Sand-blasting derusting device for I-steel

A technology of sand blasting and derusting I-beam, which is applied in the field of steel derusting, and can solve the problems of inability to reduce work efficiency, affect derusting effect, and reduce work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The application will be described in further detail below in conjunction with the accompanying drawings.

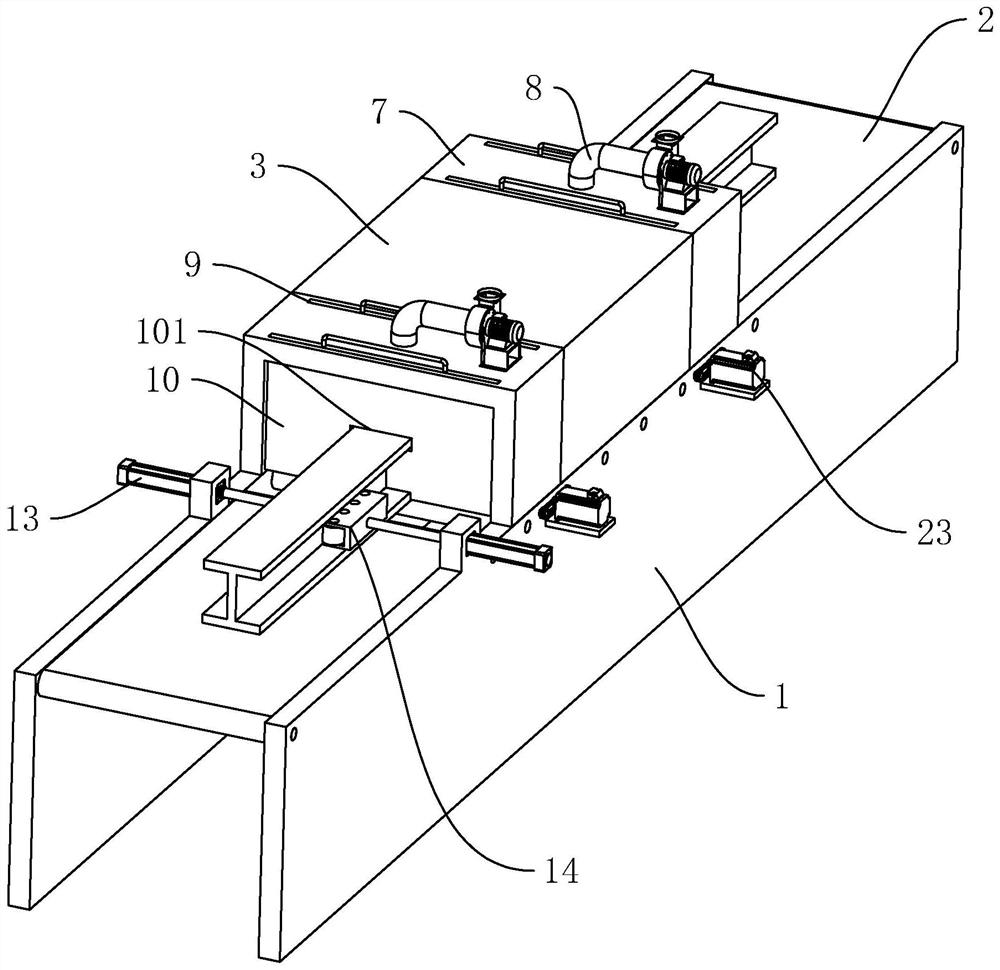

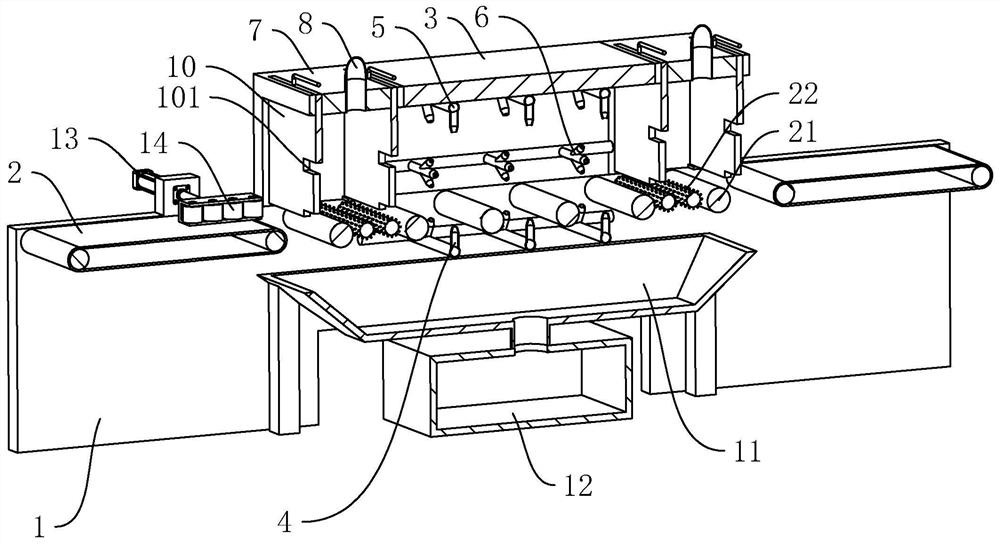

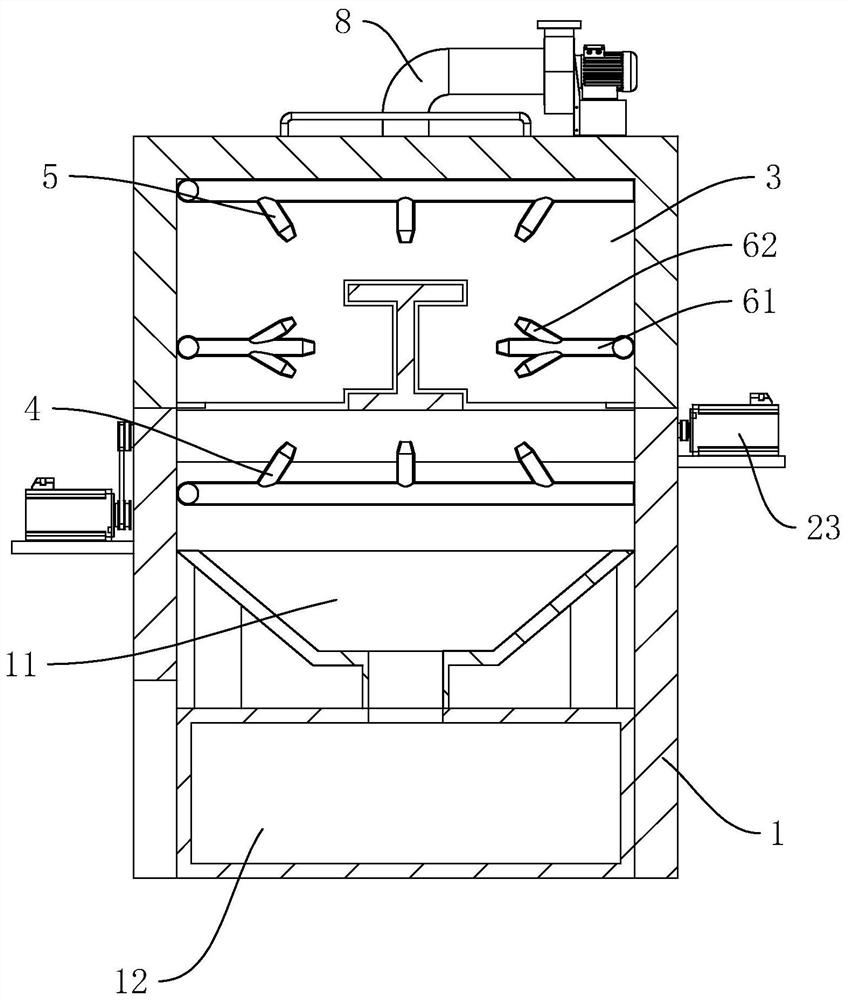

[0033] refer to figure 1 and figure 2 , is a kind of I-beam sandblasting derusting device disclosed by the present invention, comprising a frame 1. A conveyor belt 2 for transporting I-beams is arranged on the frame 1, and a cleaning chamber 3 is also installed above the conveyor belt 2 on the frame 1; in the length direction of the conveyor belt 2, the two ends of the cleaning chamber 3 are feed ports respectively. and outlet. The conveyor belt 2 includes several conveyor rollers 21, and the conveyor rollers 21 are driven to rotate by a driving motor. Several lower spray guns 4 for cleaning the lower surface of the I-beam are also arranged between the conveying rollers 21 on the frame 1 . Above the conveyor belt 2 in the cleaning room 3 are also provided with some upper spray guns 5 for cleaning the upper surface of the I-beam. Side spray gun 6 for side clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com