Waste recovery device for hardware processing

A waste recycling and hardware technology, which is applied in metal processing equipment, grinding/polishing safety devices, applications, etc., can solve the problems of human injury and other problems, and achieve the effect of avoiding mixing and matching, avoiding personal injury, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

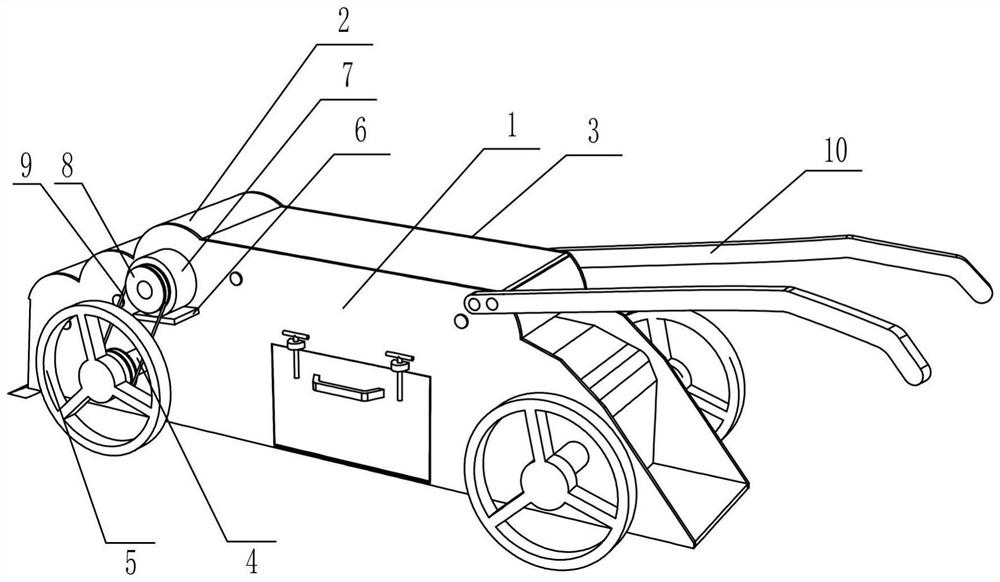

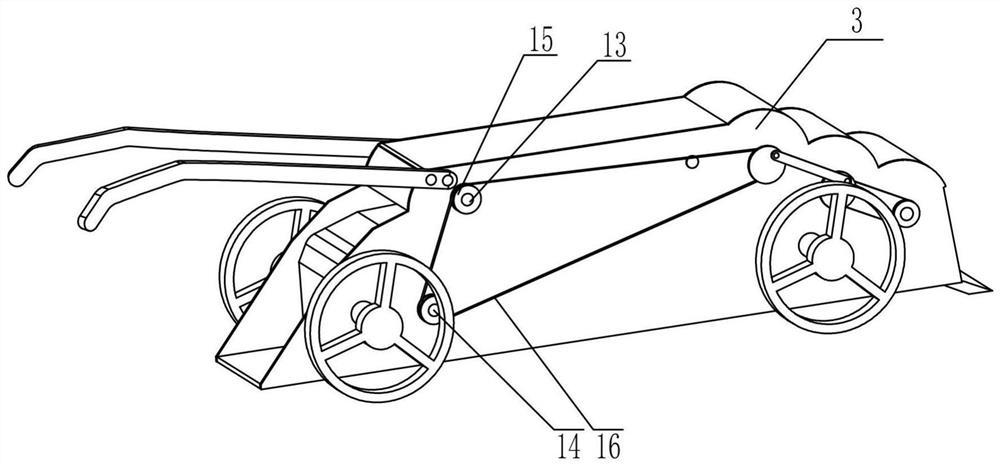

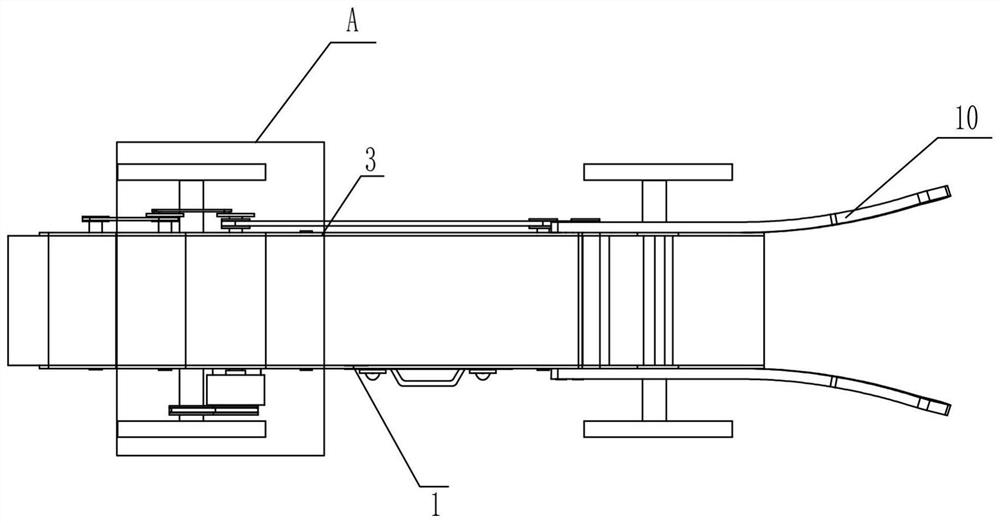

[0027] Such as Figure 1-Figure 9 As shown, a metal processing waste recycling device includes a front housing 1, a top plate 2, a feeding platform 201, a rear housing 3, a rotating shaft 4, a walking wheel 5, a supporting plate 6, a motor 7, and a pulley 8. Belt 1 9, handrail 10, transmission mechanism, compression mechanism and disassembly mechanism, the top plate 2 is consolidated on the rear side of the front shell 1, and the rear shell 3 is consolidated vertically downward at the rear end of the top plate 2, and the rear shell 3 3 is consolidated with the inner bottom of the front housing 1, and the rear housing 3 and the left inner side of the front housing 1 are consolidated with a loading table 201, and the left and right parts of the front housing 1 and the rear housing 3 are rotated by bearings. A rotating shaft 4 is connected, and the front and rear ends of the two rotating shafts 4 are connected with traveling wheels 5. The front side of the left part of the front ...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 1-Figure 9 Shown, also include feeding mechanism, feeding mechanism includes rotating disk two 29, connecting rod 30, pulley three 31, belt three 32, roller one 33, toggle lever 34 and spring 35, two rotating shafts on the right side Two 12 rear ends are fixedly connected with turntable two 29, and the rear side eccentric position of two turntable two 29 is rotatably connected with connecting rod 30; Belt three 32 are wound on belt wheel three 31, and the middle part of three rotating shafts two 12 is fixedly connected with roller one 33, and three rollers one 33 are evenly spaced and slidingly connected with toggle bar 34, and each roller one 33 The toggling rods 34 are interlaced with each other, and a spring 35 is connected between the toggling rods 34 and the inner bottom end of the sliding hole.

[0037] When starting to work, the motor 7 reverses, and the motor 7 drives the overrunning clutch 11 and the rotating shaft 2 ...

Embodiment 3

[0039] On the basis of Example 2, such as Figure 1-Figure 9 As shown, a screening mechanism is also included, and the screening mechanism also includes a roller two 36, a magnetic belt 37, a scraper plate 38 and a material leakage plate 39, and the middle part of the rotating shaft three 13 is fixedly connected with a roller two 36, and two rollers two 36 A magnetic belt 37 is installed around it, and the right part of the top plate 2 is fixedly connected with a scraper plate 38, and a material leakage plate 39 is arranged below the scraper plate 38, and the front and rear sides of the material leakage plate 39 are connected with the front casing 1 and the rear casing 3 fixed connections.

[0040] When the waste material moves to the top of the feeding platform 201, the transmission mechanism will drive the two rollers 36 to reverse, and the two rollers 36 will also drive the magnetic belt 37 to reverse, and the magnetic waste will be adsorbed on the magnetic belt 37 Go up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com