Eccentric bottle cap

A bottle cap and eccentric technology, applied in the field of bottle caps, can solve the problems of non-recyclable, inconvenient, waste of liquid, etc., and achieve the effect of reducing waste, simple structure, and practical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

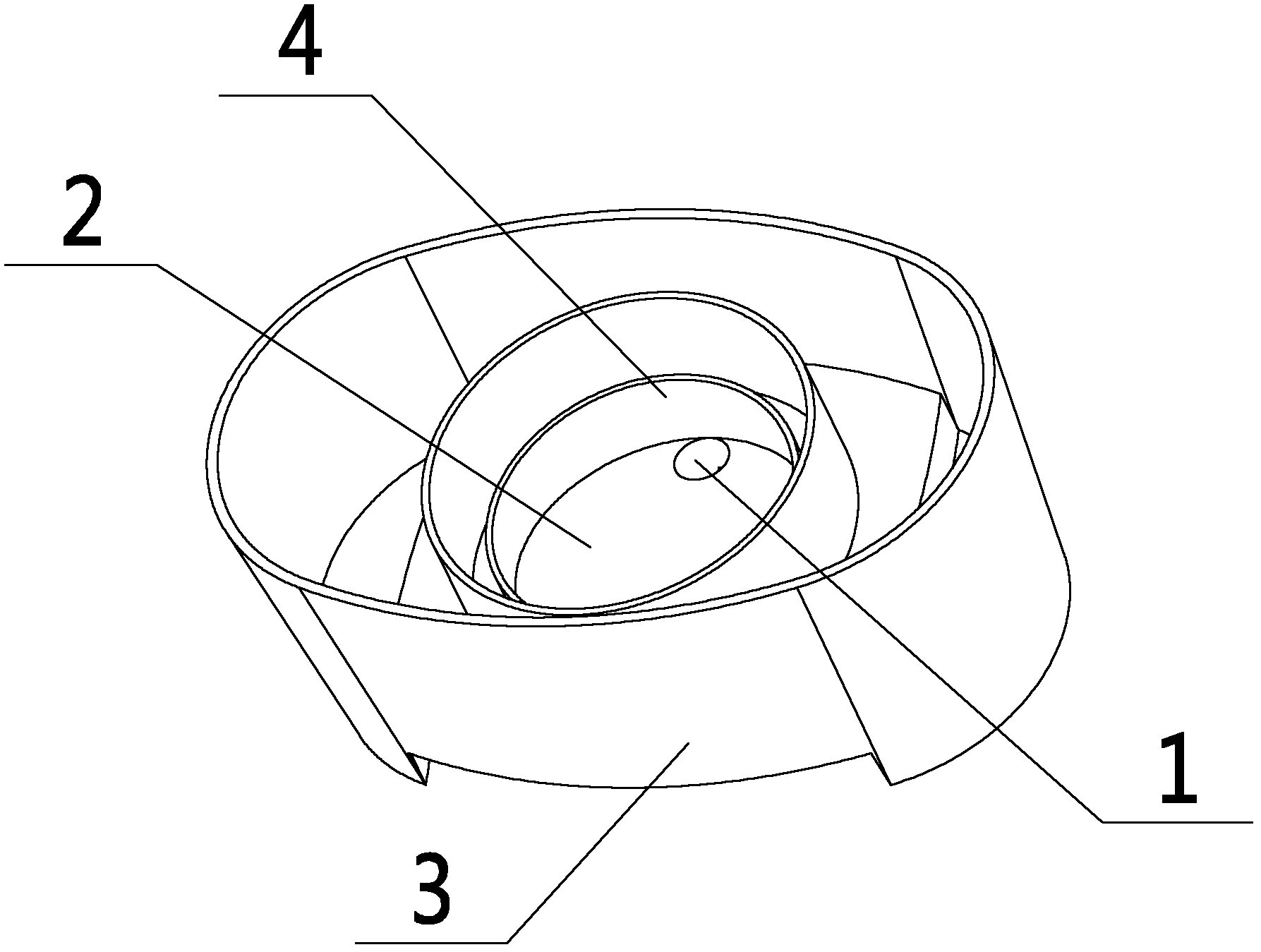

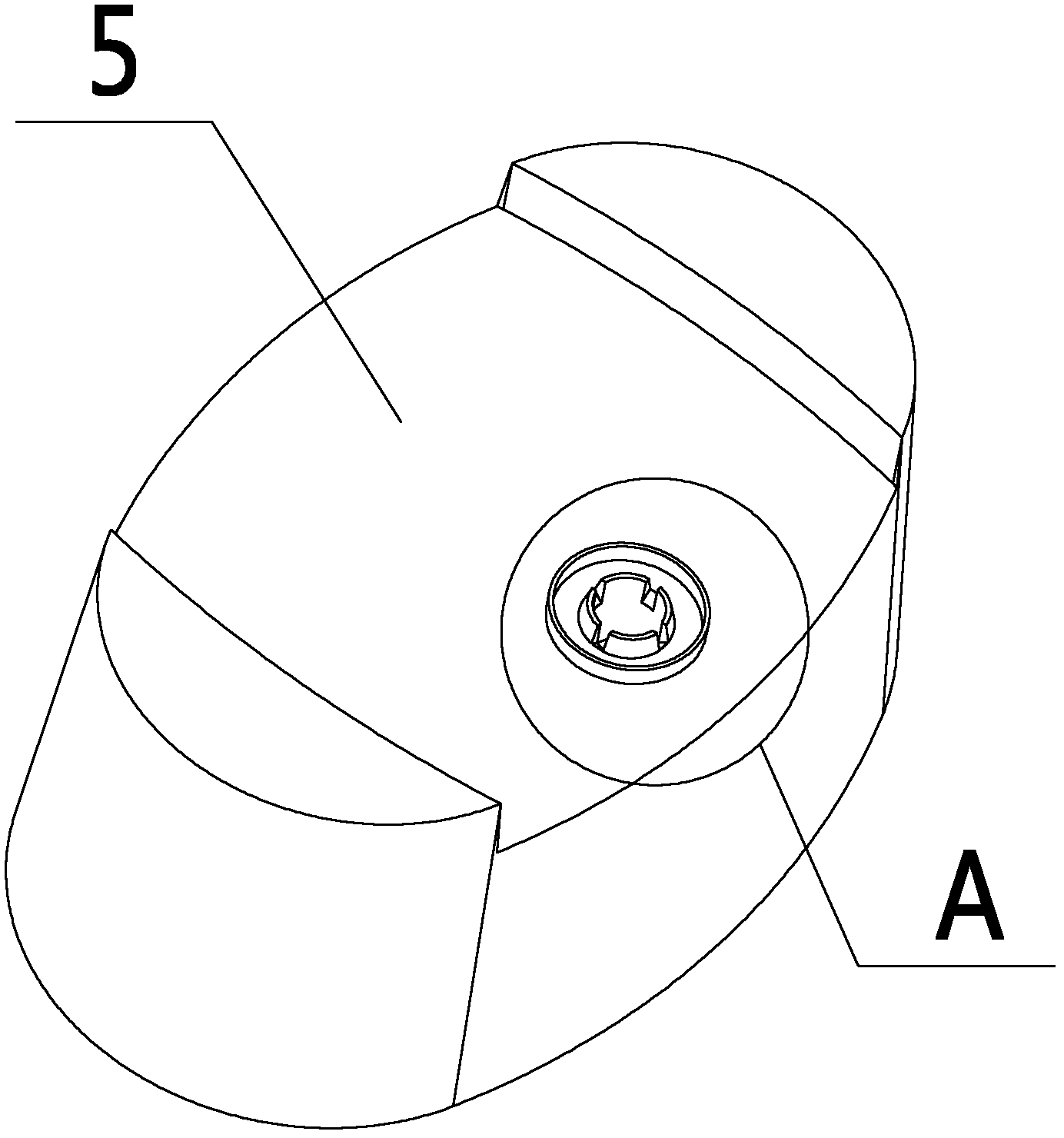

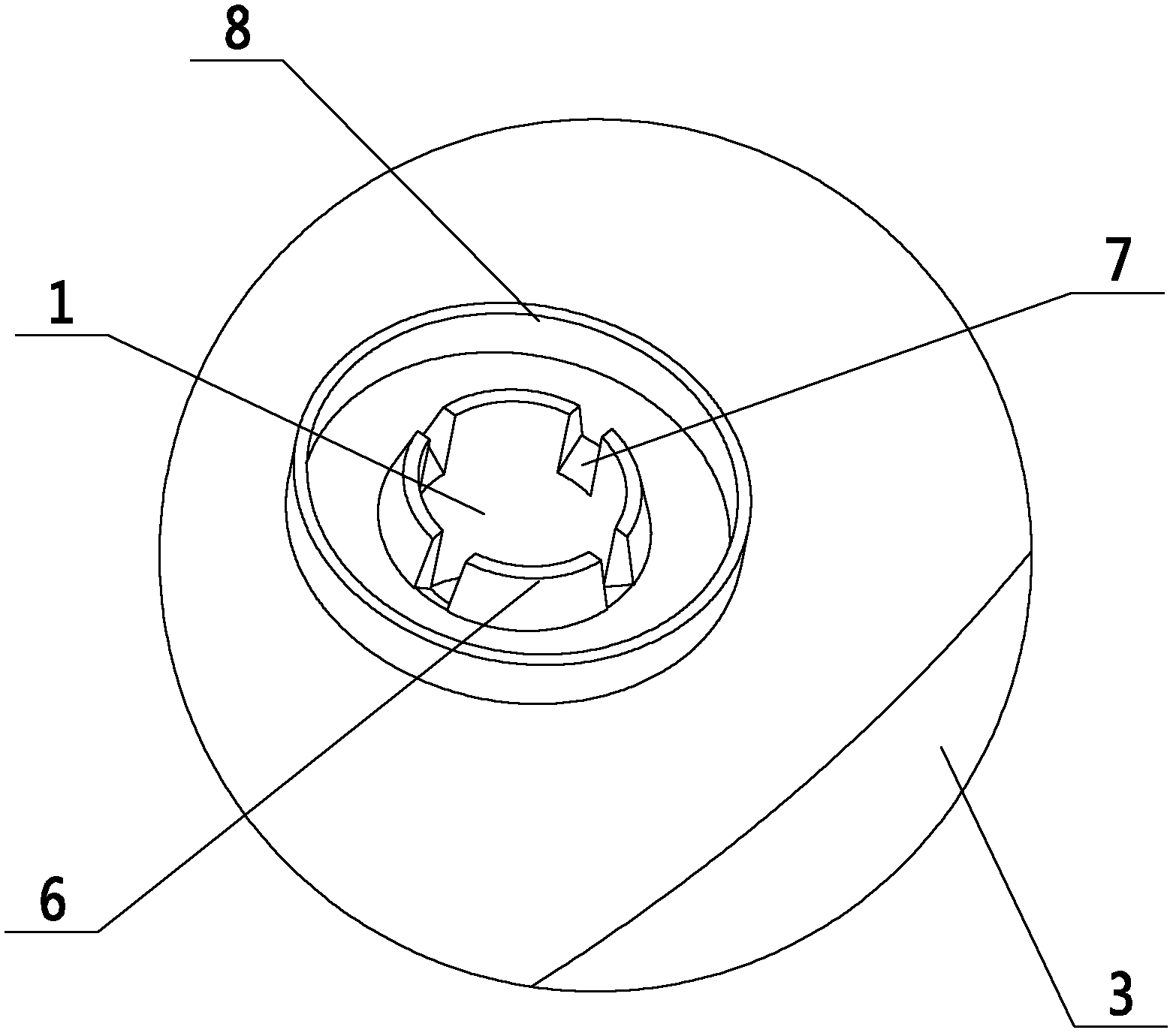

[0019] as attached Figure 1-4 It is an eccentric bottle cap of the present invention, including a cover body 3; a liquid outlet 1 is opened on the cover body 3; a protective ring 4 is provided on the inner top surface 2 of the cover body 3; the cover body 3 On the outer top surface 5 of the outer side, on the position of the liquid outlet hole 1, there is also a protruding ring 6; four notches 7 are also opened on the protruding ring 6; the bottom of the notch 7 is a slope; The inner top surface 2 is a slope; the liquid outlet hole 1 is located inside the protective ring 4, the liquid outlet hole 1 is located at the low end of the inner top surface 2, and the liquid outlet hole 1 is tangent to the inner side wall of the protective ring 4; the cover A retaining ring 8 is provided on the outer top surface 5 of the body 3 concentric with the liquid outlet hole 1 , and the retaining ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com