Air intake system of a marine diesel engine

A technology of marine diesel engine and air intake system, applied in charging system, mechanical equipment, combustion engine, etc., can solve the problems of high cost, poor stability, increased use cost, etc., to increase energy recovery rate, ensure stability, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

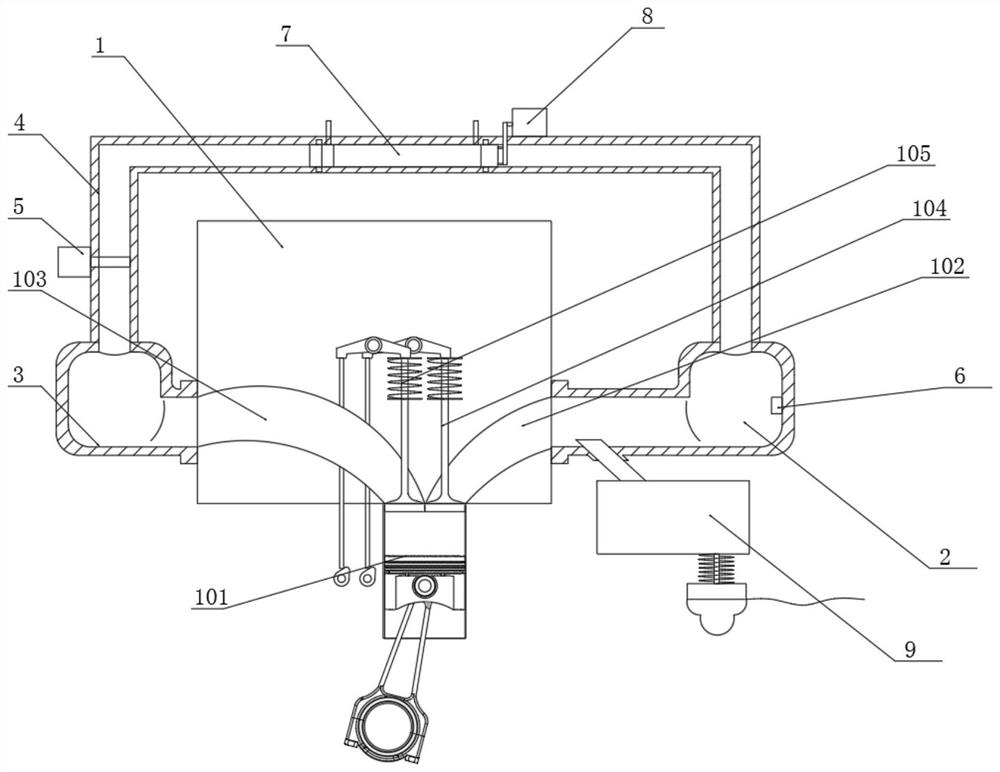

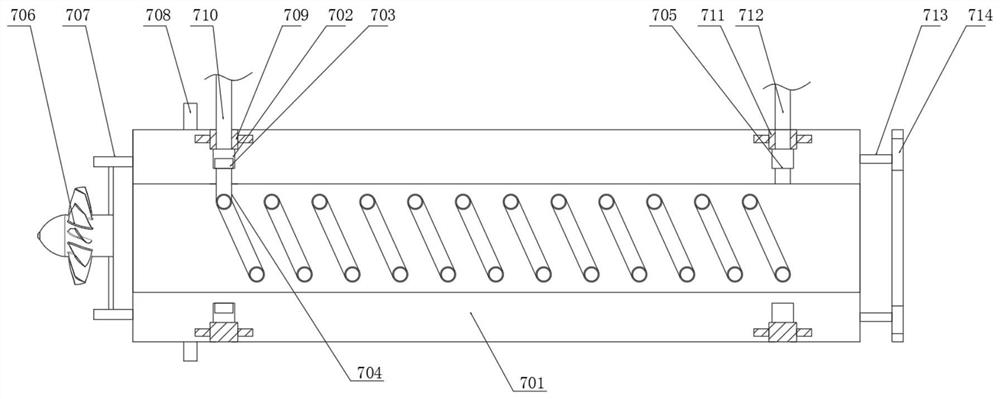

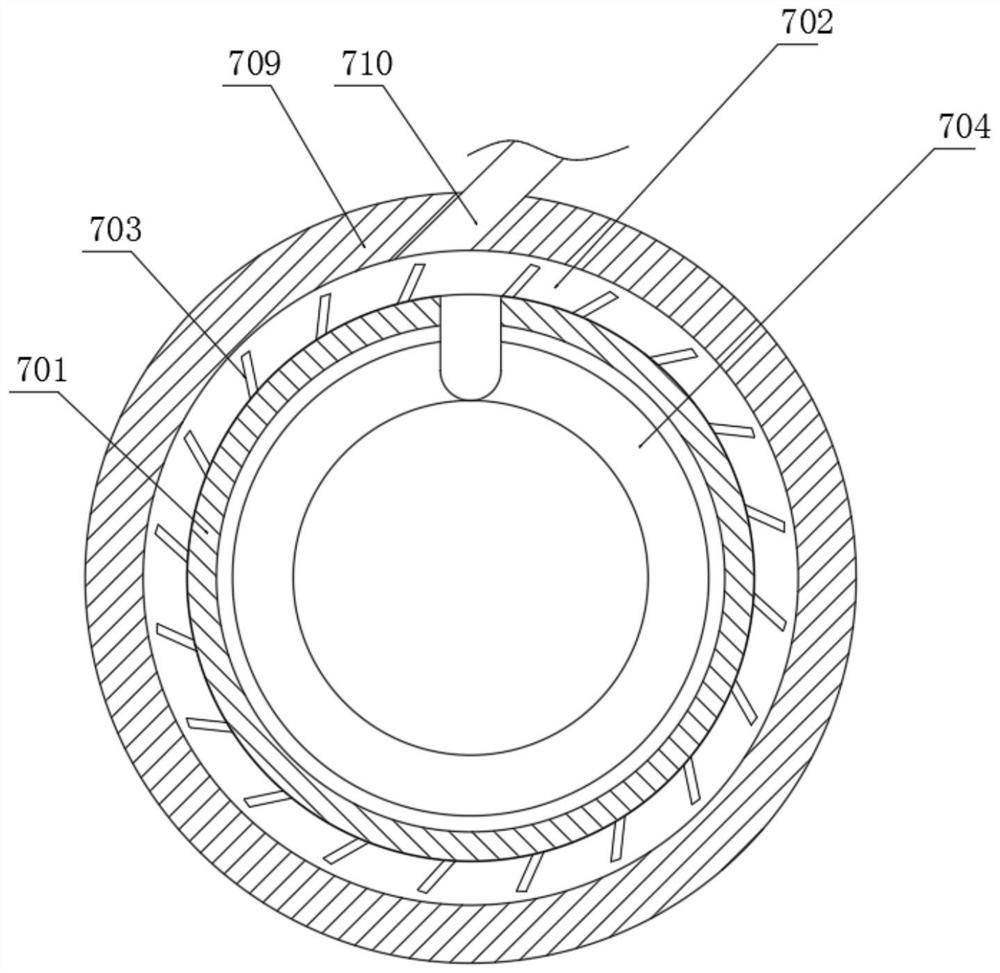

[0025] Such as Figure 1-3 As shown, an air intake system of a marine diesel engine includes a cylinder head 1, a piston connecting rod mechanism 101 arranged inside the cylinder head 1, an air intake passage 102 and an air outlet passage 103 arranged inside the cylinder head 1, an air intake passage 103 arranged in the air intake The inlet valve 104 at the passage 102, the outlet valve 105 located at the outlet passage 103, the inlet pipe 2 and the outlet pipe 3 connected to the cylinder head 1, the inlet pipe 2 and the inlet passage 102 are connected, the outlet pipe 3 and the outlet pipe 103, the air intake pipe 2 and the air outlet pipe 3 are connected with a bypass air intake pipe 4, and the bypass air intake pipe 4 is provided with an electric control valve 5, and the bypass air intake pipe 4 is provided with an energy recovery mechanism 7, and the intake pipe 2 A pressure sensor 6 is provided on the inner wall, an oxygen extraction device 9 is connected to the intake pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com