Method and apparatus for producing PTA via deep oxidation by using oxygen-deficient gas

A technology of deep oxidation and oxygen-poor gas, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of oxidative combustion loss of solvent acetic acid, high investment, and large energy consumption, etc., to avoid oxidation of acetic acid Effects of burning, reducing investment and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

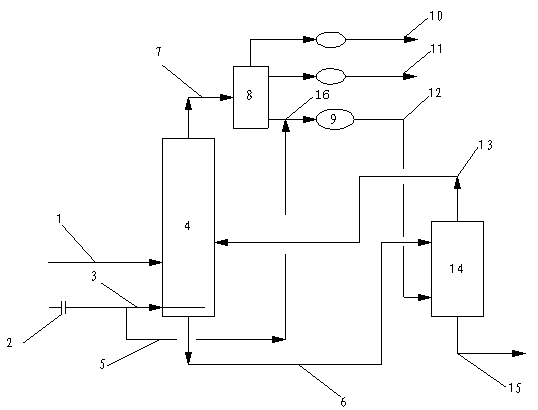

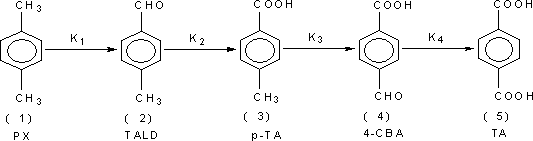

[0021] The invention provides a method for producing PTA by deep oxidation using oxygen-poor gas. The method includes two steps: step (1) is the oxidation stage, adding p-xylene (PX), acetic acid solvent and catalyst to the oxidation reaction device Usually, the oxidation gas introduced in step (1) is fresh air, which oxidizes p-xylene (PX) to terephthalic acid (TA), and at the same time generates an intermediate product: p-toluic acid (PT acid), p-carboxy basic formaldehyde (4-CBA), p-tolualdehyde (TALD), the oxidation tail gas is waiting for subsequent treatment; step (2) is the deep oxidation stage, and the mixture produced by the oxidation stage enters the deep oxidation reaction device, using Oxygen-depleted gas deeply oxidizes the mixture. The oxygen-depleted gas can be a mixture of purified exhaust gas and fresh air produced in step (1). The ratio of the two gases is about 4:1-10:1, such as 4:1 , 6:1, 8:1 or 10:1. The oxygen content in the mixed gas is preferably 4-10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com