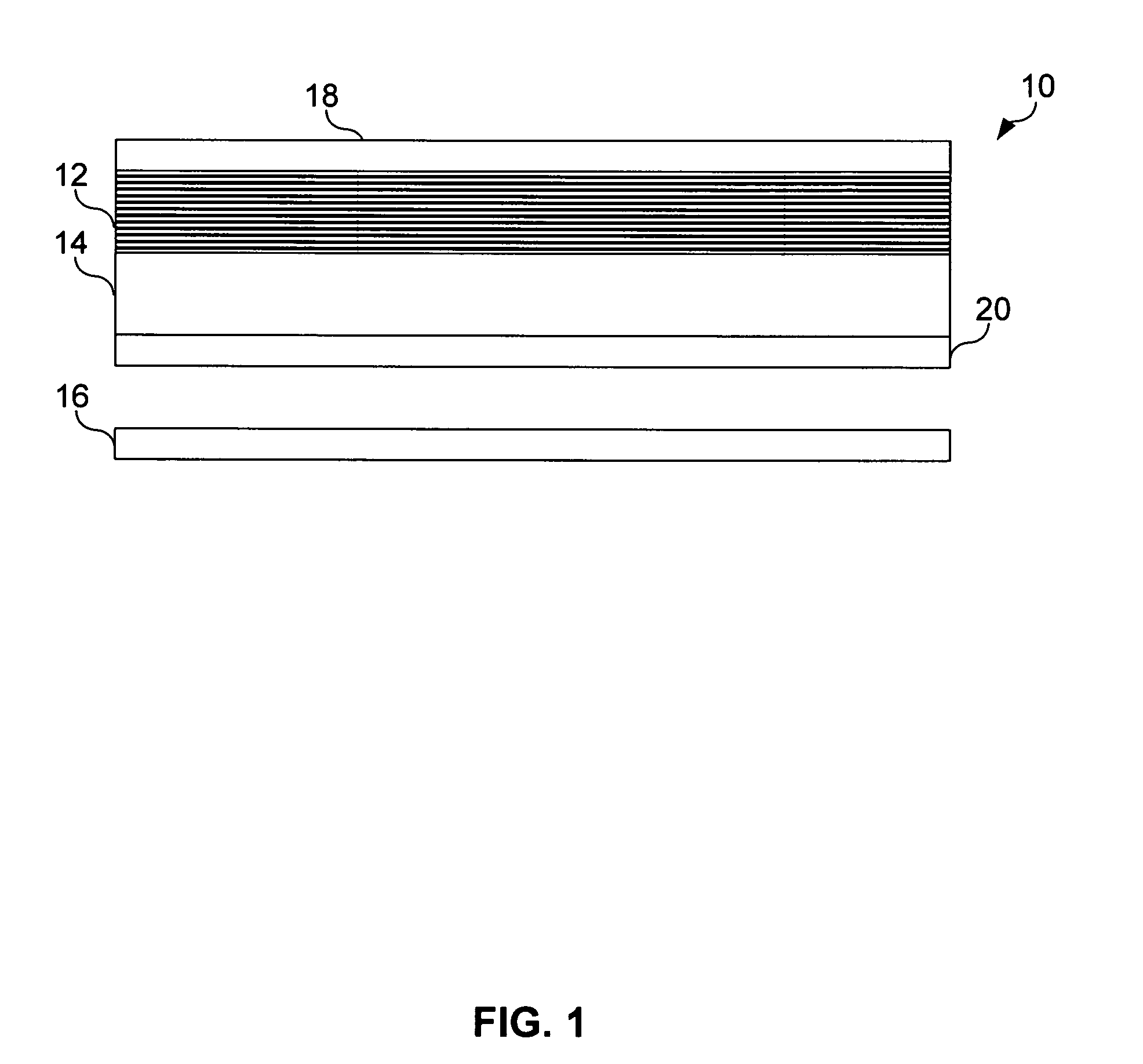

Thin two sided single crystal solar cell and manufacturing process thereof

InactiveUS20100108134A1High quality epitaxial growthImprove material qualitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationAnti-reflective coatingPorous layer

A design and manufacturing method for a photovoltaic (PV) solar cell less than 100 μm thick are disclosed. A porous silicon layer is formed on a wafer substrate. Portions of the PV cell are then formed using diffusion, epitaxy and autodoping from the substrate. All front side processing of the solar cell (junctions, passivation layer, anti-reflective coating, contacts to the N+-type layer) is performed while the thin epitaxial layer is attached to the porous layer and substrate. The wafer is then clamped and exfoliated. The back side of the PV cell is completed from the region of the wafer near the exfoliation fracture layer, with subsequent removal of the porous layer, passivation, patterning of contacts, deposition of a conductive coating, and contacts to the P+-type layer. During manufacturing, the cell is always supported by either the bulk wafer or a wafer chuck, with no processing of bare thin PV cell

Owner:CRYSTAL SOLAR INC

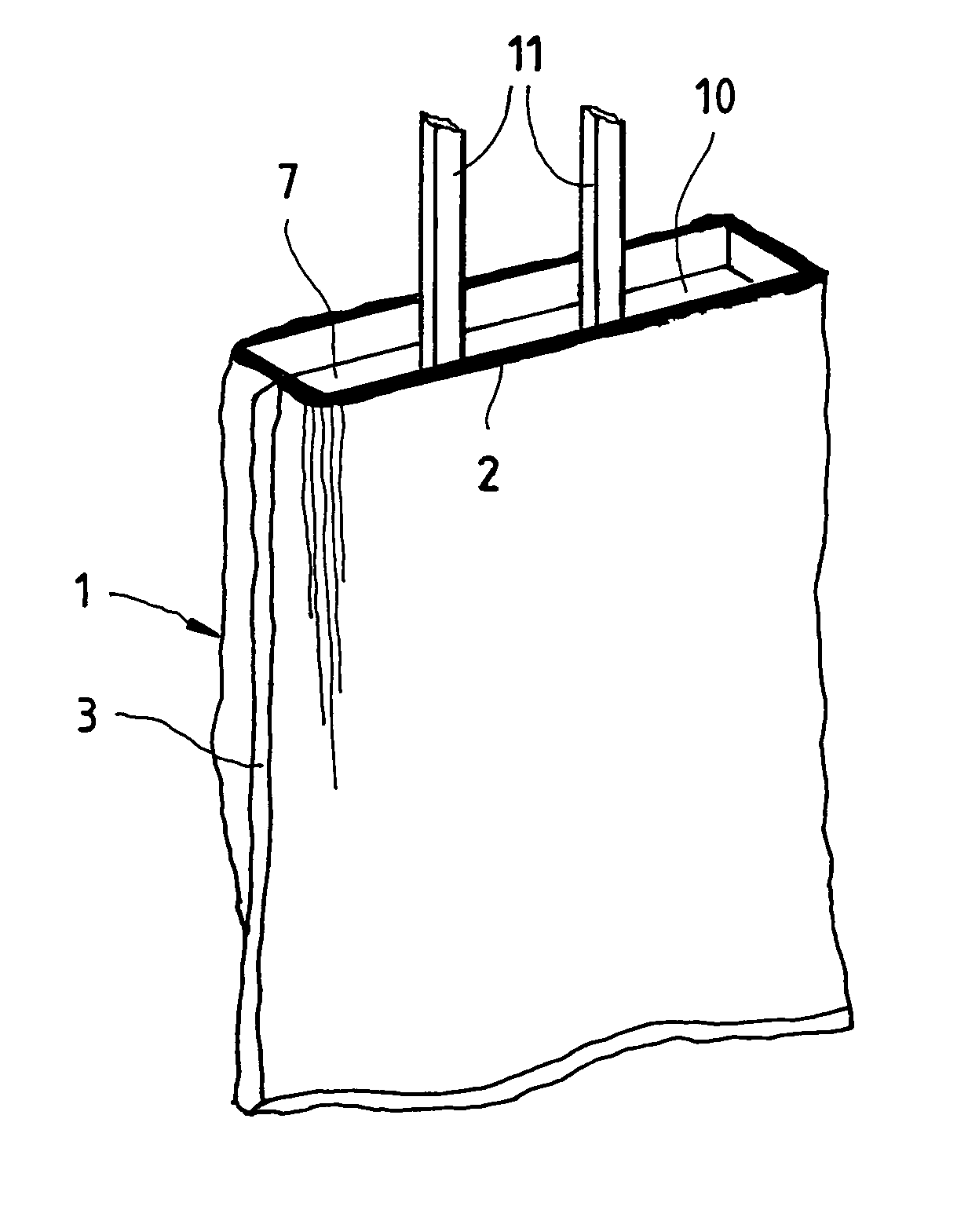

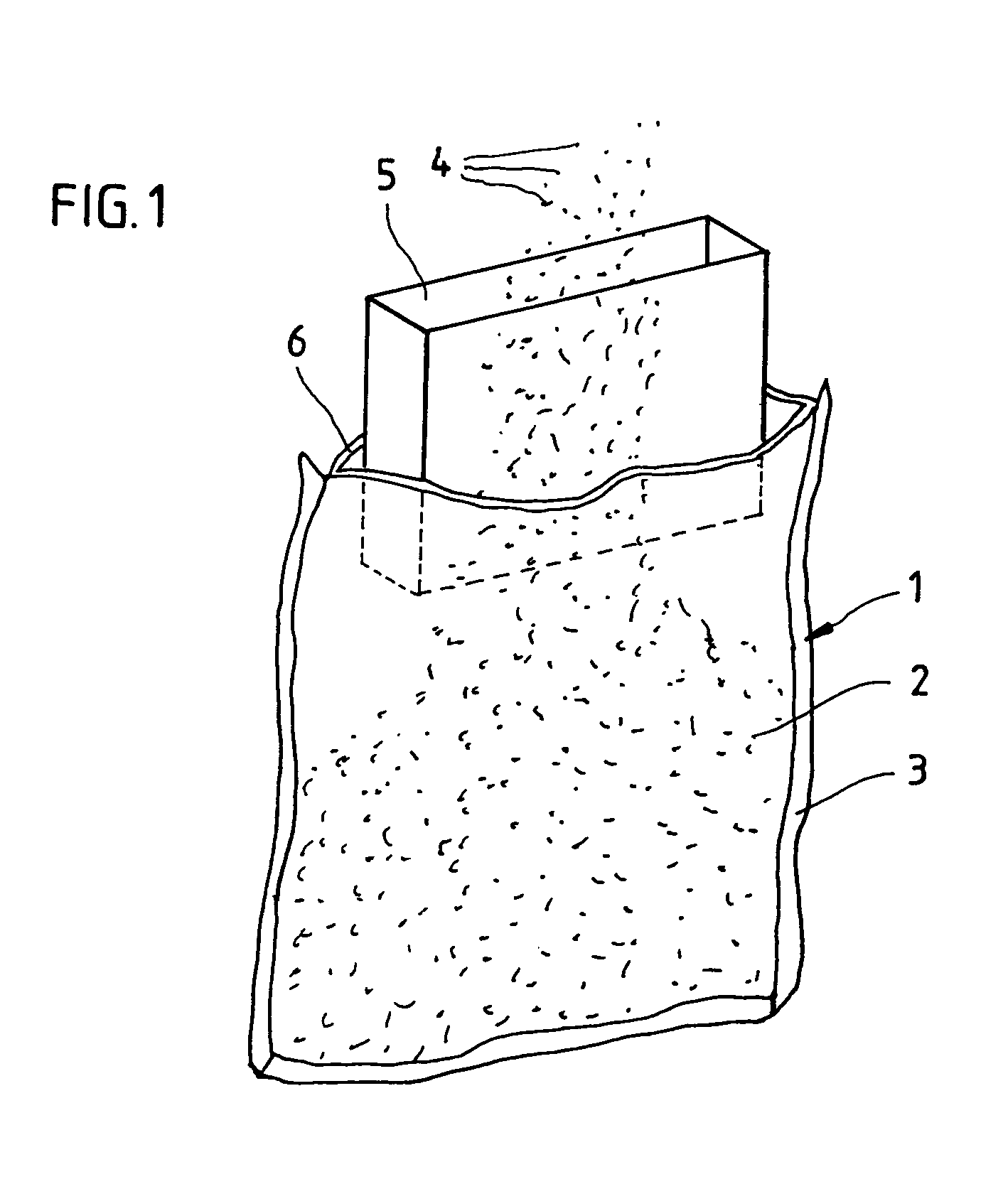

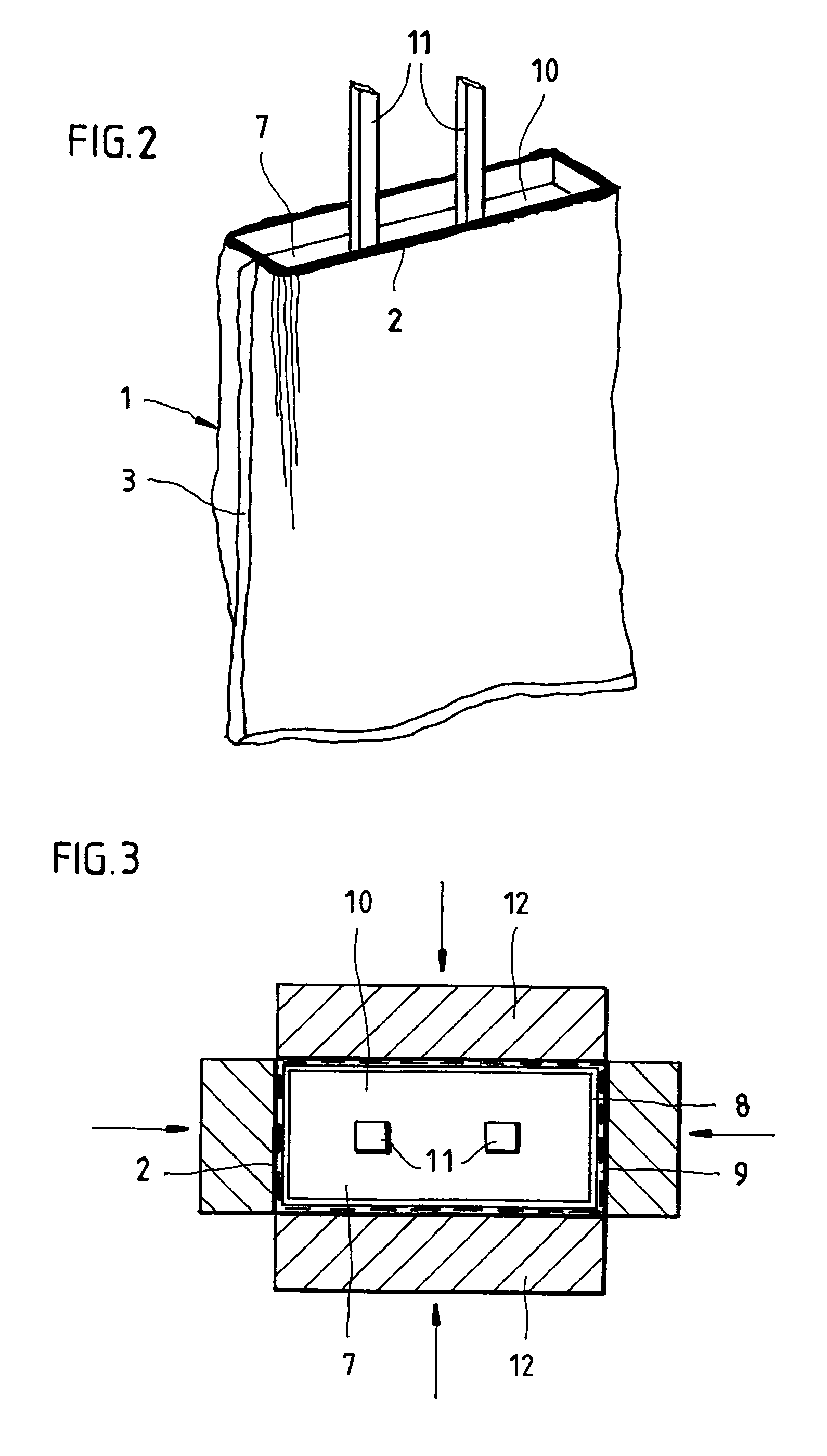

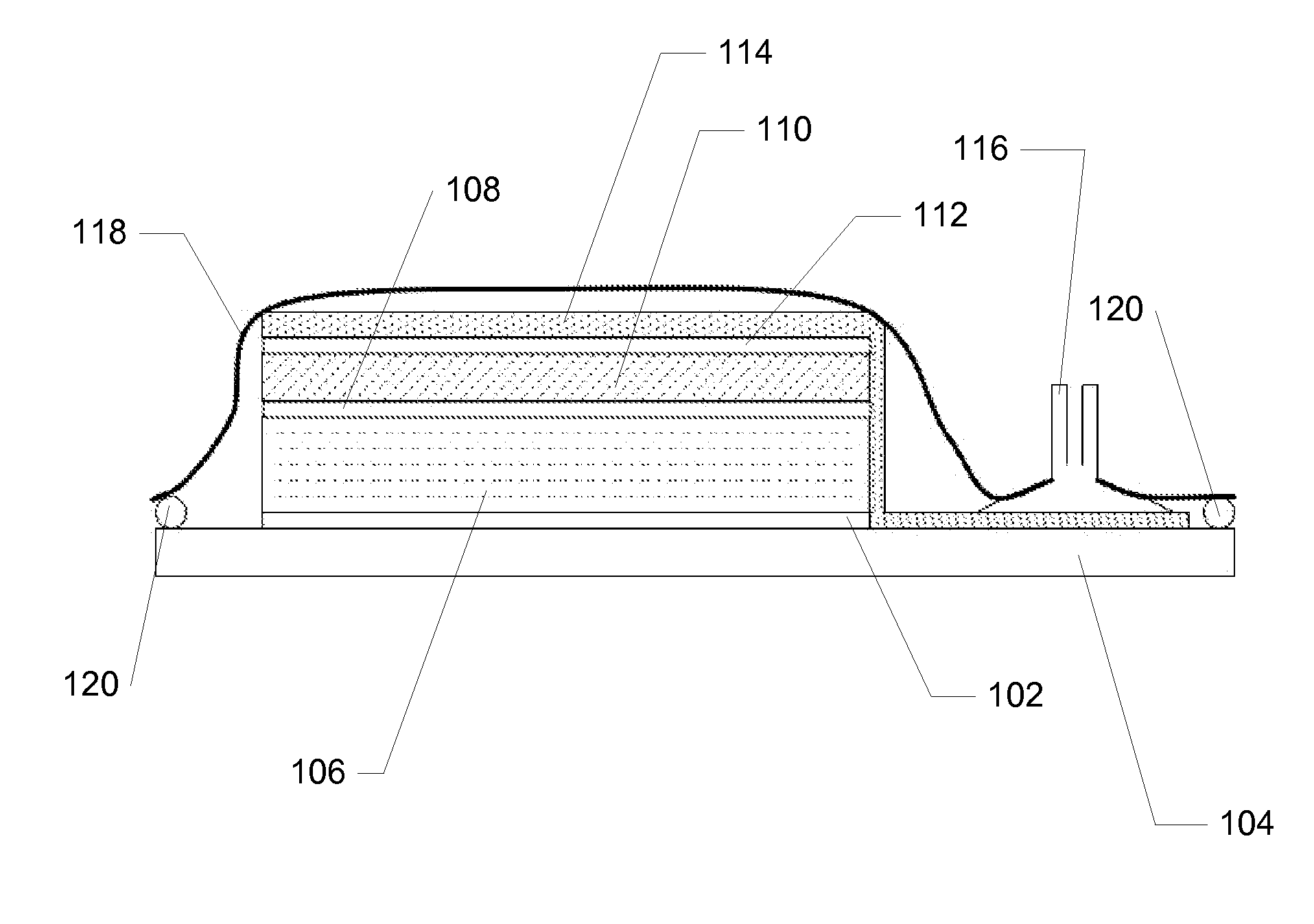

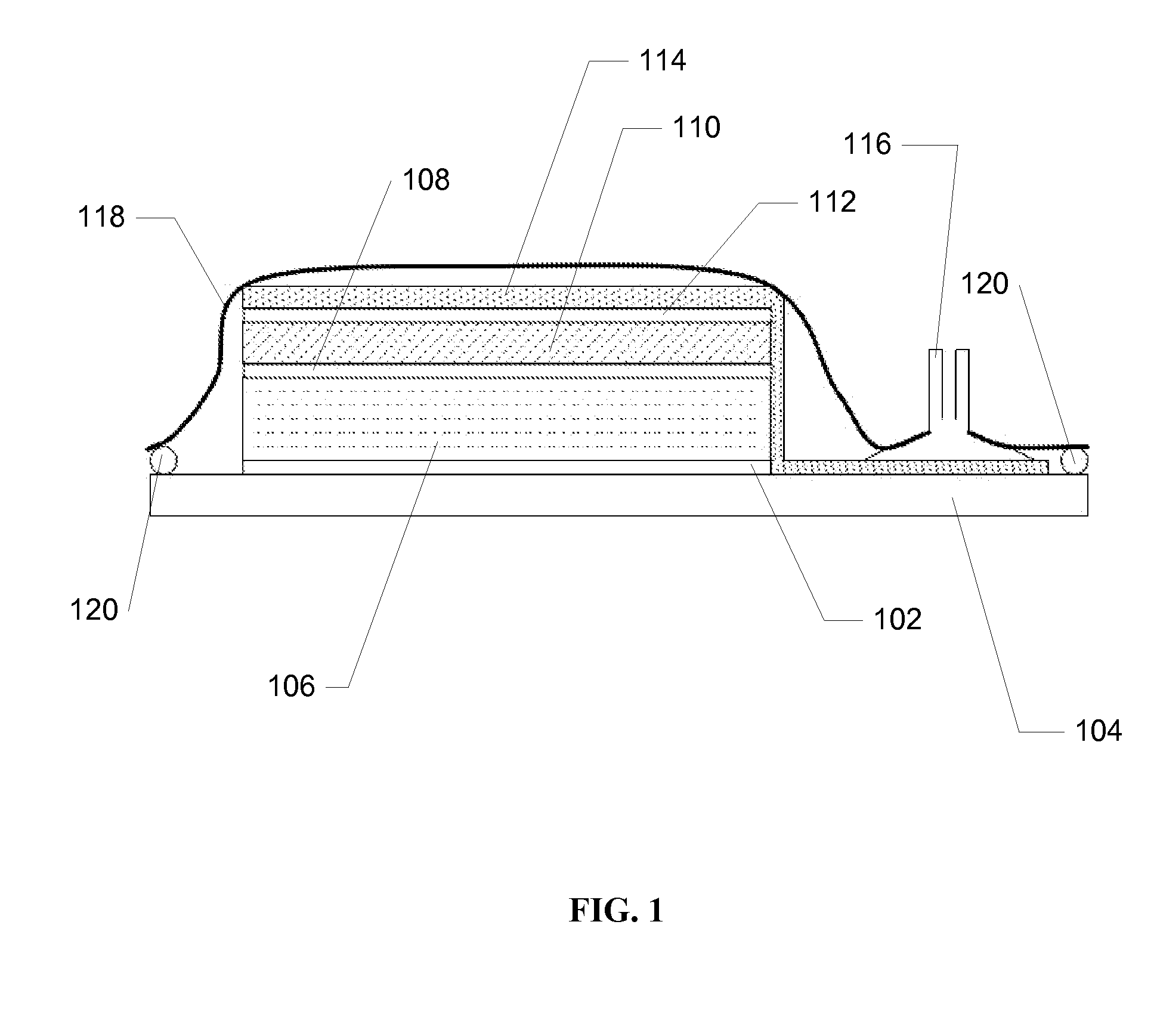

Method for the production of a vacuum insulation element wrapped in a film, filled with powder

ActiveUS8281558B2Improve pumping performancePrevent exitThermal insulationLaminationEngineeringFilter material

The invention relates to a method for producing an especially panel-shaped vacuum insulation element which is wrapped in a film and is filled with a powder. According to the method, the unmolded, loose powder is filled, particularly poured, into the opening of a bag which is formed from a high-barrier film and is open on one side. A filter material that is permeable to air and impermeable to powder dust is fixed to the internal face of the film bag in the area of the opening of the filled film bag such that the interior of the bag is closed in a dust-tight manner while air can still be discharged. The interior of the dust-tightly closed film bag is then evacuated and the evacuated film bag is air-tightly closed in a vacuum.

Owner:VA Q TEC AG

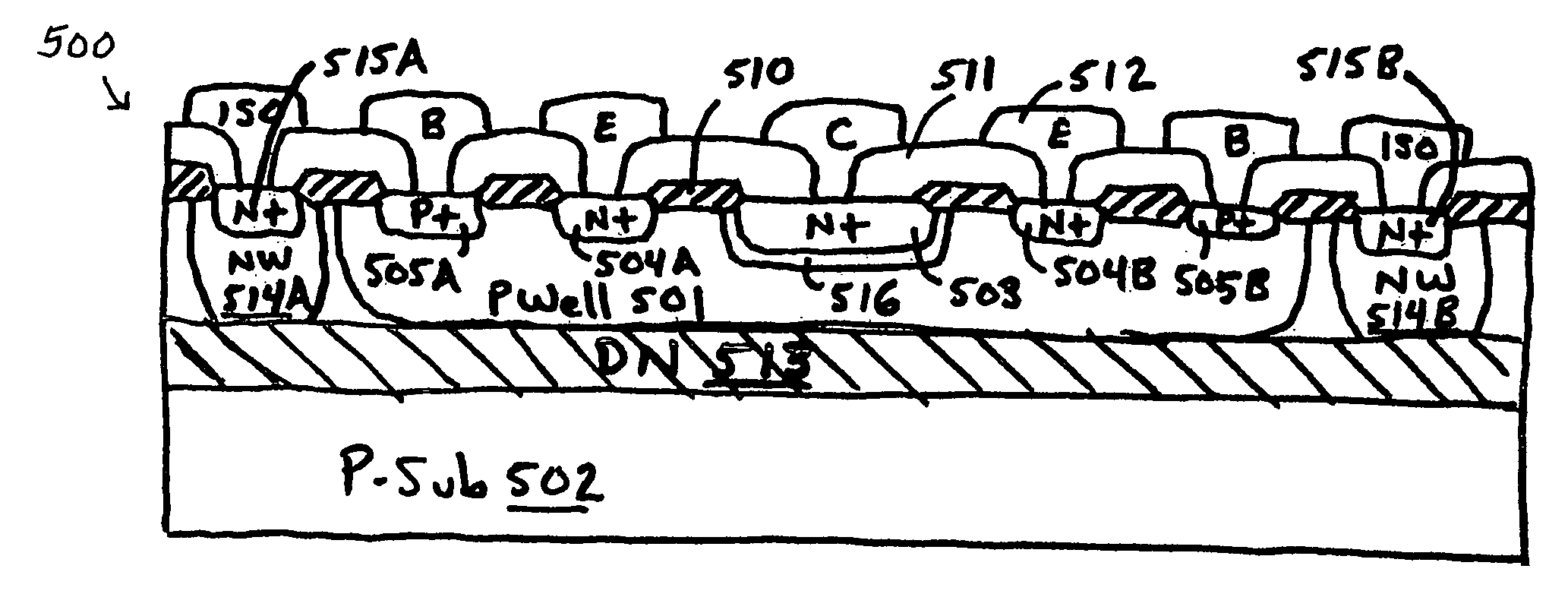

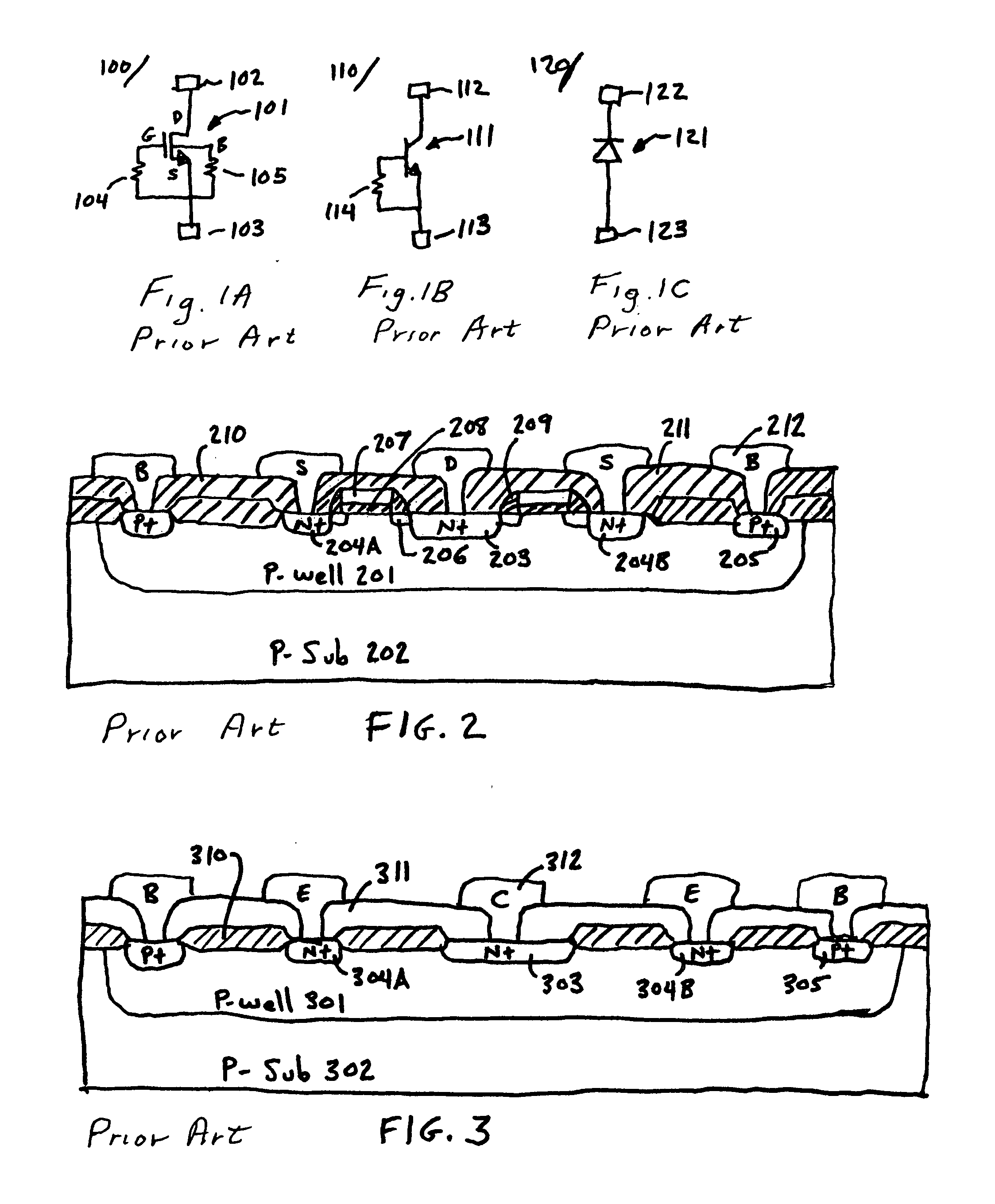

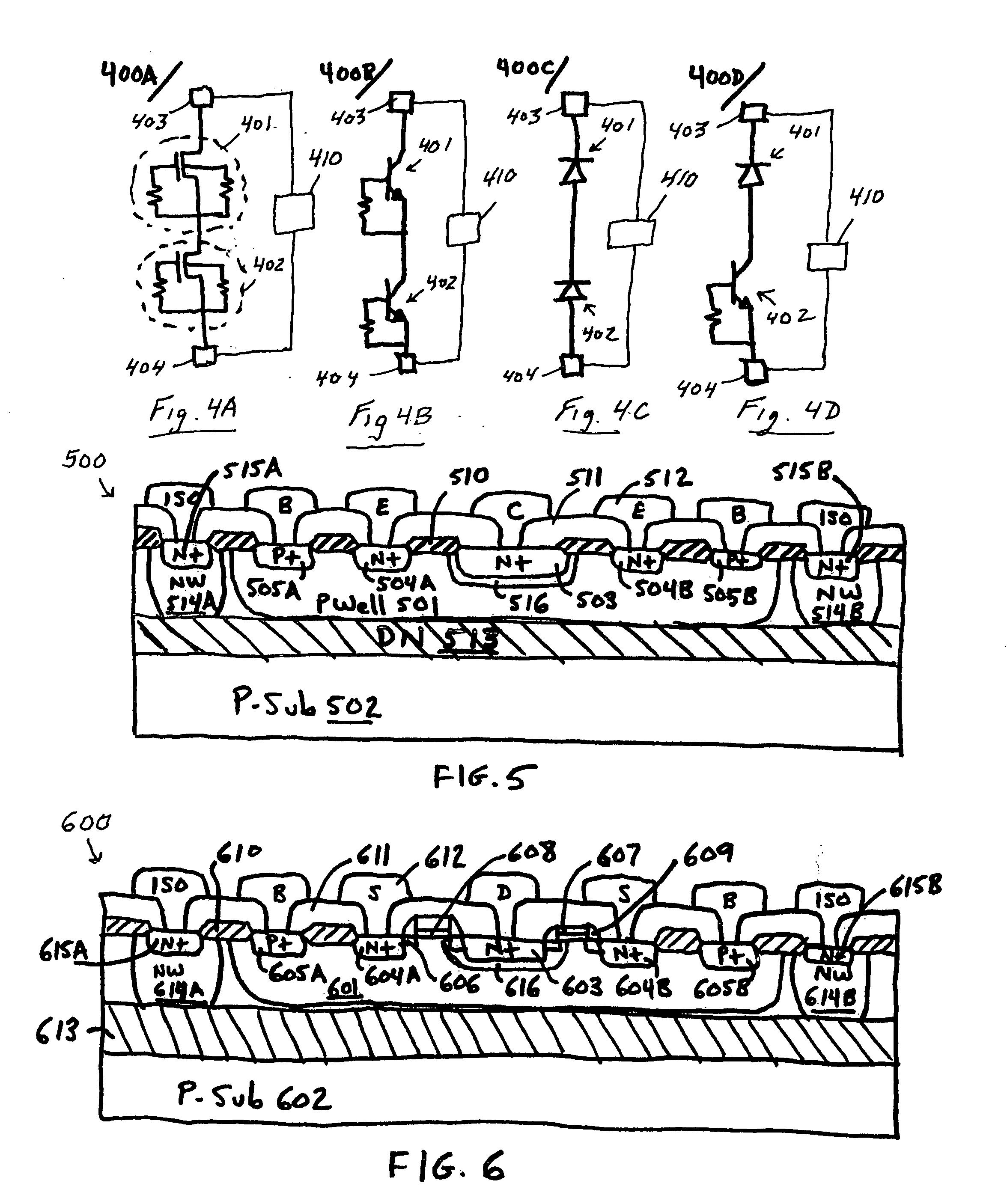

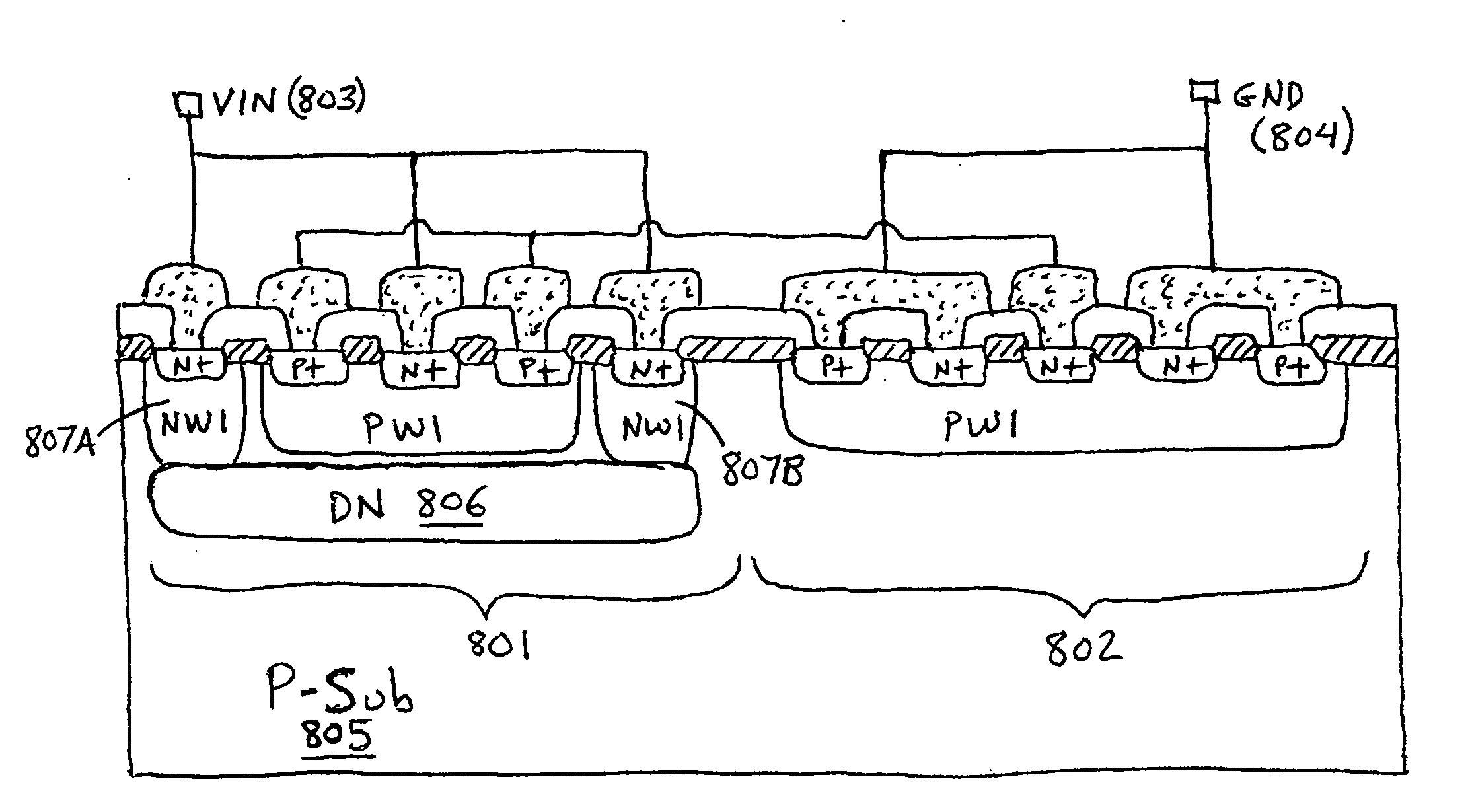

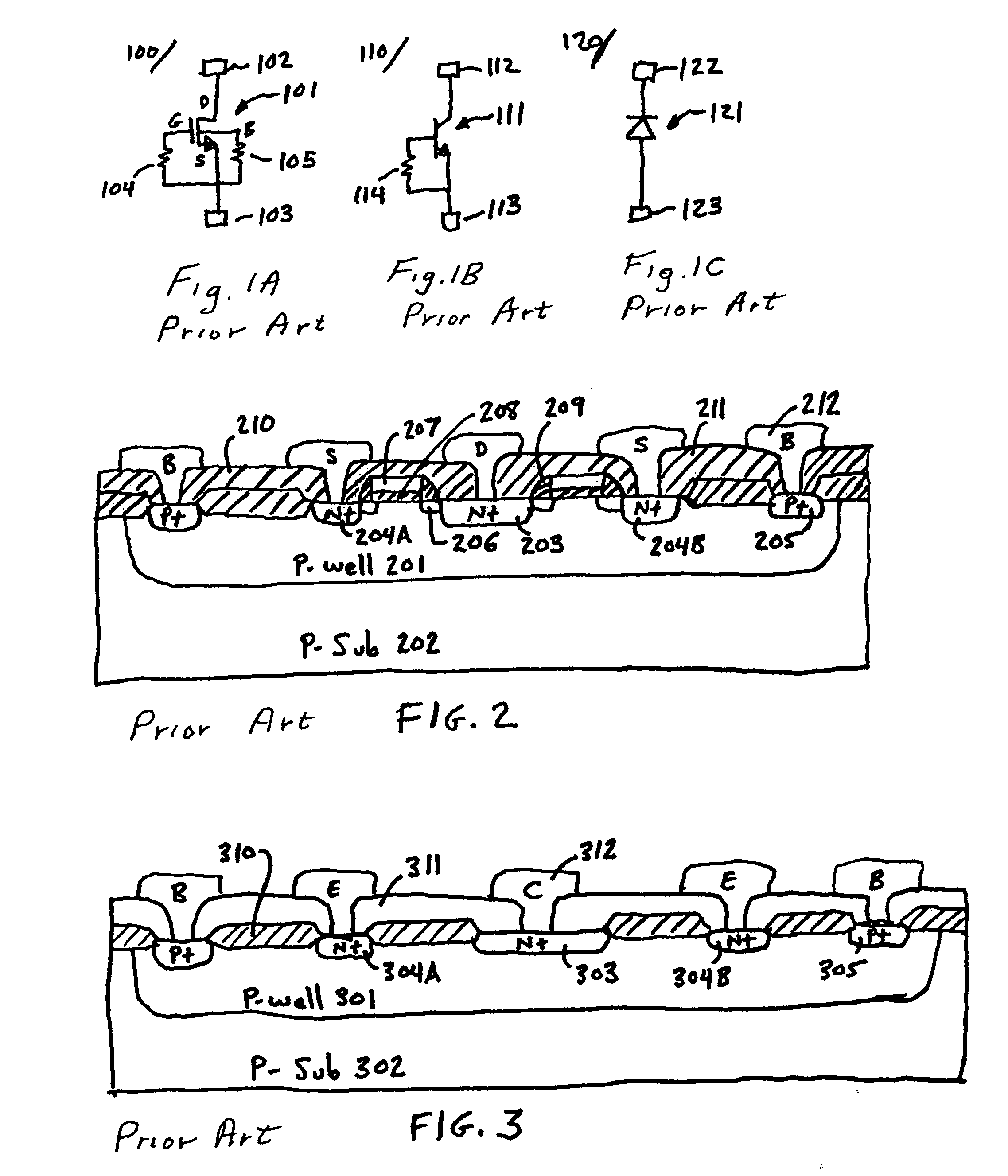

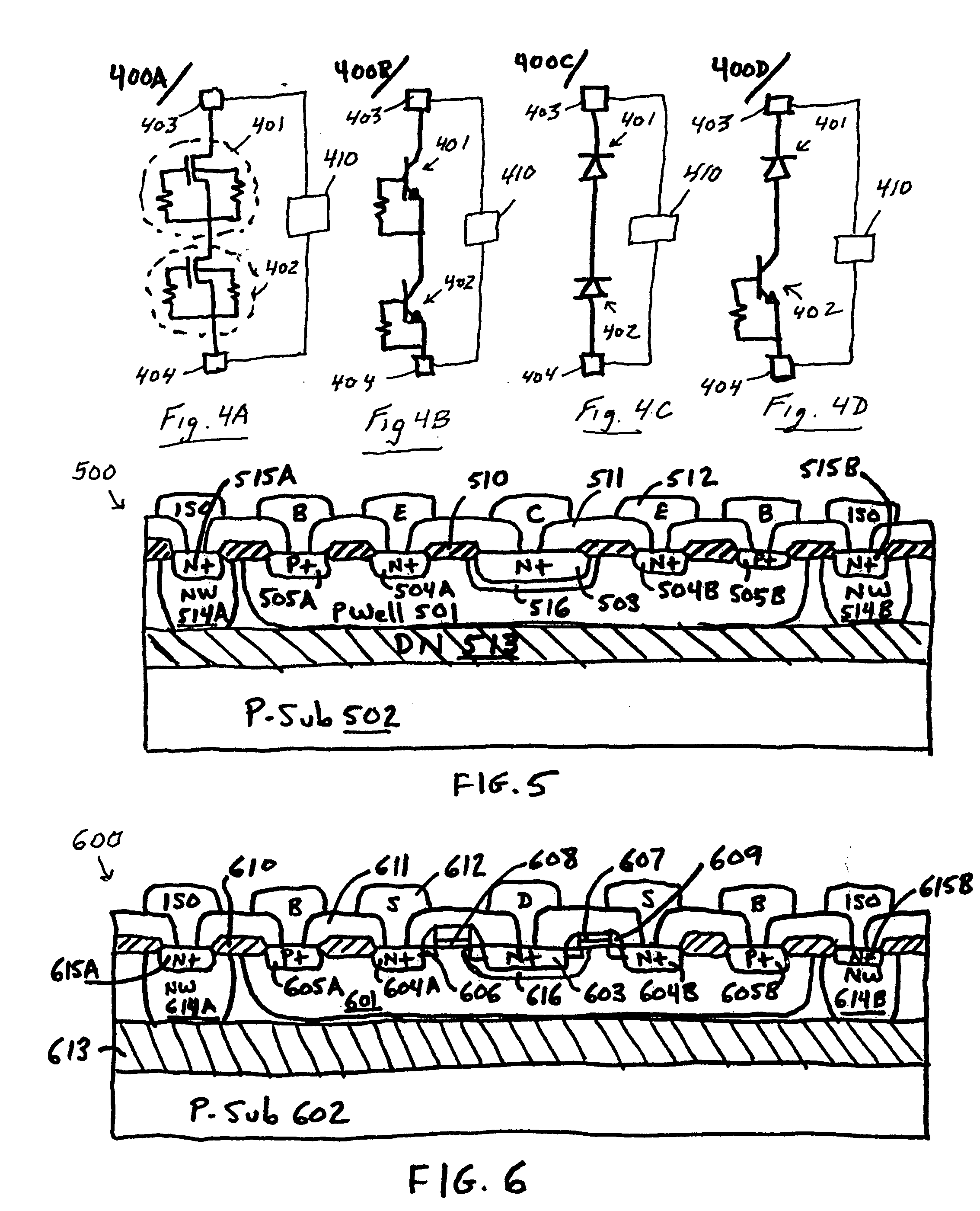

ESD protection for bipolar-CMOS-DMOS integrated circuit devices and modular method of forming the same

InactiveUS20080029820A1Eliminate processing stepsThyristorSemiconductor/solid-state device detailsCMOSEngineering

An Electro-Static Discharge (ESD) protection device is formed in an isolated region of a semiconductor substrate. The ESD protection device may be in the form of a MOS or bipolar transistor or a diode. The isolation structure may include a deep implanted floor layer and one or more implanted wells that laterally surround the isolated region. The isolation structure and ESD protection devices are fabricated using a modular process that includes virtually no thermal processing. Since the ESD device is isolated, two or more ESD devices may be electrically “stacked” on one another such that the trigger voltages of the devices are added together to achieve a higher effective trigger voltage.

Owner:ADVANCED ANALOGIC TECHNOLOGIES INCORPORATED +1

ESD protection for bipolar-CMOS-DMOS integrated circuit devices

InactiveUS20090034137A1Eliminate processing stepsThyristorSemiconductor/solid-state device detailsCMOSSemiconductor

An Electro-Static Discharge (ESD) protection device is formed in an isolated region of a semiconductor substrate. The ESD protection device may be in the form of a MOS or bipolar transistor or a diode. The isolation structure may include a deep implanted floor layer and one or more implanted wells that laterally surround the isolated region. The isolation structure and ESD protection devices are fabricated using a modular process that includes virtually no thermal processing. Since the ESD device is isolated, two or more ESD devices may be electrically “stacked” on one another such that the trigger voltages of the devices are added together to achieve a higher effective trigger voltage.

Owner:ADVANCED ANALOGIC TECHNOLOGIES INCORPORATED +1

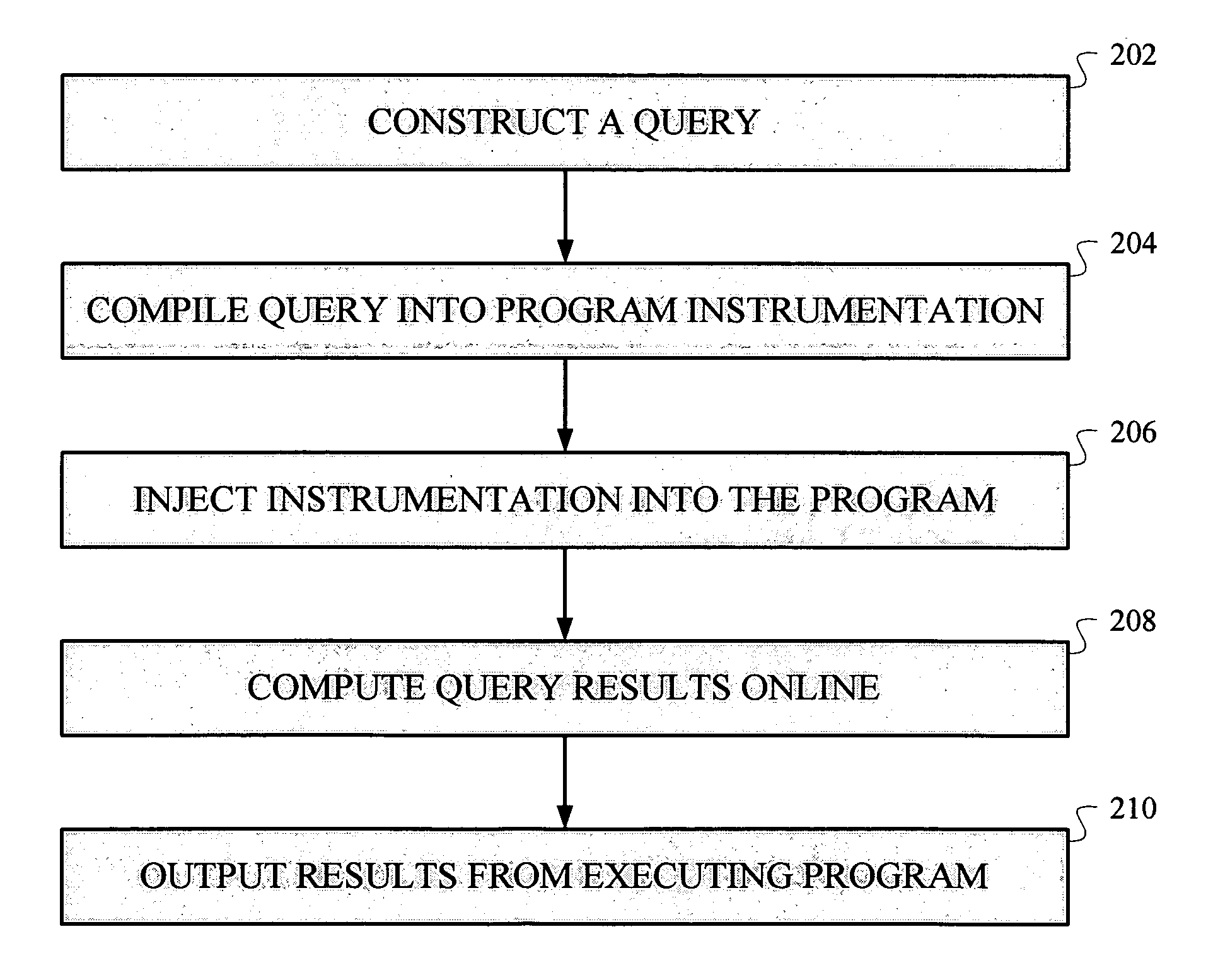

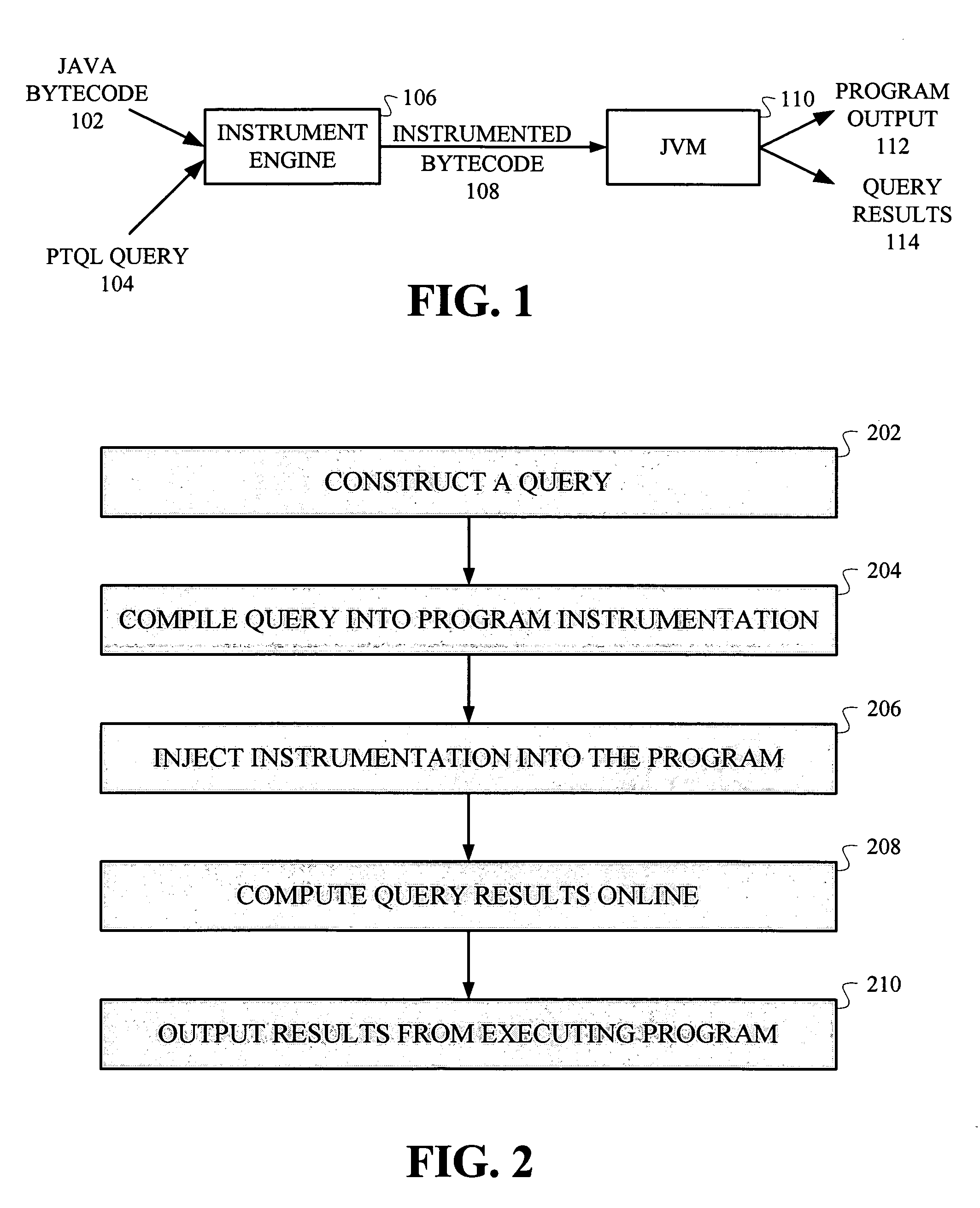

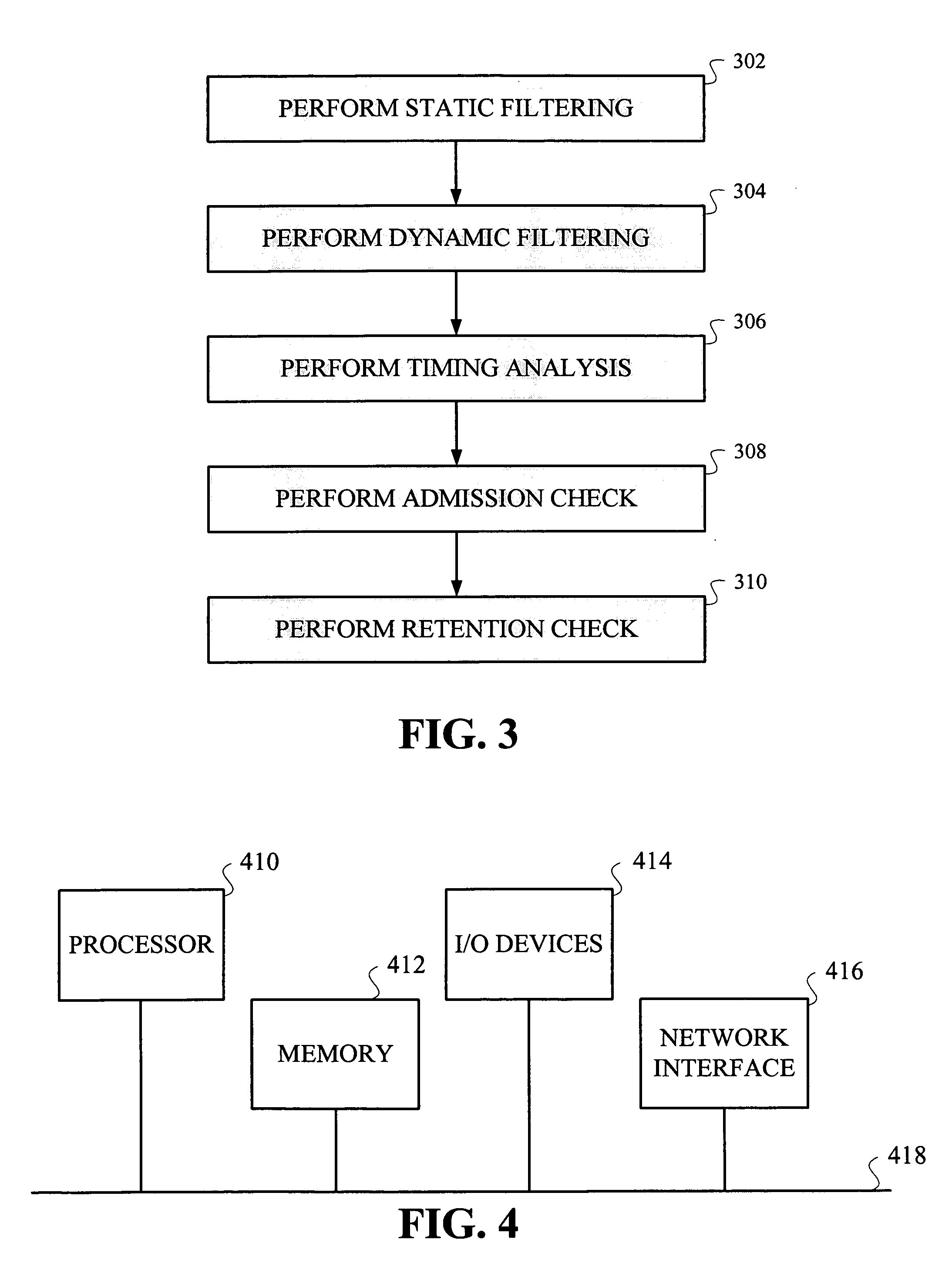

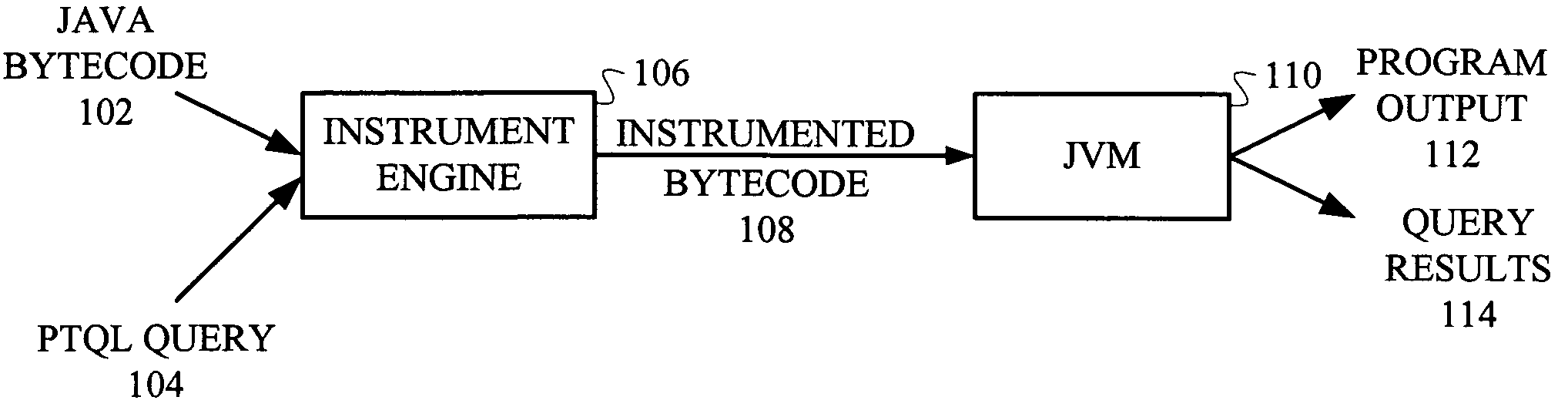

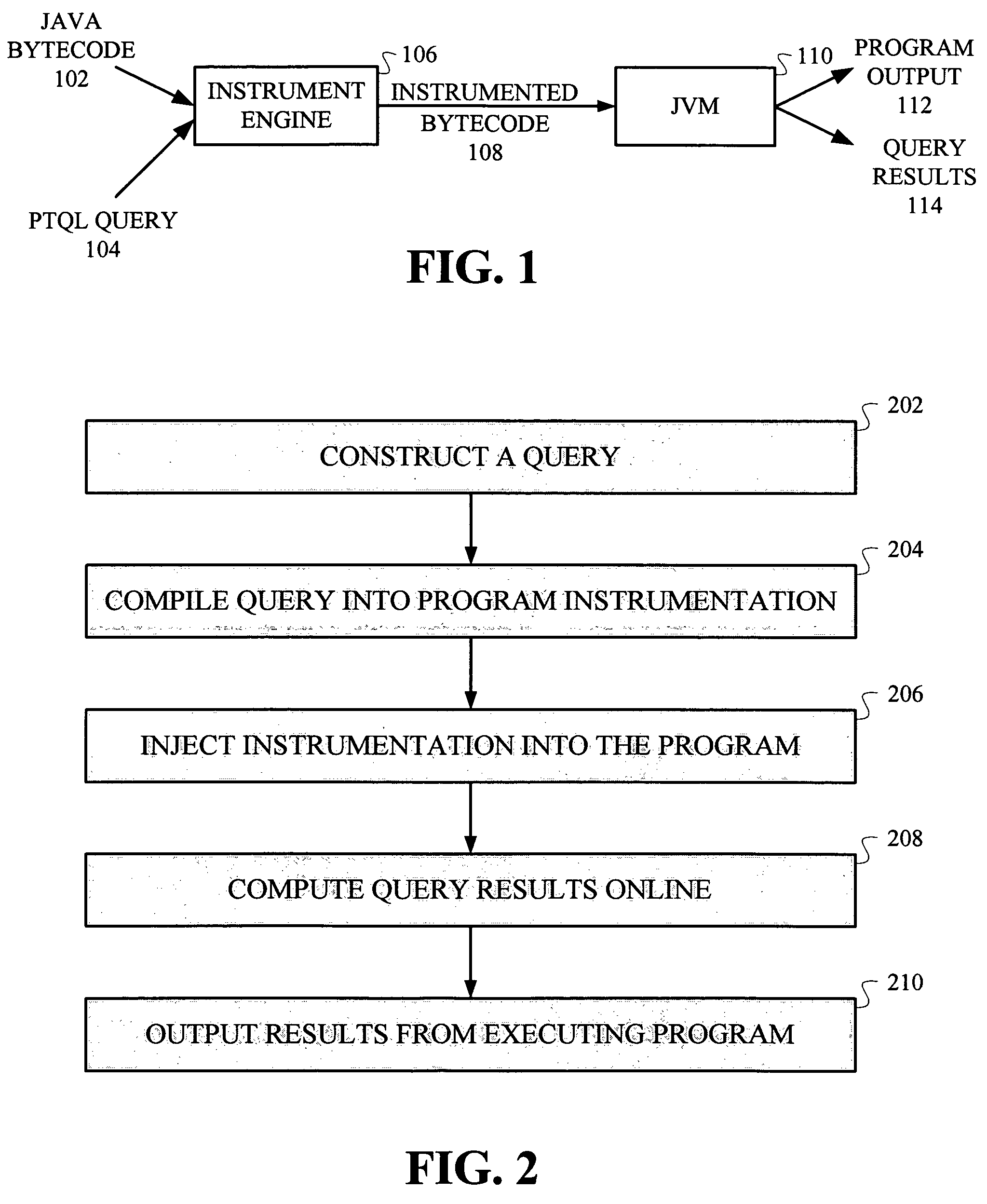

Methods and apparatus for monitoring program execution

InactiveUS20060117299A1Reduce space overheadReduce time overheadError detection/correctionSpecific program execution arrangementsProgramming languageRelational query

A technique for monitoring an execution of a program is provided. At least one relational query is constructed and compiled into a program instrumentation. The program instrumentation is incorporated into the program and one or more query results are output from the program as the program executes.

Owner:IBM CORP

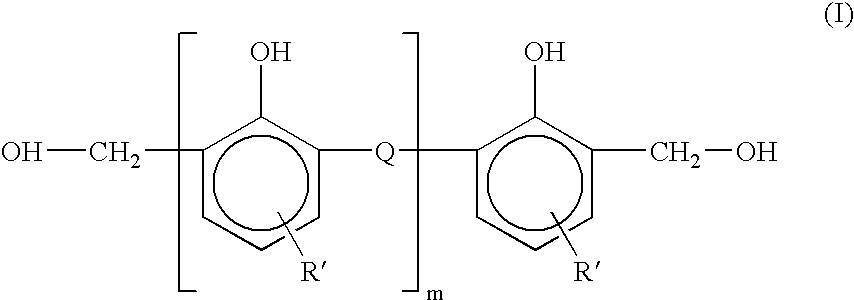

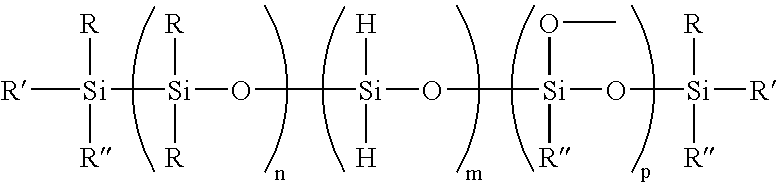

Thermoplastic elastomers and process for making same

InactiveUS20040171758A1Efficient productionEliminate certain processing stepMixingElastomerGas phase

A process for producing a thermoplastic elastomer composition, the process comprising synthesizing an elastomeric copolymer by polymerizing ethylene, an alpha-olefin, and optionally a diene monomer within the gas phase to thereby produce a gas-phase elastomeric copolymer, blending the gas-phase elastomeric copolymer with a thermoplastic polymer to form a mix of the elastomeric copolymer and thermoplastic polymer, and dynamically vulcanizing the gas-phase elastomeric copolymer within the mix of the elastomeric copolymer and thermoplastic polymer.

Owner:CELANESE INT CORP

Articles Comprising Protective Sheets and Related Methods

ActiveUS20100068446A1Promote formationEliminate process stepsSynthetic resin layered productsRecord information storageEngineering

Methods of the invention include those for applying protective sheets to articles. According to these methods and resulting articles, a protective sheet is applied to at least a portion of an exterior surface where protection is desired on an article. At least one portion of at least one exterior surface of the article to be protected can be integrally formed in the presence of the protective sheet. Improved bonding of the protective sheet to the article and improved processing efficiency are advantageously achieved according to the invention.

Owner:PPG ADVANCED SURFACE TECH LLC

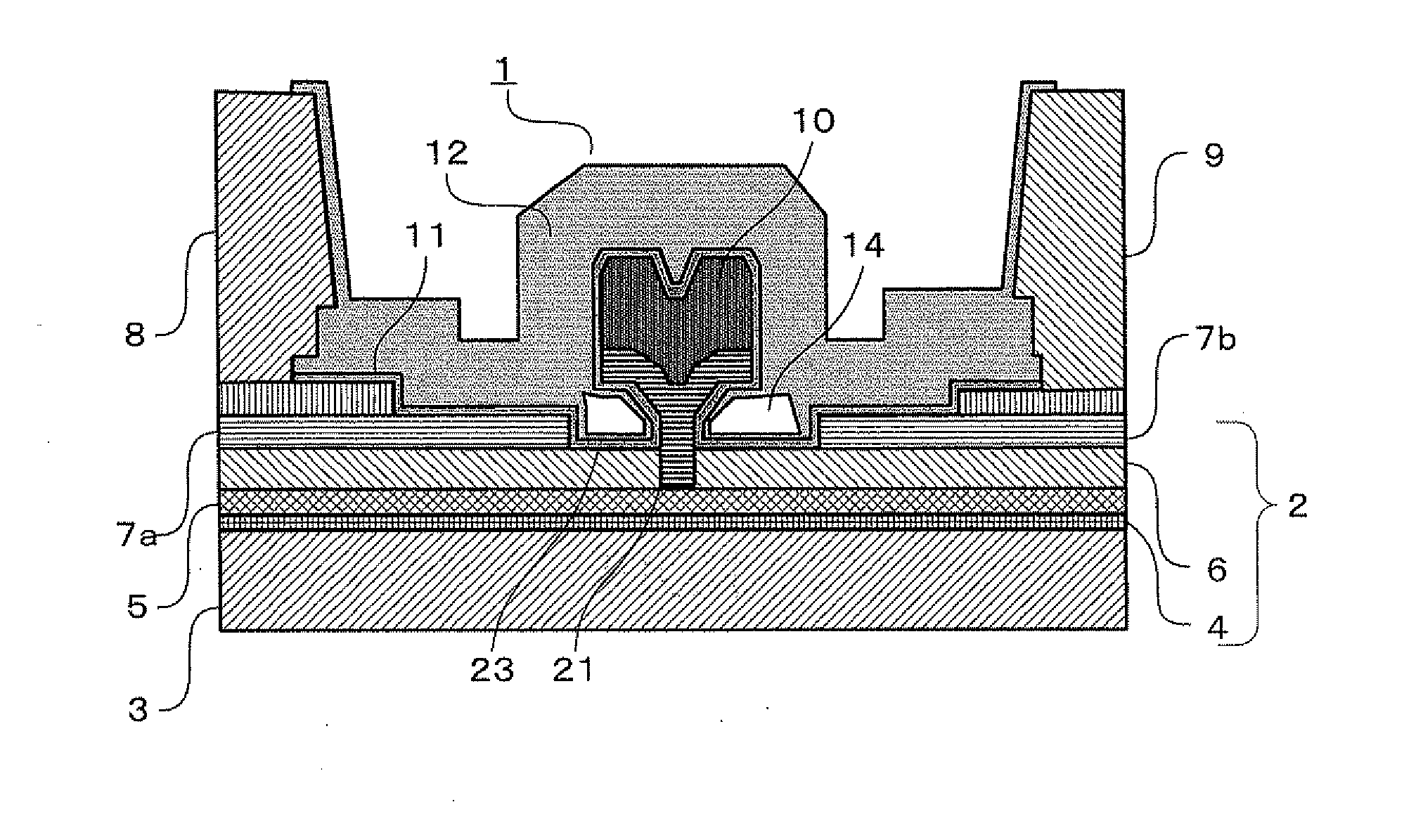

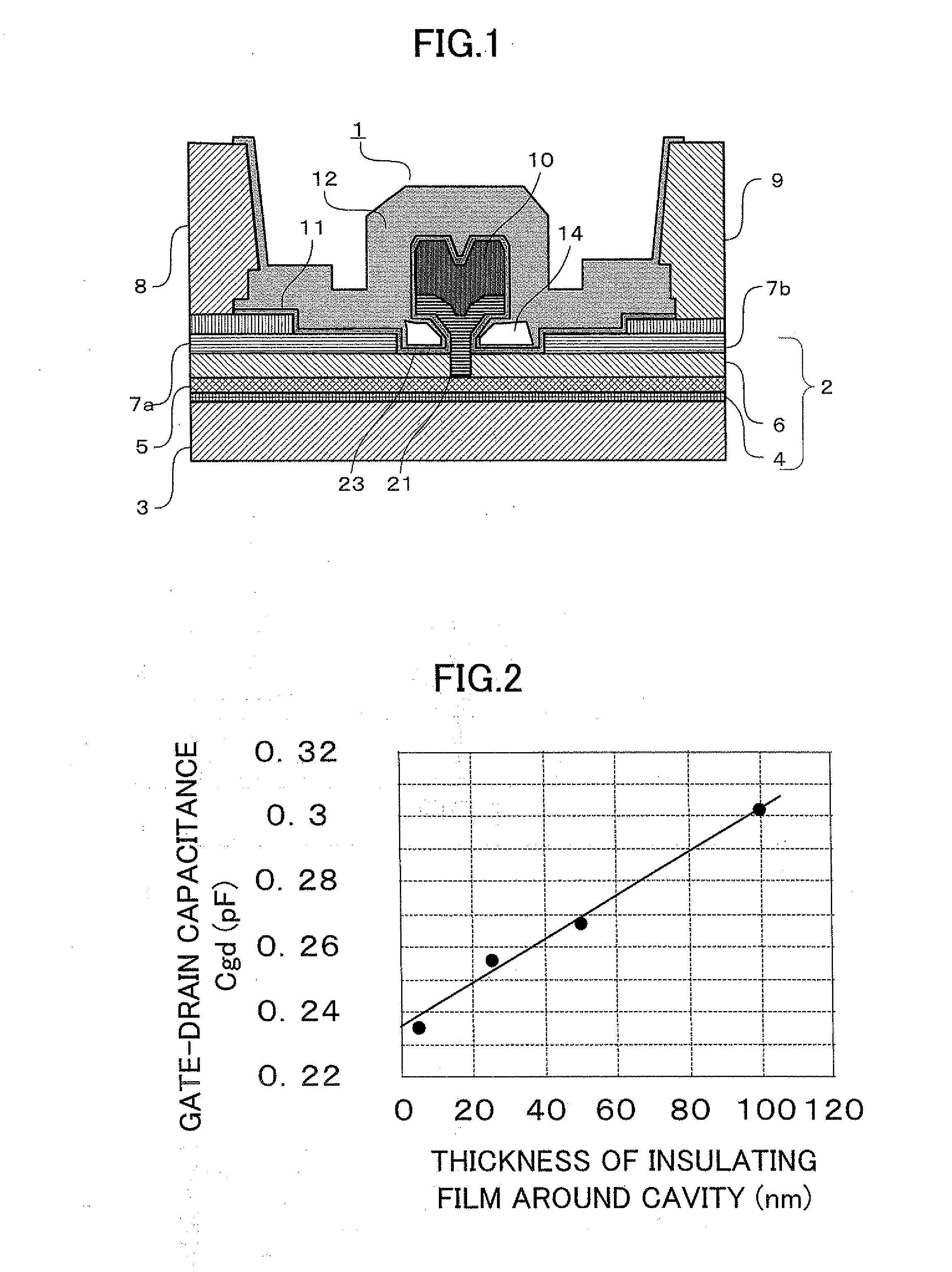

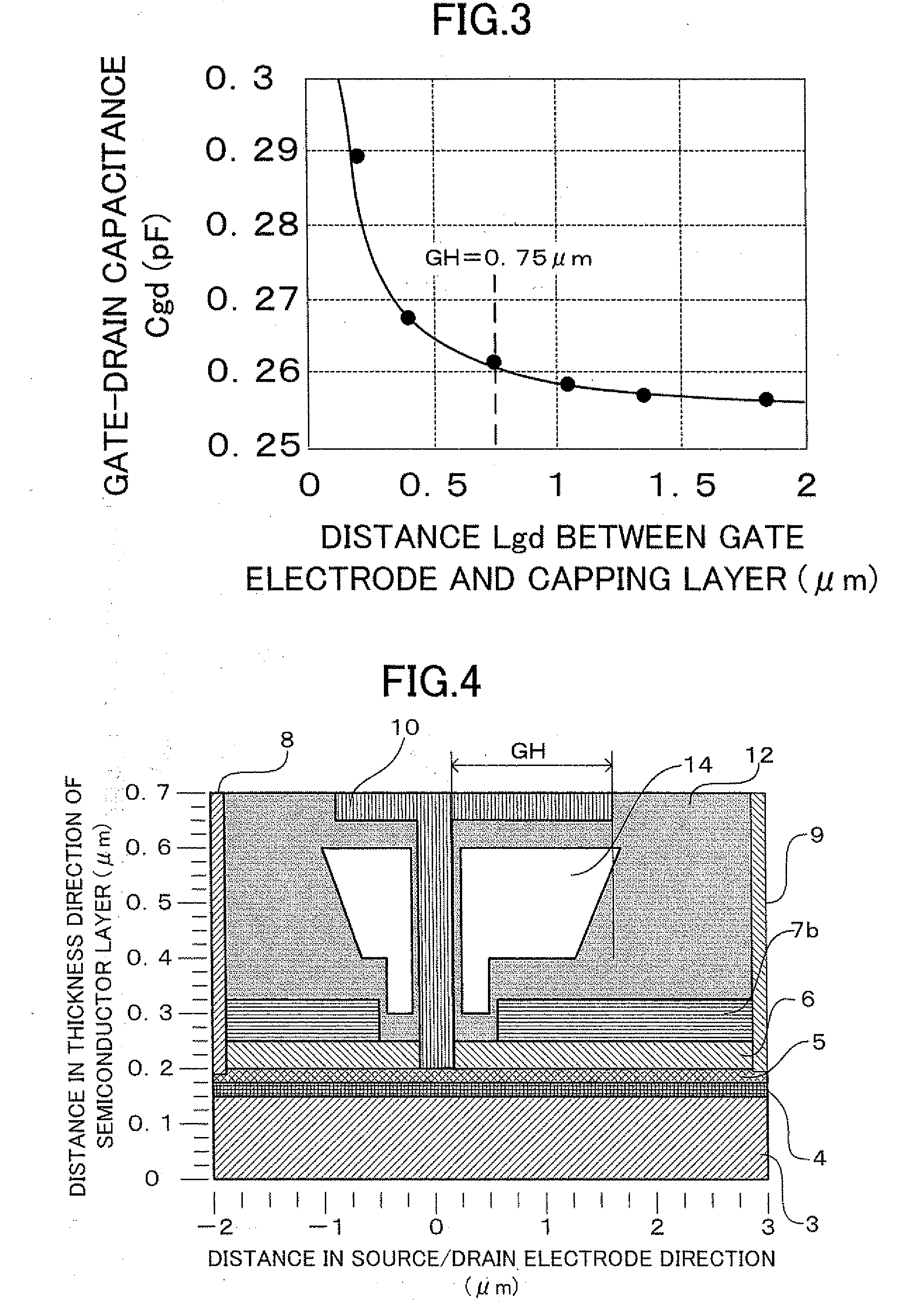

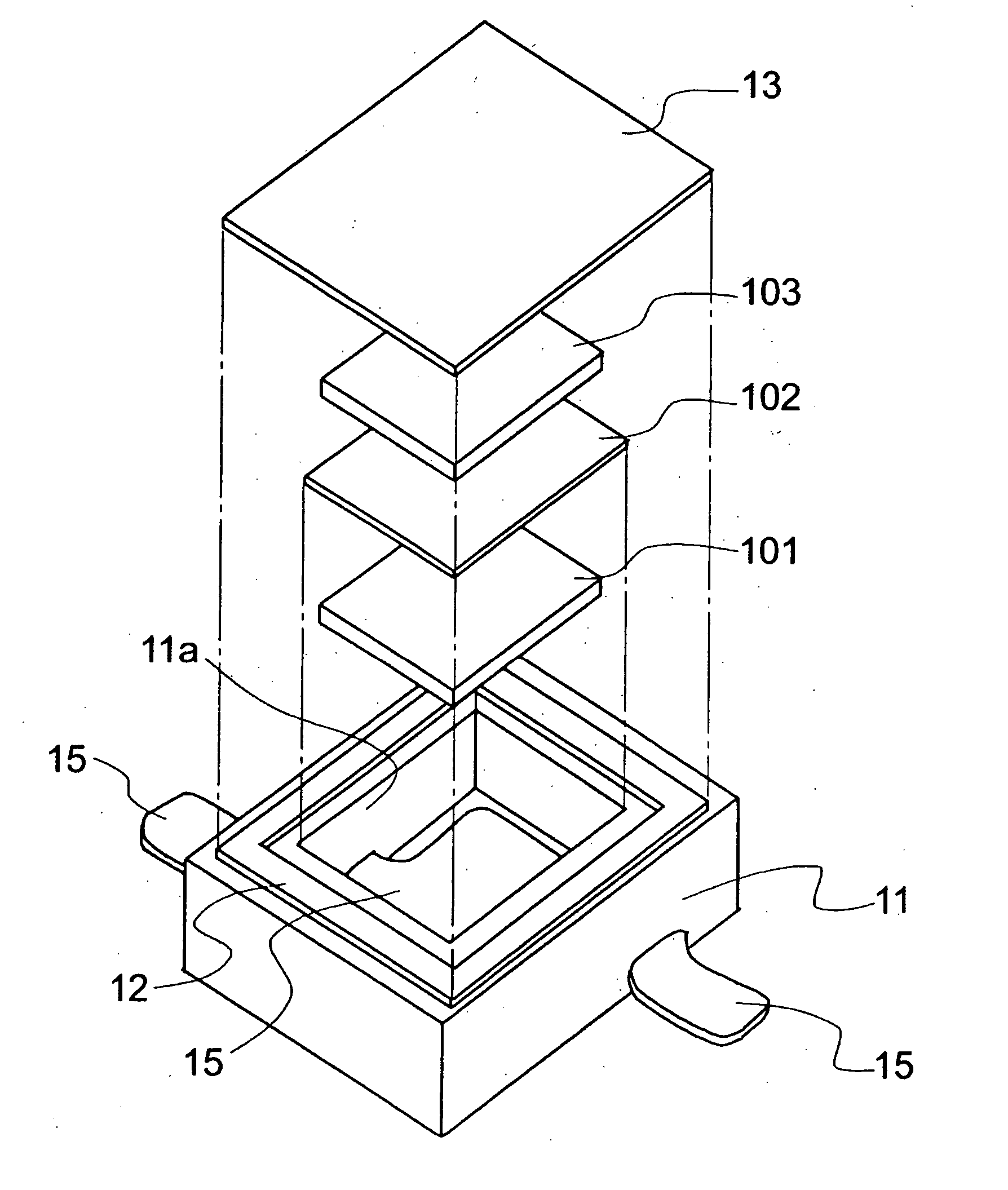

Field-effect transistor and method of manufacturing the same

ActiveUS20080087916A1Increase capacitanceEliminate processing stepsTransistorSemiconductor/solid-state device manufacturingCapacitanceEngineering

A low-cost field-effect transistor with a moisture-resistant gate covered by a thick moisture-resistant insulating film which suppresses an increase in gate capacitance, and a method of manufacturing the field-effect transistor. The field-effect transistor, has one of a T-shaped gate electrode and Γ-shaped gate electrode, a drain electrode, and a source electrode, the source electrode and the drain electrode being electrically connected through an n-doped semiconductor region. The gate, source, and drain electrodes are located on a semiconductor layer which includes an insulating film having a thickness of 50 nm or less and covering a surface of the gate electrode and a surface of the semiconductor layer. A silicon nitride film, deposited by catalytic CVD, covers the insulating film and includes a void volume located between a portion of the gate electrode corresponding to a canopy of an open umbrella and the semiconductor layer.

Owner:MITSUBISHI ELECTRIC CORP

Methods and apparatus for monitoring program execution

InactiveUS7620940B2Reduce overheadShorten the timeError detection/correctionSpecific program execution arrangementsProgramming languageRelational query

Owner:INT BUSINESS MASCH CORP

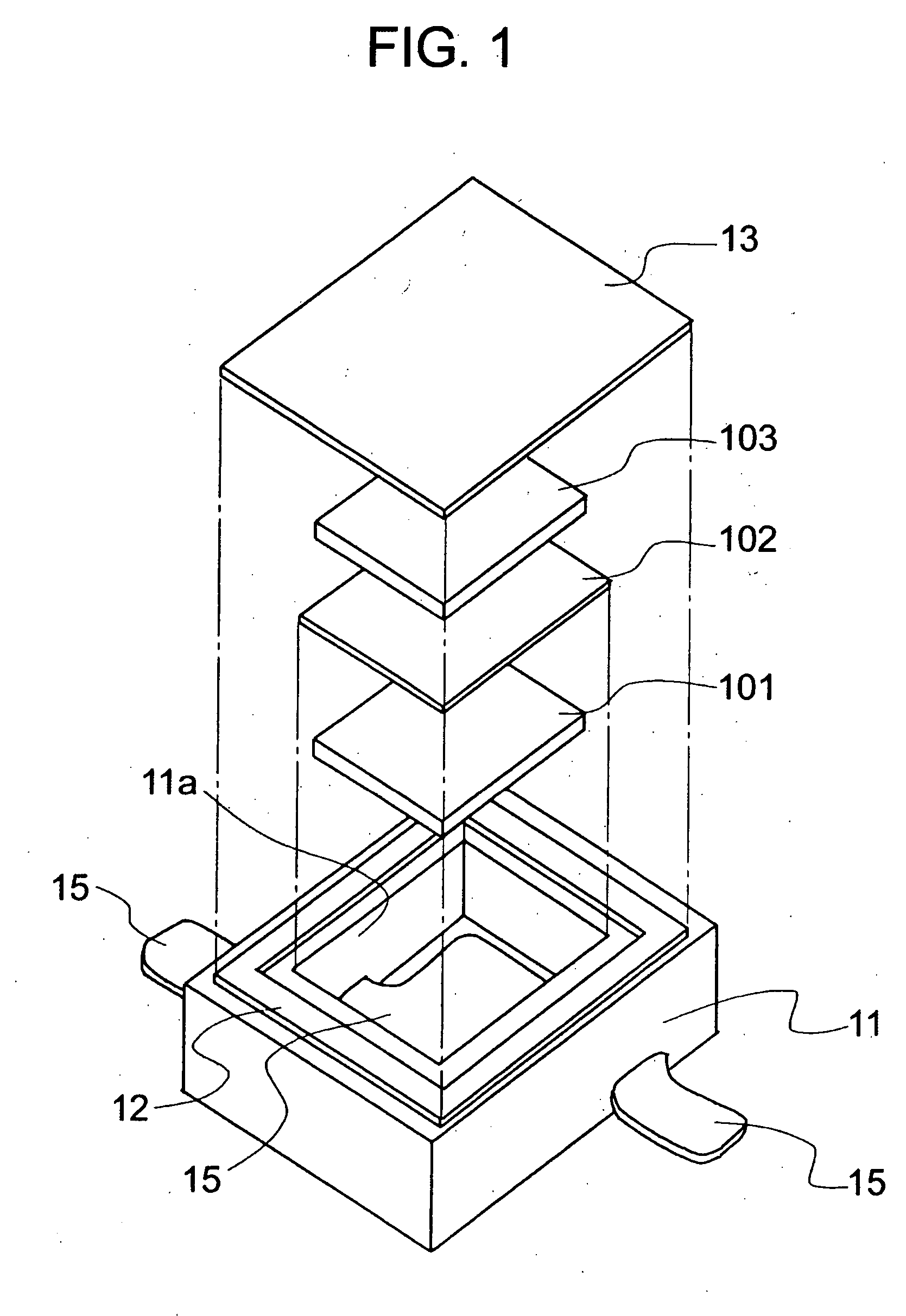

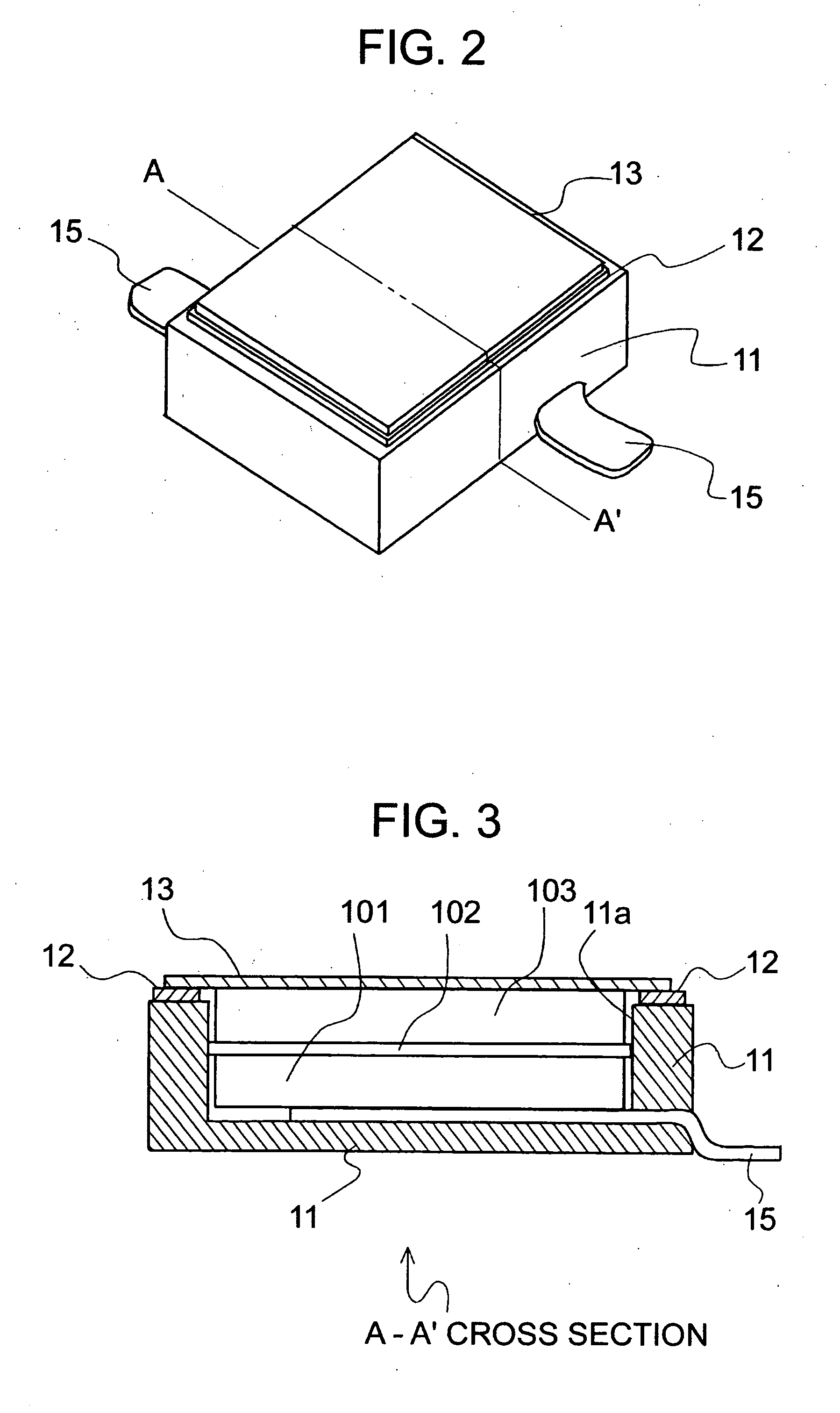

Electrochemical cell and fabrication method of the same

InactiveUS20050037258A1Increase flexibilitySmall sizeFinal product manufactureSemiconductor/solid-state device detailsMetallic materialsEngineering

An electrochemical cell is provided which facilitates the reduction in size and thickness. An electrochemical cell is configured of a base member made of a resin material and formed in a box shape, a conductive terminal made of a metallic material and fixed and penetrated from the inside to the outside of the base member, a frame member made of a metallic material and fixed to the base member, and a cover member welded with the frame member.

Owner:SEIKO INSTR INC +1

Process and systems for peptide synthesis

ActiveUS7439222B2Reduce in quantityReduce the amount requiredBiocidePeptide/protein ingredientsCouplingCombinatorial chemistry

Owner:ROCHE PALO ALTO LLC

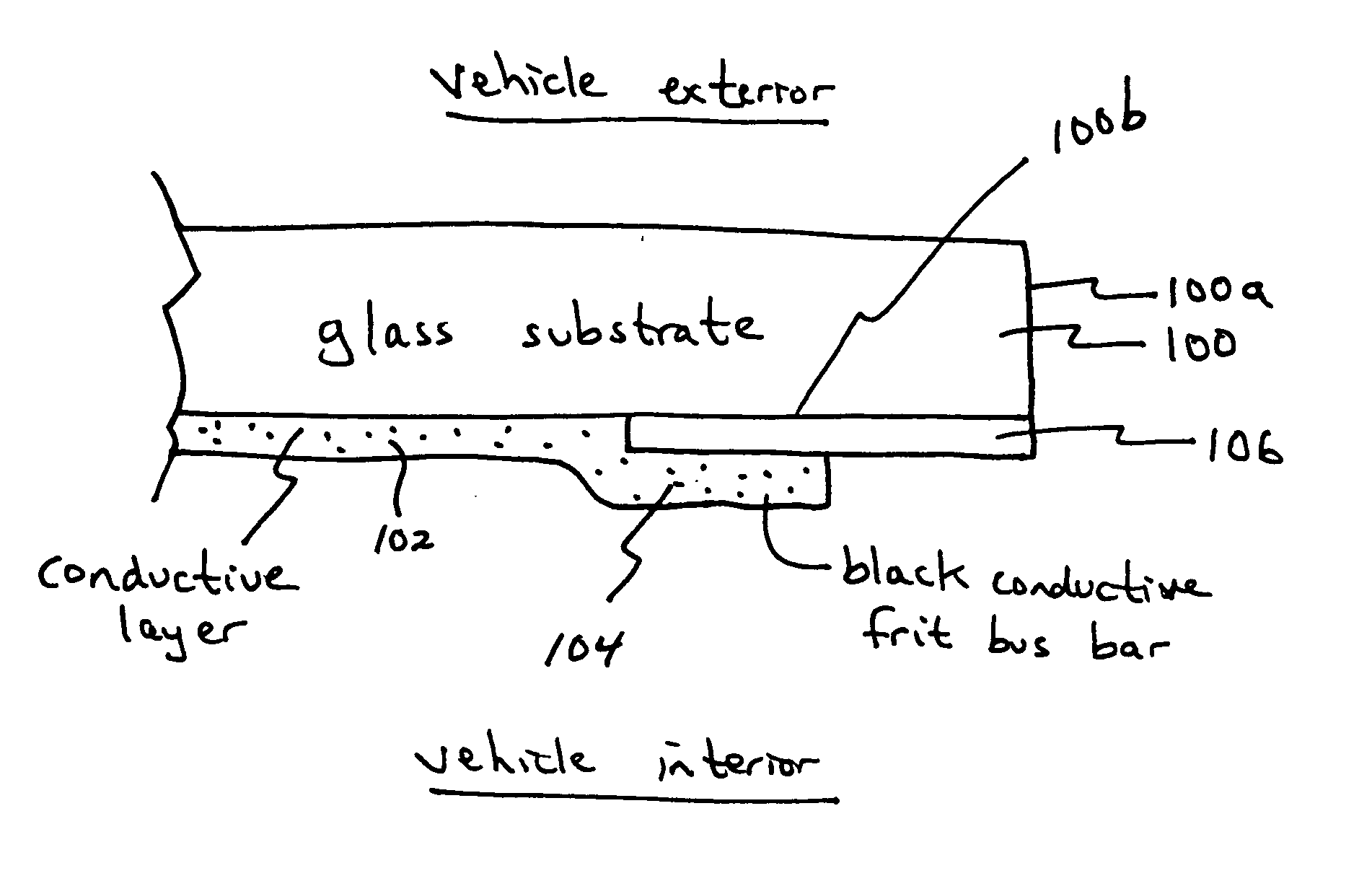

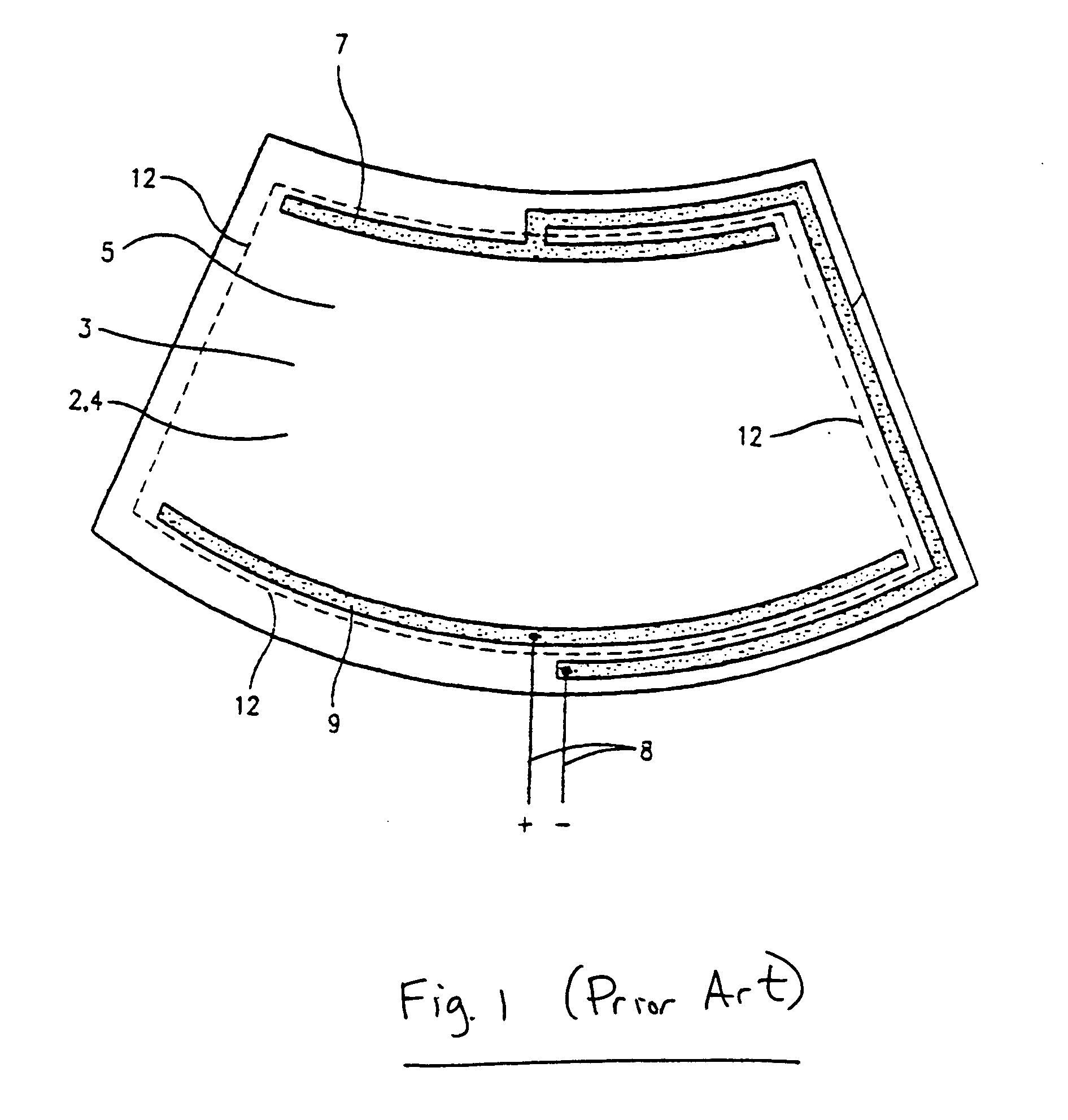

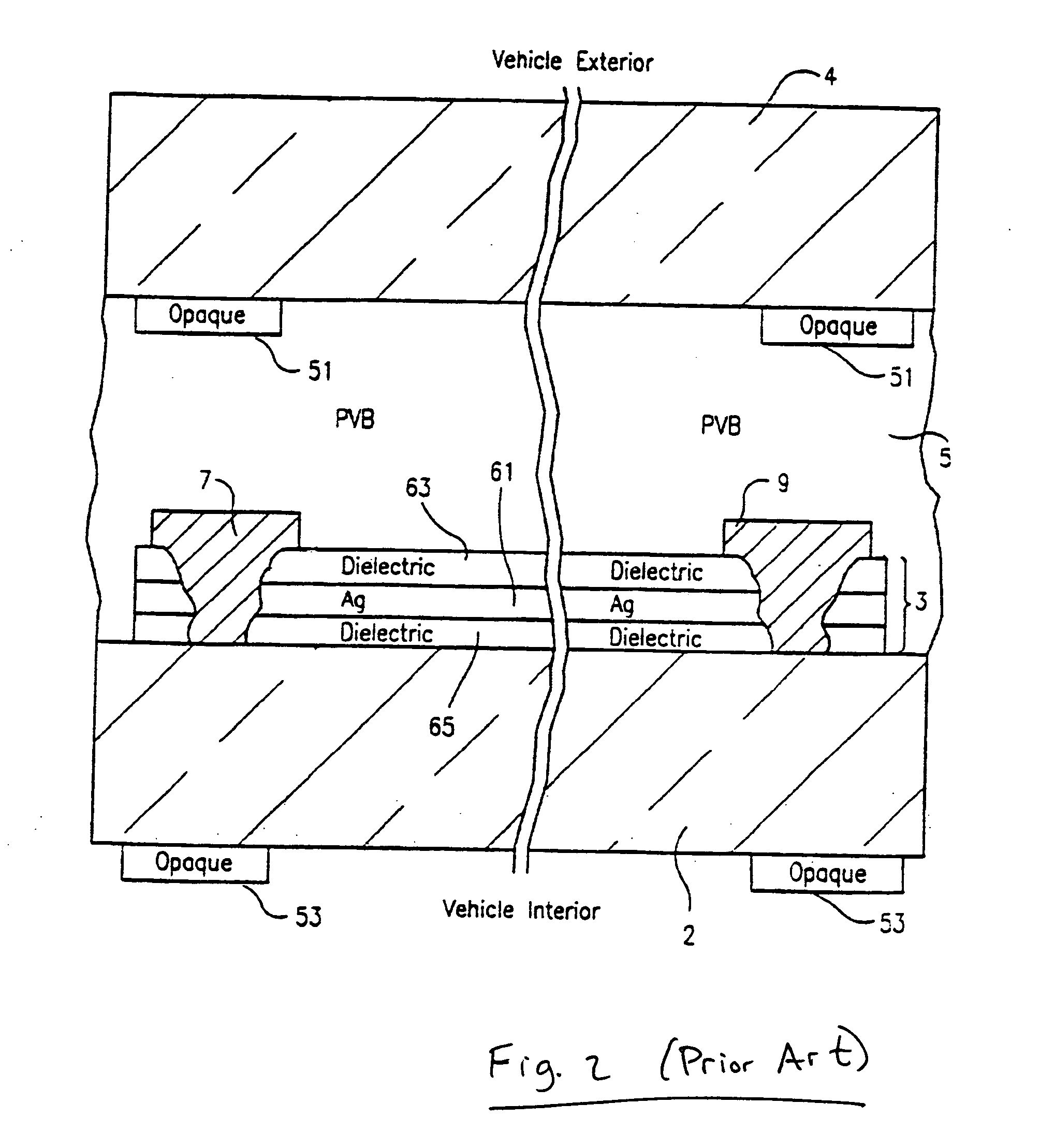

Vehicle window having bus bar(s) of conductive black frit

ActiveUS20060081581A1Eliminate process stepsEliminate processing stepsTransparent/reflecting heating arrangementsGlass/slag layered productsElectrical conductorFrit

A heatable vehicle window includes a substrate that supports a heatable conductor. The heatable conductor may be in the form of a grid of conductors, or alternatively a substantially continuous sheet. First and second conductive bus bars are electrically connected to the heatable conductor. The first and / or second bus bars are each conductive, and include black color pigment, so that the first and / or second bus bars are substantially black in color.

Owner:ACR II GLASS AMERICA INC

OFDM signal processing in a base transceiver system

ActiveUS8989088B2Significant compressionImprove communication throughputCode conversionMulti-frequency code systemsTransceiverCyclic prefix

A method and apparatus provides OFDM signal compression for transfer over serial data links in a base transceiver system (BTS) of a wireless communication network. For the uplink, an RF unit of the BTS applies OFDM cyclic prefix removal and OFDM frequency transformation of the baseband signal samples followed by frequency domain compression of the baseband signal samples, resulting from analog to digital conversion of received analog signals followed by digital downconversion, forming compressed coefficients. After transfer over the serial data link, the baseband processor applies frequency domain decompression to the compressed coefficients prior to further signal processing. For the downlink, the RF unit performs frequency domain decompression of the compressed coefficients and applies OFDM inverse frequency transformation of the decompressed coefficients and OFDM cyclic prefix insertion prior to digital upconversion and digital to analog conversion, generating the analog signal for transmission over the antenna.

Owner:INTEGRATED DEVICE TECH INC

Full scale calibration measurement for multi-touch surfaces

InactiveUS8125455B2Easy to eliminateLow costTransmission systemsCathode-ray tube indicatorsFull scaleNon-volatile memory

Normalization of regions of a sensor panel capable of detecting multi-touch events, or a sensor panel capable of detecting multi-hover events, is disclosed to enable each sensor in the sensor panel to trigger a virtual button in a similar manner, given the same amount of touch or hover. Each sensor produces an output value proportional to the level or amount of touch or hover. However, due to processing, manufacturing and physical design differences, the sensor output values can vary from region to region or panel to panel for a given amount of touch or hover. To normalize the sensor output values across regions, gain and offset information can be obtained in advance, stored in nonvolatile memory, and later used to normalize the sensor output values so that all regions in the sensor panel can trigger virtual buttons similarly, providing a uniform “response function” at any location on the sensor panel.

Owner:APPLE INC

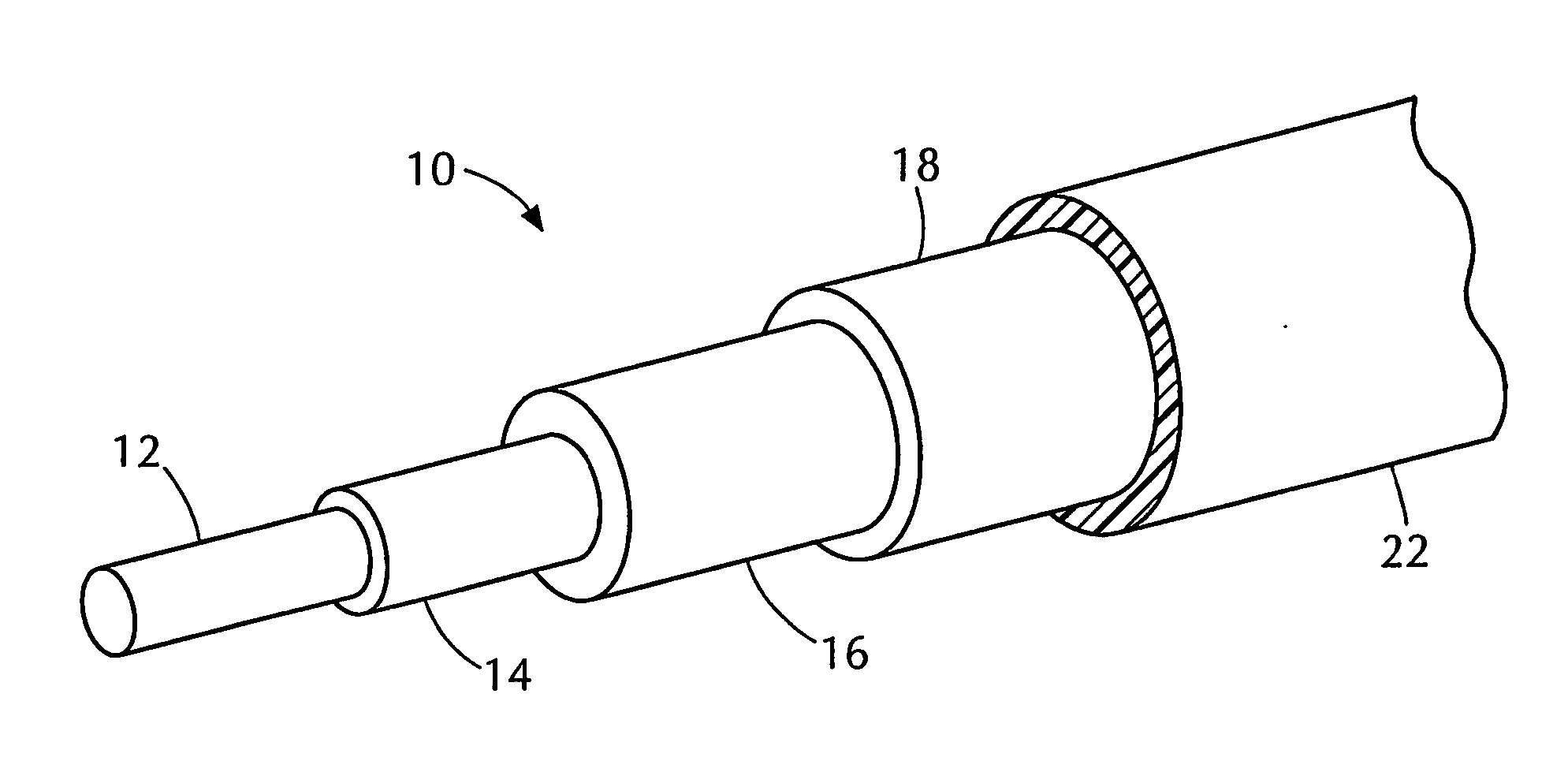

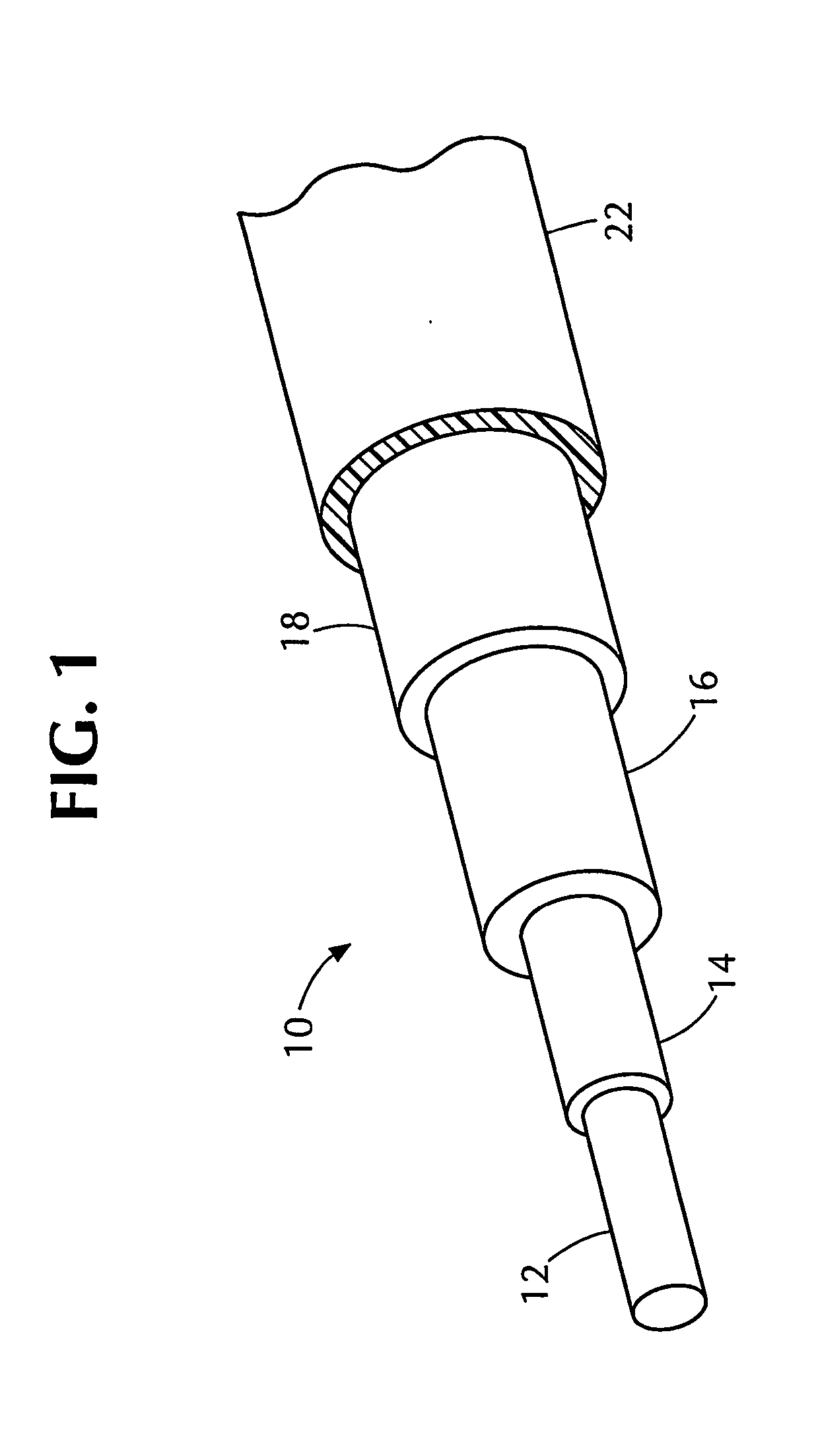

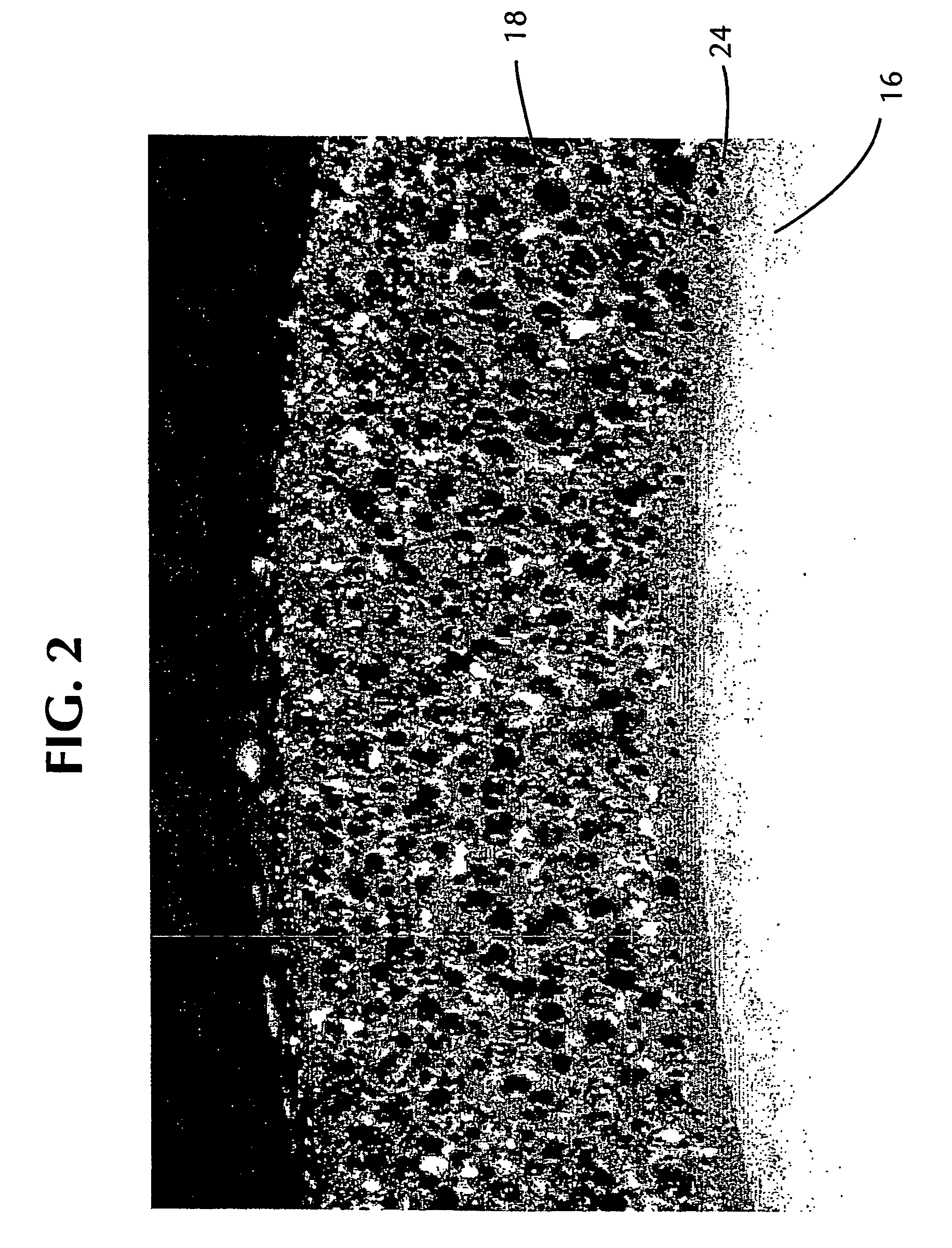

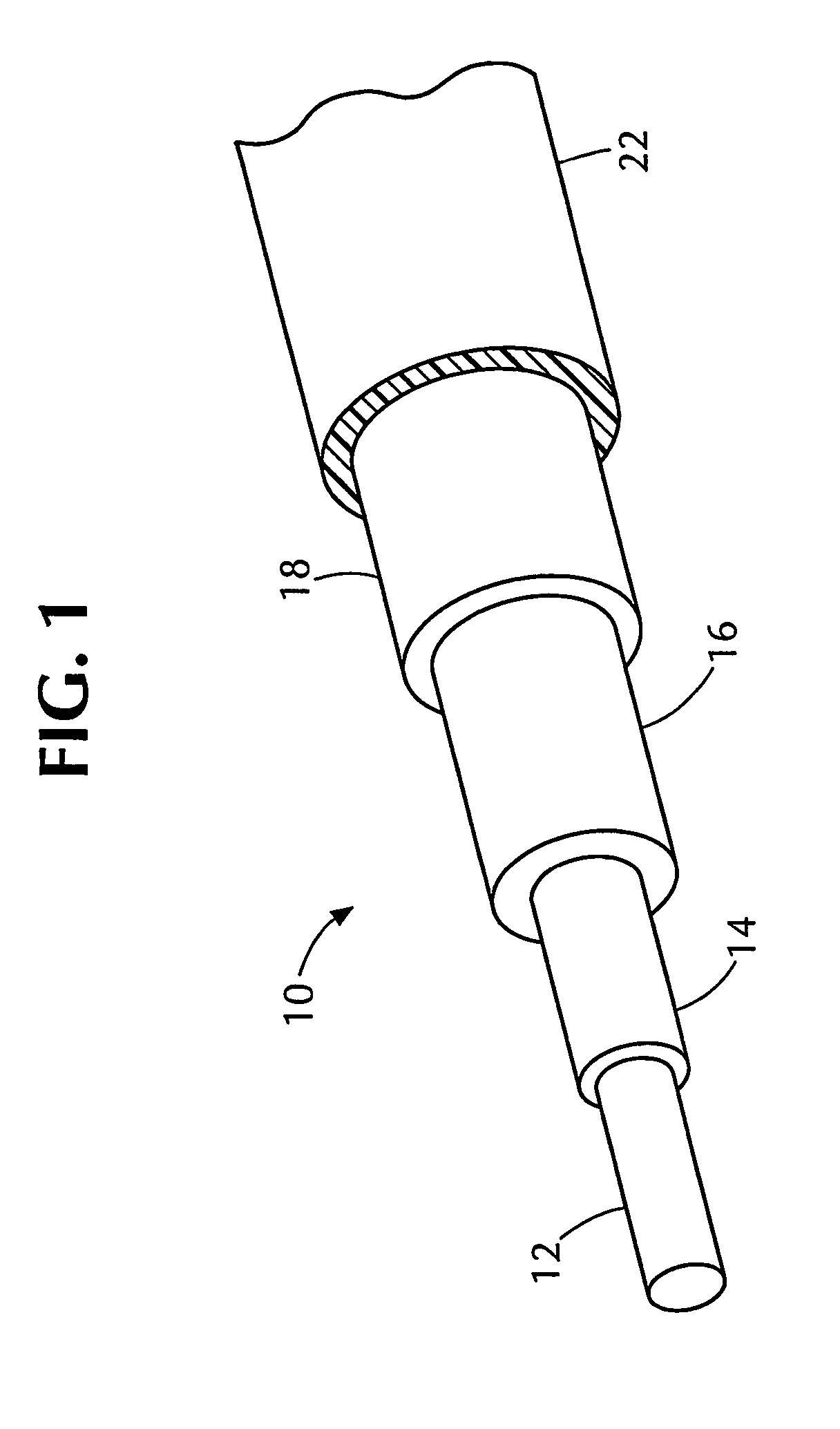

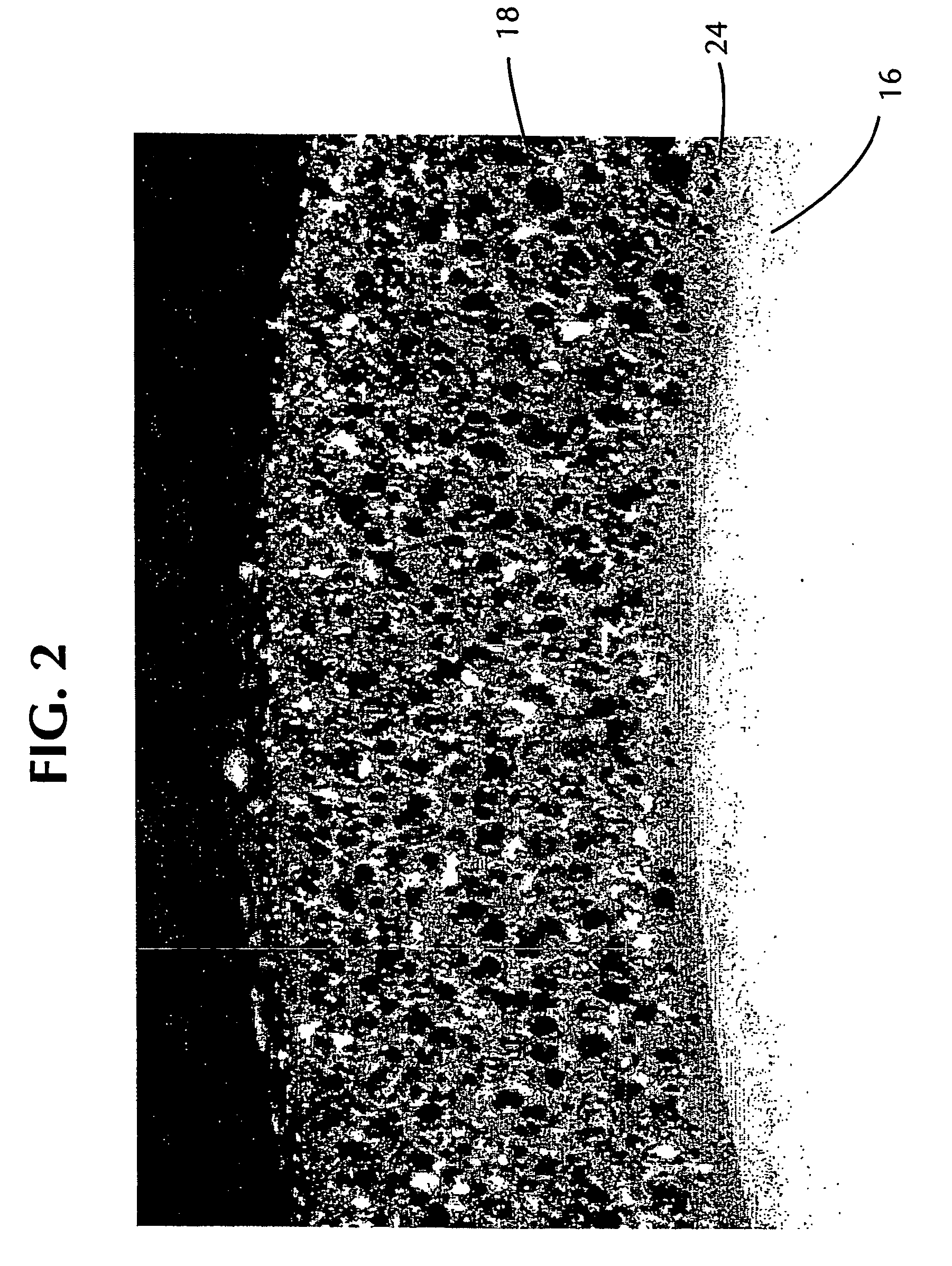

Electrical cable with foamed semiconductive insulation shield

InactiveUS20060102376A1Few voidEasy to fillConductive materialPower cables with screens/conductive layersPower cableSemiconductor

An electrical power cable with a foamed, compressible, semiconductive insulation shield which serves as both a cushioning layer and an electrical shield.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

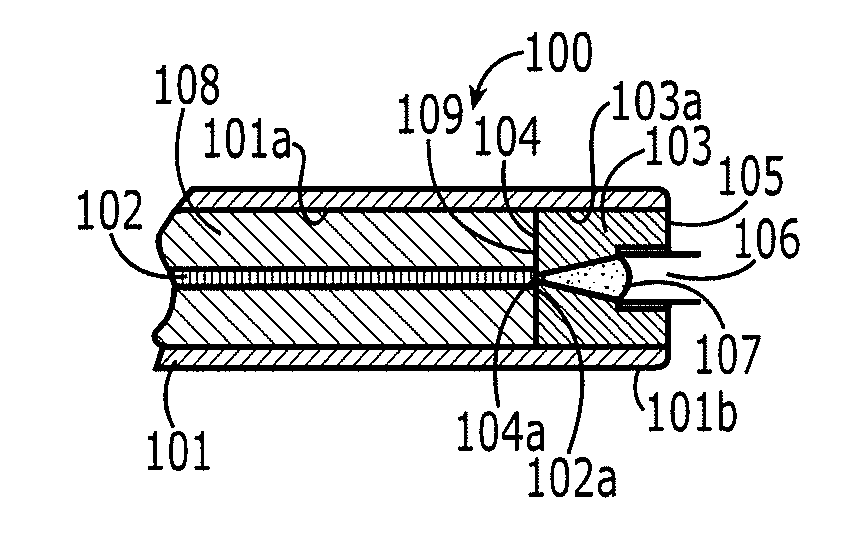

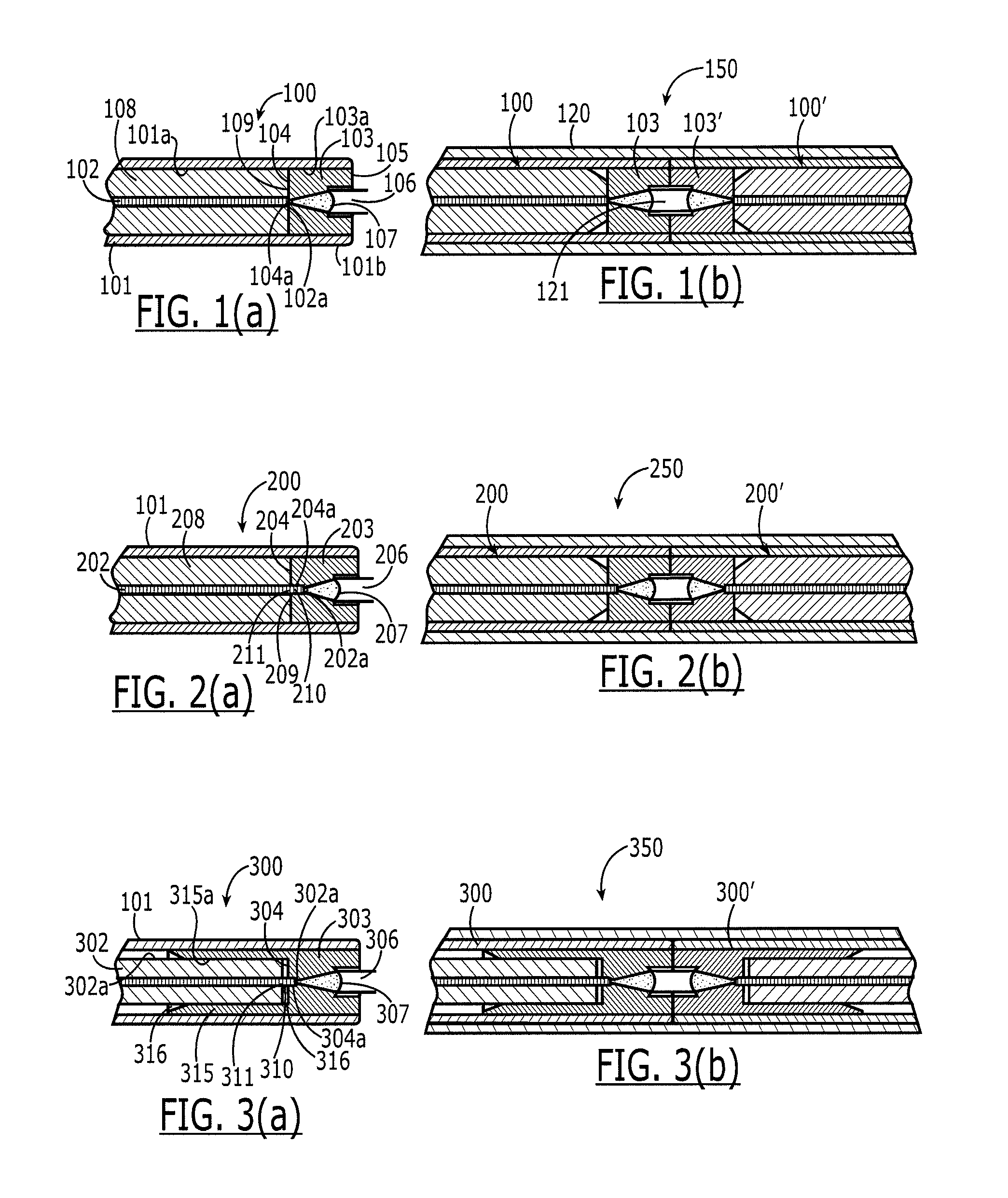

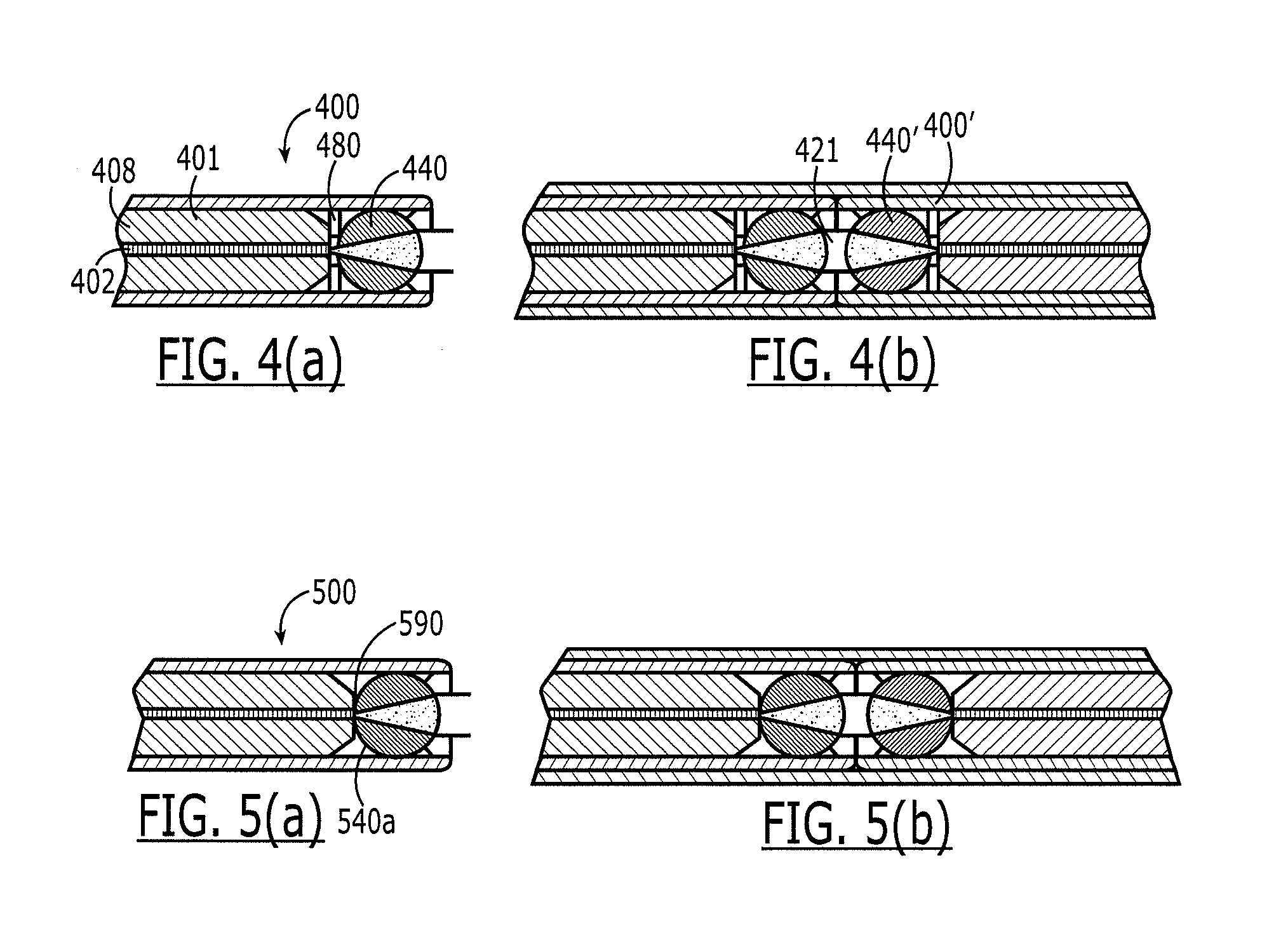

Expanded-beam connector with molded lens

ActiveUS20130322821A1Eliminate process stepsReduce back reflectionCoupling light guidesFiberRadial position

An expanded-beam connector comprising a sleeve for holding at least one fiber and one lens body, the sleeve having an interior surface having a certain geometry, a fiber having a fiber end face, and a lens body, the lens body being formed with a first face and a second face, the first and second faces being substantially planar, the first face having an interface point for optically coupling with the fiber end face, the second face having a convex surface, the interface point and the convex surface being optically coupled through the lens body, the lens body having an outer periphery at least a portion of which has the certain geometry such that the lens body is held in a precise radial position relative to the sleeve when disposed in the sleeve.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Process and systems for peptide synthesis

ActiveUS20050165217A1Reduce reagent usageLow costPeptide/protein ingredientsPeptide preparation methodsCouplingCombinatorial chemistry

The invention provides methods of synthesizing peptides, involving the steps of providing a composition including a peptide fragment, wherein the peptide fragment has at least one amino acid residue and includes a base-sensitive, N-terminal protecting group; removing the base-sensitive, N-terminal protecting group from the peptide fragment using a deprotection reagent that includes a base, whereby an N-terminal functionality on the peptide fragment is deprotected; removing the base from the composition to provide a residual base content of more than 100 ppm; causing a reactive peptide fragment having a reactive C-terminus and a base-sensitive N-terminal protecting group to react with the deprotected N-terminal functionality of the peptide fragment under conditions such that the reactive peptide fragment is added to the peptide fragment; and optionally repeating the deprotection and coupling steps until a desired peptide is obtained. Also provided are methods of synthesizing peptides, wherein base is removed from the composition to a point where the composition would provide a positive chloranil test. Also provided are methods of synthesizing peptides, wherein coupling is performed in basic reaction mixtures.

Owner:ROCHE PALO ALTO LLC

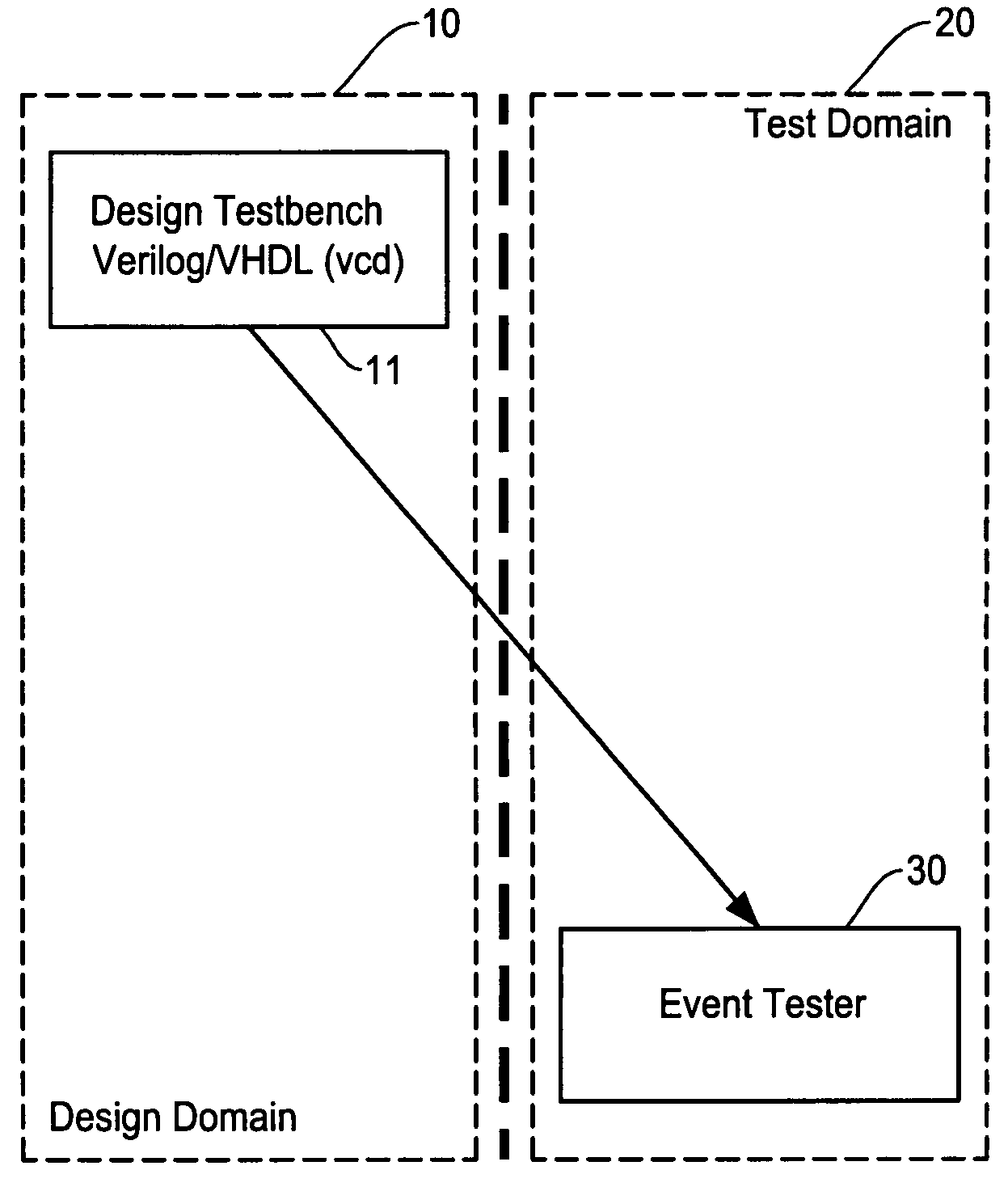

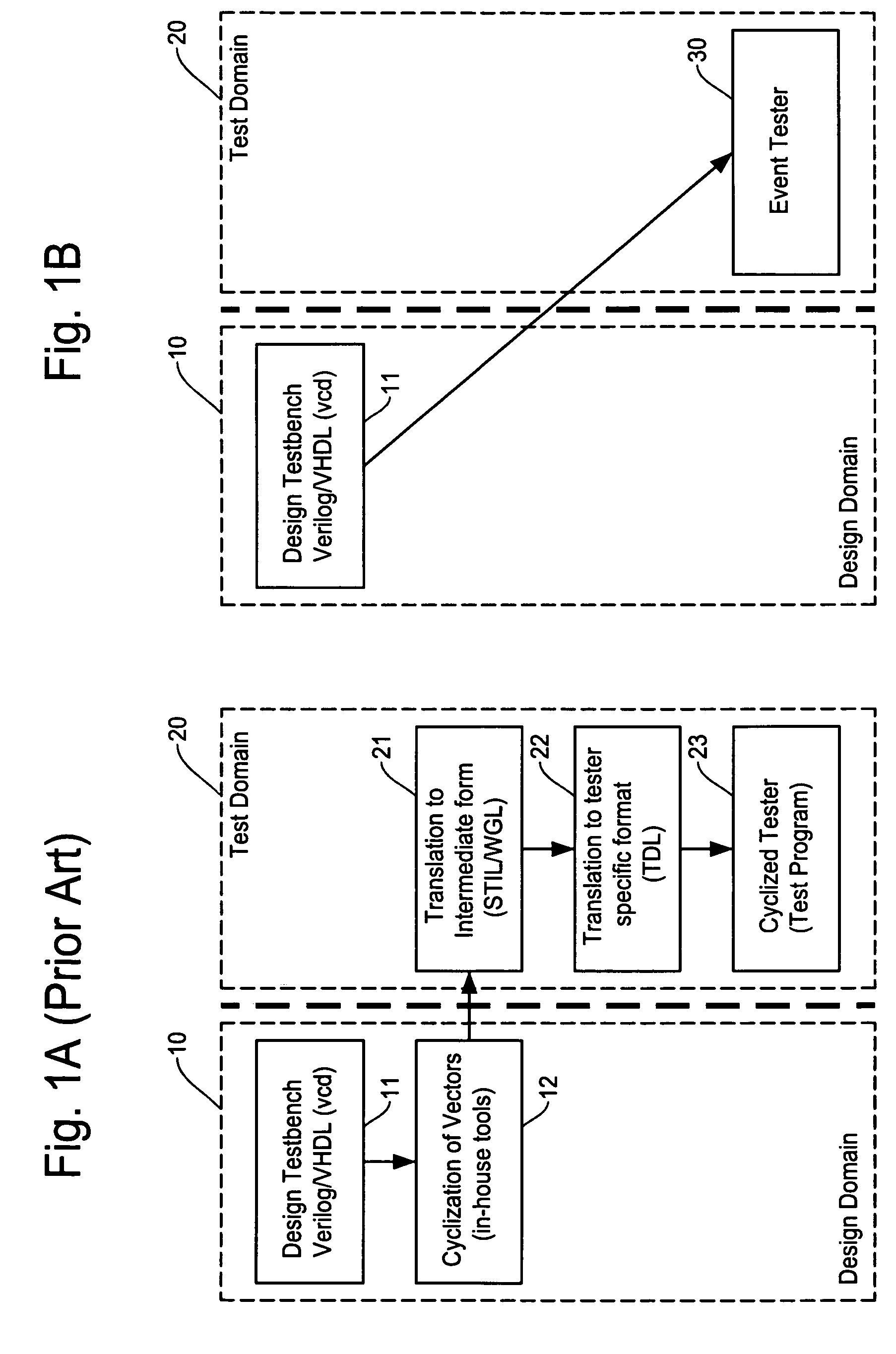

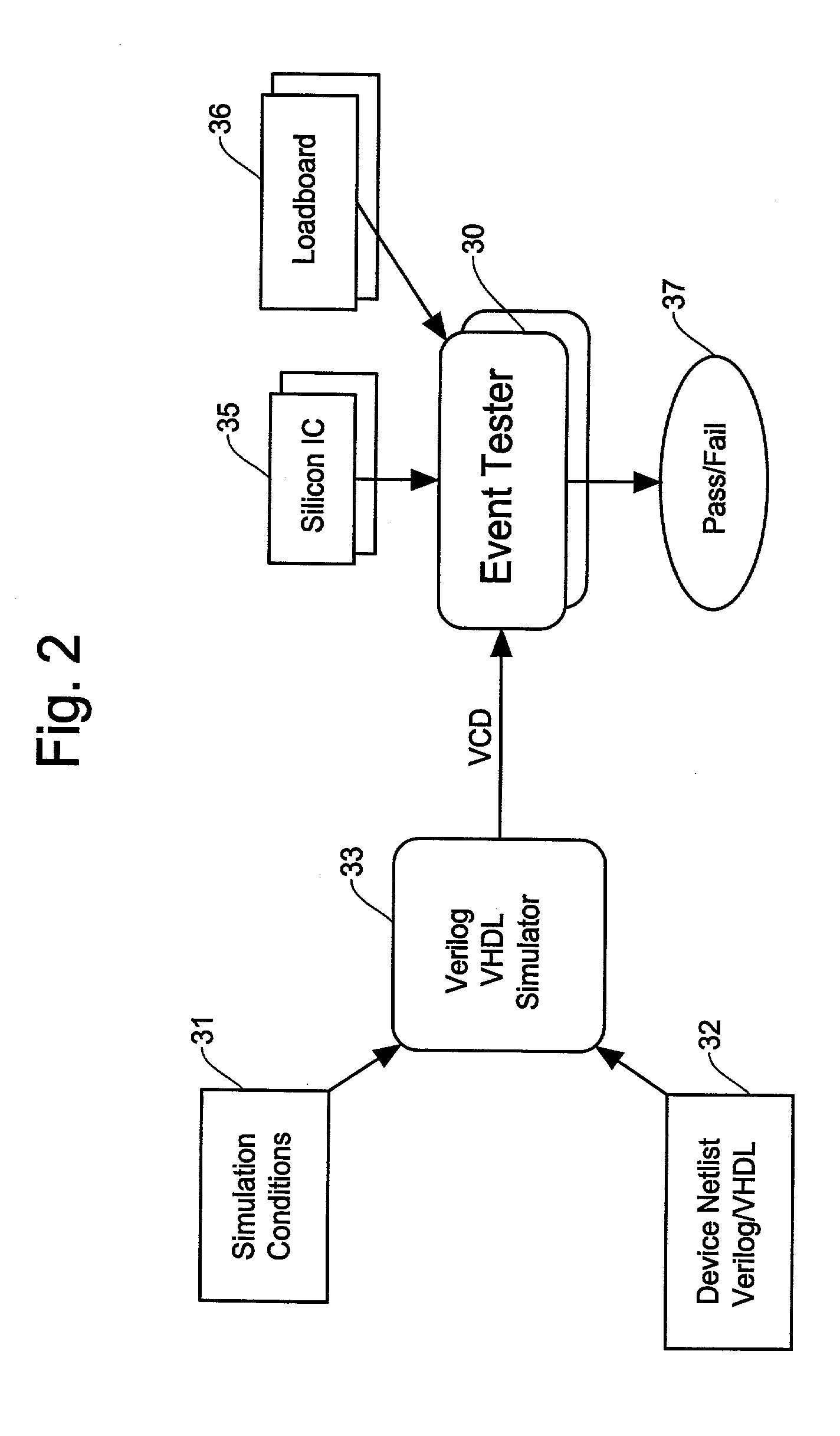

Event based IC test system

InactiveUS7089135B2Low costShorten the timeDigital circuit testingResistance/reactance/impedenceEvent typeEvent data

An event based test system for testing an IC device under test (DUT) designed under an automatic electronic design (EDA) environment. The event based test system includes an event memory for storing event data derived directly from simulation of design data for an intended IC in the EDA environment where the event data to denote each event is formed with time index indicating a time length from a predetermined point and an event type indicating a type of change at an event, an event generation unit for generating test vectors based on the event data where waveform of each vector is determined by the event type and a timing of the waveform is determined by accumulating the time index of previous events, and means for supplying test vectors to the DUT and evaluating response outputs of the DUT at predetermined timings.

Owner:ADVANTEST CORP

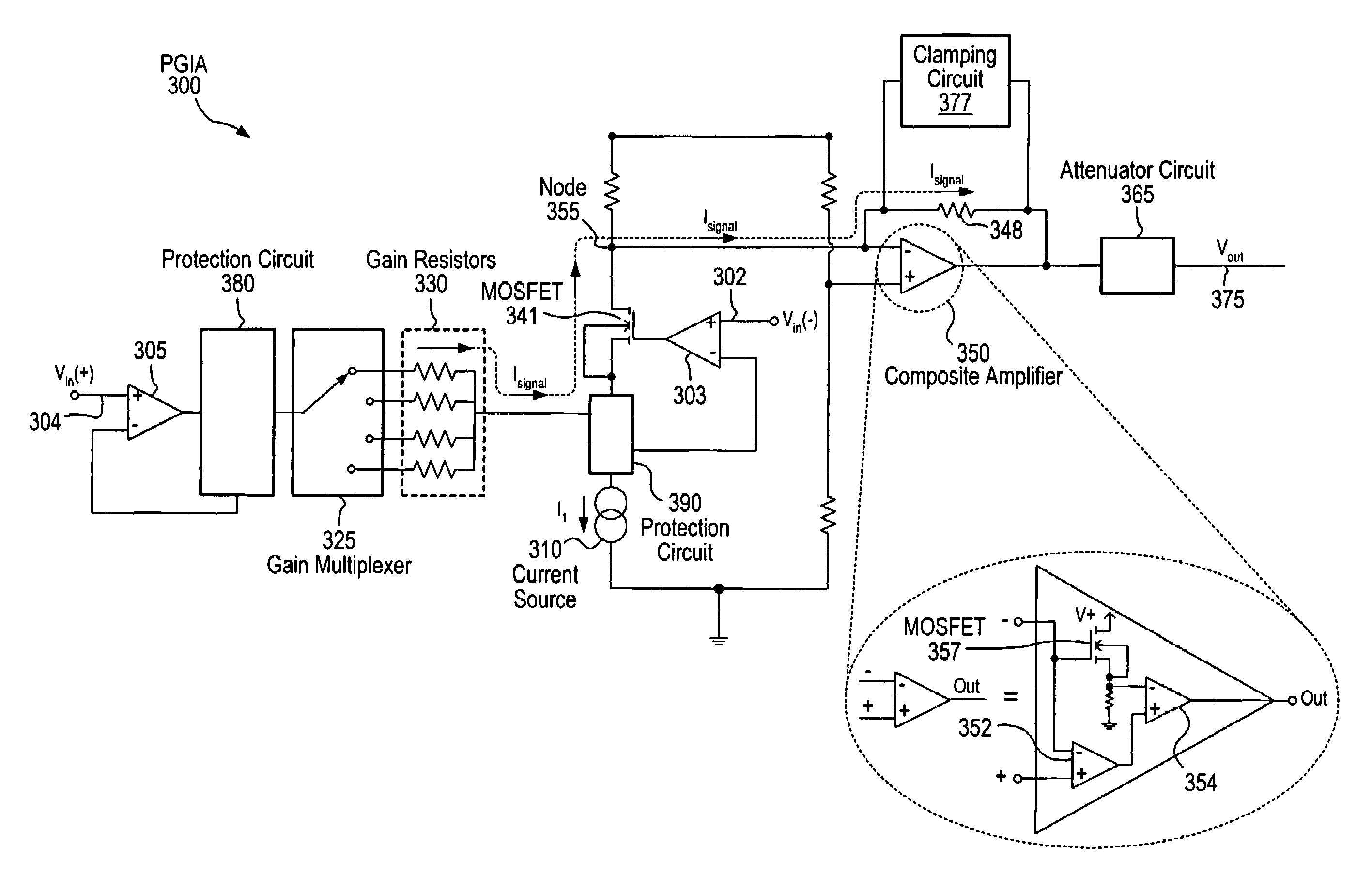

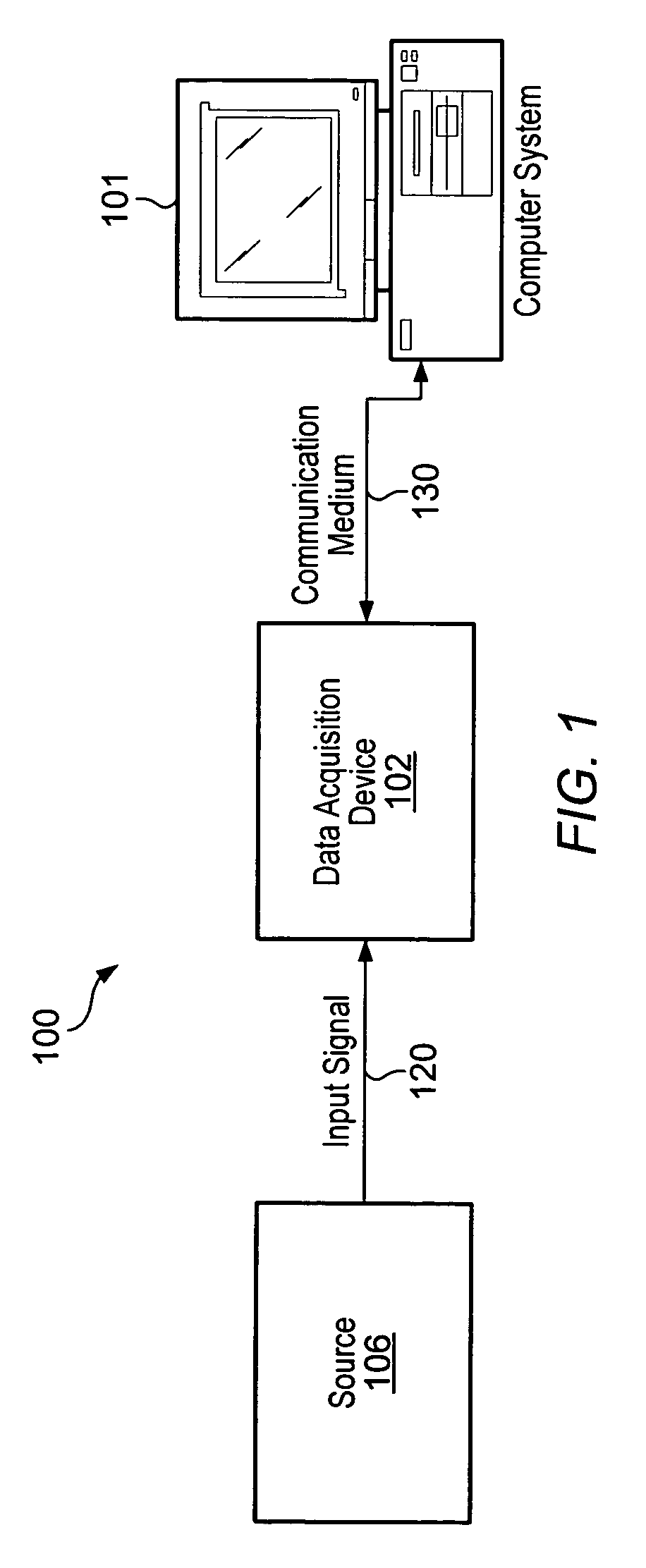

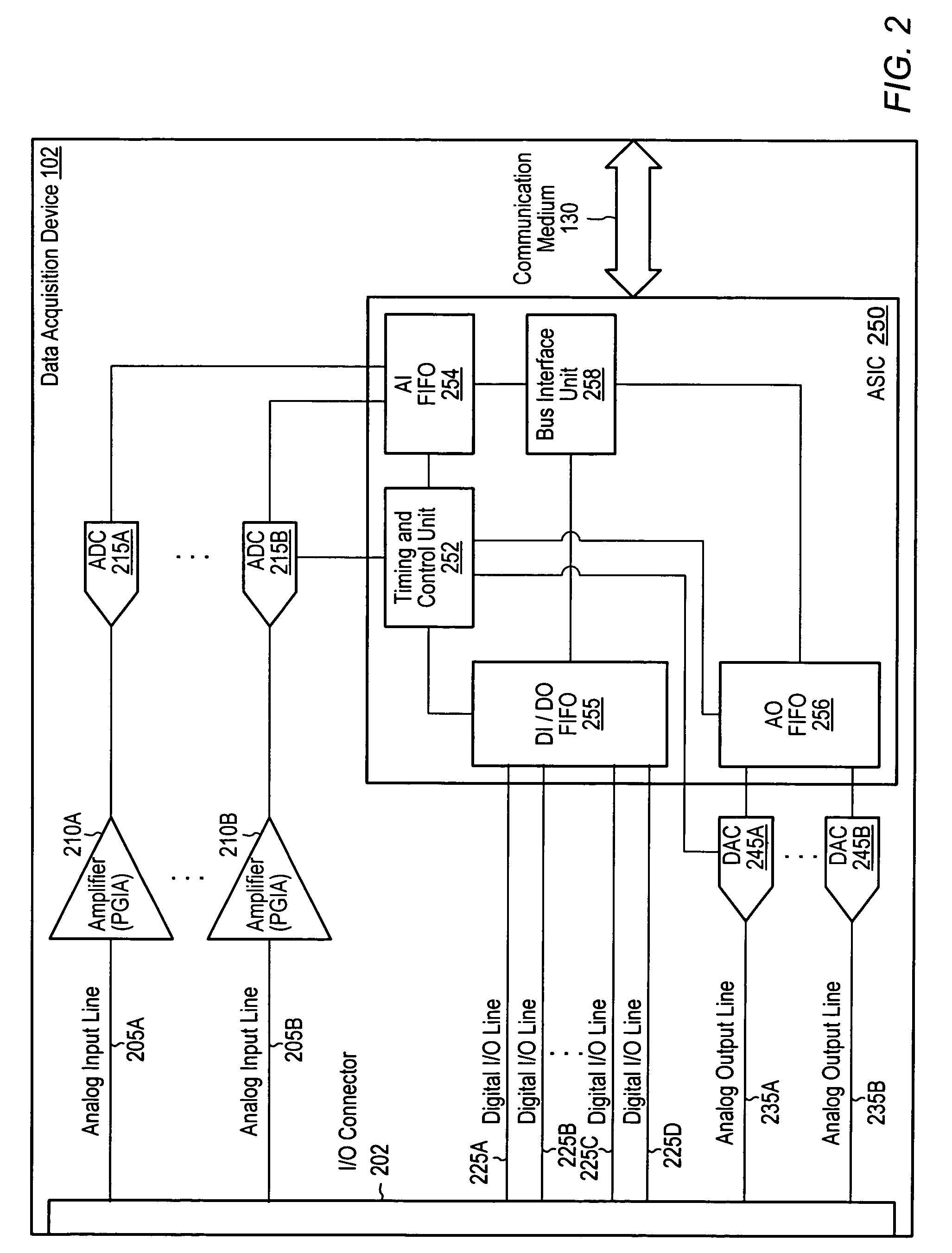

Programmable gain instrumentation amplifier including a composite amplifier for level shifting and improved signal-to-noise ratio

ActiveUS7183854B2Raise the ratioEliminate processing stepsGain controlDifferential amplifiersLevel shiftingInstrumentation amplifier

A PGIA for use in measurement devices (e.g., data acquisition device) including a composite amplifier for level shifting and improved signal-to-noise ratio. The composite amplifier may level shift from a constant common mode voltage to a lower common mode voltage with a large voltage swing. The large output signal swing of the PGIA may allow excellent signal-to-noise ratio. Additionally, input op-amps of the PGIA may be bootstrapped so that their supply rails move according to an input signal of the PGIA. The PGIA may also include protection circuitry to protect components from damage, e.g., due to over-current conditions, and to keep all op-amps in proper closed loop operation. Furthermore, the PGIA may include DA compensation circuitry to cancel some dielectric absorptions effects and improve a step response of the PGIA and CMRR enhancement circuitry to increase symmetry at inputs of the PGIA and improve a CMRR associated with the PGIA.

Owner:NATIONAL INSTRUMENTS

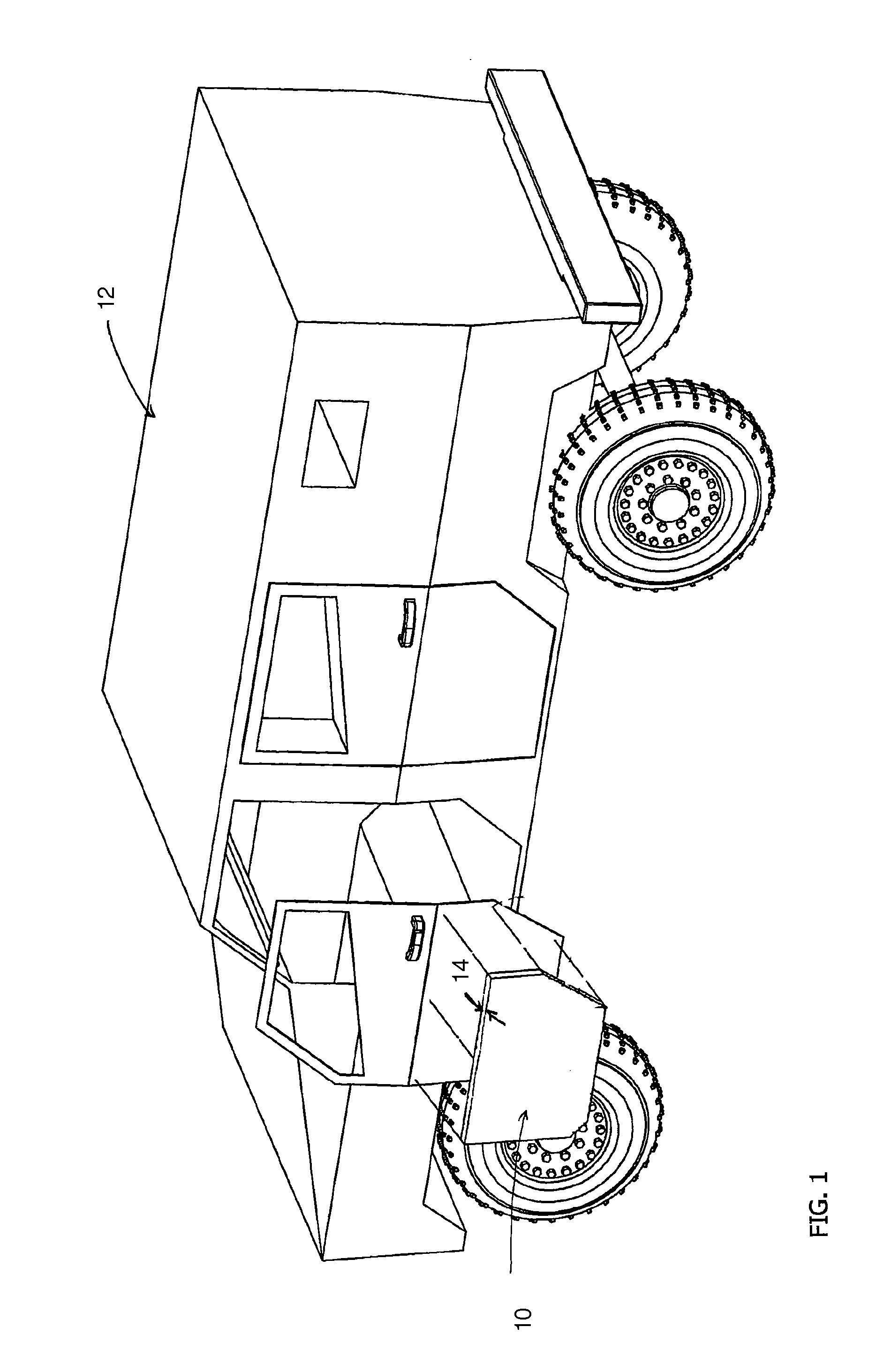

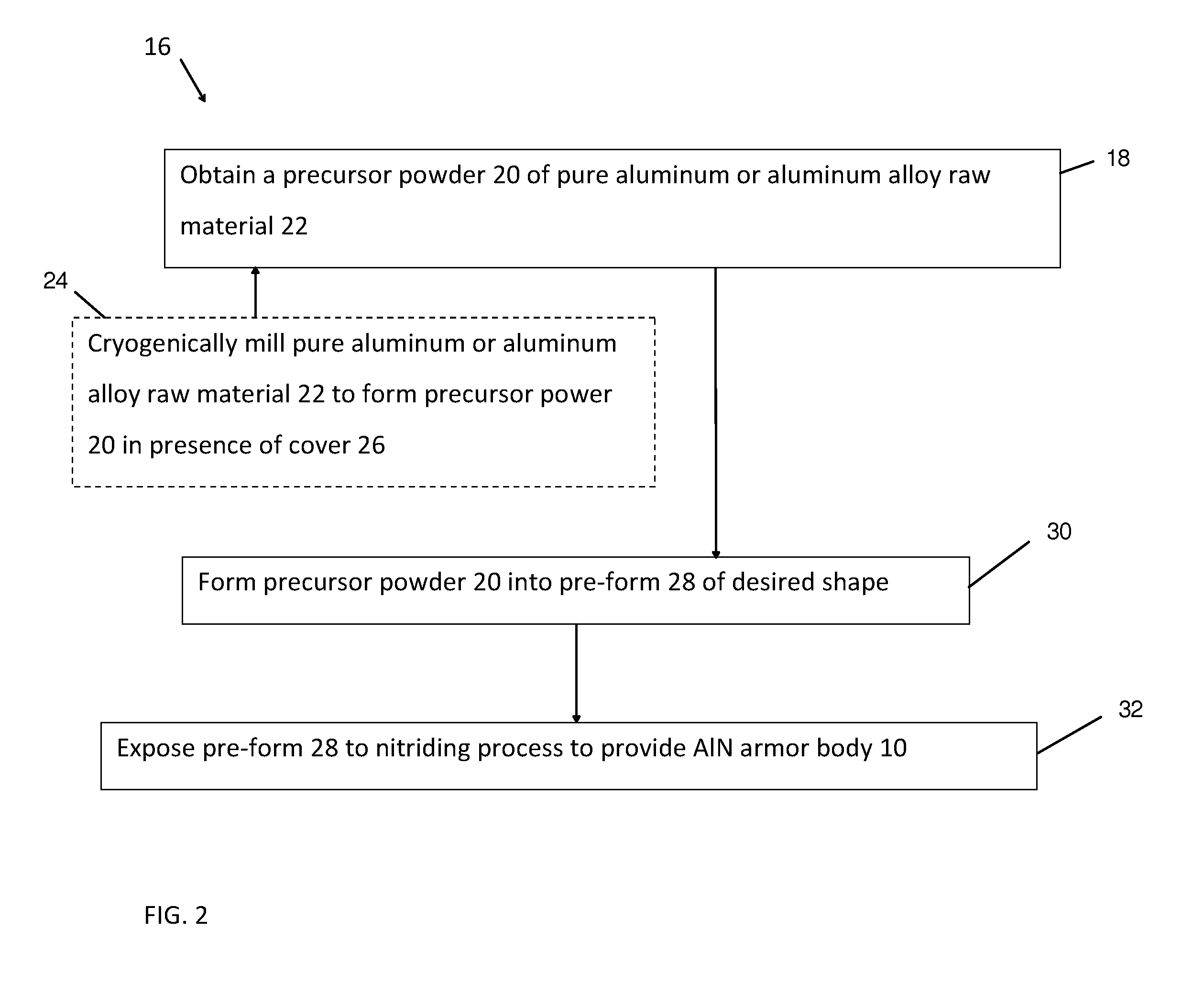

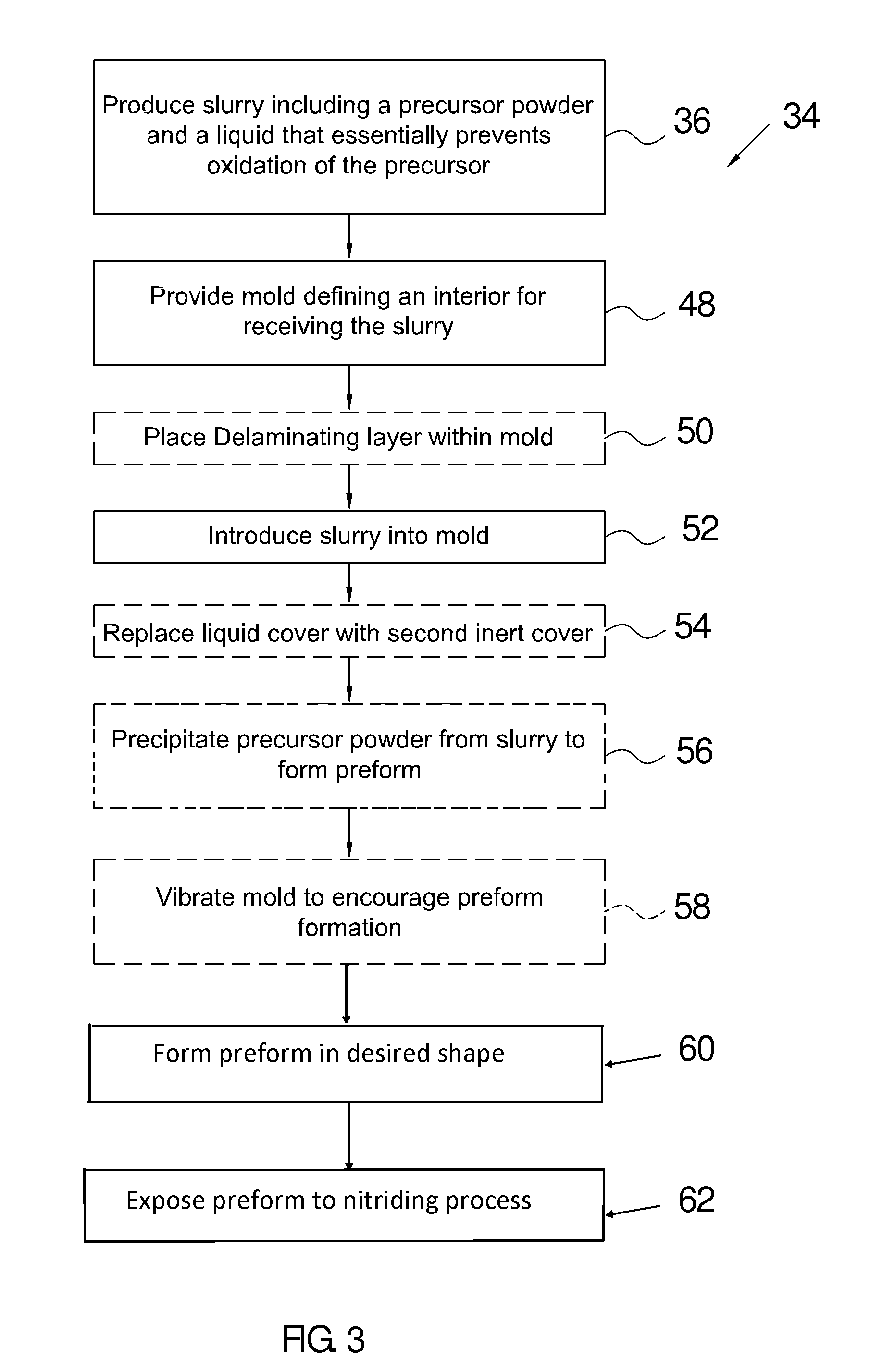

Methods for making aluminum nitride armor bodies

InactiveUS20120263620A1Lower liquid temperatureFast consumptionSolid state diffusion coatingArmour platesShell moldingResidence time

A method of making aluminum nitride armor bodies is provided. The method starts with low cost bulk raw material, in the form of aluminum or aluminum alloy, cryogenically mills the raw material into a precursor powder, which is essentially free of oxides and other undesirable impurities. The precursor powder is formed into a pre-form using low cost, short residence time molding processes. Finally, the pre-form is exposed to a nitriding process to convert the pre-form into the aluminum nitride armor body. In this manner, the method avoids the use of high cost aluminum nitride as a starting material and avoids the need for the high cost, single axis densification processes of the prior art.

Owner:SCHOTT CORP

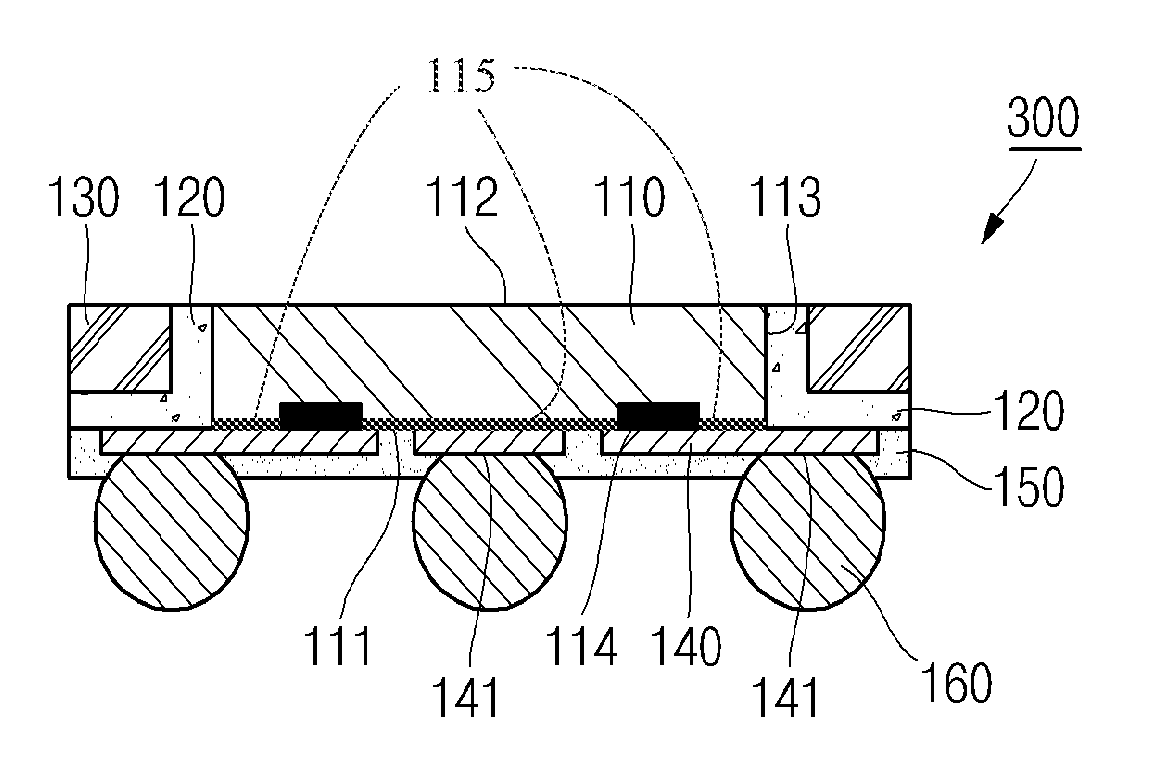

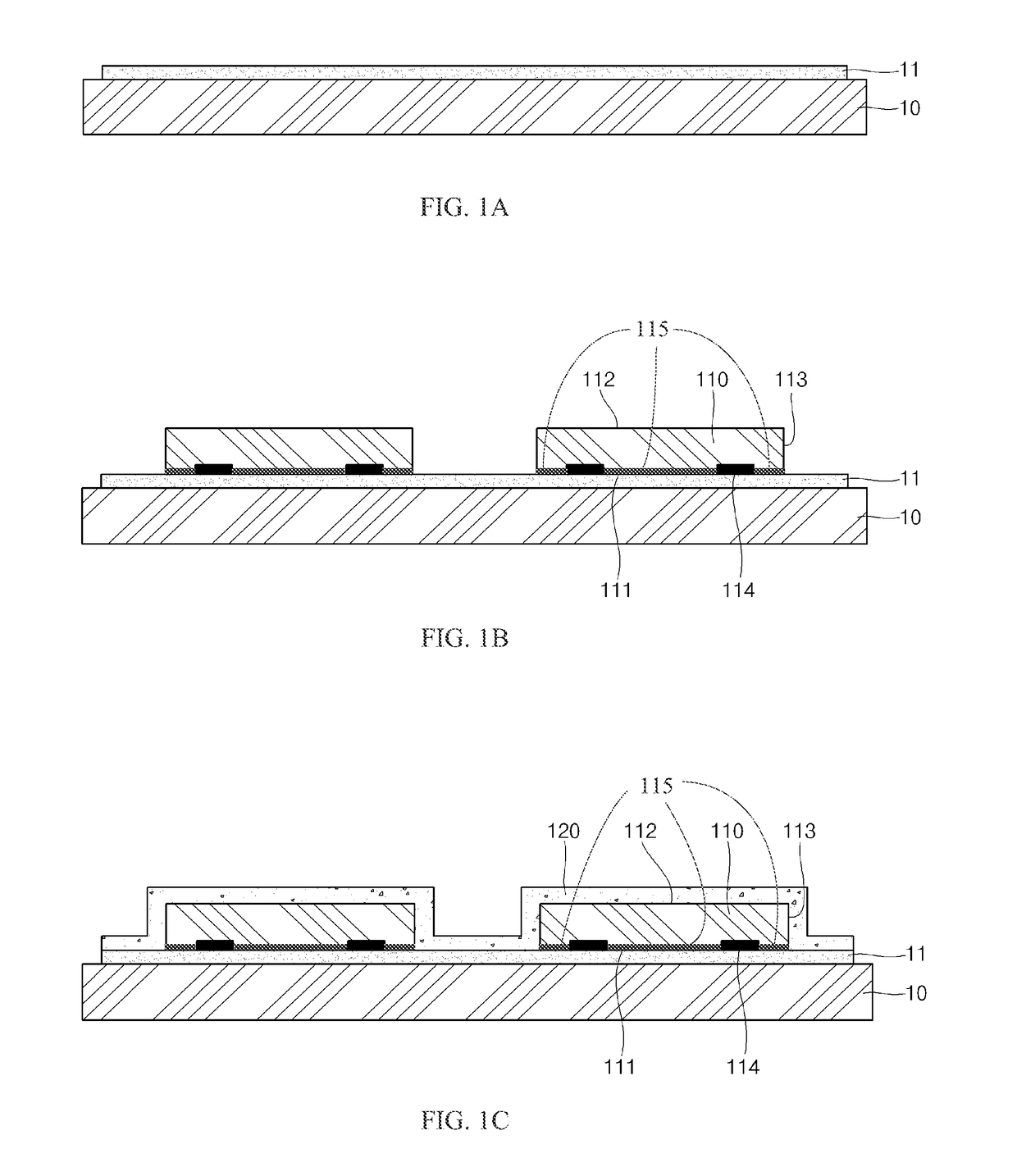

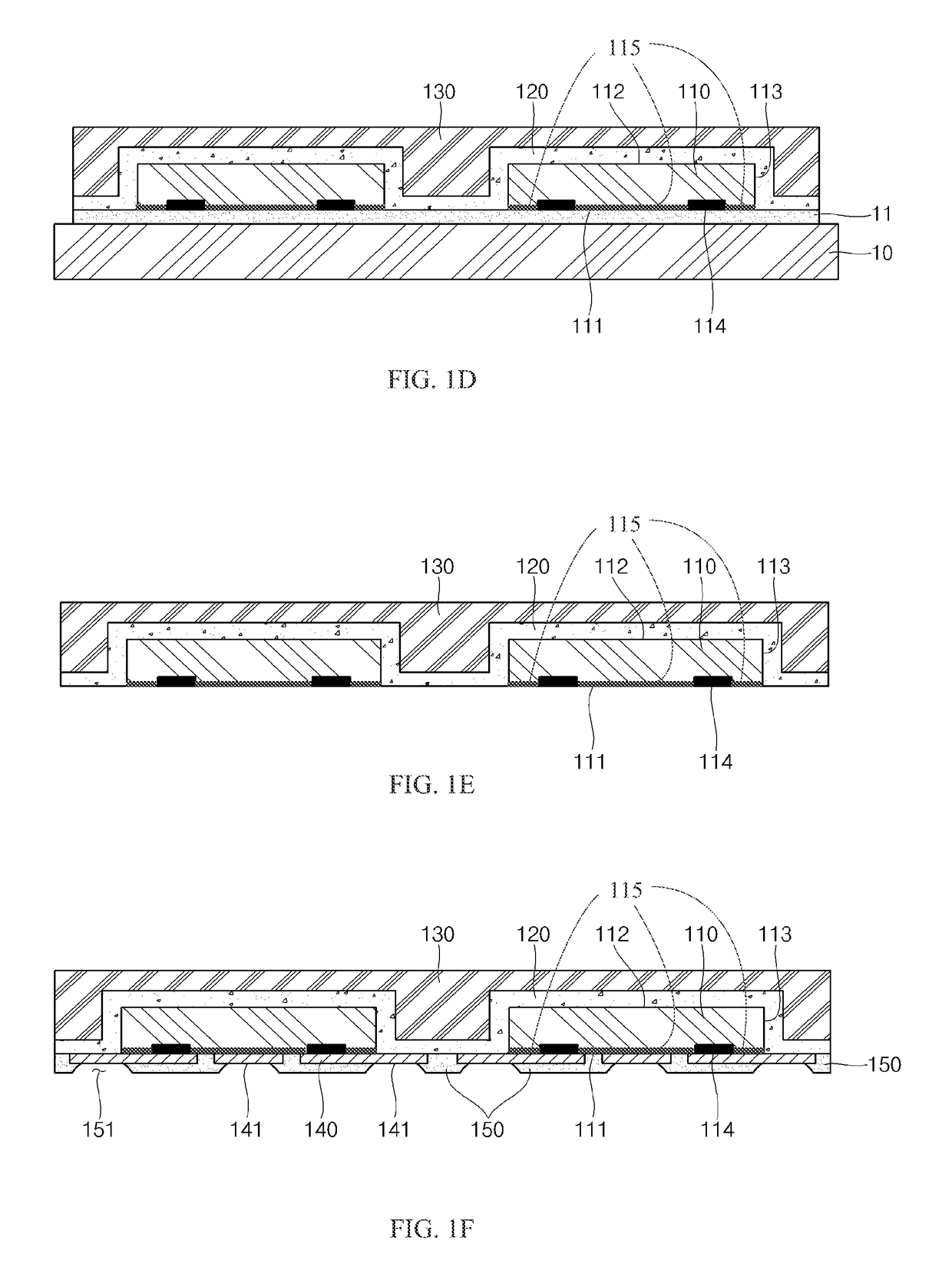

Semiconductor device and manufacturing method thereof

InactiveUS20170133334A1Reduce in quantityReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesDielectric layerSemiconductor

A semiconductor device and a manufacturing method thereof, which can reduce a number of manufacturing processes and / or can reduce a thickness of the semiconductor device. As a non-limiting example, various aspects of this disclosure provide for the elimination process steps and / or a reduction in package size based on dielectric layer characteristics.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

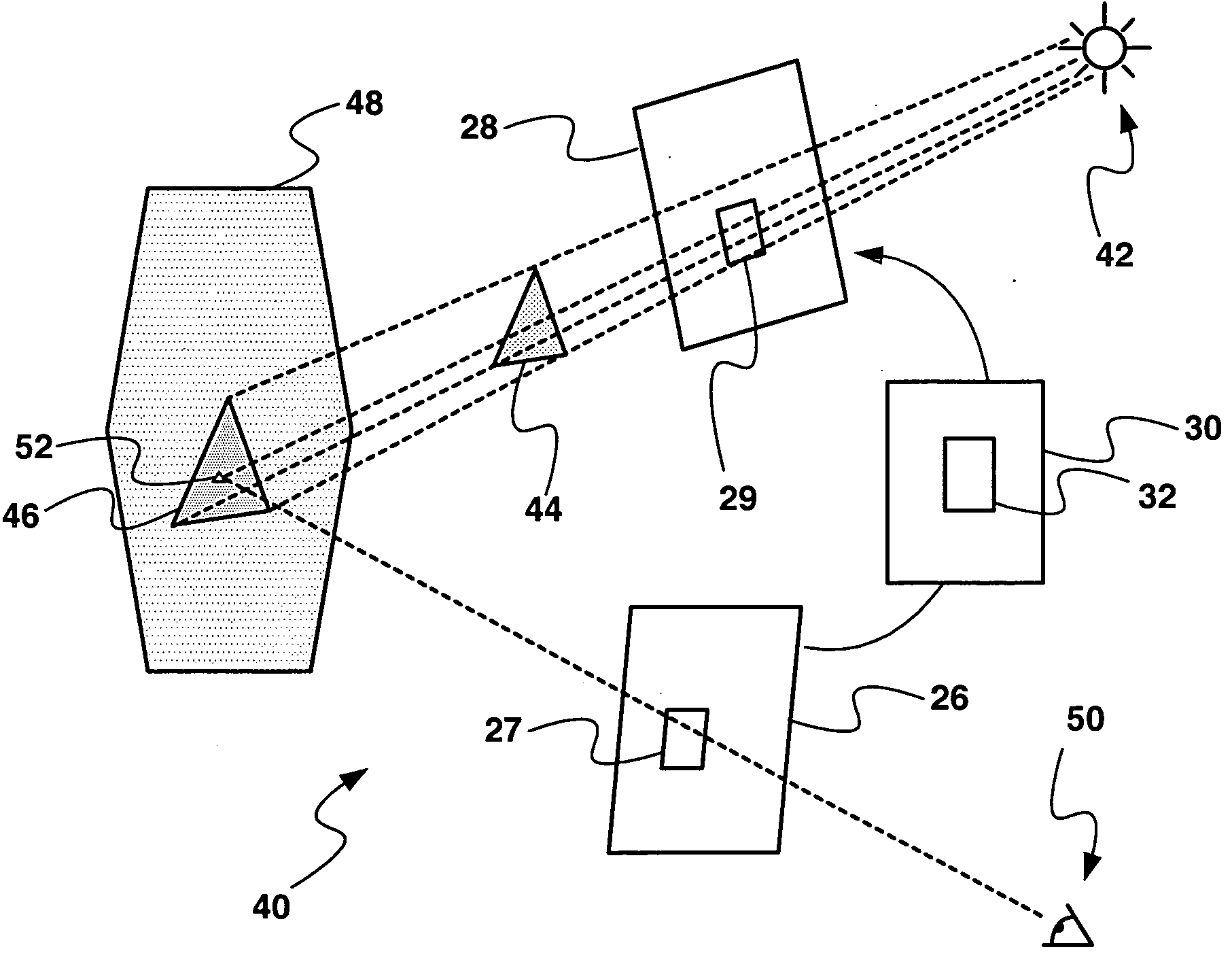

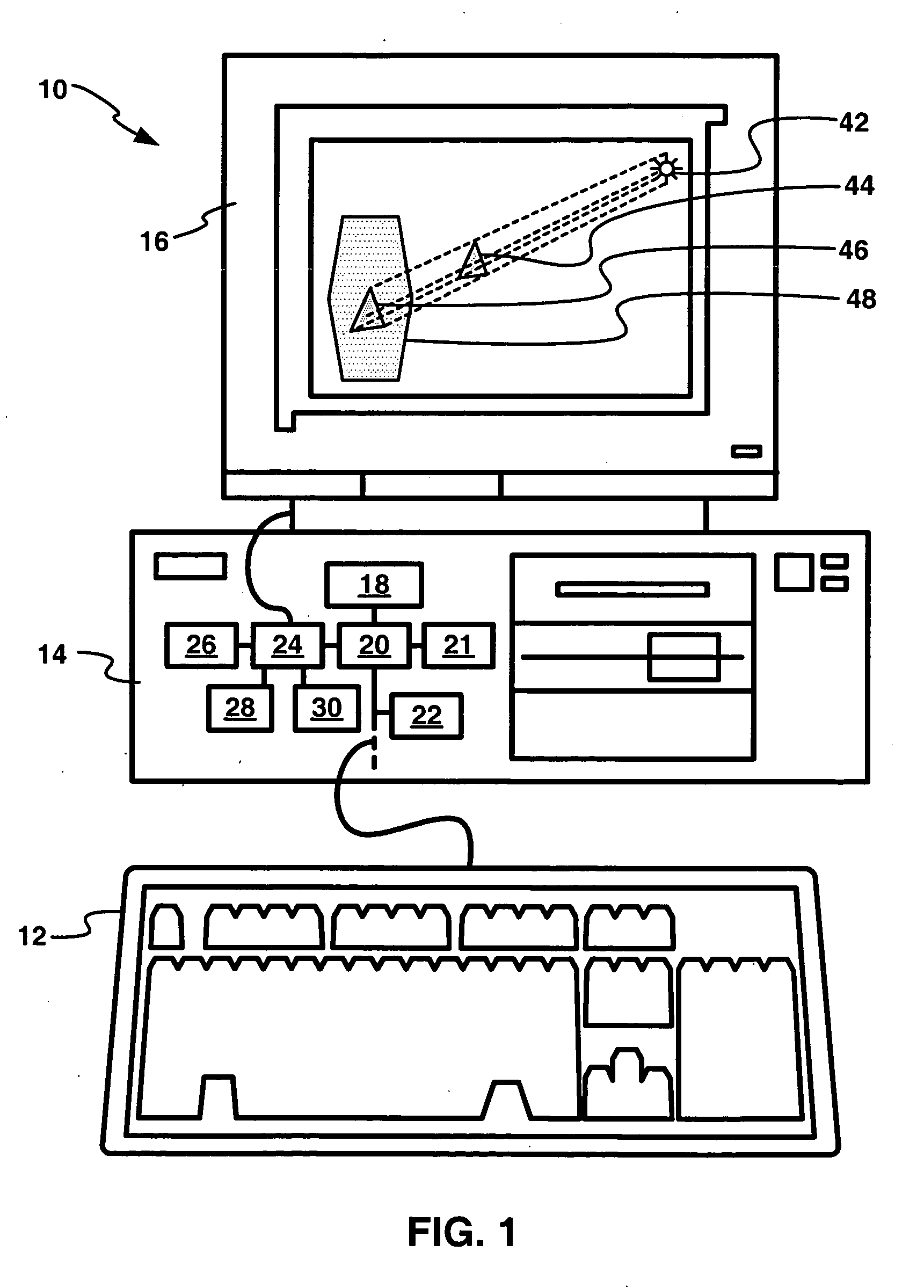

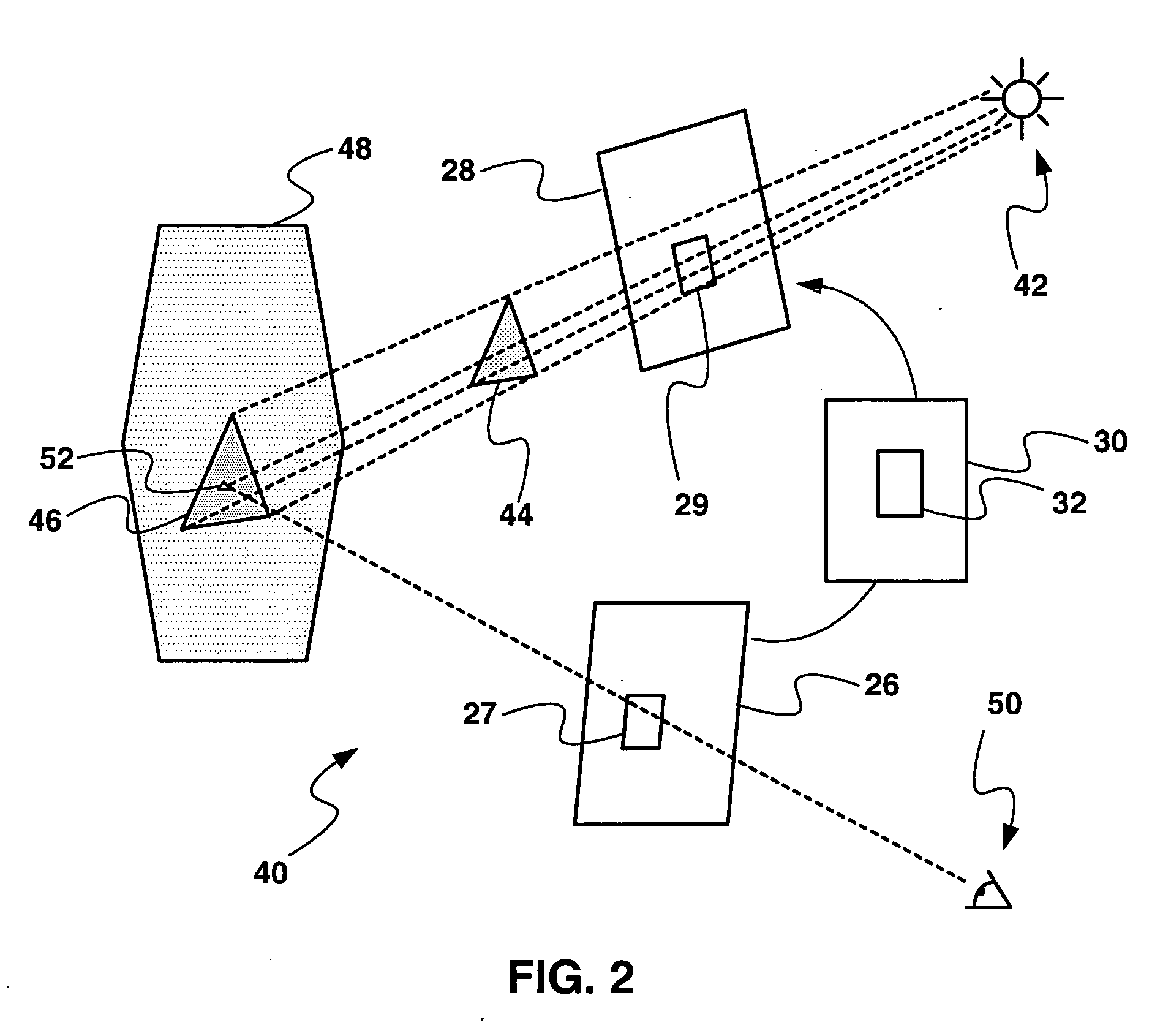

System and method for shadow rendering

InactiveUS20050017974A1Latency and needed storage capacityReduce processing time3D-image renderingDisplay device3D computer graphics

A system and method for providing shadow information for 3D computer graphics objects on a display for a graphic computer system are disclosed. The 3D objects are processed only once and the rendering and shadow generation information is stored in memory. In a subsequent two-dimensional pass, the shadow information is used to provide the color value at each rendered pixel. Thus, the latency and the need for storage capacity due to the multiple 3D pass processing are eliminated.

Owner:S3 GRAPHICS

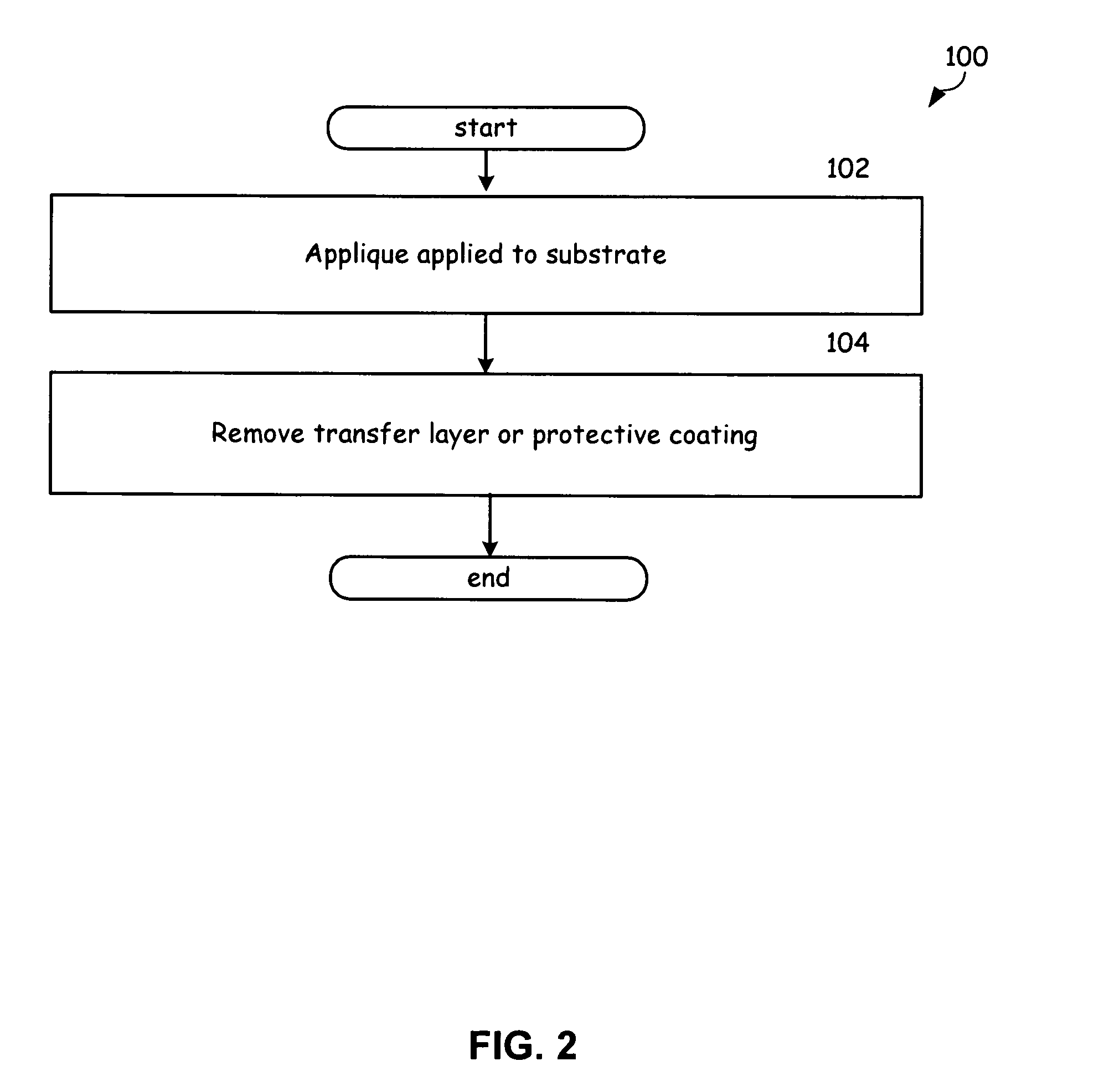

Applique system with anti-corrosion adhesive

InactiveUS20100062250A1Enhance corrosion protection capabilityCorrosion inhibiting additives reduce or eliminateLamination ancillary operationsDecorative surface effectsPressure sensitiveToxicity

An appliqué having anti-corrosive adhesive is provided by embodiments of the present invention. This appliqué includes a thin polymer film and a pressure sensitive adhesive. The pressure sensitive adhesive backs the thin polymer film and includes corrosion-inhibiting additives. These corrosion-inhibiting additives reduce or eliminate the need for a chromated primer layer beneath the appliqué. Elimination of a chromated primer layer has environmental advantages as well as cost benefits through the elimination of a processing step. Additionally, environmental benefits are realized by eliminating the toxic effects often associated with the use of chromated primers.

Owner:LOCKHEED MARTIN CORP

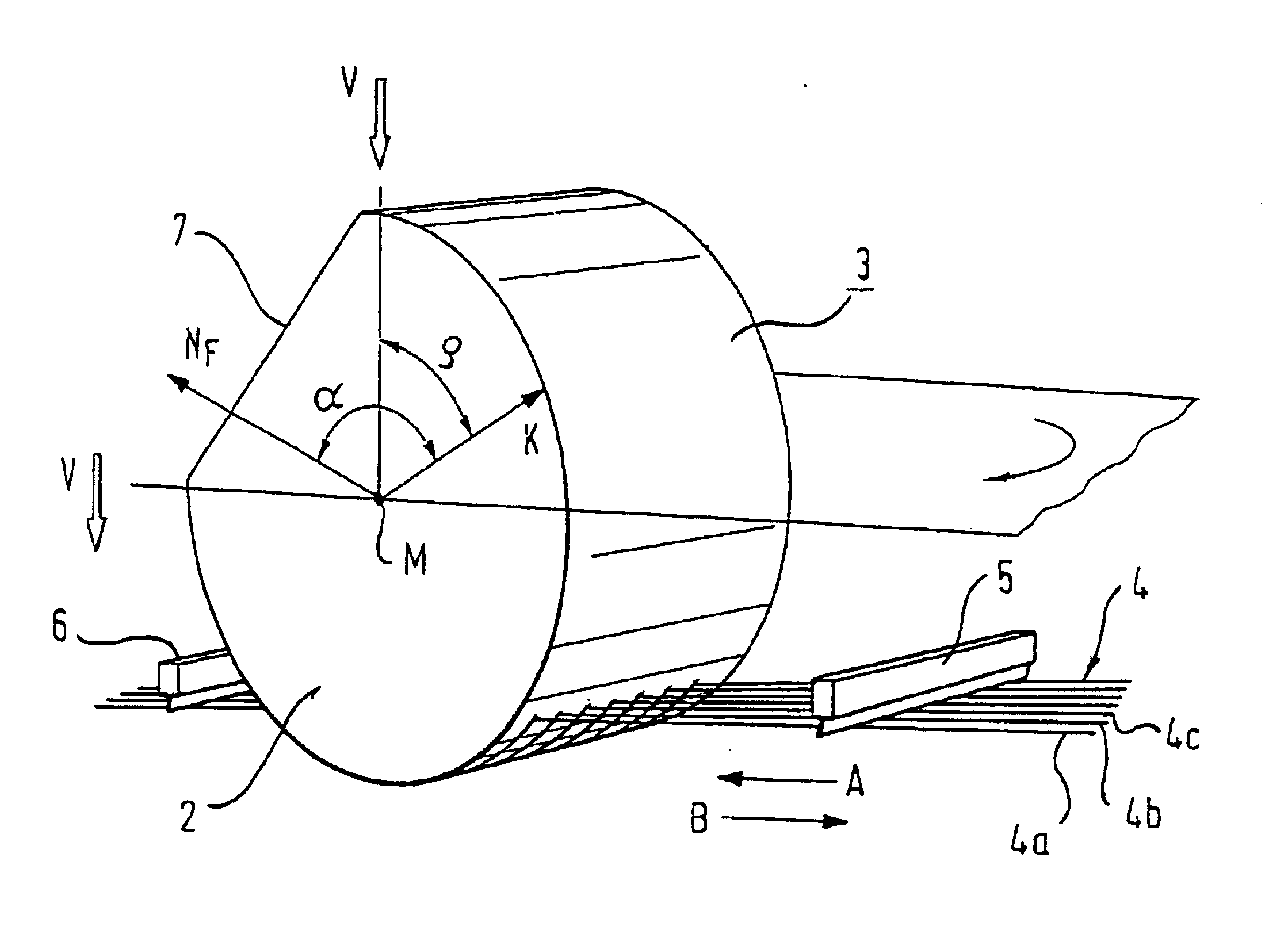

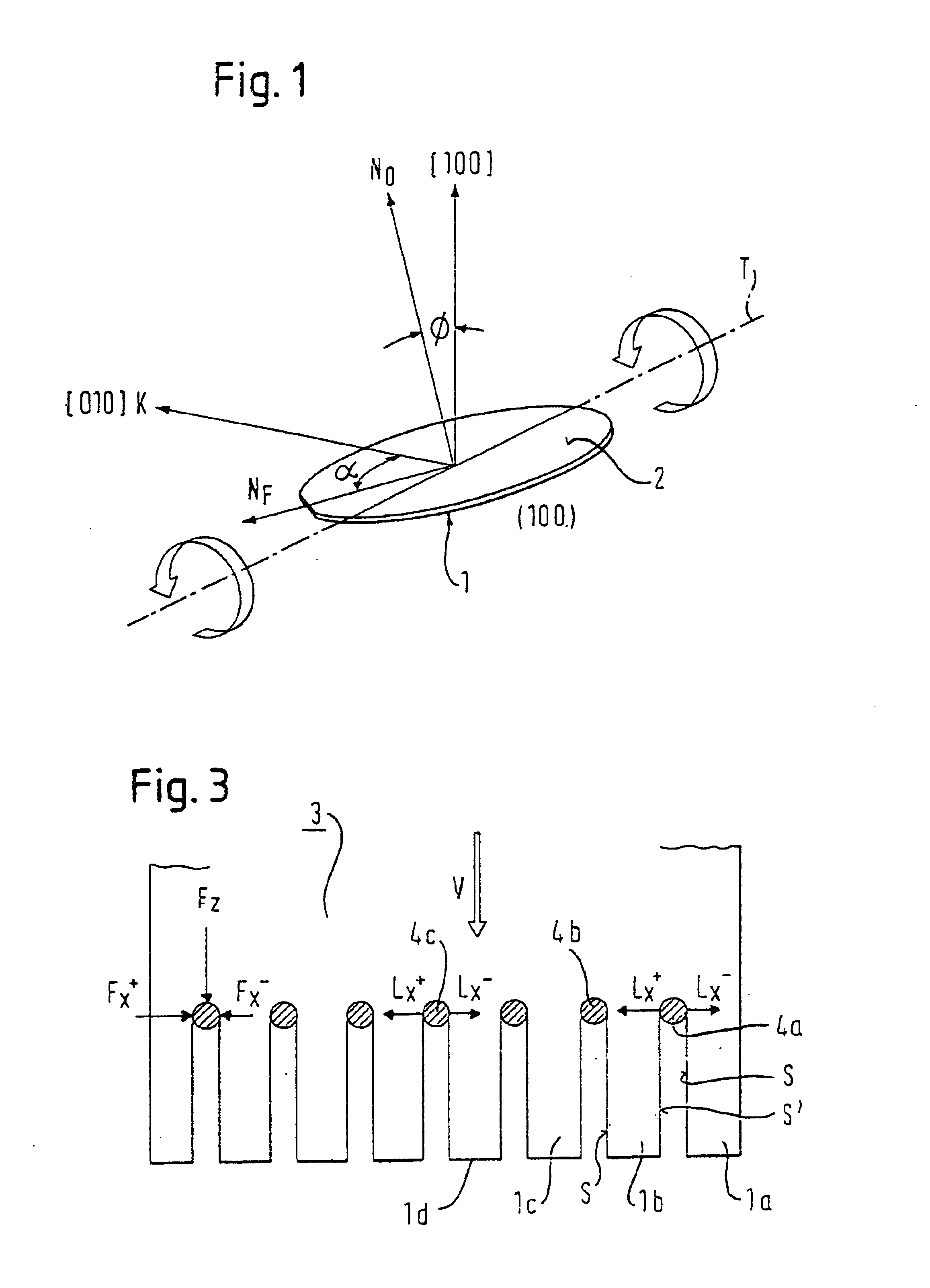

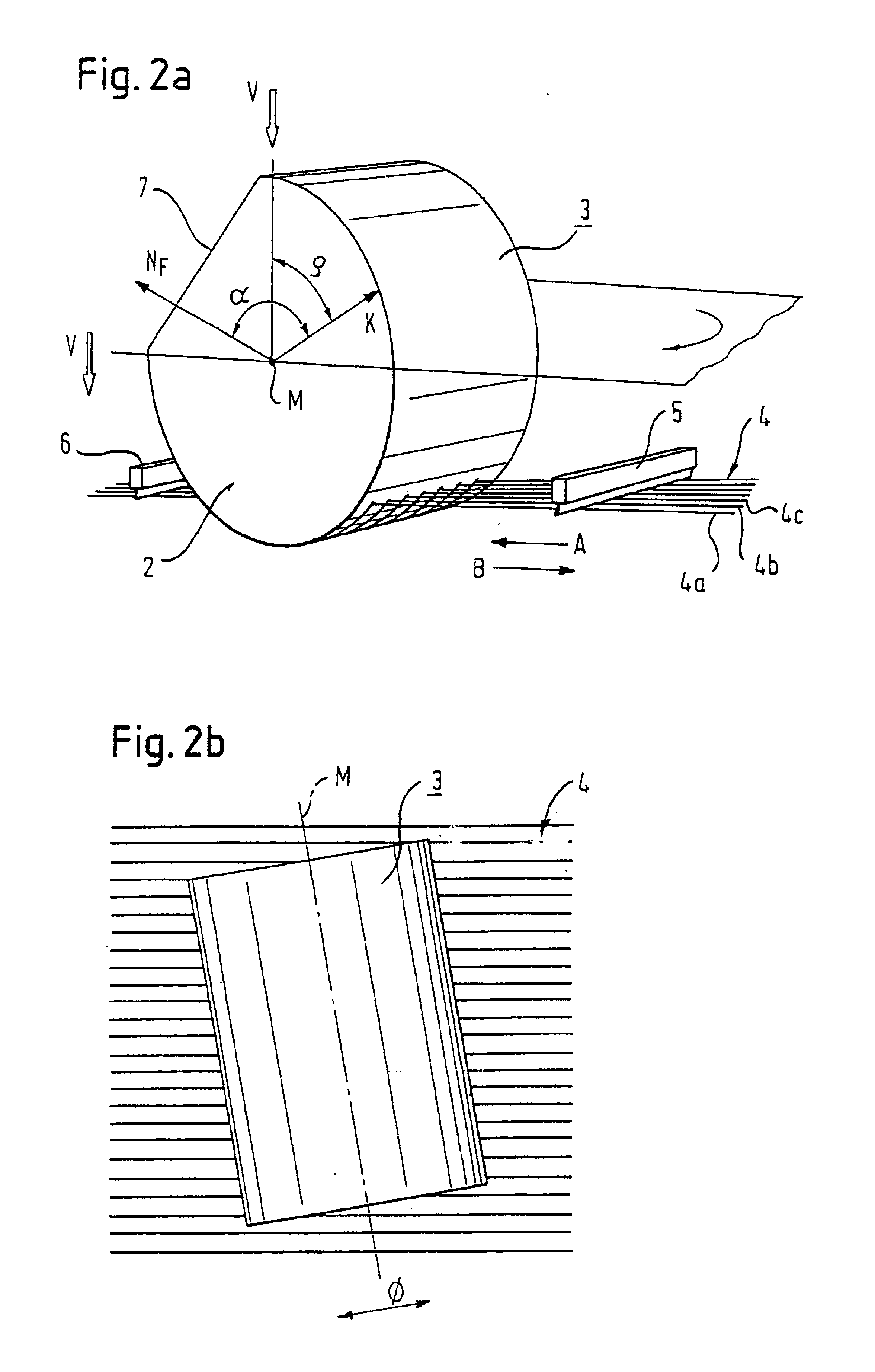

Device and method for determining the orientation of a crystallographic plane in relation to a crystal surface and device for cutting a single crystal in a cutting machine

InactiveUS6923171B2Minimize forceIncrease feed rateSemiconductor/solid-state device manufacturingFine working devicesRotational degrees of freedomSingle crystal

An apparatus and a method for determining the orientation of a crystallographic plane (100) relative to a crystal surface (2) are provided, in which the orientation is free from errors of adhesion of the crystal or contamination of the holders for the crystal. For this purpose, the angle which the crystal surface to be measured forms with a reference axis and the angle which the crystallographic plane forms with the reference axis are measured and subtracted. In a wire sawing apparatus with an X-Y positioning unit, next the desired correction is made with the aid of measurement of the orientation and at the same time the crystal is displaced in horizontal and vertical positions. As a result, there remains a further degree of freedom of rotation of the crystal in the cutting plane for achieving a cut which is free from forces perpendicular to the feed direction and wire direction, so that no tool deflection takes place or the cutting forces are minimal. Further, the precision of orientation is increased.

Owner:FREIBERGER COMPOUND MATERIALS

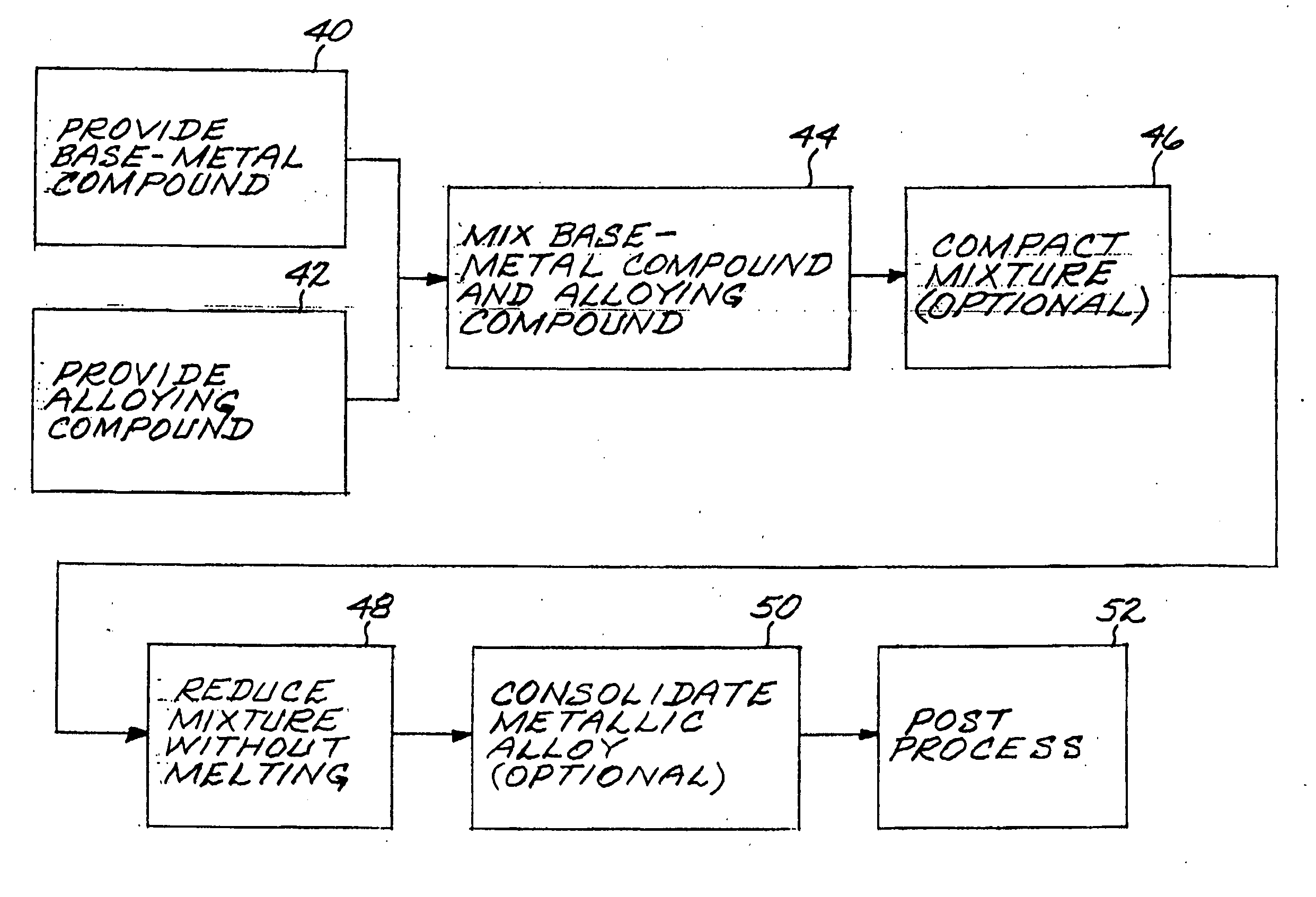

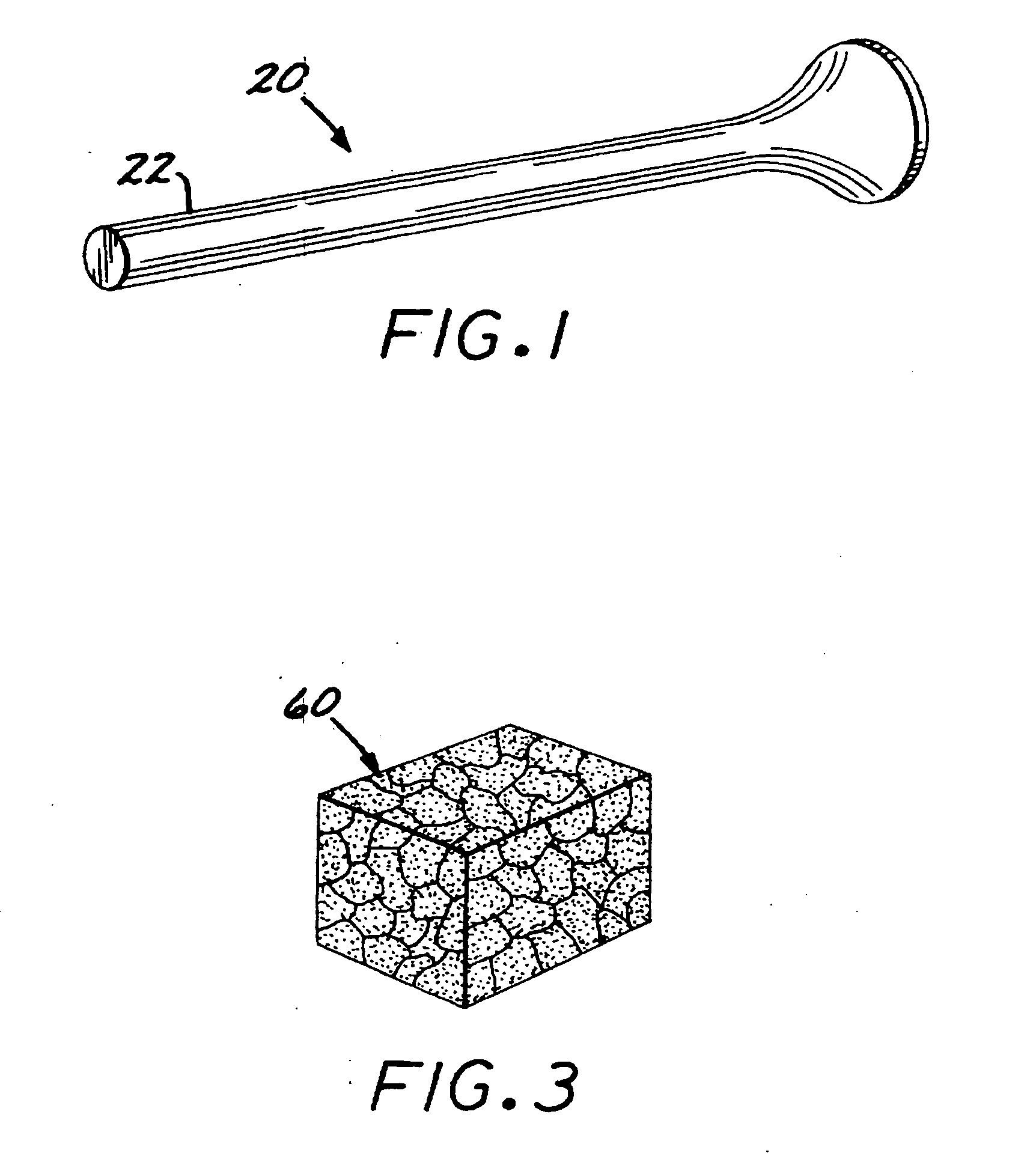

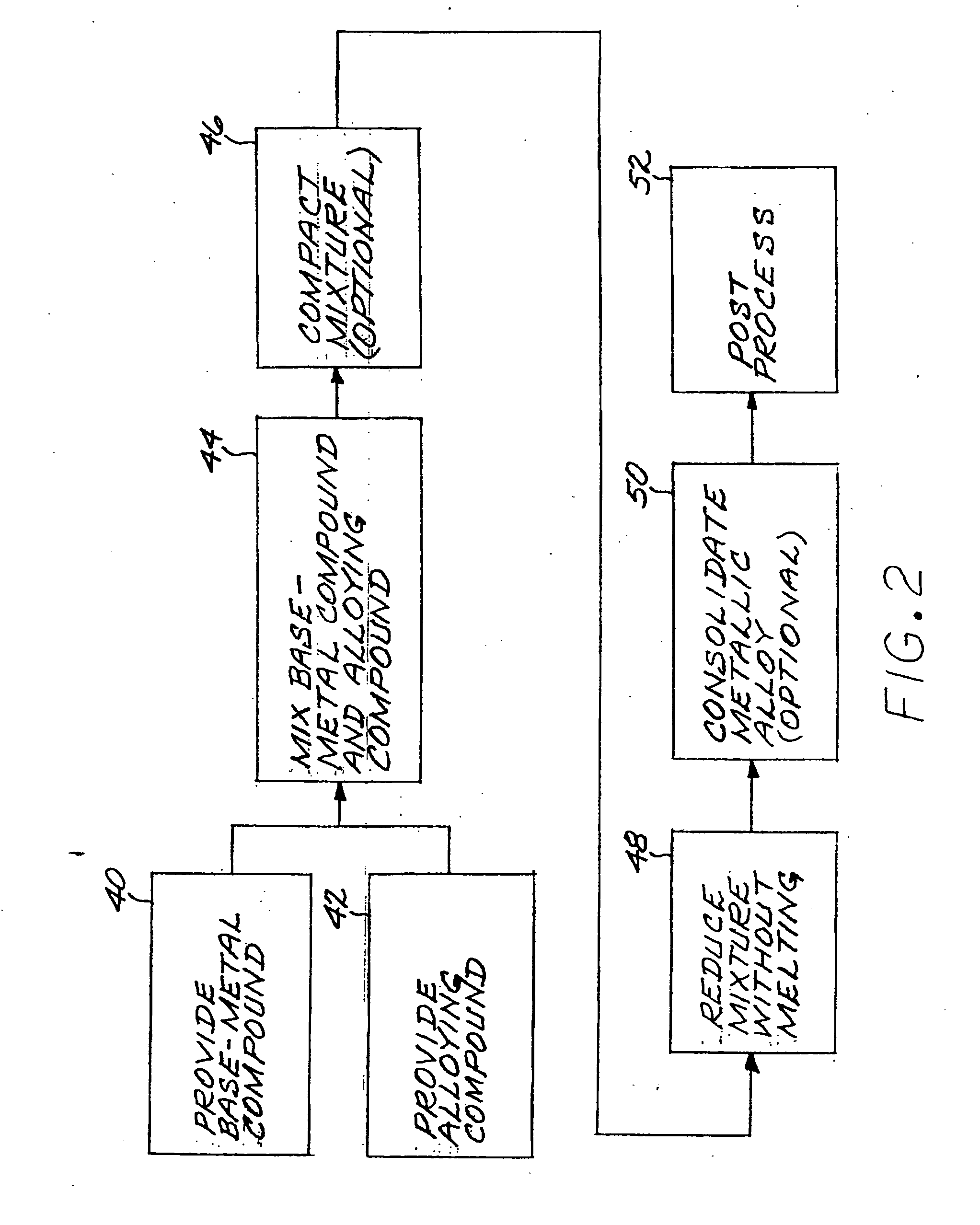

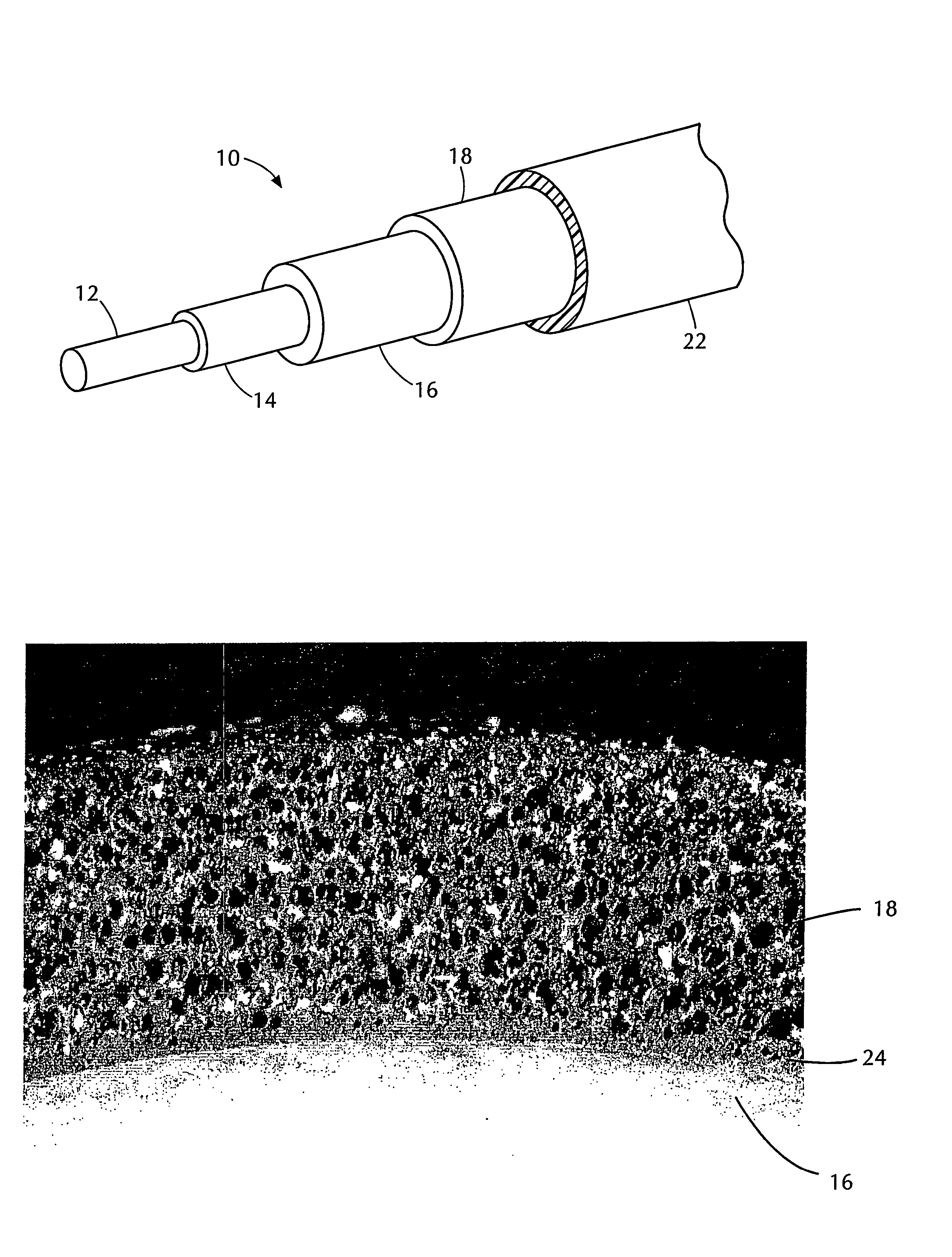

Meltless preparation of martensitic steel articles having thermophysically melt incompatible alloying elements

An article of iron base metal base metal alloyed with an alloying element is prepared by mixing a chemically reducible nonmetallic base-metal precursor compound of the iron base metal and a chemically reducible nonmetallic alloying-element precursor compound of an alloying element to form a compound mixture. The alloying element is preferably thermophysically melt incompatible with the iron base metal. The method further includes chemically reducing the compound mixture to a metallic alloy, without melting the metallic alloy, and thereafter consolidating the metallic alloy to produce a martensitic-composition consolidated metallic article, without melting the metallic alloy and without melting the consolidated metallic article.

Owner:GENERAL ELECTRIC CO

Electrical cable with foamed semiconductive insulation shield

InactiveUS7208682B2Few voidEasy to fillPlastic/resin/waxes insulatorsInsulated cablesPower cableEngineering

An electrical power cable with a foamed, compressible, semiconductive insulation shield which serves as both a cushioning layer and an electrical shield.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com