Patents

Literature

35results about How to "Play a recycling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-compressive-strength recycled concrete and preparation process thereof

The invention discloses high-compressive-strength recycled concrete and a preparation process thereof. The high-compressive-strength recycled concrete comprises the following components in parts by weight: 300-420 parts of reinforced recycled aggregate, 25-35 parts of recycled micro powder, 100-200 parts of natural coarse aggregate, 120-200 parts of natural fine sand, 120-170 parts of cement, 50-130 parts of fly ash, 50-120 parts of mineral powder, 6-12 parts of a waterproof agent, 0.8-2.2 parts of an air entraining agent, 120-160 parts of water and 20-35 parts of polypropylene mixed filler. The preparation process comprises the following steps: S1, weighing corresponding amounts of cement and natural fine sand, putting the cement and the natural fine sand into a stirrer, and stirring for40-60 seconds; S2, weighing the regenerated micro-powder, the fly ash, the mineral powder and the polypropylene mixed filler according to corresponding proportions, adding the weighed materials into the stirrer in the step S1, continuing to stir and mix for 30-40 seconds, adding half of the water according to the proportion, continuing to stir for 30-40 seconds, and mixing to obtain mortar with uniform color; and S3, adding the rest half of the water, the reinforced recycled aggregate, the natural coarse aggregate, the air entraining agent and the waterproof agent according to the proportion in the step S2, and continuously stirring for 60-80 seconds until the mixture is uniform.

Owner:西安百固源混凝土有限公司

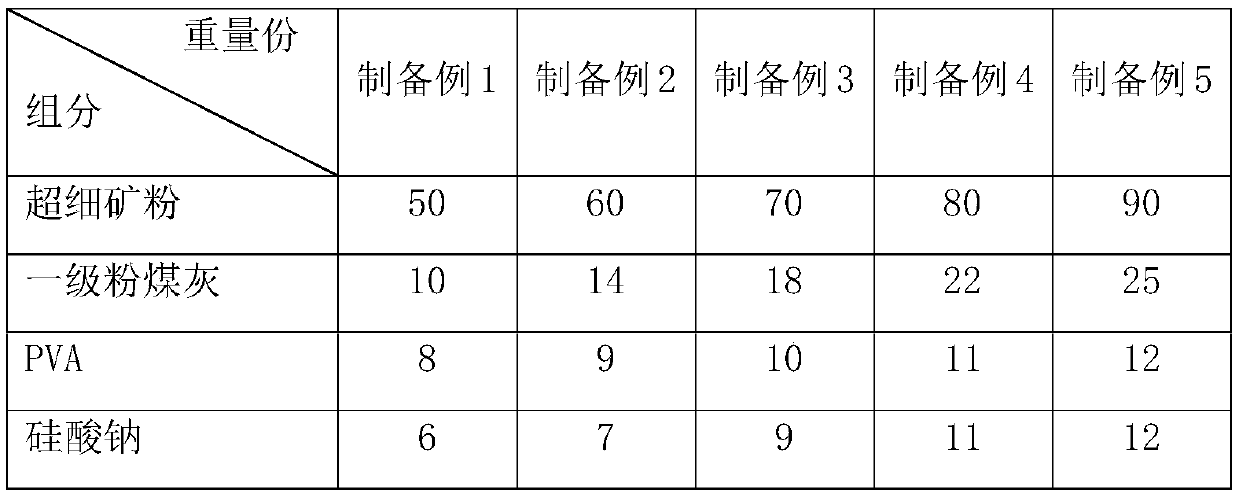

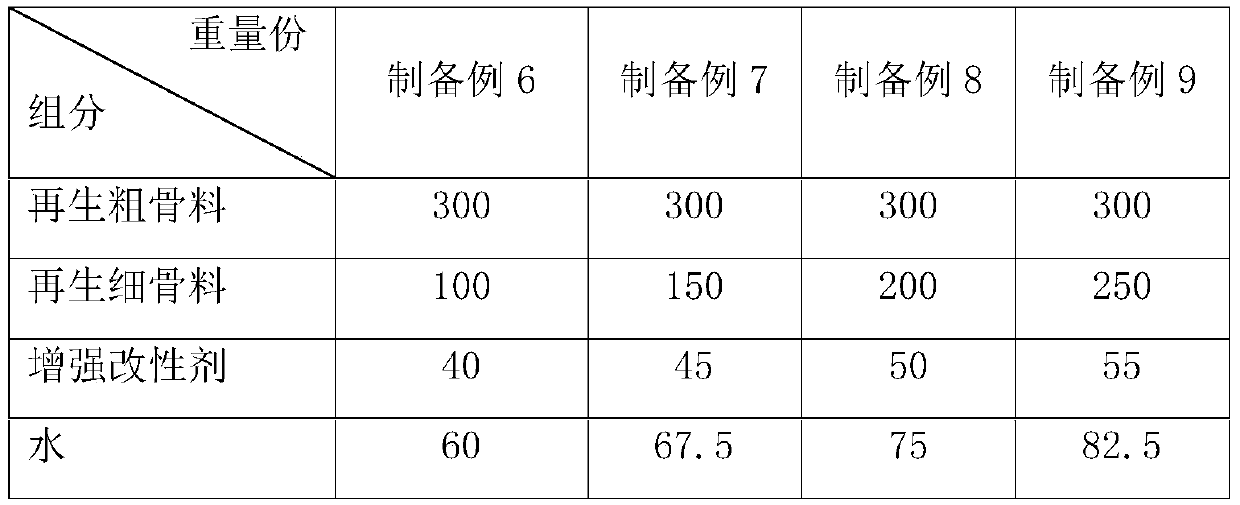

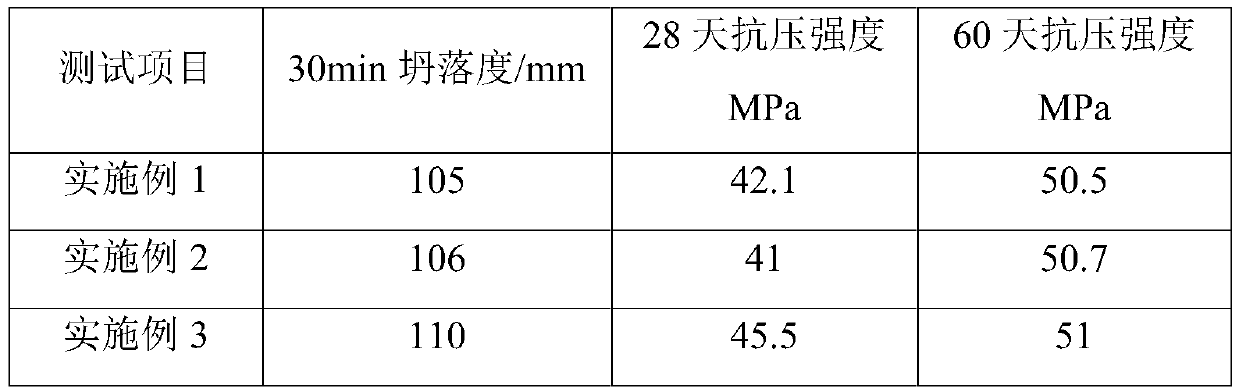

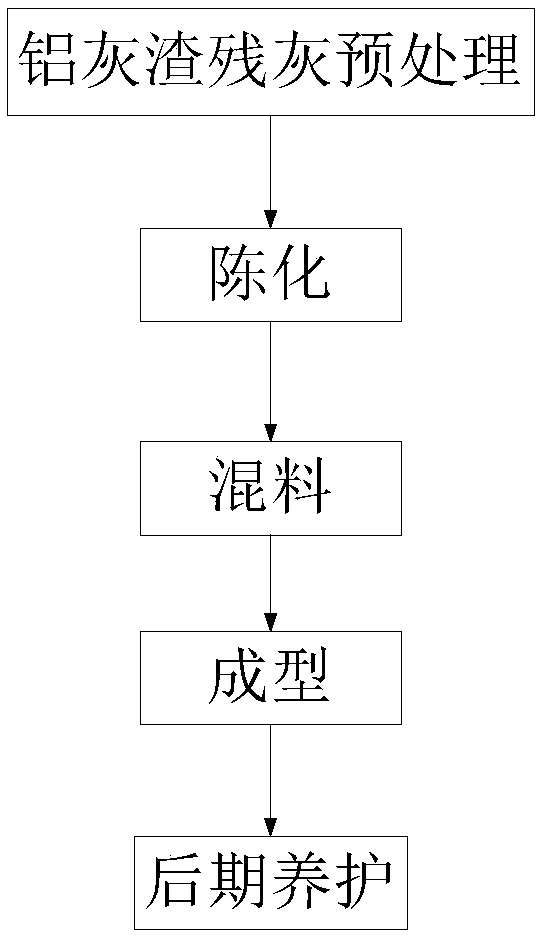

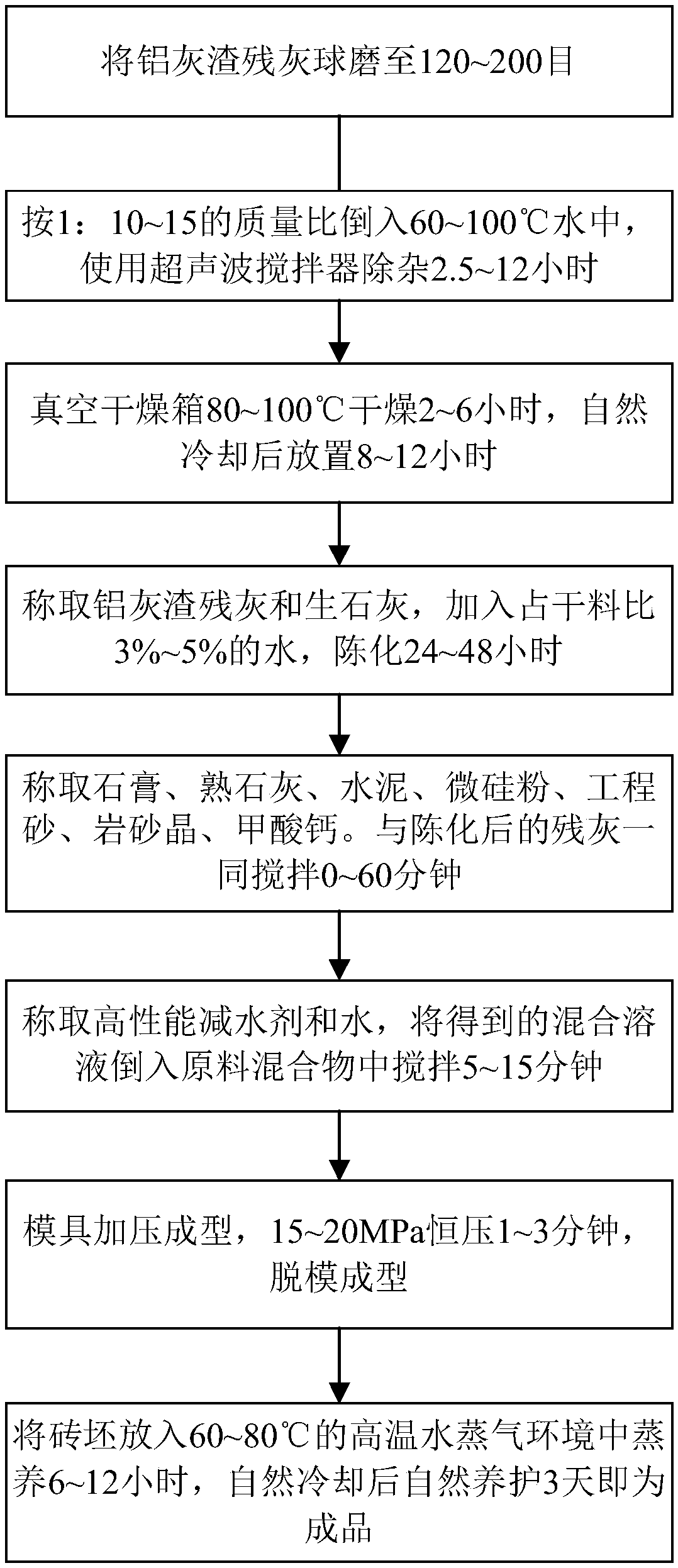

Method for preparing non-sintered sidewalk bricks from residual aluminum ash

The invention discloses a method for preparing non-sintered sidewalk bricks from residual aluminum ash. The method comprises the following steps: pretreating the residual aluminum ash, aging, mixing materials, shaping and later maintaining, wherein the residual aluminum ash to be buried is utilized as main aggregate, and activity of ingredients of aluminum oxide, silicon dioxide and the like in the residual ash can be stimulated by aging. As additives of a high-performance water reducing agent, an early strength agent and the like are added, an early strength of the sidewalk bricks is high, the sidewalk bricks are not prone to being damaged in demoulding, and compressive strength of the sidewalk bricks is also improved. By means of utilizing the residual aluminum, the method has the characteristics of low production cost, ability in effectively reducing the problem that ecological environment is affected by aluminum ash accumulation, resource recycling effect and important practical value.

Owner:NANTONG UNIVERSITY

Clay ceramsite used for highway greening

InactiveCN104909796ALow costImprove sintering efficiencyCeramic materials productionCeramicwareAbsorption rateGreening

The invention discloses a clay ceramsite used for highway greening. Clay, copper mine tailings, fly ash and a paper pulp waste liquid are adopted as raw material, so the cost is greatly reduced, and wastes are recycled. A preparation method of the clay ceramsite has the advantages of simplicity, easy industrialization and wide sources of the raw materials. The water absorption rate of the clay ceramsite is greater than 93%, the unit weight is greater than 590kg / m<3>, the compressive strength is greater than 30Mpa, and the granularity is 1-10[mu]m, so the clay ceramsite is very suitable for being used in highway greening.

Owner:淄博萃智工业设计咨询有限公司

Adsorption material based on organic-metal modified charcoal and preparation method of adsorption material

PendingCN110523385AImprove adsorption capacityReduce utilizationOther chemical processesWater contaminantsChemical reactionHydrolysis

The invention relates to the technical field of charcoal adsorption materials and discloses an adsorption material based on organic-metal modified charcoal and a preparation method of the adsorption material. The adsorption material comprises the following raw materials: fruit shell based charcoal, iron chloride hexahydrate, zinc nitrate hexahydrate, nickel oxide, 2-aminobenzamide and a coordination catalyst. By adopting the adsorption material based on organic-metal modified charcoal and the preparation method of the adsorption material, Zn-Ni ferrite modified biological activated carbon is used, and Fe and Ni in Zn-Ni ferrite Ni0.6-0.75Zn0.25-0.4Fe2O4 have very intensive magnetism, so that most heavy metal ions such as Cu<2+>, Cd<2+> and Pb<2+> can be adsorbed; due to addition of 2-aminobenzamide which has a coordination function with Zn in the Zn-Ni ferrite, the formed zinc amide salt is combined with a phosphate radical PO43- generated through hydrolysis of organophosphorus, the generated zinc phosphate amide compound can be adsorbed by the biological activated carbon, and with the combination of a chemical reaction method and a physical adsorption mode, the adsorption functionof the biological activated carbon upon organophosphorus pollutants can be improved.

Owner:罗金标

Treatment method for antibiotics in marine aquaculture wastewater

ActiveCN108002605AEfficient removalPlay a recycling effectSeawater treatmentWater contaminantsVirginiamycinMarine aquaculture

The invention relates to a treatment method for antibiotics in marine aquaculture wastewater, wherein the method is simple to operate and used for removing substances, which are difficult to be effectively treated, such as a large number of oxytetracycline, sulfamethoxazole, virginiamycin and chloramphenicol contained in the aquaculture wastewater. The method provided by the invention solves a series of environmental problems such as reinforced medicine resistance of pathogenic microorganisms, inhibition of activity of beneficial microorganisms and residual antibiotics in marine products because the aquaculture scale grows day by day, and the discharge of the marine aquaculture wastewater becomes an important way for the antibiotics to enter the environment, has an excellent effect of purifying water quality and low processing costs, and does not produce any harmful substances in the treatment process.

Owner:ZHEJIANG OCEAN UNIV

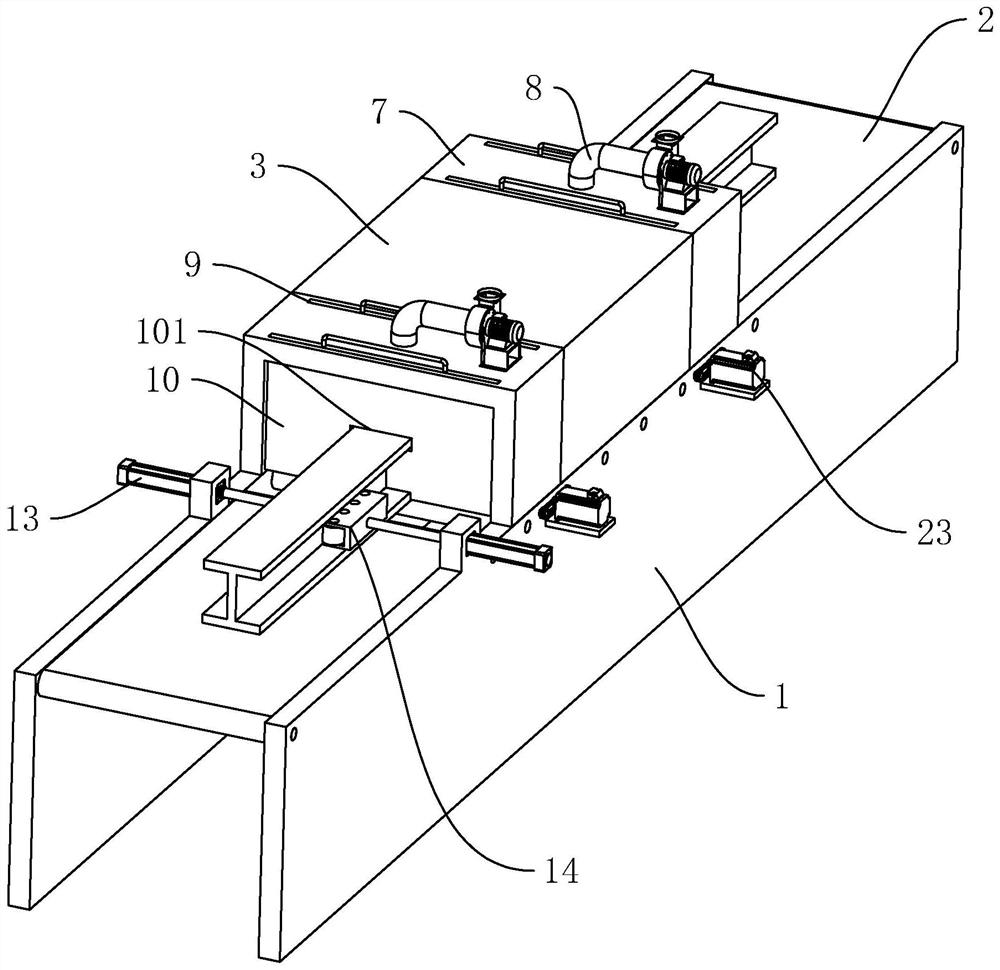

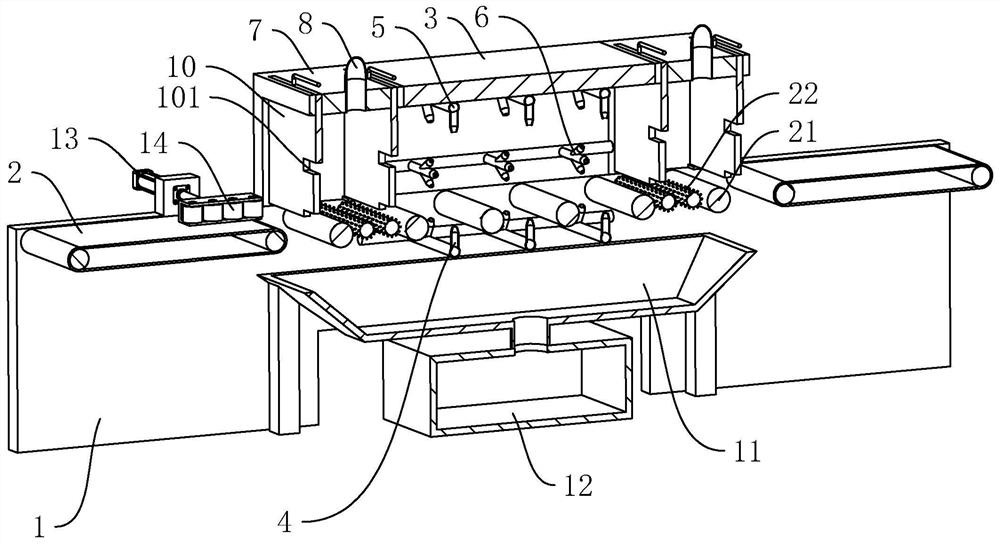

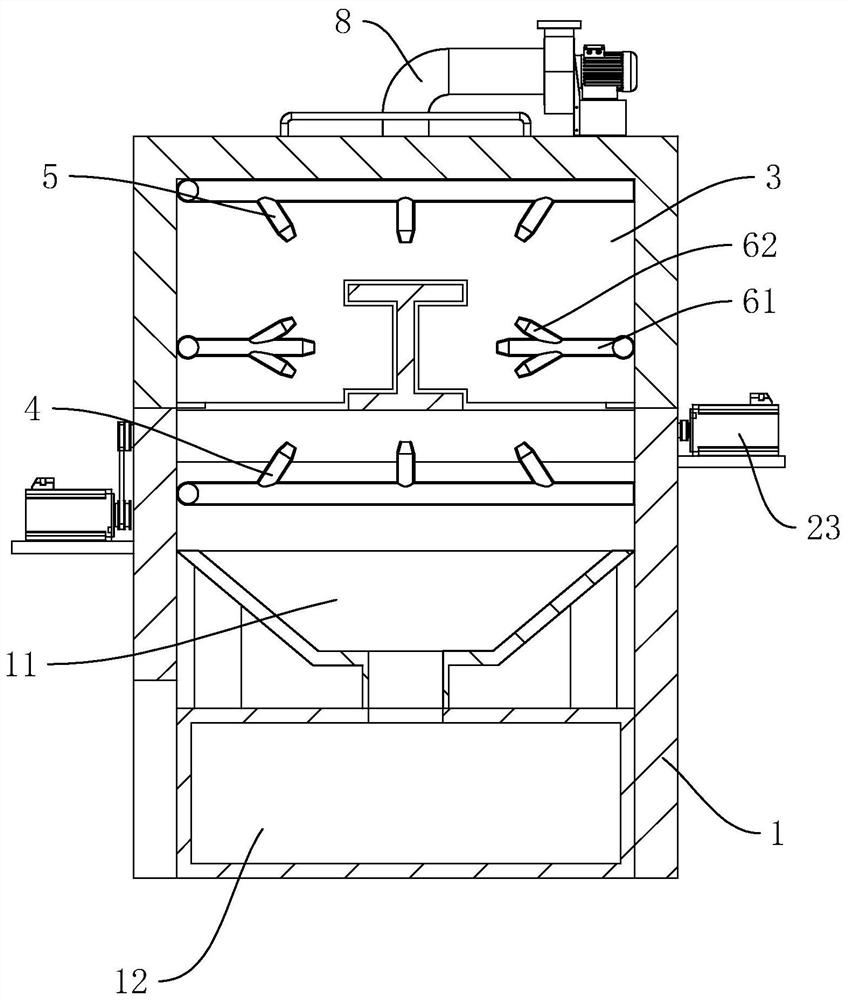

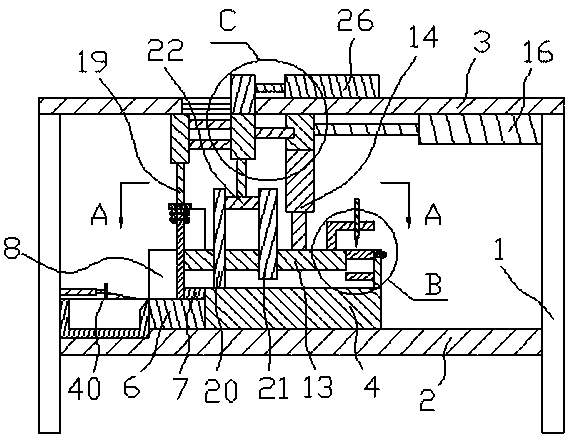

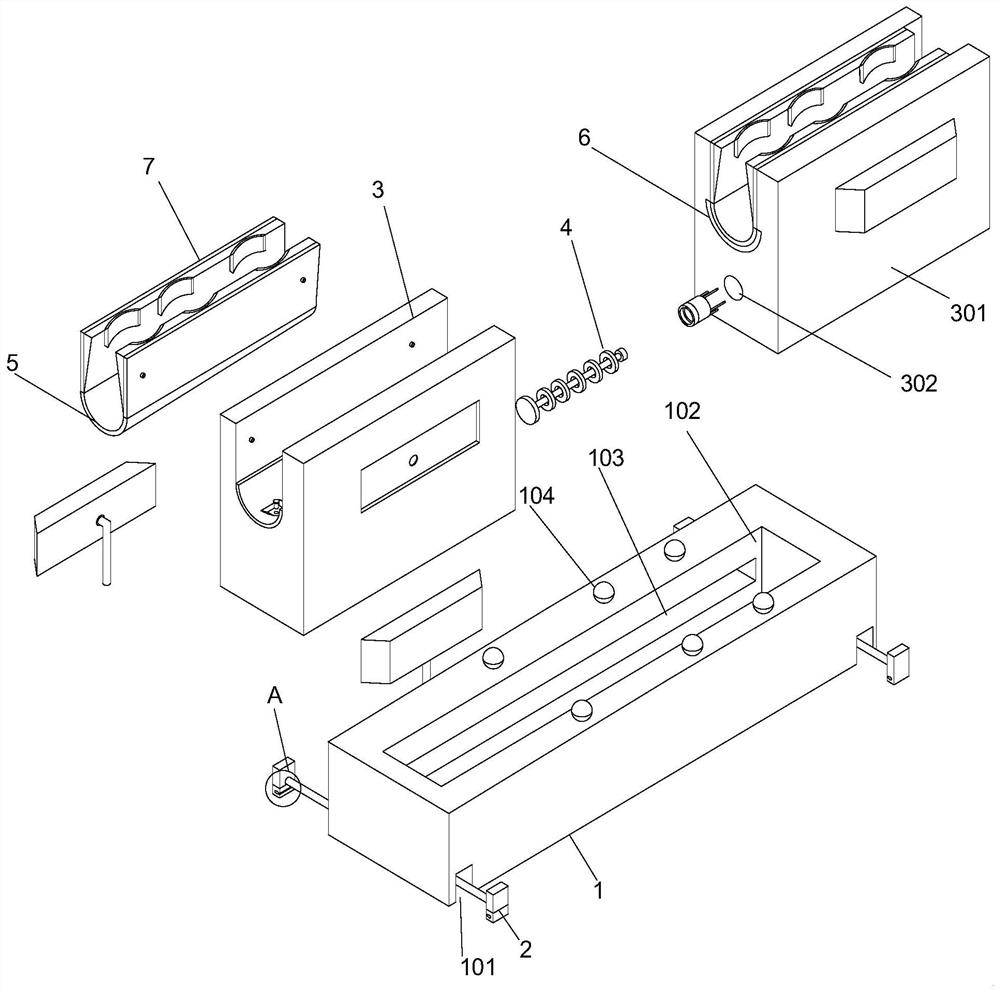

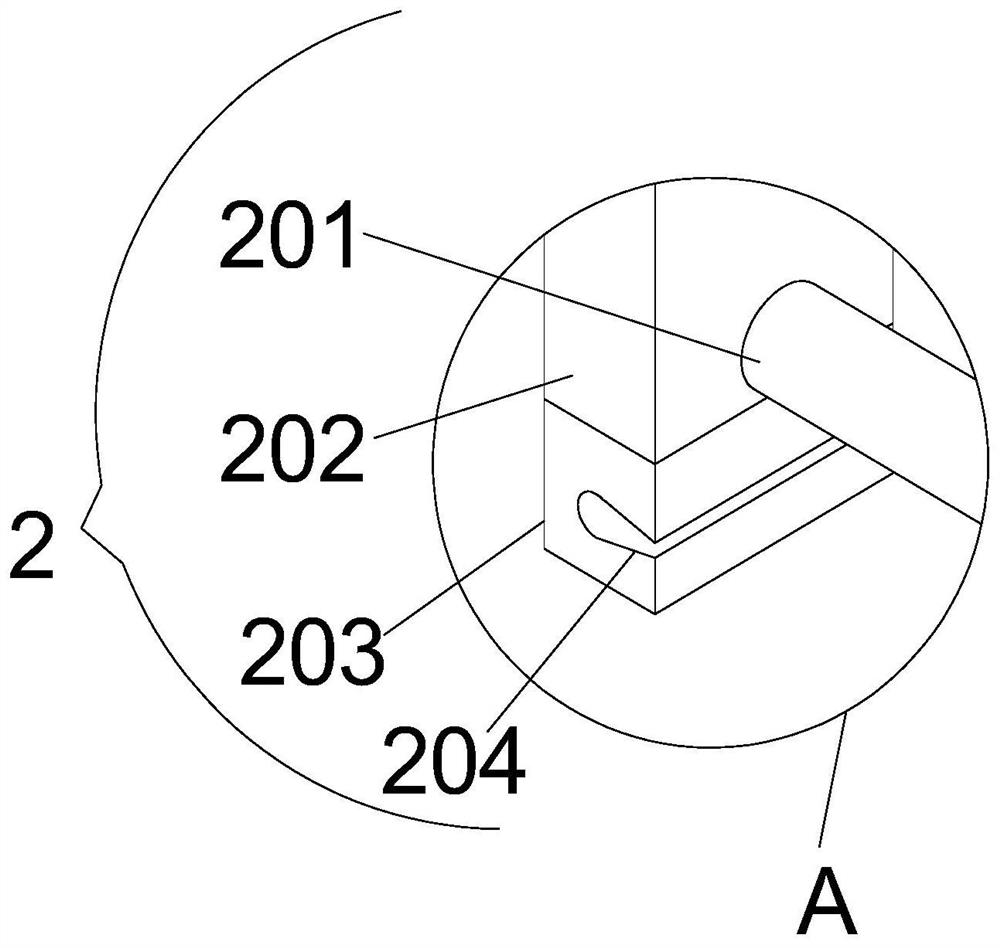

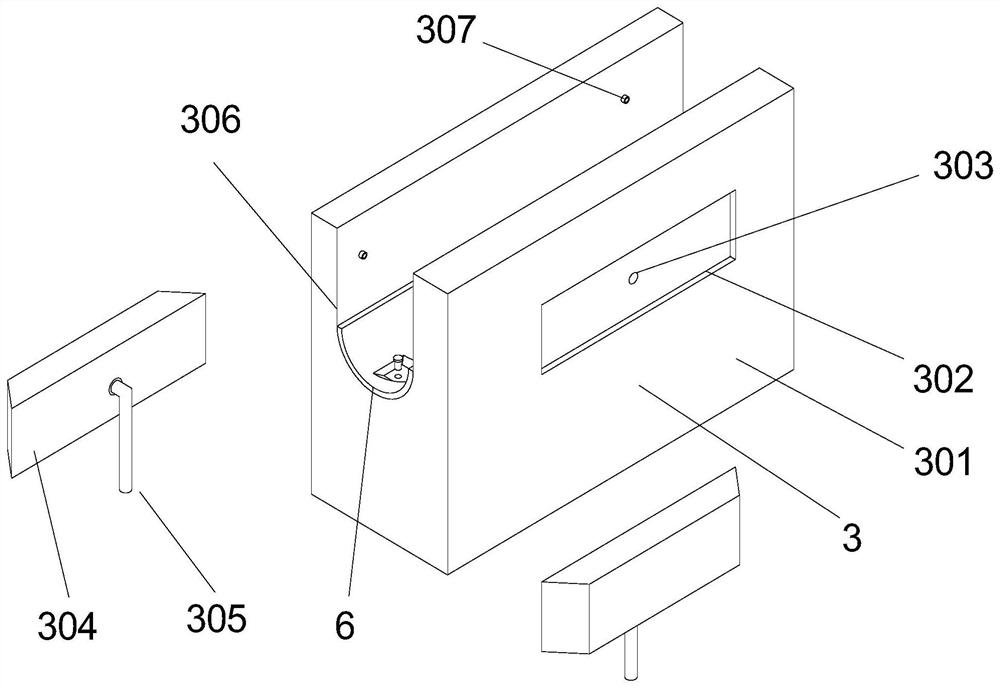

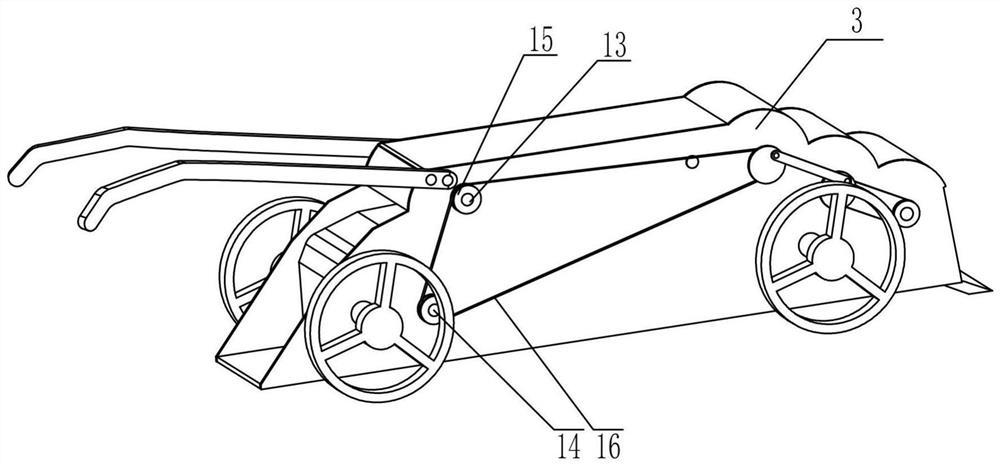

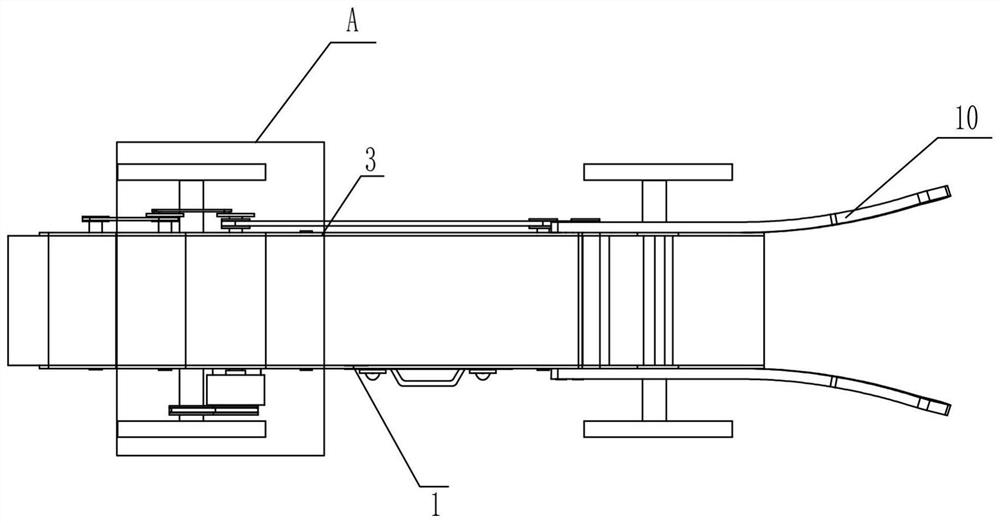

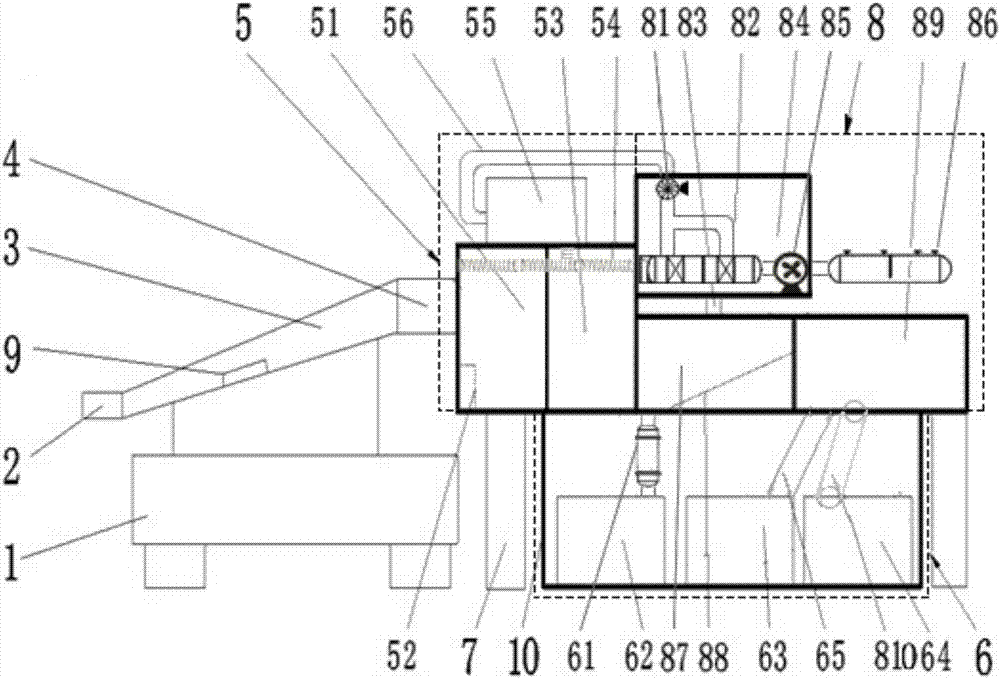

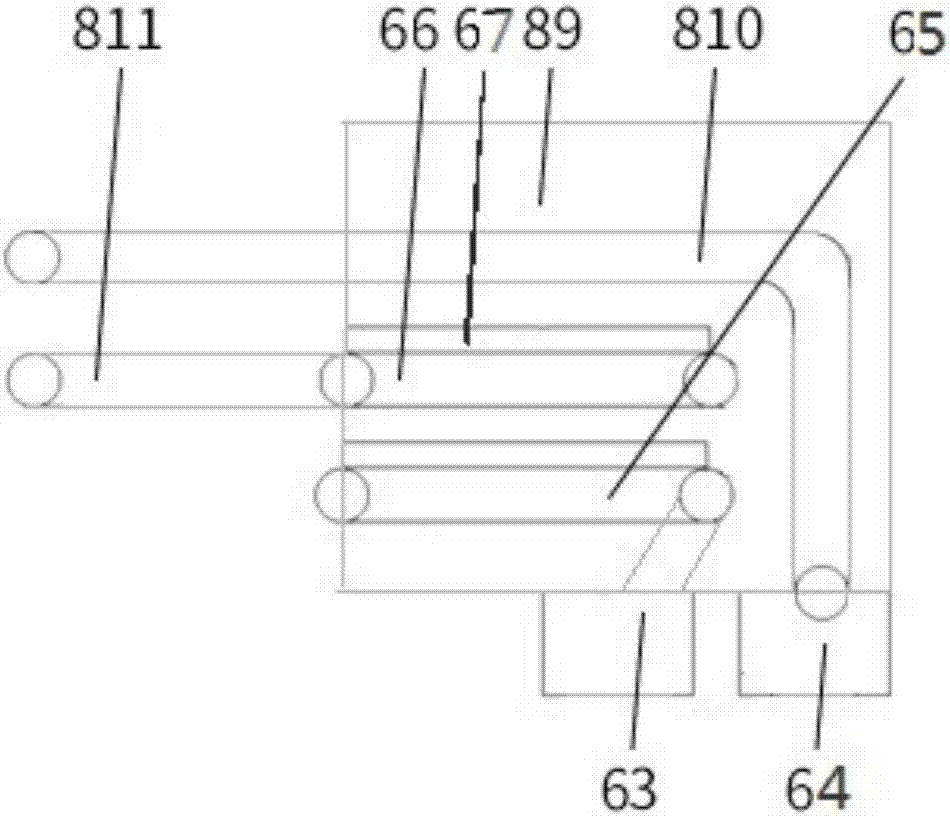

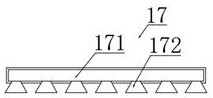

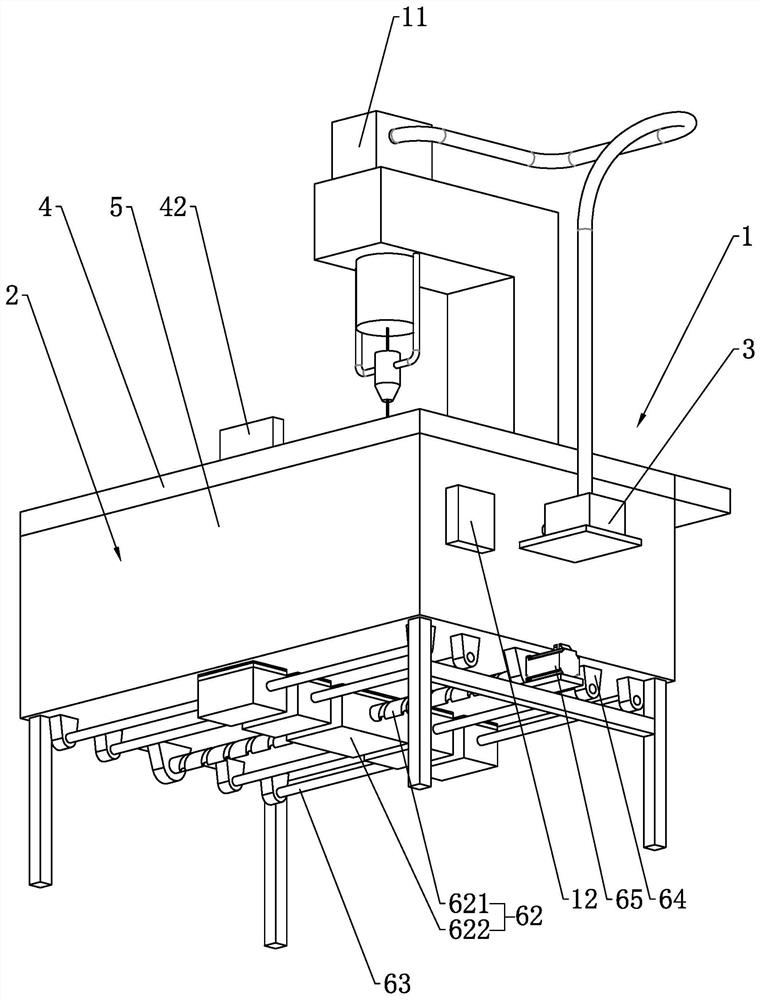

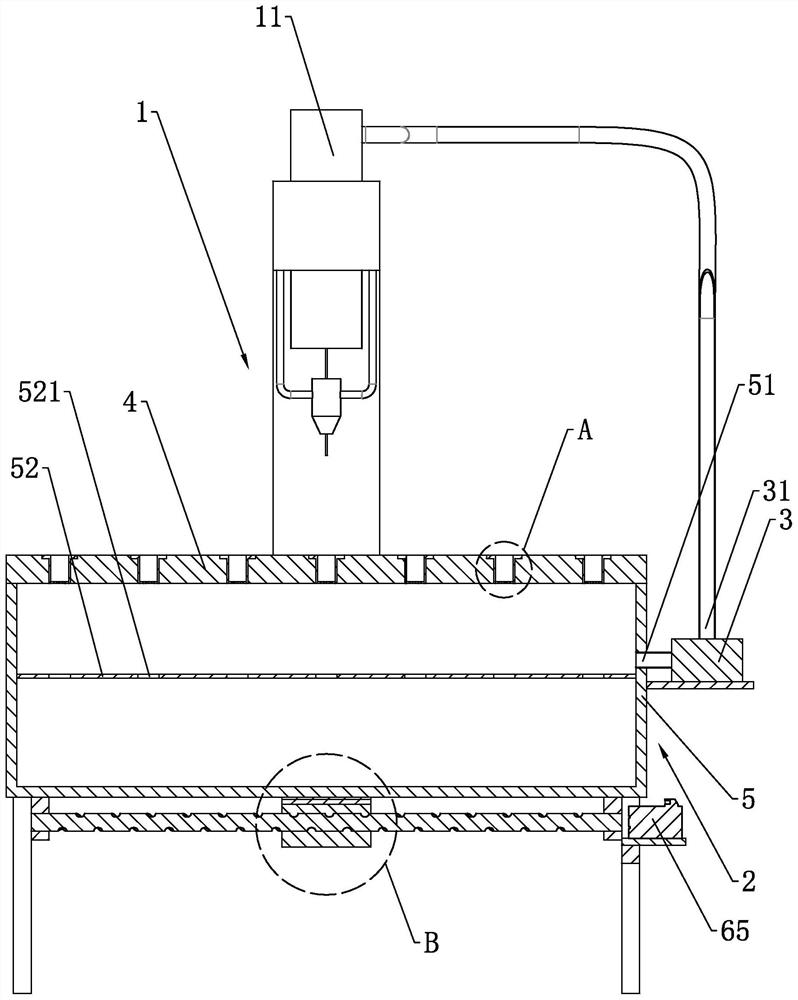

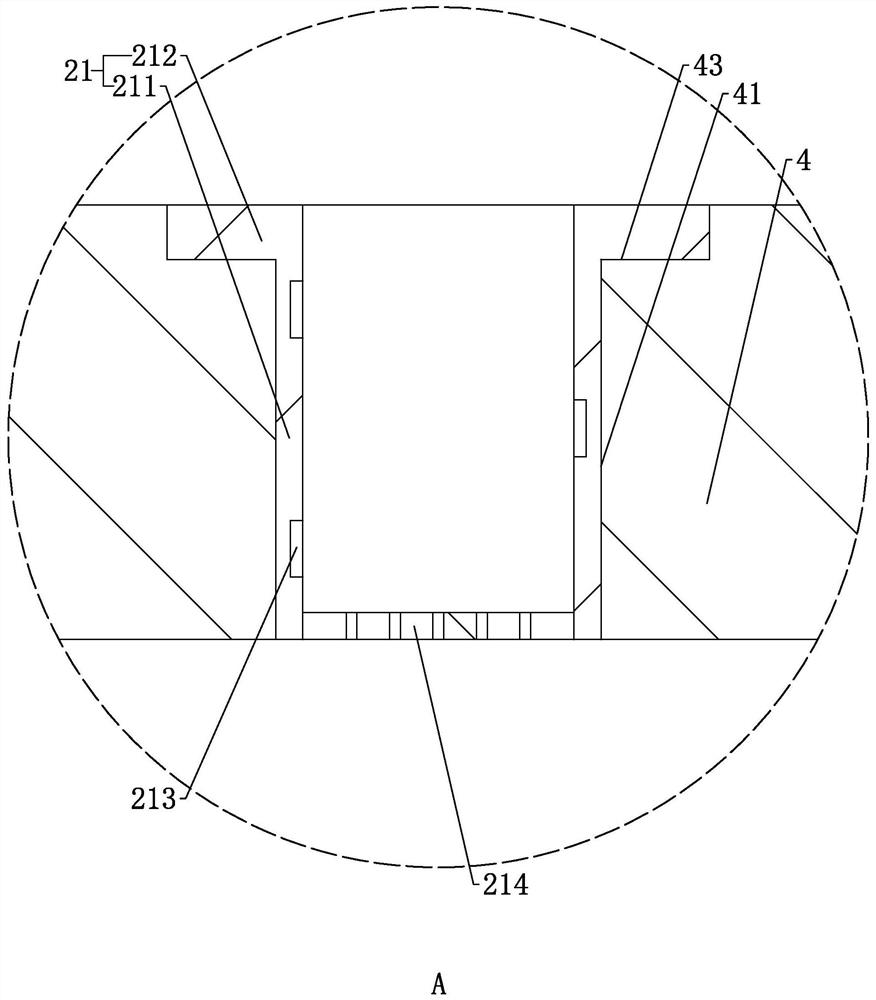

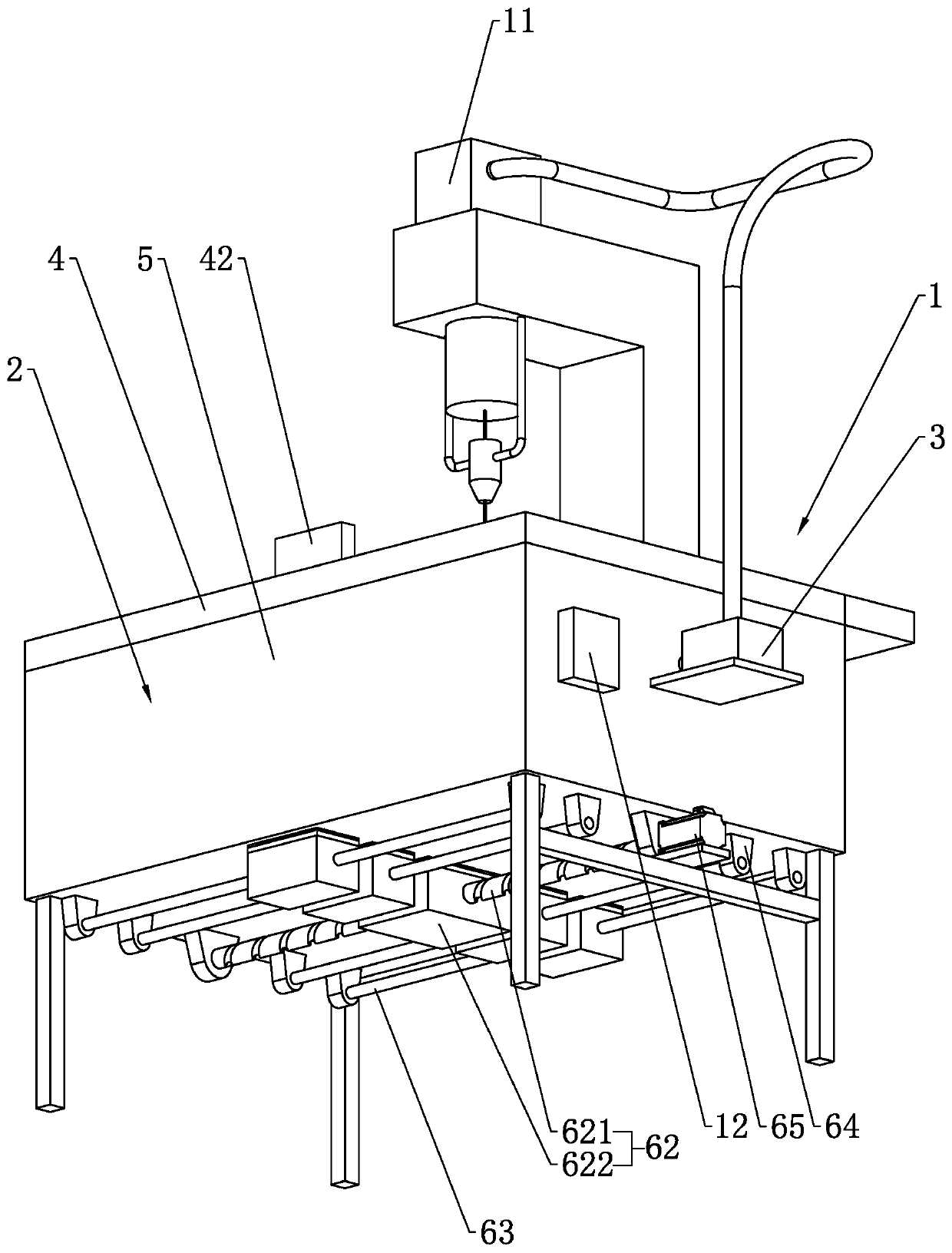

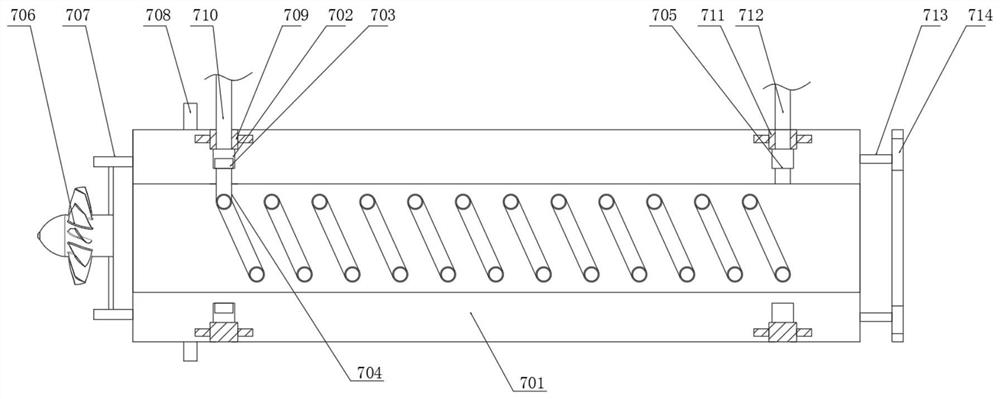

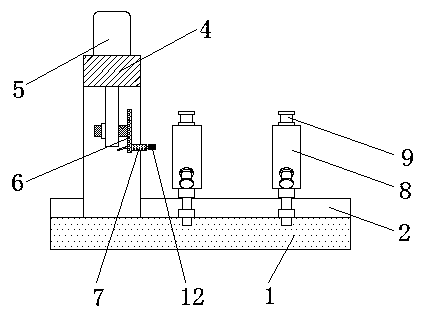

Sand-blasting derusting device for I-steel

ActiveCN111975644AFull rust removalClean up fullyAbrasive machine appurtenancesMetallurgySand blasting

The invention relates to a sand-blasting derusting device for I-steel. The sand-blasting derusting device for I-steel comprises a rack. A conveyor belt for conveying I-steel is arranged on the rack, and a cleaning chamber is further arranged above the conveyor belt on the rack; the conveyor belt comprises a plurality of transfer rollers, the transfer rollers are in contact with the lower surface of the I-steel, and a plurality of lower spray guns for cleaning the lower surface of the I-steel are further arranged between the transfer rollers on the rack; a plurality of upper spray guns for cleaning the upper surface of the I-steel are further arranged above the conveyor belt in the cleaning chamber, and a plurality of side spray guns for cleaning the side surface of the I-steel are furtherarranged on two sides of the width direction of the conveyor belt in the cleaning chamber. The s and-blasting derusting device for I-steel has an effect of derusting the surface of the I-steel fully.

Owner:杭州恒途钢结构有限公司

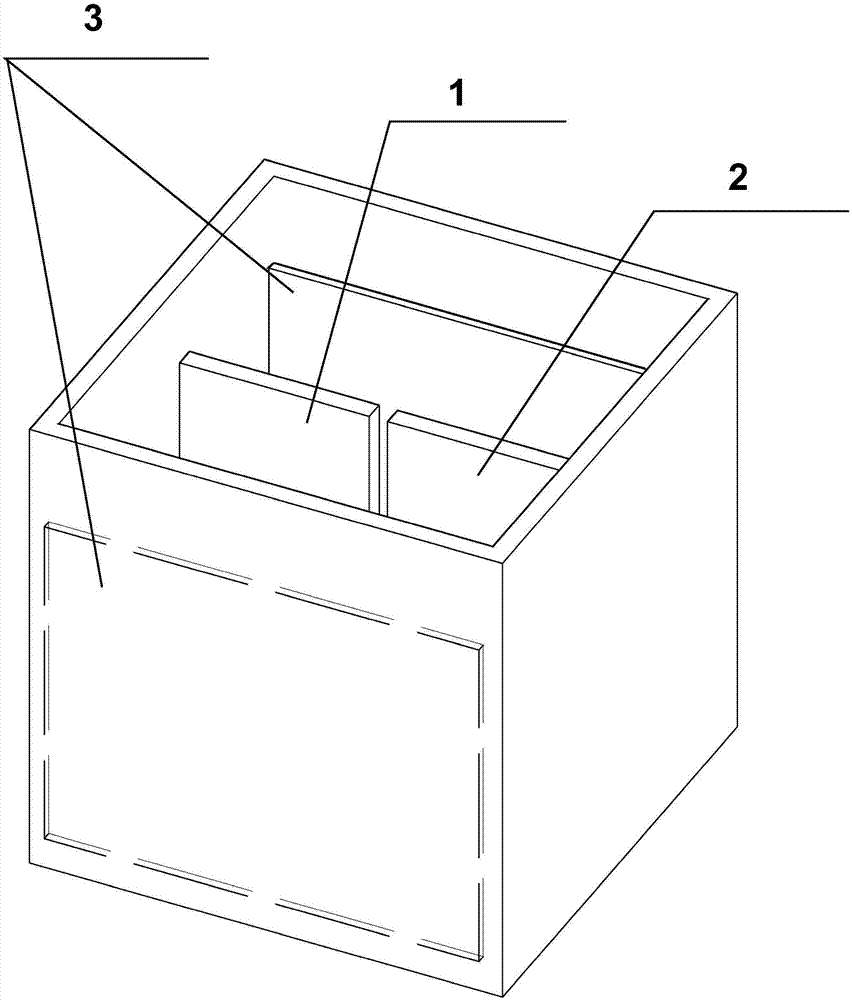

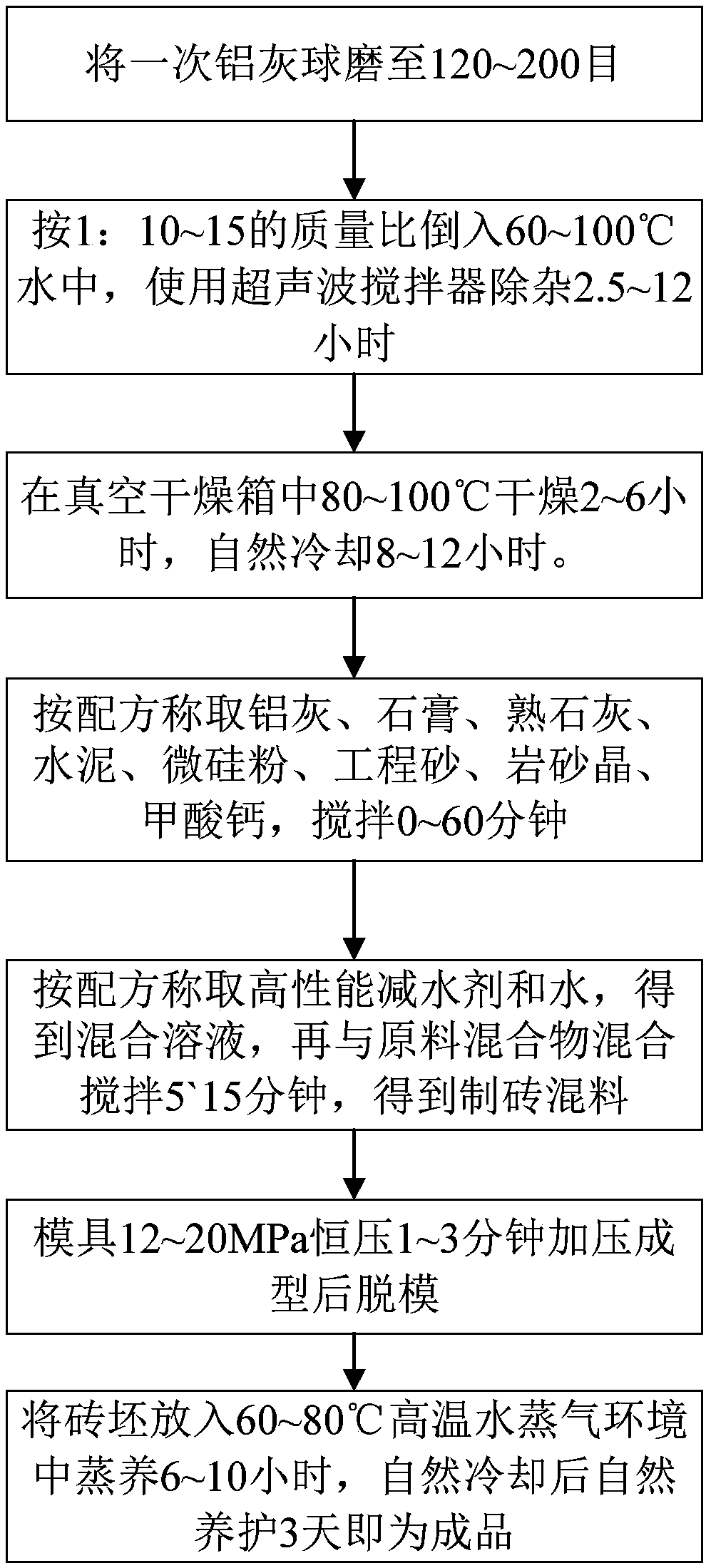

Sidewalk brick prepared from primary aluminum ash after fine grinding

InactiveCN107892539AReduce manufacturing costIncrease morning intensitySolid waste managementBrickEcological environment

The invention discloses a sidewalk brick prepared from primary aluminum ash after fine grinding. The sidewalk brick is prepared from a variety of raw materials. The raw materials include the components in parts by mass: 50-65 parts of aluminum ash, 5-8 parts of gypsum, 8-12 parts of slaked lime, 10-15 parts of common portland cement, 2-5 parts of silica fume, and 5-10 parts of engineering sand; the content of rock sand crystals is 0.5%-1% of the sum of the mass of the common portland cement and the slaked lime, the content of calcium formate is 0.3%-0.5% of the sum of the mass of the common portland cement and the slaked lime, and the content of a high performance water reducer is 0.5%-1% of the sum of the mass of the common portland cement and the slaked lime, so that the sidewalk brick has high early strength, is not easy to damage during demoulding, and has the compressive strength increased; the sidewalk brick has the characteristic of low production cost due to the utilization ofthe primary aluminum ash waste. The problem of ecological environment affected by aluminum ash accumulation is effectively solved, and the method plays a resource recycling effect and has important practical value.

Owner:NANTONG UNIVERSITY

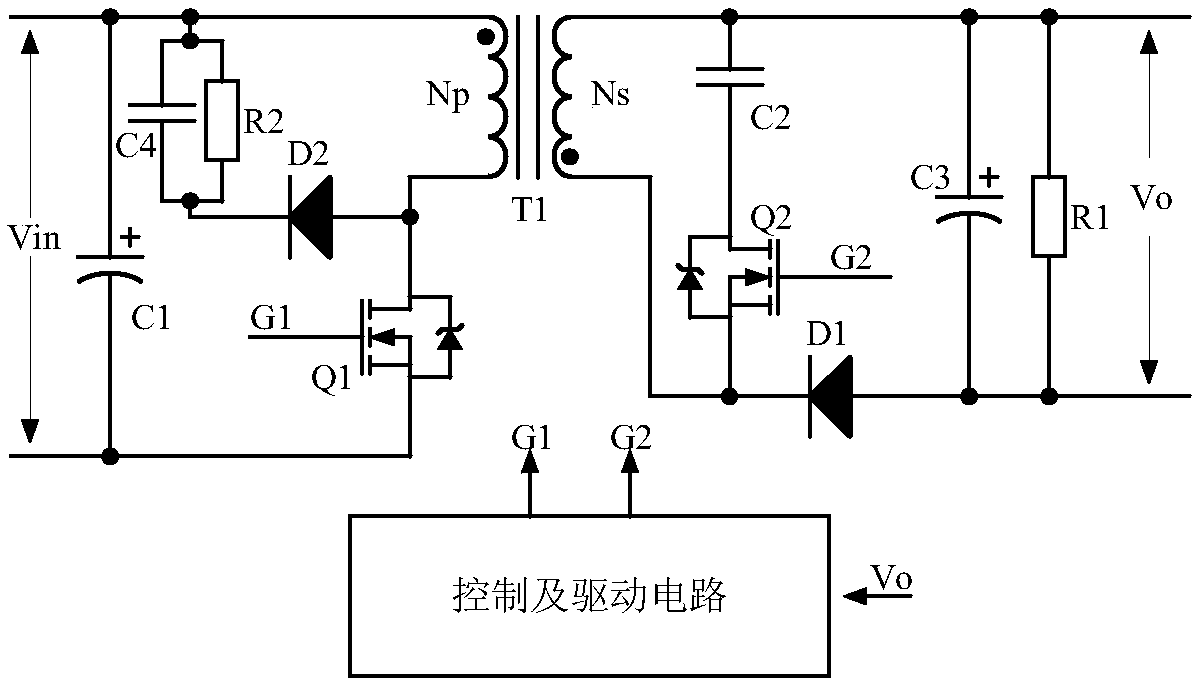

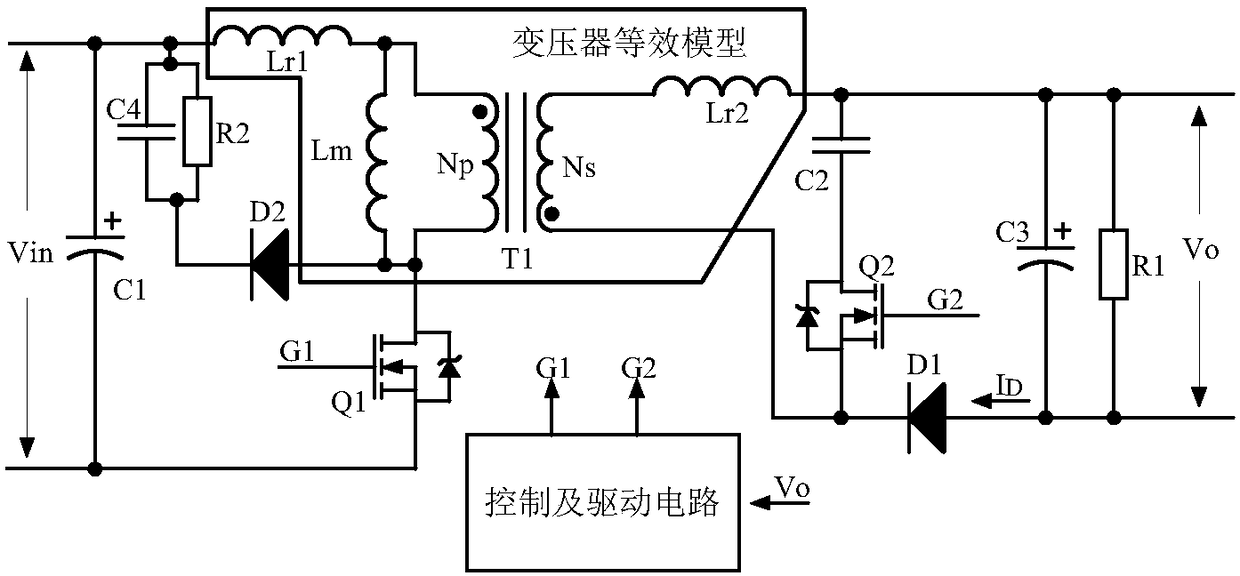

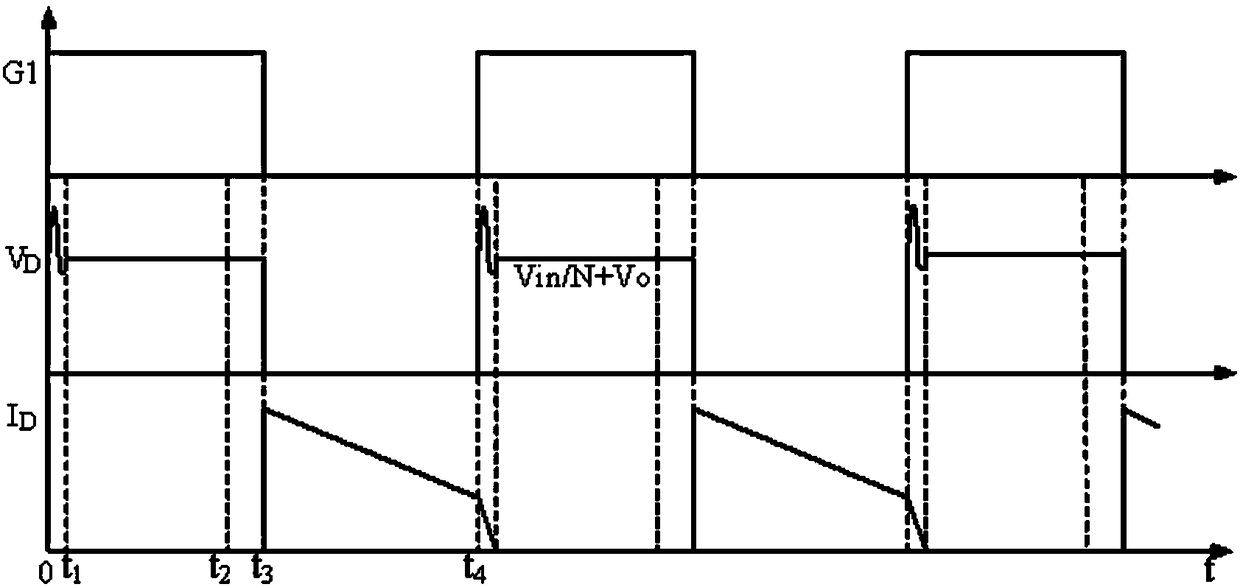

Converter and control method thereof

InactiveCN108539988AReduced turn-off lossPlay a recycling effectDc-dc conversionElectric variable regulationRectifier diodesEngineering

The invention provides a converter and a control method thereof. An absorption network is added to the conventional flyback converter. When a main switch transistor is on, voltage at two ends of a secondary side rectifier diode is clamped at Vin / N + Vo (N is the turn ratio of a primary side to a secondary side of the transformer, Vin is input voltage, and Vo is output voltage), the turn-off loss of the secondary side rectifier diode drops, energy in the absorption network can be used again, and the conversion efficiency of the flyback converter is thus improved.

Owner:MORNSUN GUANGZHOU SCI & TECH

A treatment method for antibiotics in mariculture wastewater

ActiveCN108002605BEfficient removalPlay a recycling effectSeawater treatmentWater contaminantsBiotechnologyMarine aquaculture

The invention relates to the treatment of antibiotics in mariculture wastewater with simple operation and used for removing a large amount of oxytetracycline, sulfamethoxazole, virginiamycin and chloramphenicol, etc. The method solves a series of environmental problems such as the increasing scale of aquaculture, the discharge of seawater aquaculture wastewater has become an important way for antibiotics to enter the environment, and can lead to enhanced drug resistance of pathogenic microorganisms, inhibition of beneficial microbial activity, and antibiotic residues in seafood , has an excellent effect of purifying water quality, and the treatment cost is low, and no harmful substances are produced during the treatment process.

Owner:ZHEJIANG OCEAN UNIV

Production method of high-efficiency cement

InactiveCN104086106APlay a recycling effectSolve processing problemsCement productionMethods of productionGypsum

The invention discloses a production method of high-efficiency cement, relating to the field of building production. According to the method, shells are used instead of limestone as the substrate to fire the cement. The method comprises the following steps: making the shells, gypsum and kaolin into fine powder, respectively calcining in a high-temperature furnace in a ratio of 4:3:3, and finally, uniformly mixing. The method is economical and practical; and since the amount of the shells is not limited, the shells can be taken freely, thereby saving abundant cost.

Owner:安徽珍珠水泥集团股份有限公司

Cement preparation method

The invention discloses a cement preparation method and relates to the field of construction production. According to the method, recycled marble is used for replacing limestone so as to prepare cement at a low temperature. The method comprises the following steps: processing the marble, gypsum and kaolin into fine powder; separately calcining in a high-temperature furnace; finally, evenly mixing. Cost is saved greatly by utilizing the method, which conforms to the current slogans and calling very well.

Owner:FENGYANG ZHONGDU CEMENT

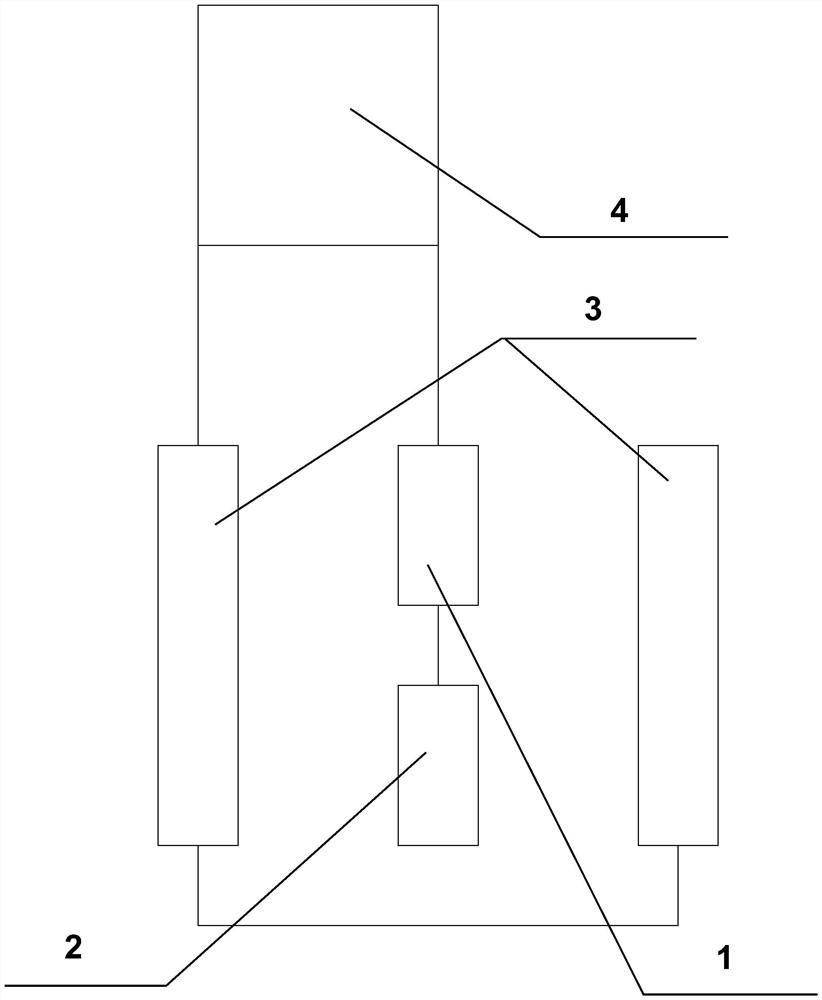

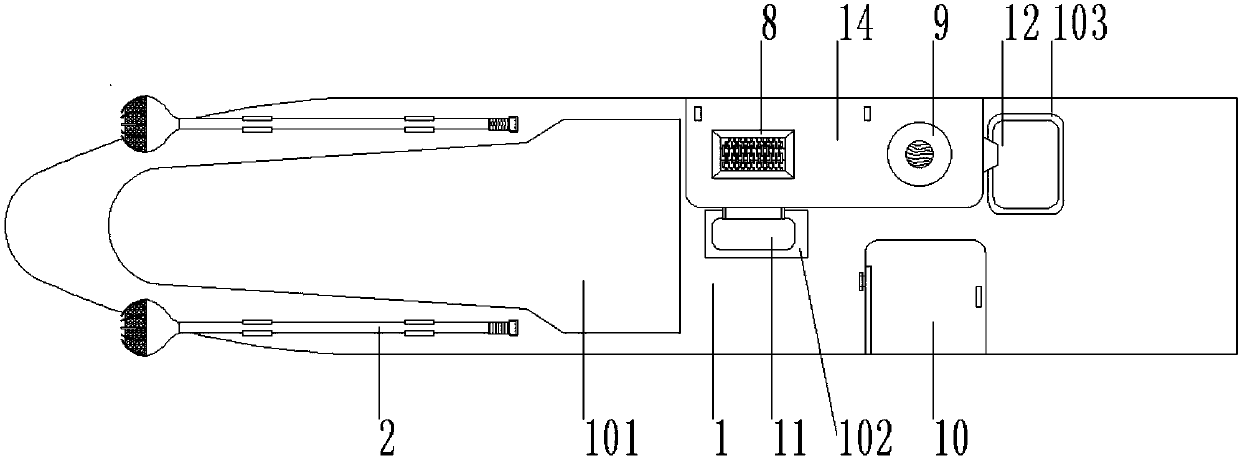

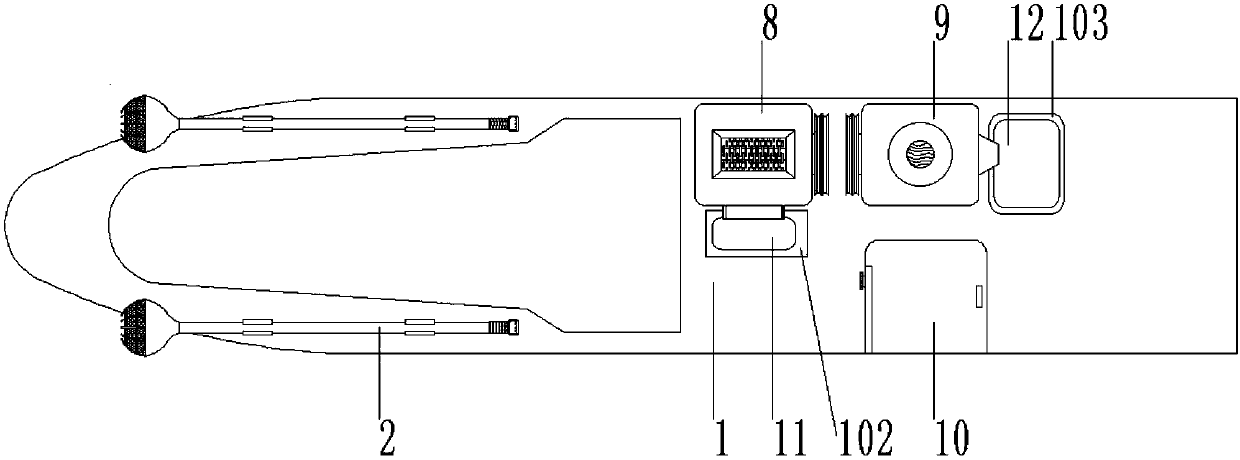

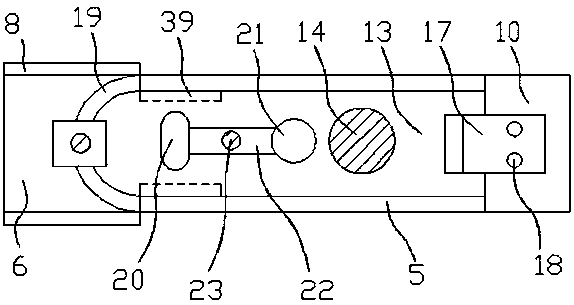

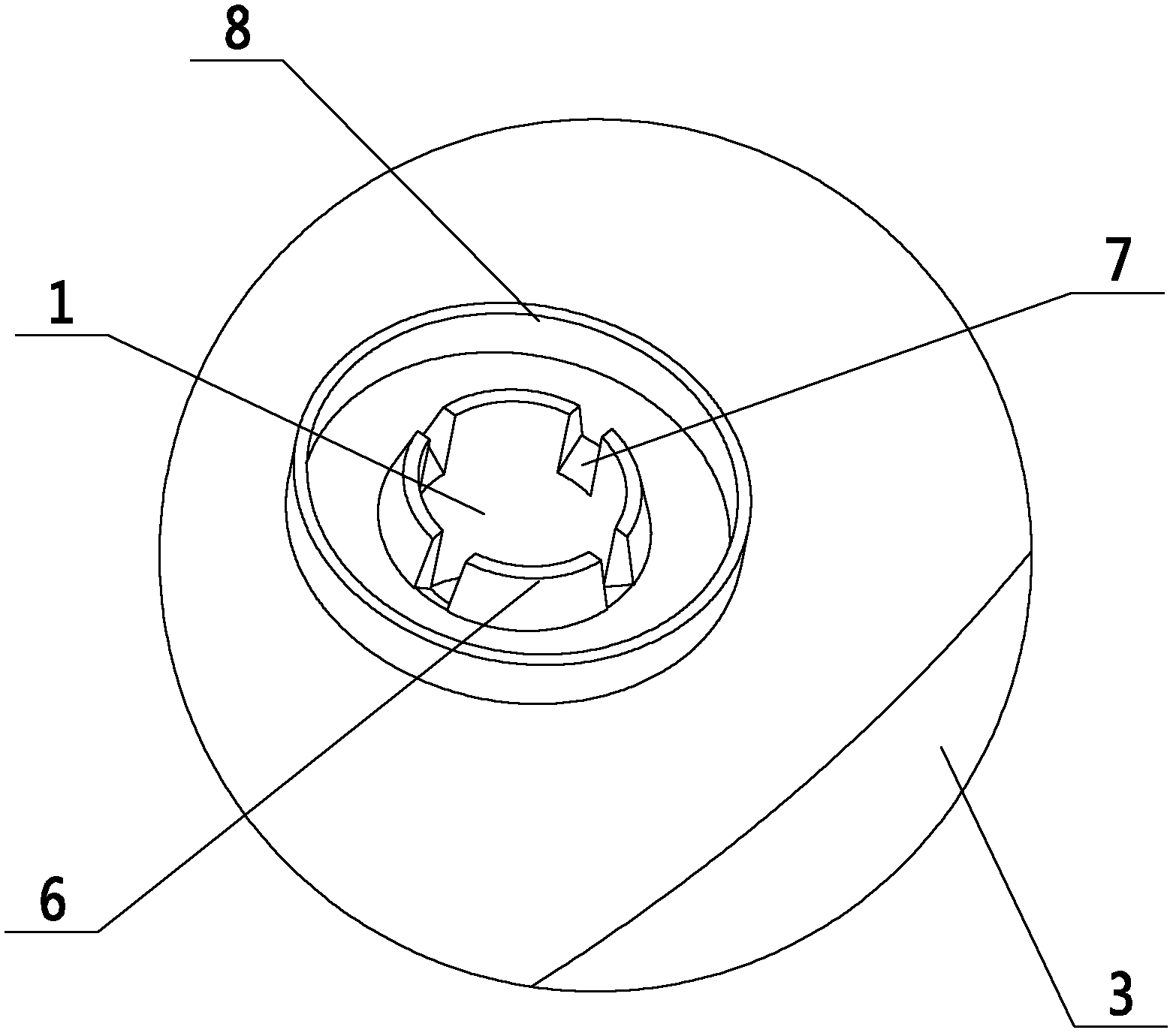

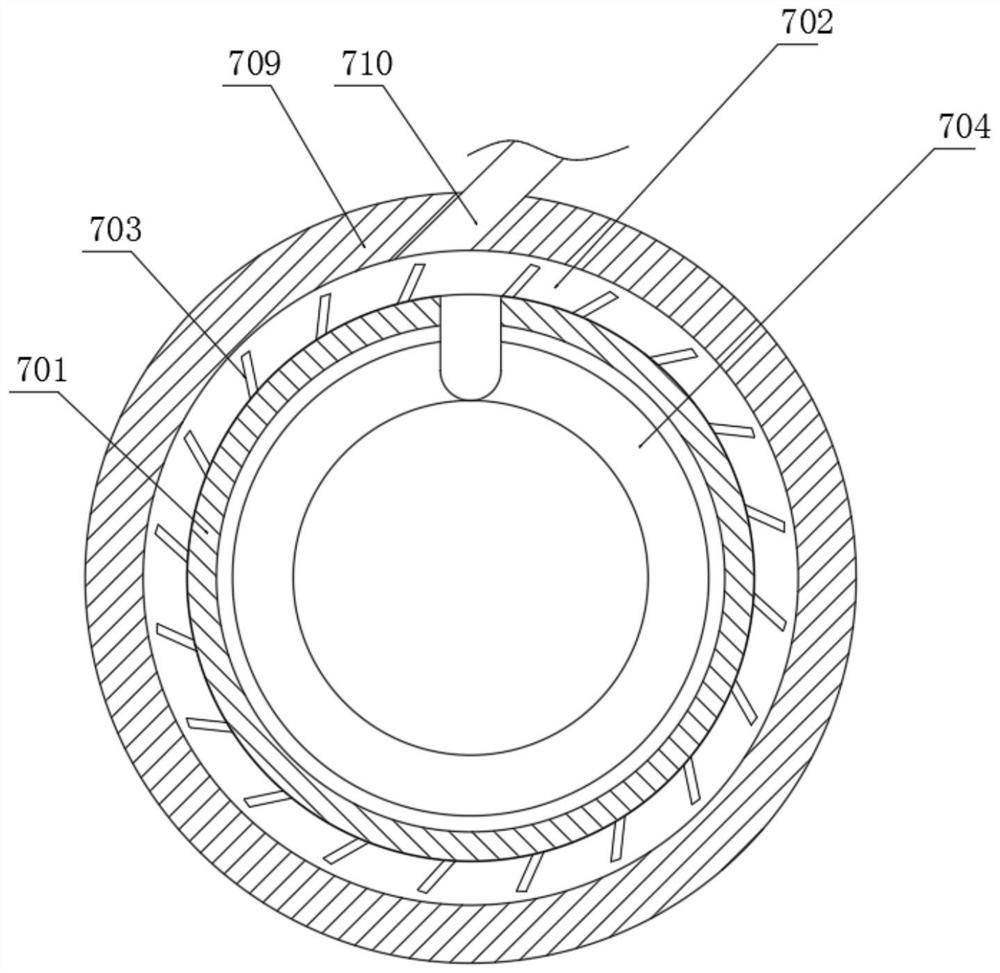

Silicon rod producing and machining polishing device with convenience in adjusting polishing directions

ActiveCN107639493AAdjust the grinding directionEasy to put inEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention discloses a silicon rod producing and machining polishing device with convenience in adjusting polishing directions. The silicon rod producing and machining polishing device comprises abottom plate, a turntable and a disc. Support tables are mounted on two lower sides of the bottom plate, an accommodating tank is arranged between the support tables, a support frame is arranged on the upper side of the bottom plate, a cylinder is mounted on the upper side of the support frame, a driving machine is fixed to the front side of the turntable, fixing screws are mounted on the side surfaces of the disc, a movable rod is arranged below the disc, a fixing device is arranged on the outer side of the movable rod, a polishing wheel is mounted on the front side of the driving machine, apolishing sheet is arranged on the front side of the polishing wheel, a rotary shaft is arranged between the polishing wheel and the driving machine, compressing sheets are arranged at ports of the fixing screws, and rubber layers are arranged on the compressing sheets. The silicon rod producing and machining polishing device with the convenience in adjusting the polishing directions has the advantages that the characteristics of fragility of silicon rods are taken into consideration, the silicon rods can be protected in silicon rod polishing procedures, and the polishing directions can be adjusted.

Owner:内蒙古和光新能源有限公司

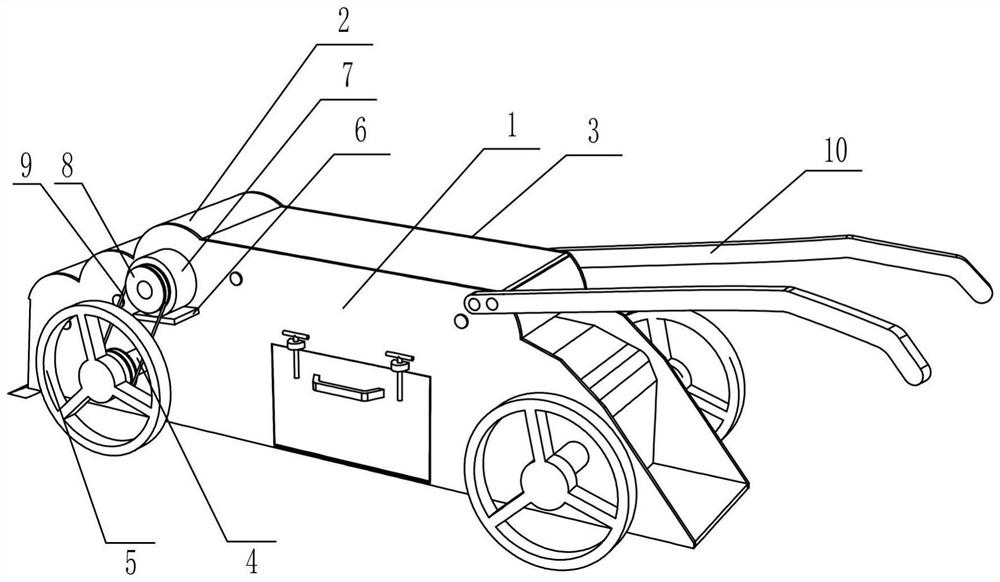

Disabled and dead fish collector for aquaculture

ActiveCN107926879AEasy to grabPrevent escapeWaterborne vesselsSpecial purpose vesselsEngineeringCrusher

The invention provides a disabled and dead fish collector for aquaculture. The disabled and dead fish collector comprises a fishing net, a crusher, a pulverizer, a high-temperature drying box, a firststorage bucket, a second storage bucket, a protective cover, a battery and a motor. A boat groove, a first storage groove and a second storage groove are formed in the end surface of the top of a boat body, two fishing rods are arranged at the front end of the end surface of the top of the boat body, and eight sliding holes are formed in the right ends of the fishing rods to facilitate the capture of disabled and dead fish, so that the situation that the harmful bacteria contained in the disabled and dead fish pollute the aquaculture water and cause damage to the fish within the aquaculture water is avoided. Unlike other exiting fishing devices prone to escape of wounded fish when used, the collector effectively avoids the escape of the wounded fish and improves the efficiency of water cleaning by trapping the wounded fish inside a spherical structure composed of eight grab bars and the fishing net.

Owner:苏州培恩特生物科技有限公司

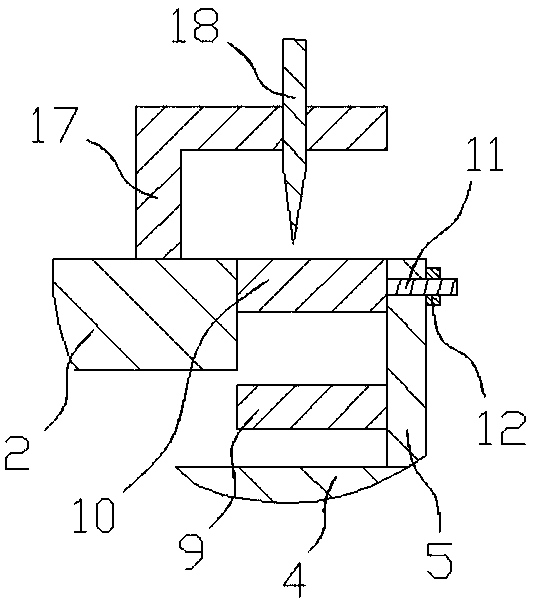

Die-casting machine for plug-and-socket fasteners

The invention relates to a die-casting machine for plug-and-socket fasteners. The die-casting machine comprises a machine frame; a lower working plate and an upper working plate are arranged on the machine frame; the lower working plate is provided with a lower module, and side plates are arranged on the front side, the rear side and the right side of the lower module; a clamping opening forming block and a clamping opening forming cover plate are arranged on the inner side of the right side plate of the lower module; a pressing block lifting cylinder is arranged below the upper working plate;the lower portion of the pressing block lifting cylinder is connected with an upper mold pressing block matched with the lower module; the left end of the upper mold pressing block is arc, and buckleplate forming openings are formed in the lower portions of the front side and the rear side of the left end; a socket opening forming column is arranged on the upper mold pressing plate and located between the two buckle plate forming openings in a penetrating and inserting fit mode; the upper end of the socket opening forming column is connected with a socket opening forming lifting block; the upper portion of the socket opening forming lifting block is connected with a socket opening forming lifting cylinder which is matched with a mold unloading movable device on the upper working plate; and the upper working plate is further provided with a side mold device in arc fit with the left end of the upper mold pressing block. By means of the die-casting machine, lateral mold-loading can be achieved, and the fastener machining efficiency is improved significantly.

Owner:DONGGUAN UNIV OF TECH

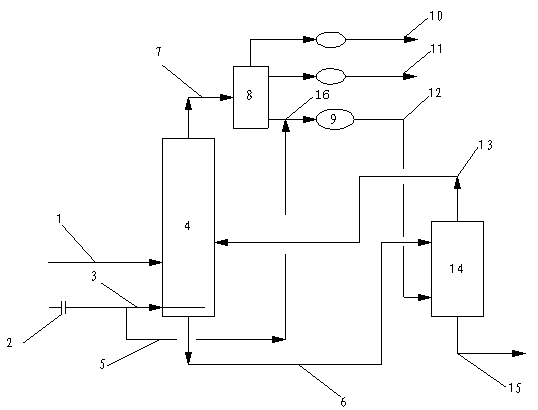

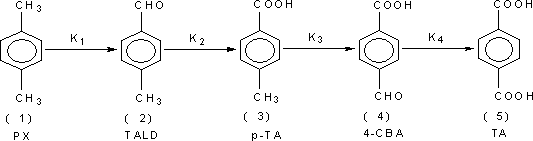

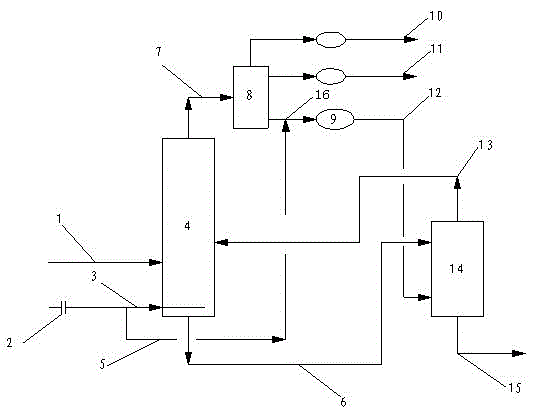

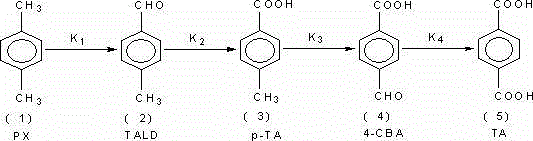

Method and apparatus for producing PTA via deep oxidation by using oxygen-deficient gas

ActiveCN102993000APlay a recycling effectEfficient recyclingOrganic compound preparationCarboxylic compound preparationAcetic acidSlurry

The invention relates to a method and an apparatus for producing PTA via deep oxidation by using an oxygen-deficient gas. The method comprises the following steps of (1) oxidizing p-xylene in an acetic acid solvent by using an oxygen-containing gas to form oxidation slurry of p-xylene and intermediate products; and (2) performing deep oxidation on the oxidation slurry obtained from the step (1) by using the oxygen-deficient gas so as to obtain PTA. The apparatus comprises an oxidation reaction device, a deep oxidation reaction device and a tail gas purification treatment device. The material outlet of the oxidation reaction device is connected with the material inlet of the deep oxidation reaction device; the gas inlet of the deep oxidation reaction device is connected with the gas outlet of the tail gas purification treatment device through a tail gas delivery pipeline; and the gas inlet of the deep oxidation reaction device is also connected with a compressed air delivery pipeline. The deep oxidation is carried out by using the oxygen-deficient gas, so that requirements for oxygen concentration of a deep oxidation reaction can be met; oxidation combustion of acetic acid caused by too high oxygen content in the gas can be prevented; and gas volume fraction in the reaction slurry can be increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

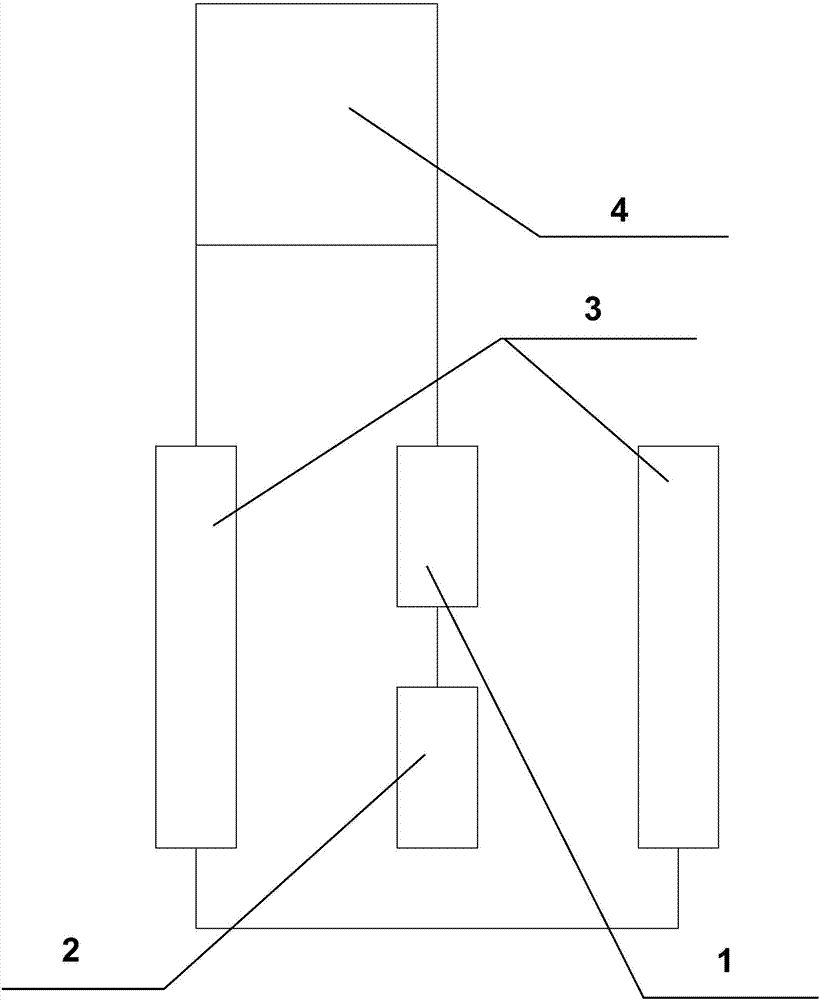

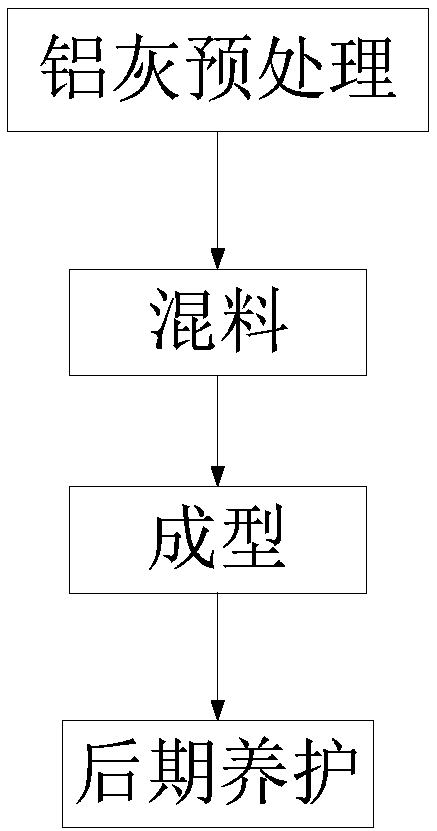

Method for preparing non-sintered sidewalk brick with primary aluminum ash after fine grinding

InactiveCN107892540AEarly morning high intensityNot easy to damageSolid waste managementPre treatmentScrap

The invention discloses a method for preparing a non-sintered sidewalk brick with primary aluminum ash after fine grinding, wherein the method includes the following steps of aluminum ash pretreatment, mixing, molding, and later maintenance; waste aluminum ash is used as a main aggregate, and additives such as a high performance water reducing agent, an early strength agent and the like are added,so that the sidewalk brick has high early strength, is not easy to damage during demoulding, and has the compressive strength increased. The sidewalk brick prepared by the method has the characteristic of low production cost due to utilization of the primary aluminum ash waste. The problem of ecological environment affected by aluminum ash accumulation is effectively solved, and the method playsa resource recycling effect and has important practical value.

Owner:NANTONG UNIVERSITY

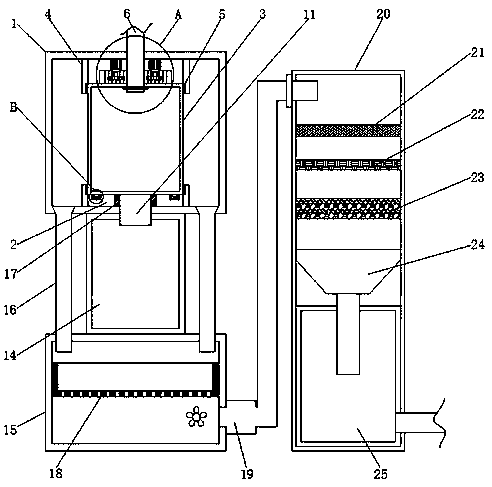

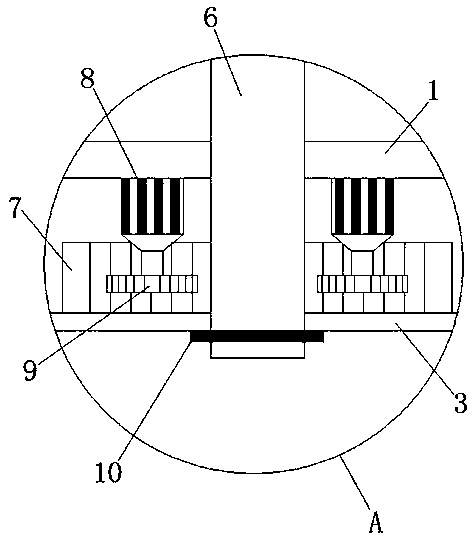

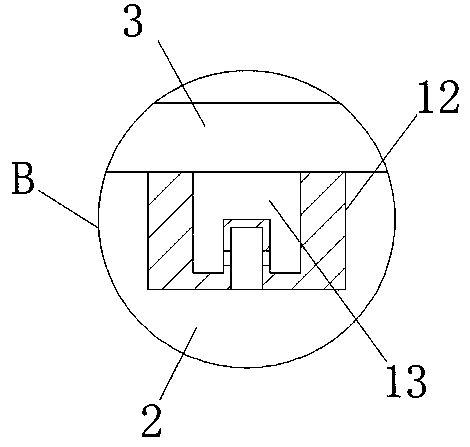

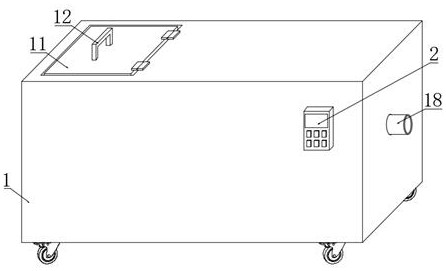

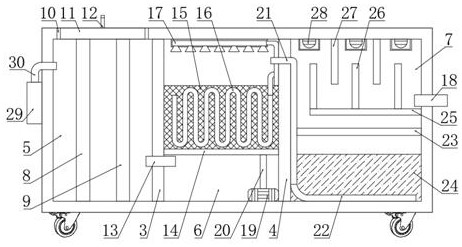

Wastewater treatment device with good metal recovery effect

InactiveCN110627291AGood for metal recyclingEasy to handleTreatment involving filtrationWater/sewage treatment by ion-exchangeMotor driveResource recovery

The invention provides a wastewater treatment device with good metal recovery effect, and relates to the field of environmental protection equipment. The wastewater treatment device comprises a filtering box, wherein a supporting seat is fixedly mounted at the bottom of the inner wall of the filtering box, a filtering roller is arranged at the top of the supporting seat, filtering holes are formedin the outer surface of the filtering roller, the top of the filtering roller is communicated to a water inlet pipe, the top of the water inlet pipe penetrates through the top of the inner wall of the filtering box and extends to the upper side of the filtering box, and a gear ring is fixedly mounted at the top of the filtering roller and located on the outer side of the water inlet pipe. According to the wastewater treatment device of the invention, the motor drives the gear to rotate so as to make the gear ring drive the filtering roller to rotate, the wastewater and the metal particles areseparated by utilizing the centrifugal rate so as to improve the wastewater treatment effect, and the metal particles are collected through the collecting box, such that the metal recycling effect isachieved, and the effects of environment protection and resource recycling are achieved.

Owner:刘真荣

Graphene-containing textile fabric printing and dyeing device and printing and dyeing method thereof

PendingCN114703612AGuaranteed uniformityReduce use costLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsReciprocating motionProcess engineering

The invention discloses a graphene-containing textile fabric printing and dyeing device and a printing and dyeing method thereof, and belongs to the technical field of textile fabric printing and dyeing. The graphene-containing textile fabric printing and dyeing device comprises a treatment box, a drainage gas transmission assembly is arranged on the right side of the outer surface of the treatment box, and a stirring device is arranged on one side of the drainage gas transmission assembly and located in the treatment box; the stirring device is in transmission connection with a reciprocating motion structure, and the reciprocating motion structure is located in the treatment box. According to the graphene-containing textile fabric printing and dyeing device and the printing and dyeing method thereof, the stirring device, the drainage gas transmission assembly and the reciprocating motion structure are arranged, and under transmission cooperation of the stirring device, the drainage gas transmission assembly and the reciprocating motion structure, stirring, printing and dyeing and drying work can be synchronously driven; multiple processing modes of the device are integrated, the uniformity of printing, dyeing and drying can be guaranteed, intervention of too many driving devices is not needed, and the overall use cost is greatly reduced.

Owner:江苏申久纺织科技有限公司

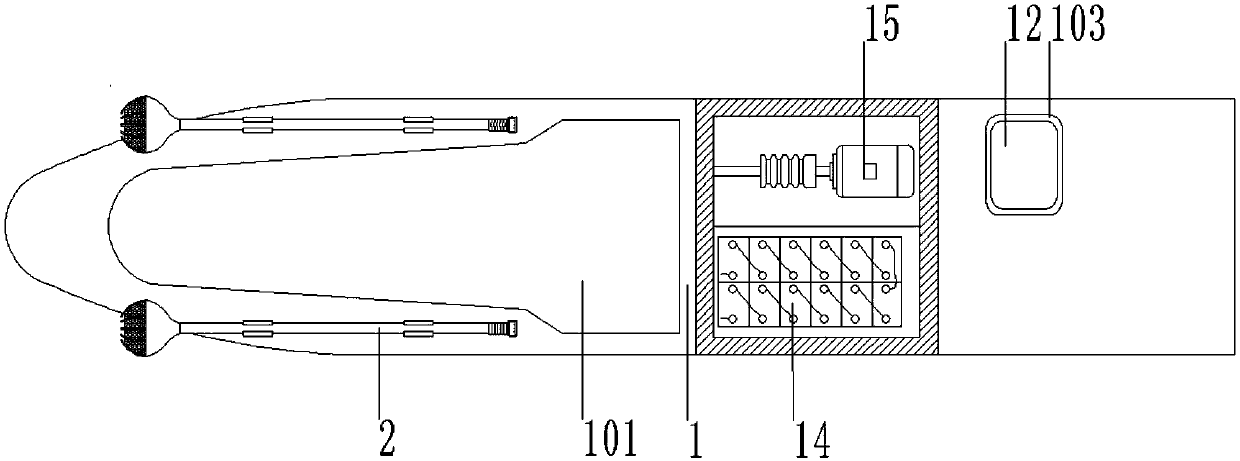

Treatment mechanism for cleaning test tube for chemical experiment

InactiveCN113182305APlay a recycling effectAvoid pollutionHollow article cleaningLavatory sanitoryTest tubeStructural engineering

The invention relates to the technical field of chemical laboratory equipment, and discloses a treatment mechanism for cleaning a test tube for a chemical experiment. The treatment mechanism comprises a main body, wherein a movable groove is formed in the top of the main body; two limiting grooves are symmetrically formed in the inner wall surface of the movable groove; telescopic grooves are formed in four corners of the left outer wall surface and the right outer wall surface of the main body; telescopic stabilizing devices are movably arranged in the telescopic grooves; and two groups of clamping devices are arranged in the movable groove in a sliding mode. According to the treatment mechanism, telescopic rods, stabilizing blocks, rubber plates, stabilizing grooves and the movable groove are arranged, the two stabilizing blocks are pulled to face the two sides of a test table according to the length and width of the test table, then openings of the stabilizing grooves are moved downwards, at the moment, the stabilizing grooves are elastically deformed, after the stabilizing grooves are loosened, the two stabilizing grooves are clamped at the two ends of the side edge of the test table, so that a stable supporting environment is provided for the experiment main body, and the situation that the test tube on the main body slides due to shaking of the main body is avoided.

Owner:汪斌

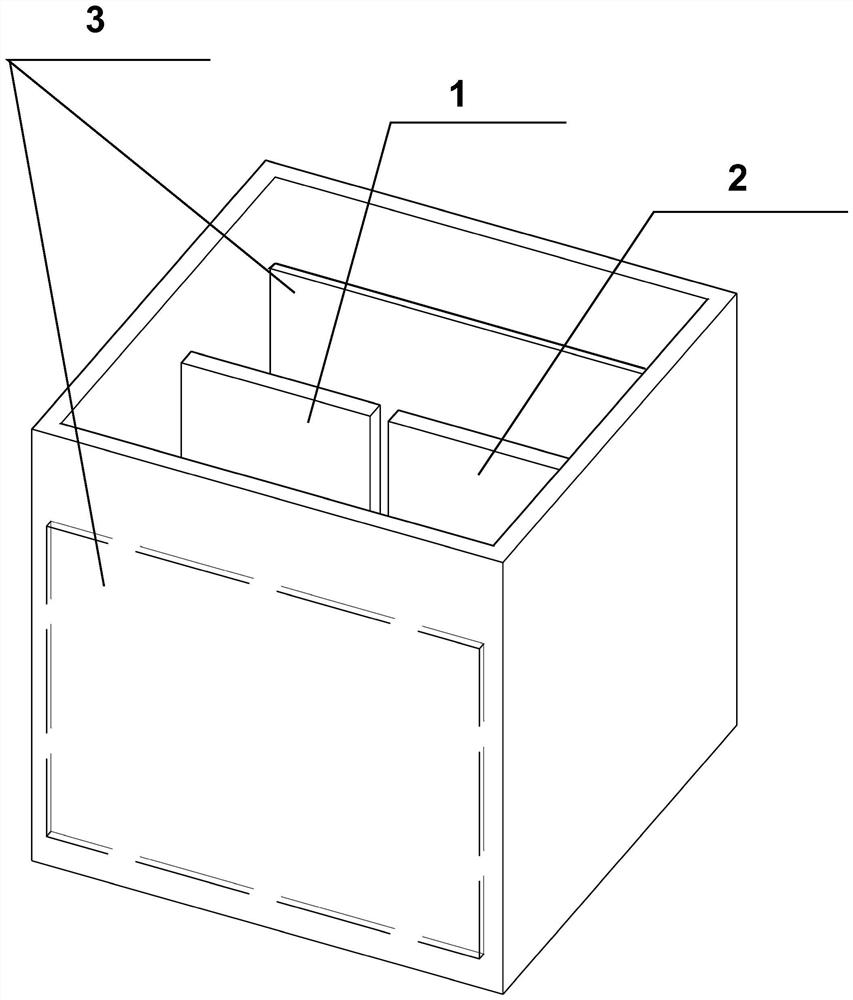

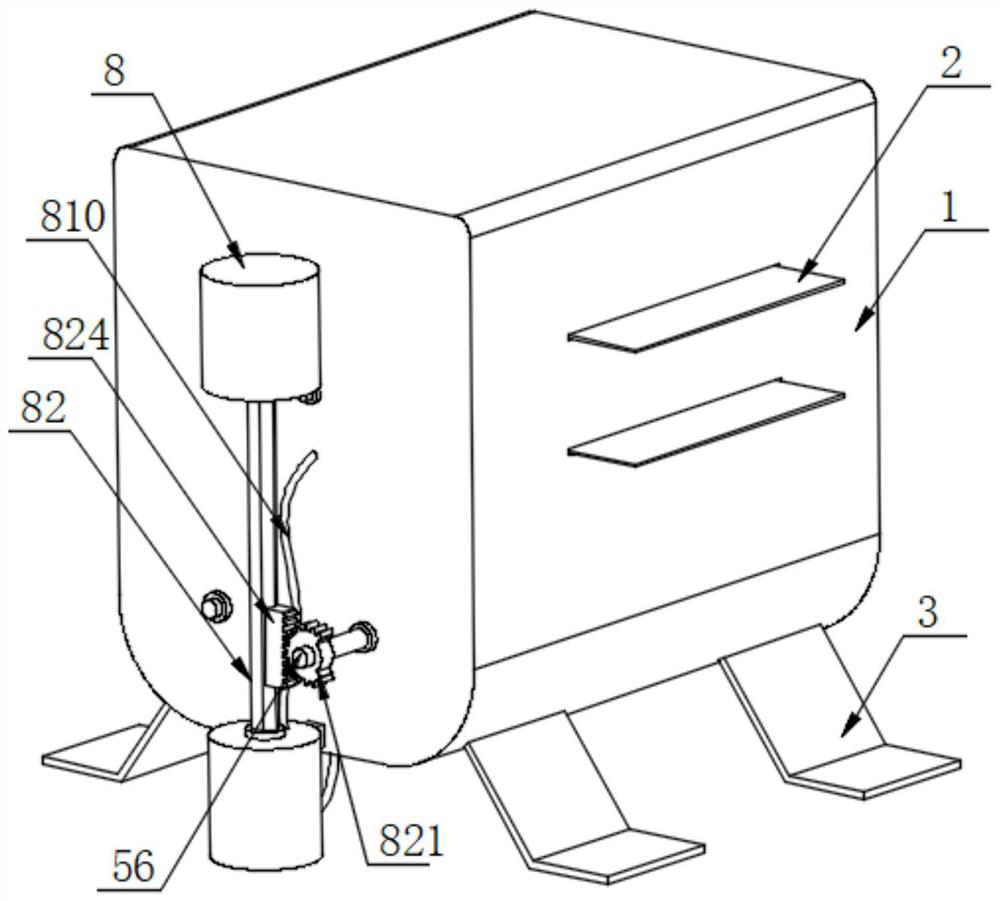

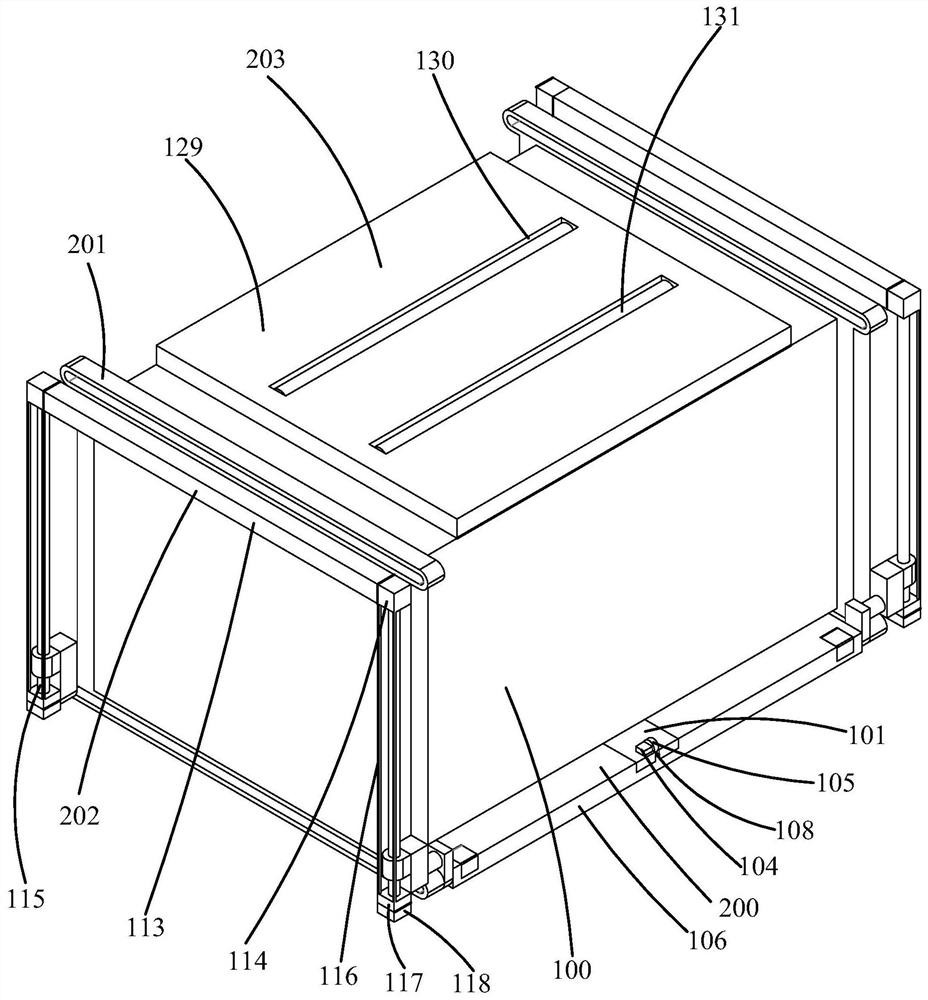

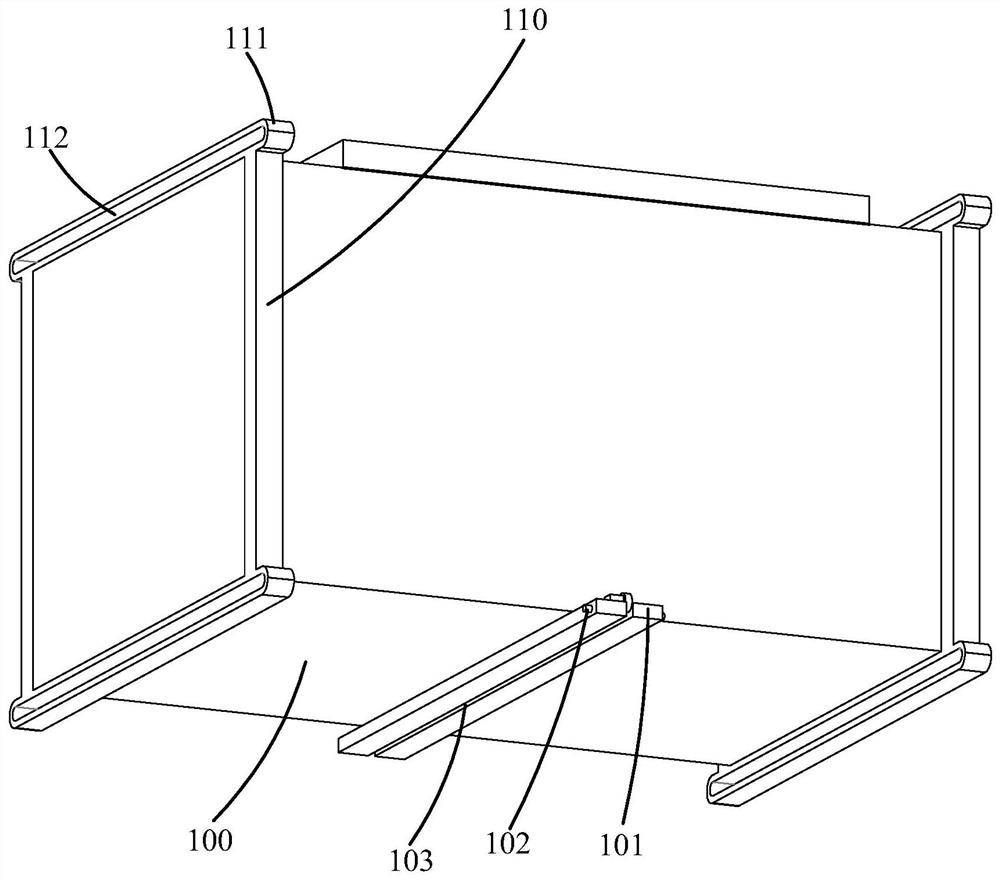

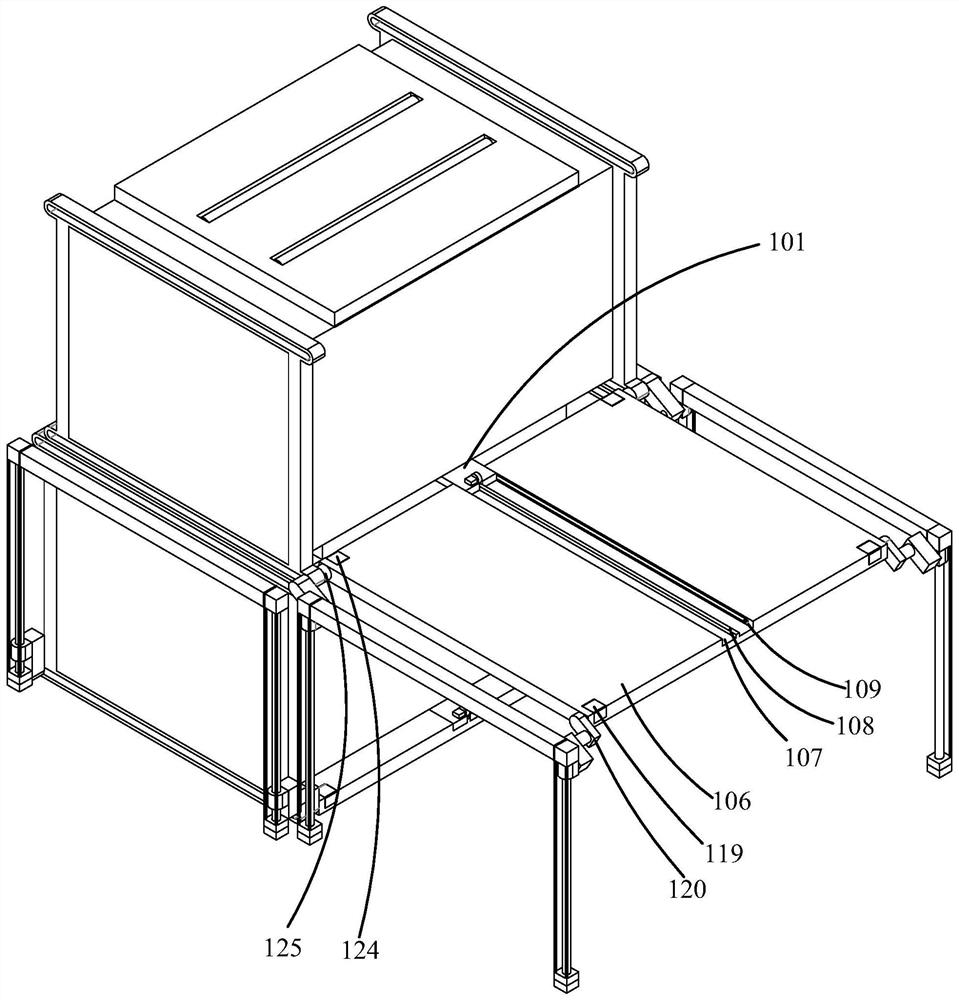

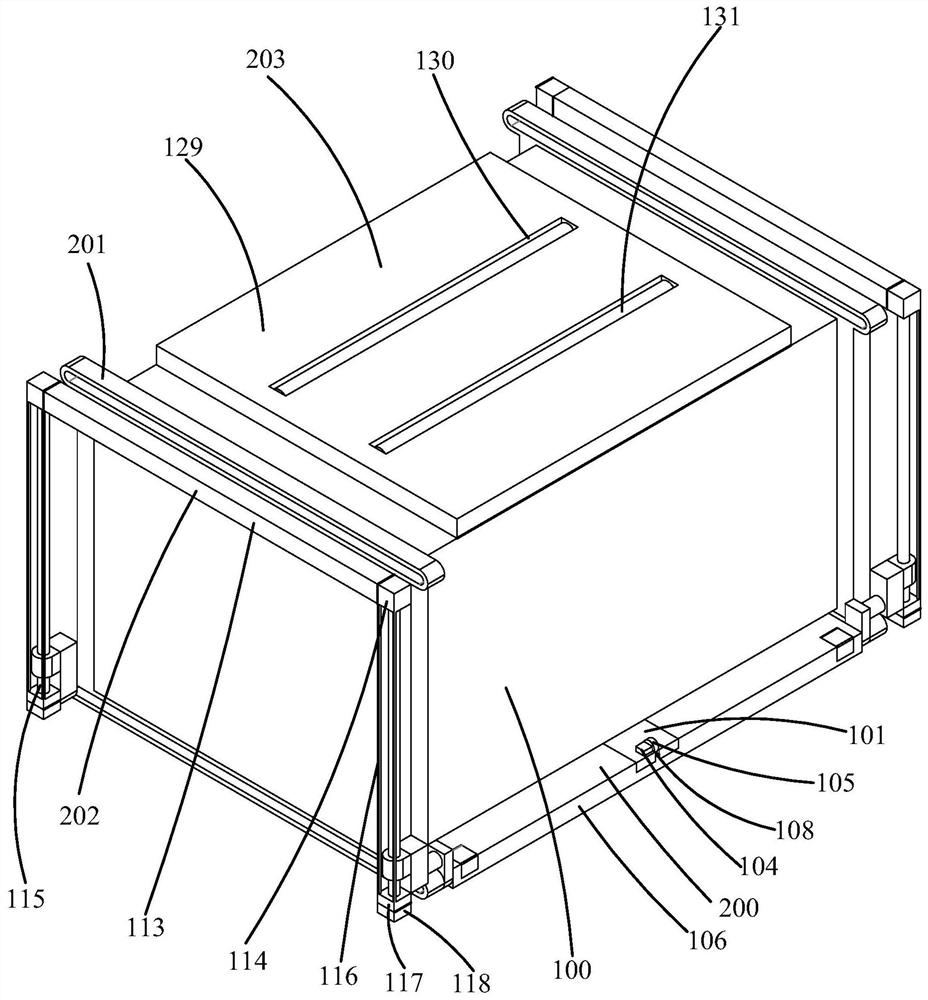

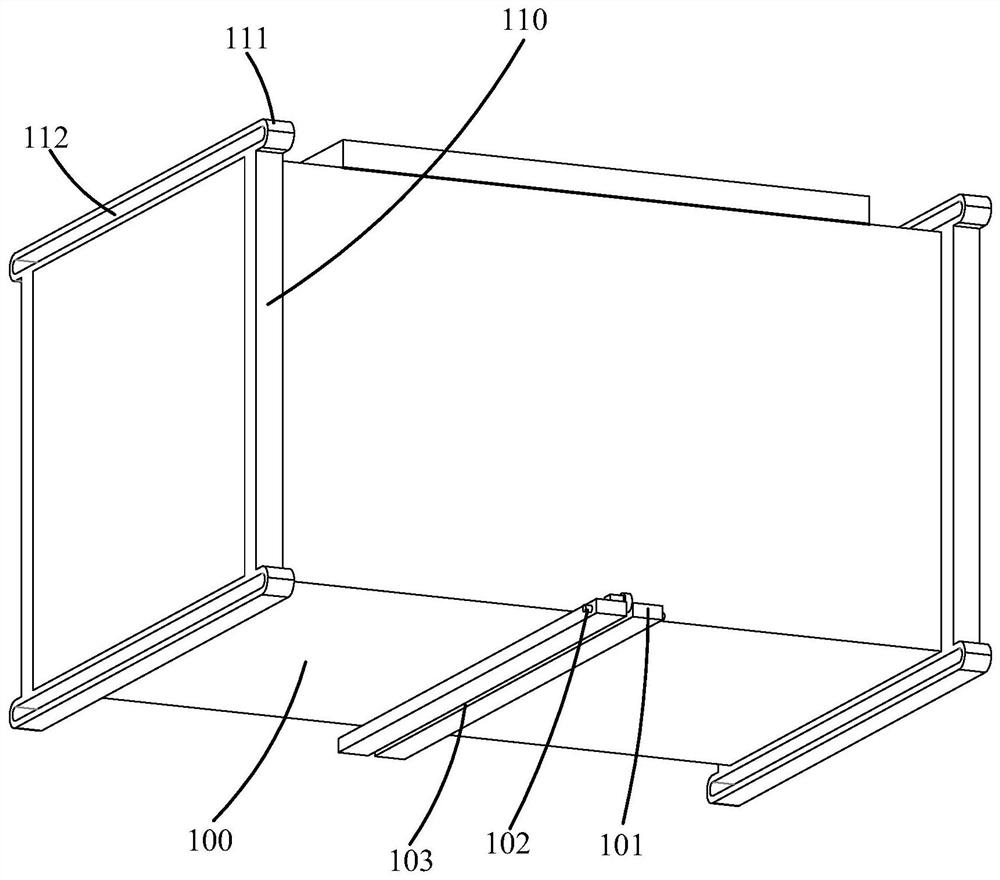

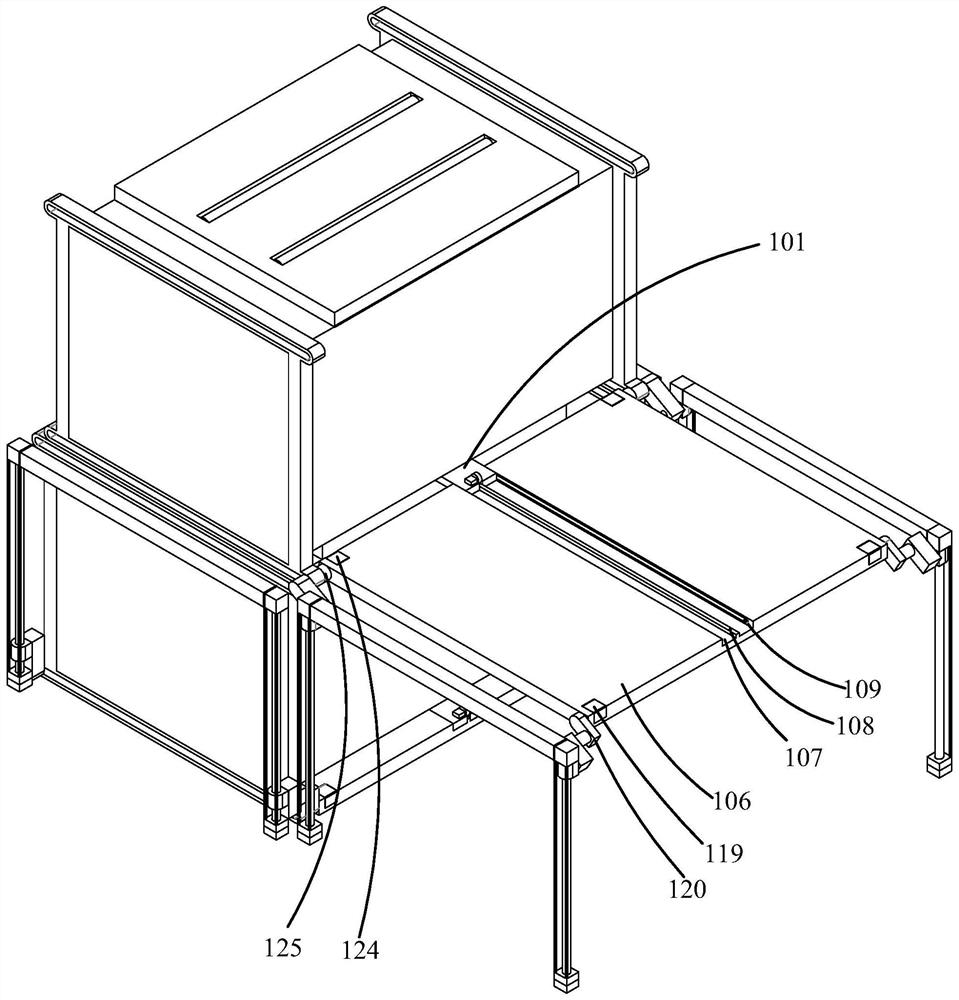

Board room convenient to install

ActiveCN112196116AImprove construction efficiencyReduce the risk of construction workBuilding constructionsStructural engineeringMechanical equipment

The invention discloses a board room convenient to install. The board room structurally comprises a board room body; a bearing supporting plate assembly used for bearing the board room body and driving the board room body to move is arranged below the board room body, and reinforcing frame assemblies used for reinforcing the board room body and capable of being connected with other assemblies arearranged on the two sides of the board room body; and a lifting carrying assembly used for ascending and descending the board room body to facilitate stacking of the board room body is arranged on theouter side of the board room body, and a horizontal-moving power assembly used for driving the board room body in stacked contact to horizontally move is arranged at the top of the board room body. Through work of a driving structure in a board room unit, setting up of a plurality of layers of board room groups is realized, the setting up efficiency is effectively improved, and the setting up operation risk is reduced.

Owner:安徽雄康建设工程有限公司

A board room that is easy to install

ActiveCN112196116BImprove construction efficiencyReduce the risk of construction workBuilding constructionsConstruction engineeringMechanical equipment

The invention discloses a prefabricated house which is easy to install. The structure includes a prefabricated house. A supporting plate assembly for carrying the prefabricated house and driving the prefabricated house to move is arranged under the prefabricated house. The board room can be connected to the reinforced frame assembly of the other components. The outside of the board room is provided with lifting and carrying components for the lifting of the board room to facilitate the stacking of the board room. Power components, the present invention can be installed without the help of large-scale mechanical equipment in the external space, and can make the prefabricated house into a prefabricated house unit, and realize the construction of multi-layered prefabricated house groups through the work of the driving structure in the prefabricated house unit, effectively improving the construction efficiency And reduce the risk of construction work.

Owner:安徽雄康建设工程有限公司

Waste recovery device for hardware processing

InactiveCN111922911AReduce labor intensityCause personal injuryCarpet cleanersFloor cleanersElectric machineryWaste material

The invention relates to a waste recovery device for hardware processing. The waste recovery device comprises a front case, a top plate, a material loading platform, a rear case, rotating shafts I, walking wheels, a support plate, a motor, a belt wheel I, a belt I, a handrail, a transmission mechanism, a compression mechanism and a disassembly mechanism. The top plate is fixedly connected to one side of the front case, the rear case is fixedly connected to one end of the top plate, the rear case is fixedly connected with the bottom of one side of the front case, the material loading platform is fixedly connected to one side of the rear case and one side of the front case, the two sides of the front case and the two sides of the rear case are all rotatably connected with the rotating shaftsI through bearings, the transmission mechanism is arranged on one side of the rear case and used for transmitting power, the compression mechanism is arranged on one side of the front case and one side of the rear case and facilitates compressing hardware waste materials, and the disassembly mechanism is arranged on one side of the front case and is used for taking out the compressed waste materials conveniently. According to the waste recovery device for hardware processing, the labor intensity of workers is reduced when the waste materials are collected, personal injury to the workers during collection is avoided, and the collection and cleaning can be rapidly realized by starting the motor.

Owner:株洲市东亨科技有限责任公司

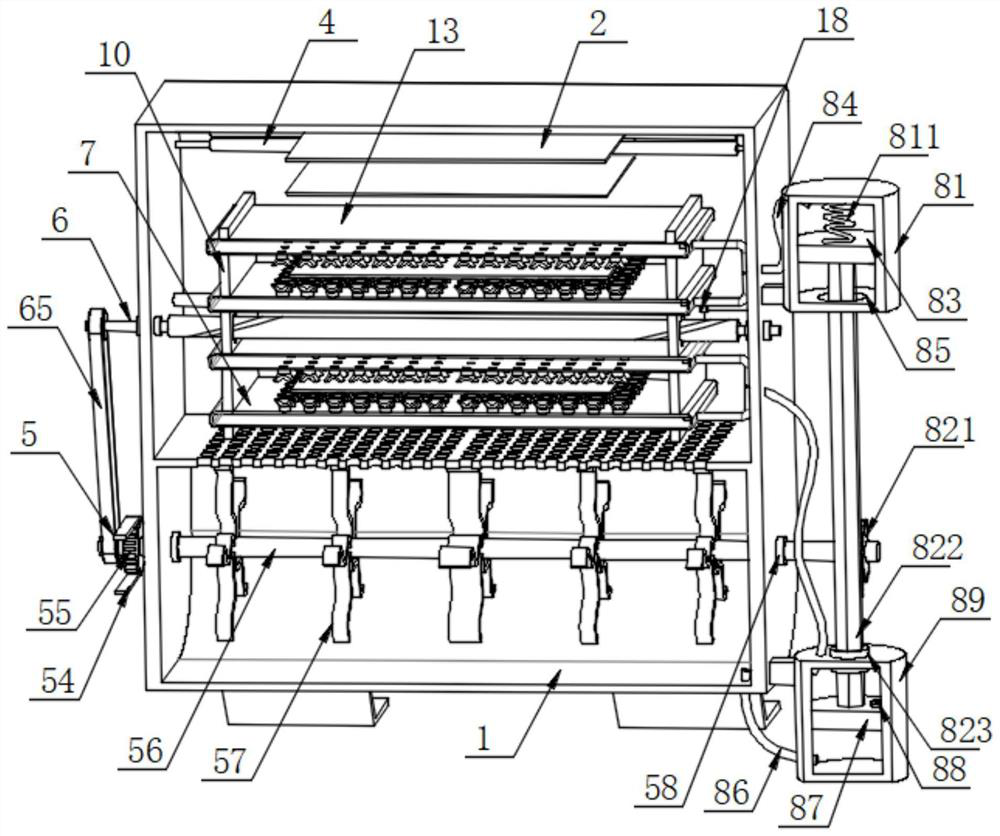

Waste tire recycling device

InactiveCN107189807AEasy to recycleEnvironmental protection is goodCombination devicesPigmenting treatmentActivated carbonButt joint

The invention provides a waste tire recycling device. The waste tire recycling device comprises a base and a support frame, wherein the base is provided with a conveying device; the support frame is provided with a pyrolytic reaction device and a discharging device; a recycling device is arranged inside the support frame; the head and the tail of the conveying device are connected with a charging hole and a discharging hole respectively; the discharging hole is connected with the pyrolytic reaction device; one side of pyrolytic reaction device is in butt joint with the discharging hole; the other side of pyrolytic reaction device is provided with the discharging device; the recycling device is arranged below the pyrolytic reaction device and the discharging device. The waste tire recycling device is simple in structure, is safe and convenient to use, and has a reasonable regeneration system. By adopting the waste tire recycling device, the influence on an external environment can be lowered effectively, the implementation of environmental policies is ensured, the oil producing rate and the recycling rates of activated carbon and steel wires can be increased effectively, the labor strength of operators is lowered effectively, and the working efficiency is increased.

Owner:WUHAN UNIV OF SCI & TECH

Method and device for producing pta by deep oxidation using oxygen-poor gas

ActiveCN102993000BPlay a recycling effectEfficient recyclingOrganic compound preparationCarboxylic compound preparationAcetic acidSlurry

The invention relates to a method and an apparatus for producing PTA via deep oxidation by using an oxygen-deficient gas. The method comprises the following steps of (1) oxidizing p-xylene in an acetic acid solvent by using an oxygen-containing gas to form oxidation slurry of p-xylene and intermediate products; and (2) performing deep oxidation on the oxidation slurry obtained from the step (1) by using the oxygen-deficient gas so as to obtain PTA. The apparatus comprises an oxidation reaction device, a deep oxidation reaction device and a tail gas purification treatment device. The material outlet of the oxidation reaction device is connected with the material inlet of the deep oxidation reaction device; the gas inlet of the deep oxidation reaction device is connected with the gas outlet of the tail gas purification treatment device through a tail gas delivery pipeline; and the gas inlet of the deep oxidation reaction device is also connected with a compressed air delivery pipeline. The deep oxidation is carried out by using the oxygen-deficient gas, so that requirements for oxygen concentration of a deep oxidation reaction can be met; oxidation combustion of acetic acid caused by too high oxygen content in the gas can be prevented; and gas volume fraction in the reaction slurry can be increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Biological deodorization equipment

PendingCN112915773APlay a recycling effectAvoid wastingGas treatmentDispersed particle filtrationMicroorganismDisinfectant

The invention belongs to the technical field of biological deodorization, and particularly relates to biological deodorization equipment. The equipment comprises a box body; a first partition plate and a second partition plate are fixedly connected to the inner wall of the box body and divide the inner wall of the box body into a filter chamber, a deodorization chamber and a purification chamber, wherein the filter chamber is communicated with the deodorization chamber through a connecting pipe. According to the device, through the arrangement of the circulating pipeline and the spraying assembly, a nutrient solution can be uniformly sprayed into the biological filler layer to ensure the growth and development of microorganisms, so that the deodorization effect is improved, through the combined action of a water pump, a three-way pipe and a first hollow plate, the effect of recycling the redundant nutrient solution can be achieved, and the waste of the nutrient solution is prevented; through the arrangement of a disinfectant and an ultraviolet lamp, the sterilization and purification effect on gas is improved, through the combined action of a second hollow plate, a transverse plate, a first vertical plate and a second vertical plate, the circulation duration of the gas in the purification chamber is prolonged, and then the sterilization effect of the ultraviolet lamp on the gas is improved.

Owner:湖南宜青环保科技有限公司

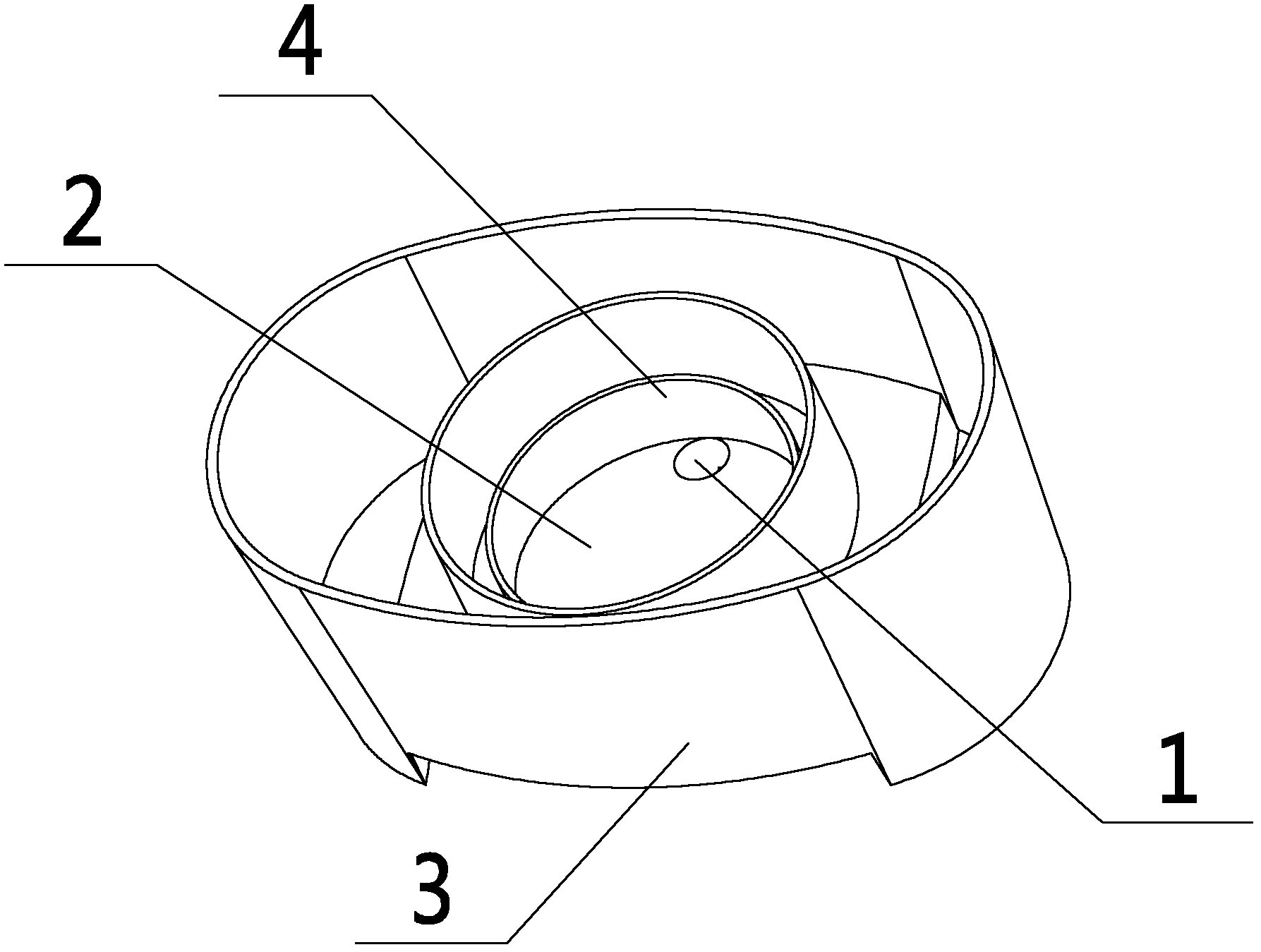

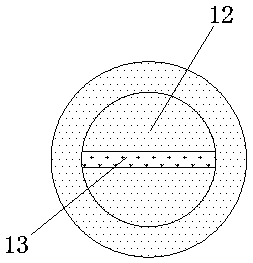

Eccentric bottle cap

The invention discloses a eccentric bottle cap, which is characterized in that: the eccentric bottle cap comprises a cap body, a liquid outlet opening is arranged on the cap body, a protective ring is arranged on a top surface of an inner side of the cap body, and a convex ring is arranged on the extension position of the a top surface of an outer side of the cap body and the liquid outlet opening; the top surface of the inner side is a inclined plane; and the liquid outlet opening is located in the lower end of the top surface of the inner side in interior of the protective ring. According to the eccentric bottle cap of the invention, because of a eccentric position of the liquid outlet opening, so when there is little liquid in the bottles, vertically pouring is not needed, and only a bit inclination is needed for pouring out the liquid. The bottle cap has simple structure and practical operation, and because a groove opening with inclination is arranged on the convex ring and a check ring is added on the outer of concentric position of the liquid outlet opening, the waste of liquid can be reduced to the greatest extent during usage, and a certain recycling effect is taken.

Owner:SUZHOU YAER PLASTIC TECH

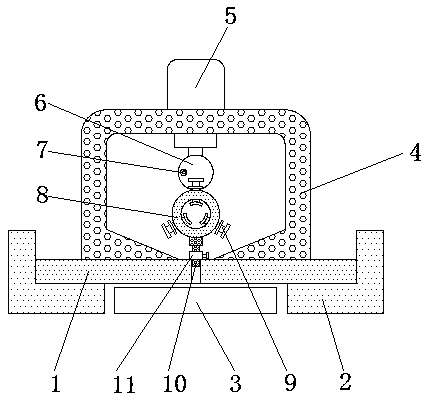

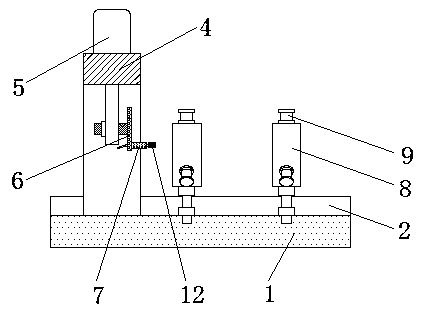

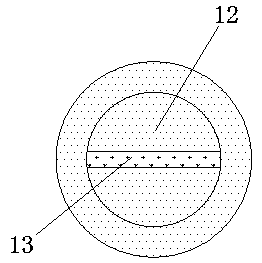

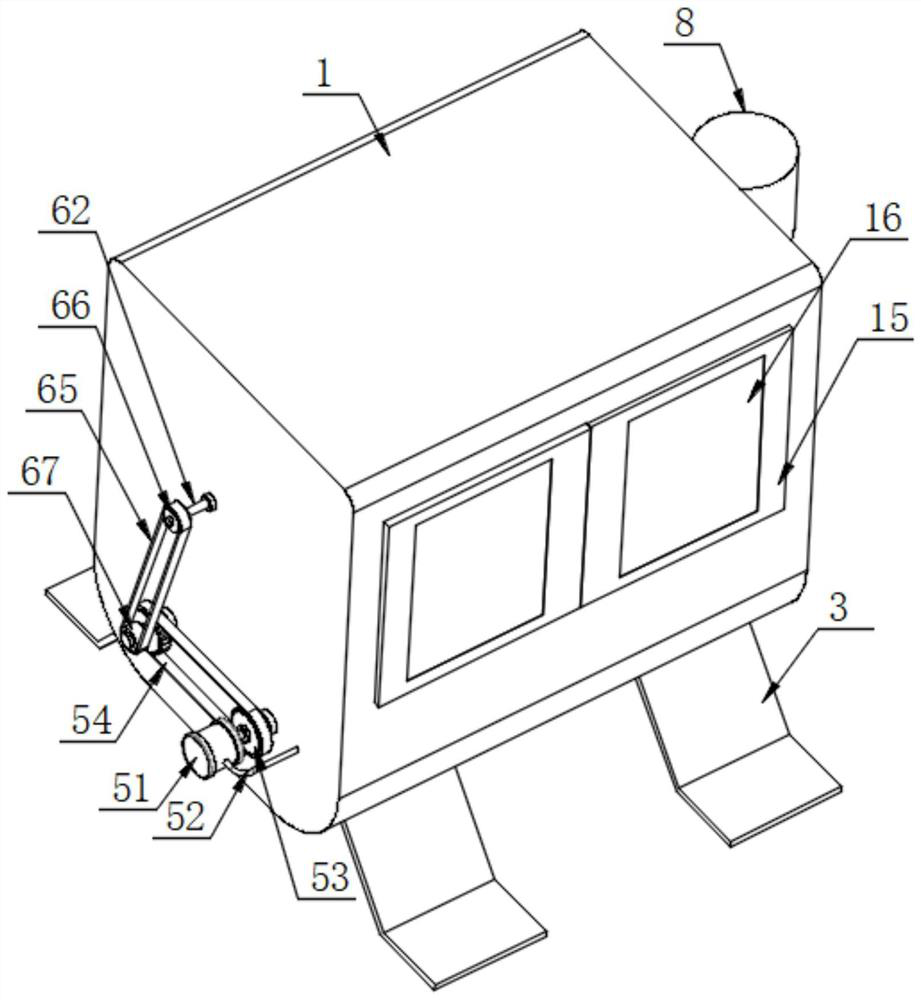

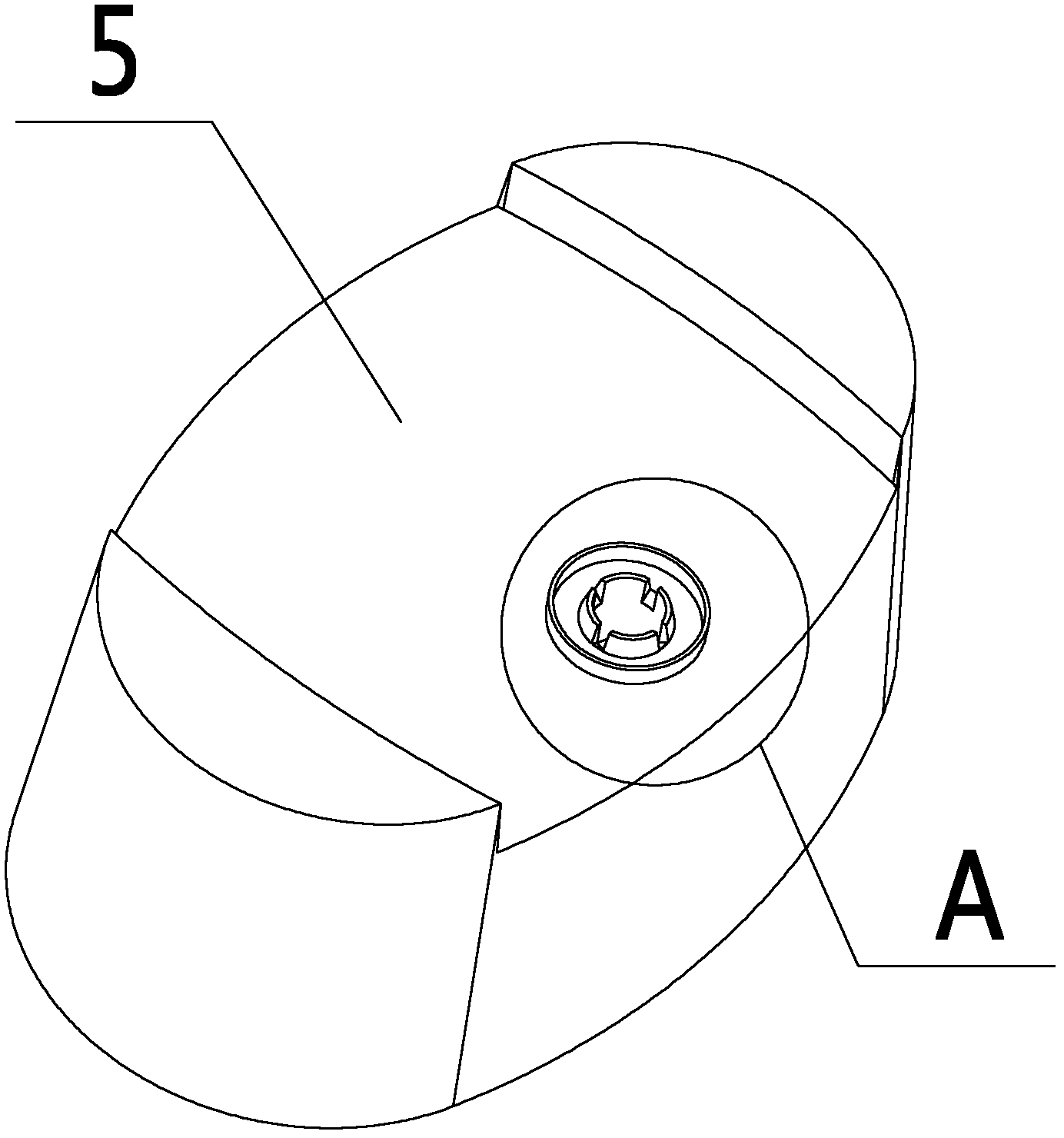

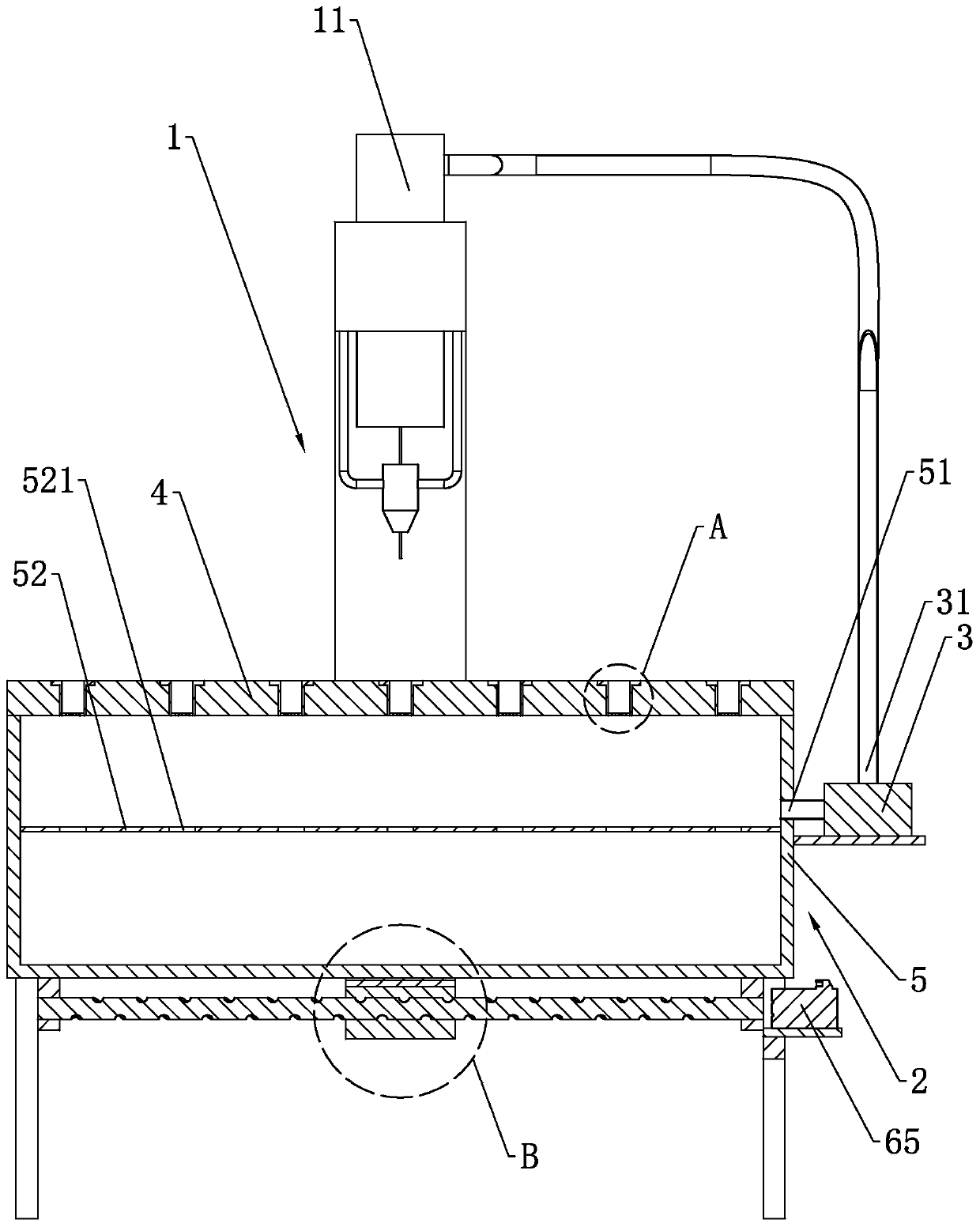

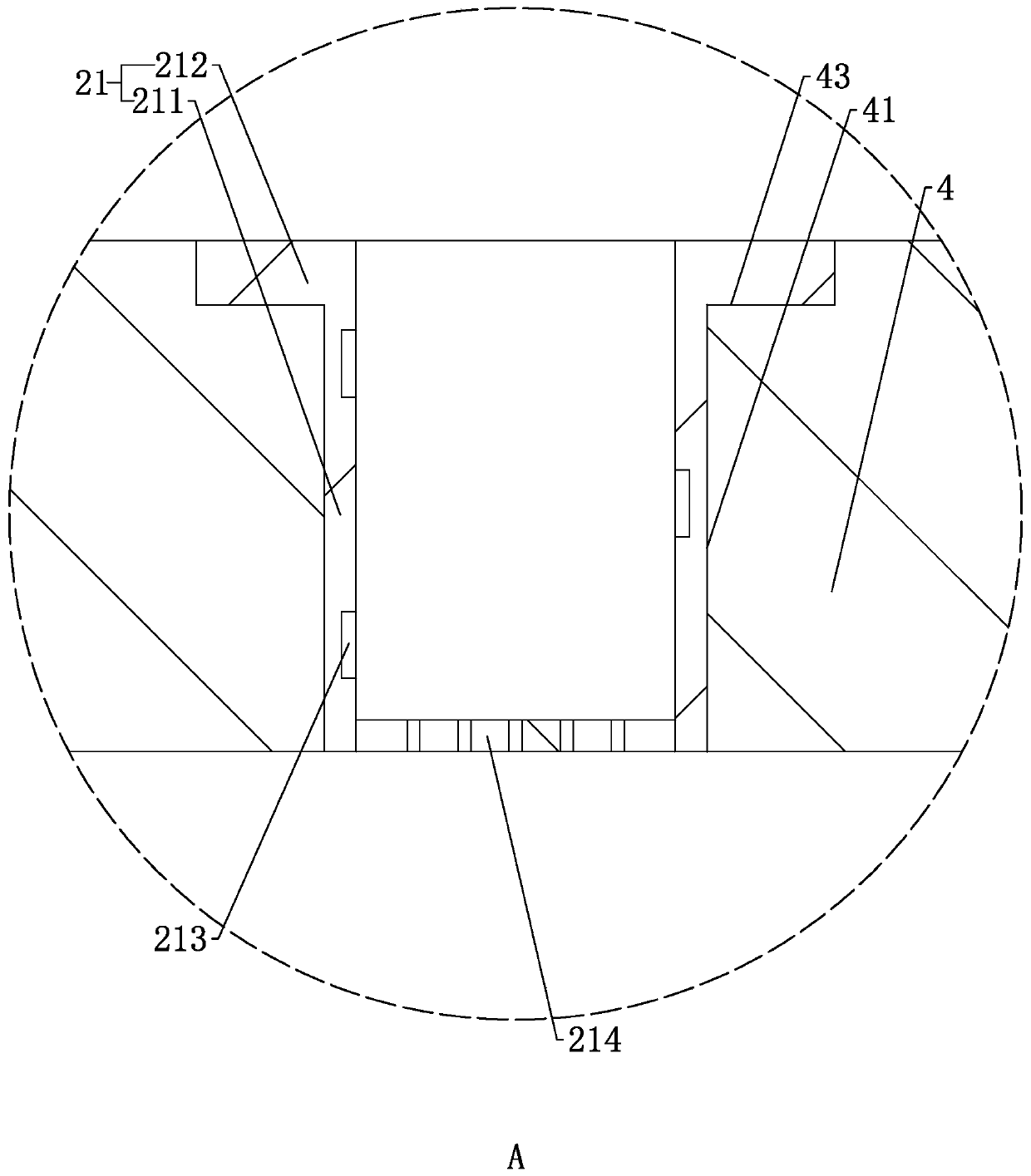

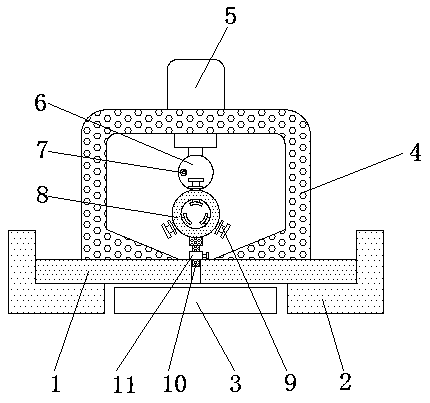

Dielectric liquid filtration, separation and recovery device for electric spark piercer

ActiveCN111056684BPlay a recycling effectPlay a pre-collection effectWater/sewage treatment by centrifugal separationTreatment involving filtrationThermodynamicsEngineering

The invention relates to a dielectric liquid filtration, separation and recovery device for an electric spark piercer, which includes a collection device and a centrifugal separation device. The collection device includes a number of drainage holes set on a workbench, and a A water collection tank, the upper edge of the water collection tank is attached to the lower surface of the workbench, the side wall of the water collection tank is provided with a liquid outlet, and the liquid outlet is communicated with the centrifugal separation device through a pipeline, and the centrifugal separation The device is provided with a clear liquid outlet, and the electric spark piercer includes a dielectric liquid supply device, and the clear liquid outlet is connected with the dielectric liquid supply device. The invention has the effect that the dielectric liquid can be recycled after being filtered to effectively reduce the processing cost.

Owner:常州庆源机械科技有限公司

Dielectric liquid filtering, separating and recycling apparatus of spark erosion drilling machine

ActiveCN111056684APlay a recycling effectPlay a pre-collection effectWater/sewage treatment by centrifugal separationTreatment involving filtrationThermodynamicsWorkbench

The invention relates to a dielectric liquid filtering, separating and recycling apparatus of a spark erosion drilling machine. The apparatus comprises a collection device and a centrifugal separationdevice, the collection device comprises a plurality of drainage holes formed in a workbench, a water tank for collecting is arranged below the workbench, the edge of the upper end of the water tank for collecting is attached to the lower surface of the workbench, a liquid outlet is formed in the side wall of the water tank, the liquid outlet is communicated with the centrifugal separation devicethrough a pipeline, a clear liquid outlet is formed in the centrifugal separation device, the spark erosion drilling machine comprises a dielectric liquid supply device, and the clear liquid outlet iscommunicated with the dielectric liquid supply device. The dielectric liquid can be recycled after being filtered so as to effectively reduce the processing cost.

Owner:常州庆源机械科技有限公司

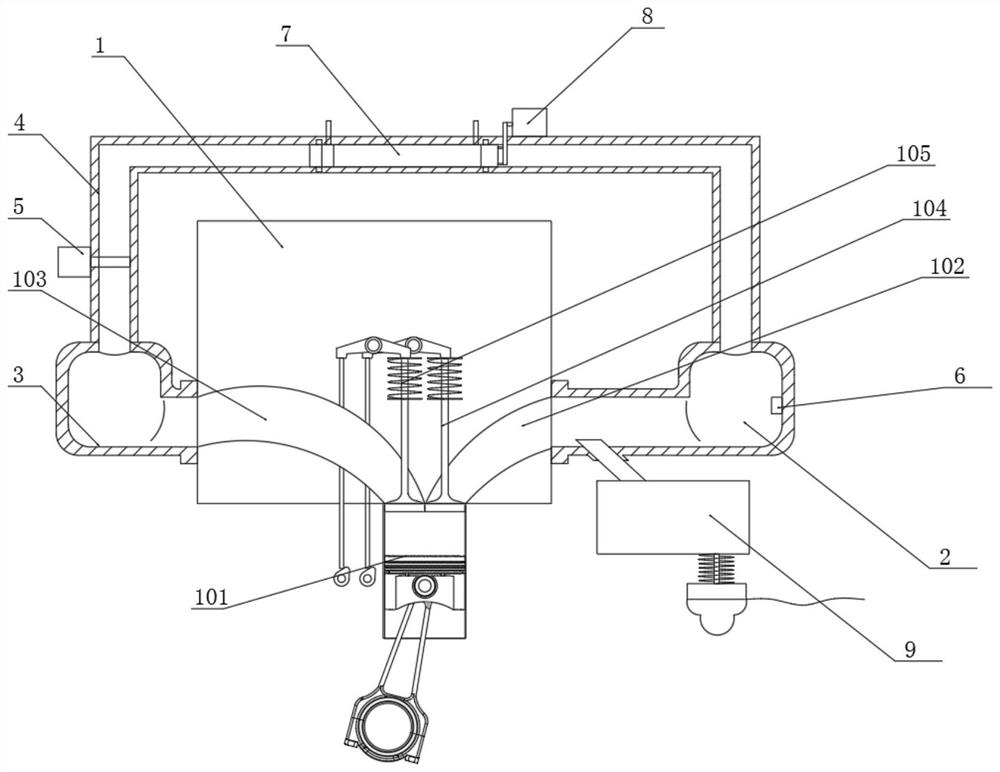

Air intake system of a marine diesel engine

ActiveCN112267960BPlay a recycling effectImprove recycling ratesNon-fuel substance addition to fuelInternal combustion piston enginesInlet valveEnergy recovery

The invention relates to an air intake system of a marine diesel engine, comprising a cylinder head, a piston connecting rod mechanism arranged inside the cylinder head, an air inlet and an air outlet arranged in the cylinder head, and an air intake valve arranged at the air inlet , the air outlet valve located at the air outlet place, the air intake pipe and the air outlet pipe connected to the cylinder head, the air inlet pipe is connected with the air inlet pipe, the air outlet pipe is connected with the air outlet pipe, and the air inlet pipe and the air outlet pipe are connected A bypass air intake pipe is connected, and an electric control valve is provided on the bypass air intake pipe, an energy recovery mechanism is installed in the bypass air intake pipe, a pressure sensor is installed on the inner wall of the intake pipe, and an oxygen gas is connected to the intake pipe extraction device. In the air intake system of the marine diesel engine, the diesel engine uses pure oxygen mixed with exhaust gas as the intake air of the diesel engine for combustion. The energy recovery mechanism in the bypass air intake pipe can recover energy from the exhaust gas and use the recovered energy for power generation. , Energy saving and environmental protection can also ensure the working stability of the diesel engine.

Owner:ANQING CSSC DIESEL ENGINE

A grinding device for silicon rod production and processing that is convenient for adjusting the grinding direction

ActiveCN107639493BAdjust the grinding directionEasy to put inEdge grinding machinesGrinding carriagesCircular discEngineering

The invention discloses a silicon rod producing and machining polishing device with convenience in adjusting polishing directions. The silicon rod producing and machining polishing device comprises abottom plate, a turntable and a disc. Support tables are mounted on two lower sides of the bottom plate, an accommodating tank is arranged between the support tables, a support frame is arranged on the upper side of the bottom plate, a cylinder is mounted on the upper side of the support frame, a driving machine is fixed to the front side of the turntable, fixing screws are mounted on the side surfaces of the disc, a movable rod is arranged below the disc, a fixing device is arranged on the outer side of the movable rod, a polishing wheel is mounted on the front side of the driving machine, apolishing sheet is arranged on the front side of the polishing wheel, a rotary shaft is arranged between the polishing wheel and the driving machine, compressing sheets are arranged at ports of the fixing screws, and rubber layers are arranged on the compressing sheets. The silicon rod producing and machining polishing device with the convenience in adjusting the polishing directions has the advantages that the characteristics of fragility of silicon rods are taken into consideration, the silicon rods can be protected in silicon rod polishing procedures, and the polishing directions can be adjusted.

Owner:内蒙古和光新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com