Method for improving graphite boat treatment effect

A treatment effect, graphite boat technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve the problem of insufficient cleaning effect of graphite boat, and achieve the effect of improving washing effect, improving cleaning effect, and improving cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

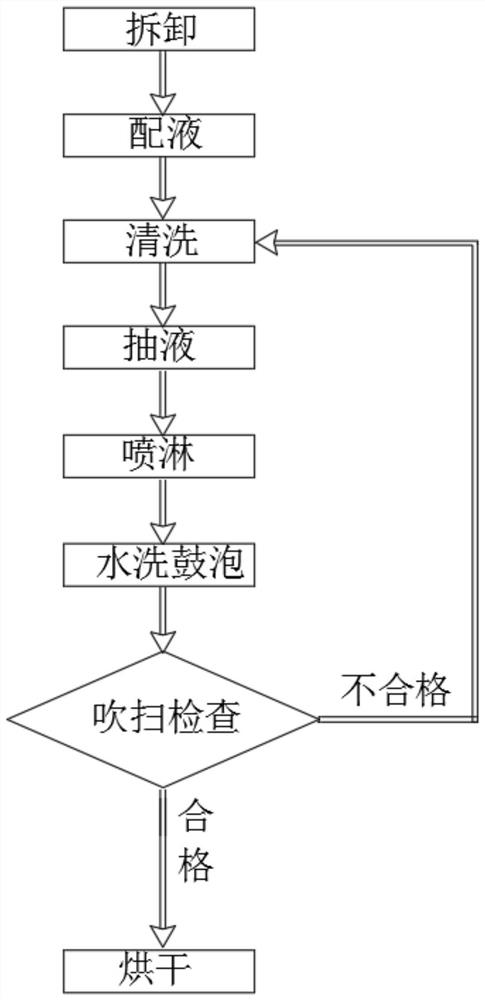

[0034] refer to figure 1 , a method for improving graphite boat treatment effect, comprising the following steps:

[0035] S1: Disassembly: Prepare the graphite boat that needs to be cleaned, disassemble it, and clean the graphite boat and process stuck points separately;

[0036] S2: Dosing: configure a hydrofluoric acid solution with a concentration of 7% to 15% in the cleaning tank;

[0037] S3: Cleaning: Put the graphite boat as a whole into the prepared hydrofluoric acid solution, soak for 5-7 hours, and start bubbling while soaking;

[0038] S4: pumping liquid: after the whole graphite boat is soaked for 5-7 hours, pump out the hydrofluoric acid solution in the above steps;

[0039] S5: Spray: Spray the soaked graphite boat with deionized water, and set the spray time to 5-15 minutes;

[0040] S6: Washing and bubbling: use deionized water to bubble the sprayed graphite boat as a whole;

[0041] S7: Purge inspection: Use an air gun to purge the surface of the graphite...

Embodiment 2

[0046] refer to figure 1 , a method for improving graphite boat treatment effect, comprising the following steps:

[0047] S1: Disassembly: Prepare the graphite boat that needs to be cleaned, disassemble it, and clean the graphite boat and process stuck points separately;

[0048] S2: Dosing: configure a hydrofluoric acid solution with a concentration of 9% to 15% in the cleaning tank;

[0049] S3: Cleaning: Put the graphite boat as a whole into the prepared hydrofluoric acid solution, soak for 5-7 hours, and start bubbling while soaking;

[0050] S4: pumping liquid: after the whole graphite boat is soaked for 5-7 hours, pump out the hydrofluoric acid solution in the above steps;

[0051] S5: Spray: Spray the soaked graphite boat with deionized water, and set the spray time to 5-15 minutes;

[0052] S6: Washing and bubbling: use deionized water to bubble the sprayed graphite boat as a whole;

[0053] S7: Purge inspection: Use an air gun to purge the surface of the graphite b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com